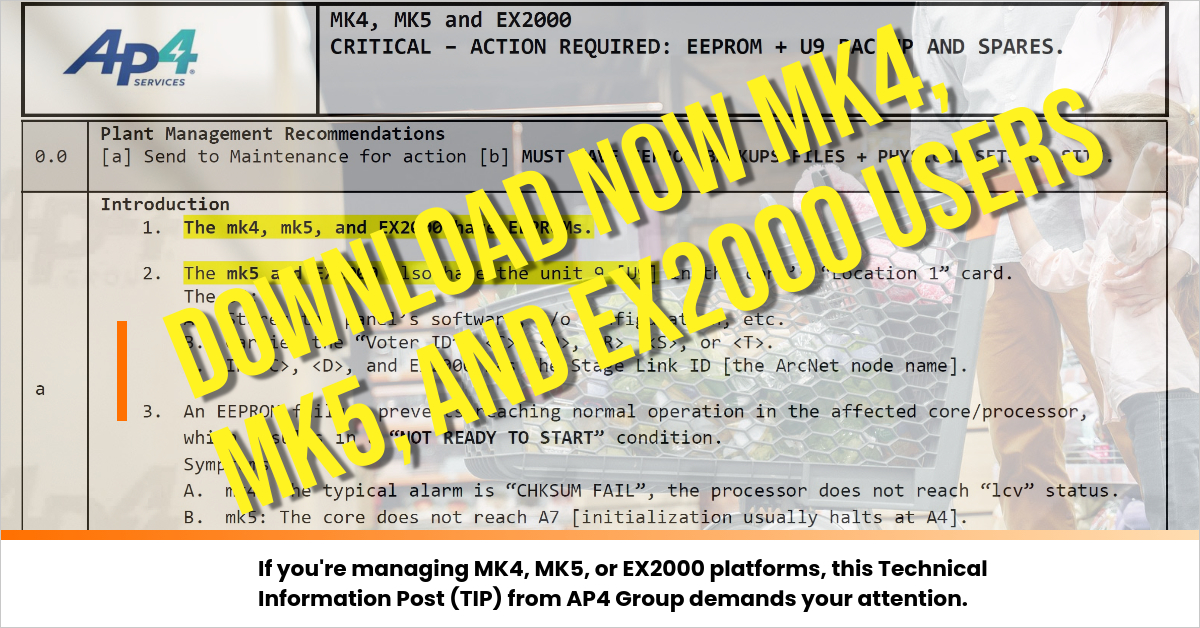

If you’re managing MK4, MK5, or EX2000 platforms, this Technical Information Post (TIP) from AP4 Group demands your attention (Download here). These “classic” control systems rely on EEPROMs—and in the case of MK5 and EX2000, the U9 chip—to store essential software and configuration data. Failures of these components, increasingly common in systems over 25 years old, can prevent turbine start-up and trigger a “NOT READY TO START” condition with no OEM-supported recovery path.

Abel Rochwarger, controls field engineer at AP4 Services, recently reached out to the editors of Combined Cycle Journal to raise awareness of this issue. He emphasized that end-users must proactively secure both EEPROM backup files and physical spares to avoid unplanned downtime. His outreach is especially timely: Abel will be presenting at the Power Plant Controls Users Group (PPCUG), part of the grander Power Users Group Annual Conference, this August in Washington, D.C., where he’ll speak on controls lifetime assessments and strategies for maintaining systems well beyond OEM’s obsolescence notice.

With no OEM replacements available and migration options often unnecessary and costly, this TIP provides practical, low-cost actions you should take today to protect your future unit’s availability and reliability. CCJ