CPV St. Charles Energy Center

Owned by CPV Maryland LLC

Operated by Consolidated Asset Management Services

745 MW, 2 × 1 7F.05-powered combined cycle equipped with a GE D11A steam turbine, located in Waldorf, Md

Plant manager: Nick Bohl

Influent water monitoring upgrade for permit compliance

Challenge. St. Charles Energy Center uses recycled wastewater from the local municipality to meet the facility’s cooling needs. Treated wastewater is piped 14 miles to the plant and stored in the reclaimed-water tank. After use, water is returned to the wastewater treatment facility for processing.

The use of reclaimed water is governed by a permit specifying the parameters that must be met for its discharge—including restricting TSS to less than 400 mg/l. The standing process for evaluating TSS was to take a 24-hr composite sample monthly and send it to a local lab for testing. This was not ideal because it takes seven to 10 days to receive the results. The site needed a way to evaluate TSS in real time.

Solution. While evaluating options for real-time TSS monitoring, personnel realized the instrumentation setup for the existing wastewater sampling panel presented multiple maintenance challenges. Example: It relied on four instruments to measure specific conductivity, pH, ORP, and turbidity (Fig 1). The four probes were on a common sample line without individual isolations; thus, all four had to be taken out of service to maintain one of the elements. Plus, the panel had multiple transmitters of different models, requiring different sets of spare parts.

Staff reached out to companies specializing in wastewater monitoring to identify and evaluate equipment that could be implemented to monitor the influent and effluent water. Solution was to purchase an Endress + Hauser product that uses light sources and detectors to measure suspended solids in the water while allowing personnel to monitor and compare the incoming and outgoing TSS levels.

A review of the local human/machine interface system revealed that the plant had a DCS indication for incoming free chlorine, but its measurement was based solely on ORP data. Free-chlorine calculations should consider both ORP and pH. This issue was resolved by creating logic that uses the pH and ORP measurements to interpolate the free-chlorine value.

After planning and review, the site was able to install the new influent water sampling system (Fig 2) which addresses the maintenance challenges of the old system. The new panel is configured for all the instruments to run off a common transmitter, reducing the amount of spare inventory required. Plus, it allows isolation of one instrument at a time for maintenance.

An online TSS probe was added to the effluent water sample panel, allowing staff to compare TSS in the incoming water to that in the water discharged.

Result. The online TSS and sample-panel upgrade give the plant better insight into the quality of the reclaimed water—both incoming and discharged. Having the sample values displayed on the DCS allows the operations team to react quickly to changes in incoming water quality to protect equipment that relies on this water for cooling.

Additionally, it is now possible to monitor and evaluate TSS trends in the incoming and outgoing water to determine cleaning frequencies for the cooling-tower basin and wastewater sumps.

Project participants:

Jacob Boyd, plant engineer

Lauren Sparks

William Bates

Chris Higgs

NOx controls project mitigates CEMS maintenance challenges

Background. St. Charles Energy Center is equipped with a selective catalytic reduction (SCR) system to regulate NOx emissions released to atmosphere. It includes an ammonia injection grid to treat the flue gas before it reaches the SCR catalyst bed. The control system responsible for managing NOx levels relies on a continuous emissions monitoring system (CEMS) to regulate the amount of ammonia injected into the flue-gas stream.

Challenge. During extended periods of operation, the CDMS needs online troubleshooting, updates, and/or inspection, requiring the system to enter a “maintenance mode.” However, placing the CEMS in maintenance mode leads to a loss of reference input for the Mark VIe control system, preventing commands from being issued to the ammonia flow control valves. This requires the operations team to manually control ammonia injection based on stack NOx levels to ensure compliance with air permit regulations.

Solution. To address this challenge, St. Charles initiated an “Ammonia Flow to Load” project within the control system. It eliminates the need for manual intervention by operators in controlling the ammonia valve and provides a more robust control mechanism for NOx emissions.

The new controls arrangement incorporates these two additional distinct strategies to enhance flexibility and accuracy in NOx emissions control:

- Mass-balance control strategy uses exhaust-gas mass flow, actual NOx measurements before the SCR, and target NOx levels at the stack to provide commands to the ammonia control valves. This required data from multiple months of operation—including run profiles and startups and shutdowns—which were collected from the PI system. The data provided insight to the stoichiometric relationships between different elements to ensure proper control of ammonia injection.

- Load-based control strategy acts as the third level of control for the ammonia injection system. It is used if the SCR inlet-NOx measurement is unreliable or unavailable. Control of the ammonia injection system is determined based on gas-turbine megawatt load and DB Btu output.

Result. The project successfully mitigated operational challenges associated with CEMS maintenance, enhancing the overall reliability and accuracy of the NOx emissions control system.

Implementation of ammonia-flow-to-load controls provided several benefits, including the following:

- The new logic aids operators in controlling NOx while the CEMS is in the maintenance mode, eliminating the need for manual control. This allows the site to remain compliant under the current air permit assigned by the state of Maryland.

- The logic provides an extra level of control for the ammonia injection system.

- Doubles the control scheme for the ammonia control system—including CEMS, mass-balance, and megawatt control, with manual control a last resort.

Project participants:

Plant personnel with the participation of AtkinsRéalis (formerly SNC-Lavalin) as the lead controls engineering team

Drones enhance plant safety, reliability

Challenge. St. Charles Energy Center faced numerous obstacles hindering efficient completion of inspection tasks—including high costs, time constraints, and limited physical access—all while placing personnel in a higher-risk environment to accomplish the work required.

The facility property line encompasses diverse terrain, ranging from woodlands to hills and marshes, thereby posing significant challenges for access by foot or utility terrain vehicles (UTVs). Inspections and maintenance of the heat-recovery steam generators (HRSG) were particularly laborious and expensive. Nearly all tasks involved scaffolding, which often led to additional costs and delays.

The site needed a way to conduct comprehensive visual inspections of plant grounds, buildings, and equipment in a cost-effective and timely manner.

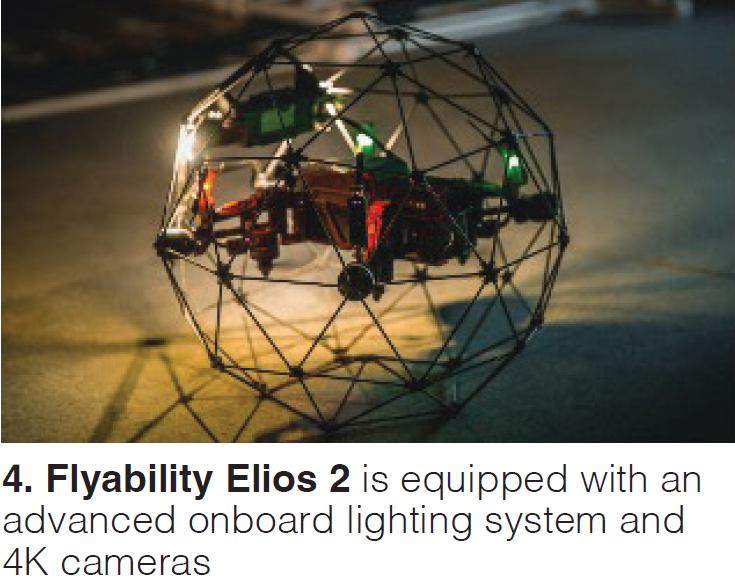

Solution. To overcome these challenges, St. Charles invested in a DJI Air 3 camera drone (Fig 3) for external inspections and leased a Flyability Elios 2 drone (Fig 4) for internal checks of HRSGs and stacks. This strategic combination of drone technologies revolutionized the plant’s inspection processes, enabling it to avoid the limitations previously encountered. Important to success was the site’s ability to leverage the operation manager’s remote pilot’s license issued by the Federal Aviation Administration.

The DJI Air 3 enables the capture of high-resolution photos and videos from vantage points previously inaccessible, providing unparalleled visibility of the plant’s exterior. Meanwhile, the Flyability Elios 2, equipped with advanced onboard lighting and 4K cameras, permits internal inspections of HRSGs and stacks with precision and thoroughness.

Results. Beyond the initial intended applications of conducting perimeter and HRSG internal inspections, the drones have unveiled a multitude of additional use cases. St. Charles has leveraged these versatile tools to capture timelapse footage of newly installed capital projects, assess building roofs and gutters before and after severe weather events, conduct winter insulation audits, perform stack inspections, and examine silencers for maintenance needs.

Moreover, the HRSG internal inspections yielded significant improvements in workflow efficiency. As a direct result of insights gained from the inspection process, modifications were made to the work scope, optimizing scaffolding placement. This adjustment reduced scaffolding erection time by eight hours, demonstrating one of the tangible benefits derived from the integration of drone technology into plant operations.

Furthermore, the use of aerial views on gutter inspections eliminated the necessity for operators to climb ladders in areas inaccessible by manlifts. Additionally, staff was able to pinpoint specific locations for clearance via manlift, improving safety and reducing total job duration by 75%.

During a post-storm perimeter check, the drone enabled its operator to identify a damaged fence caused by a fallen tree. This allowed the plant to bring in resources to remove the tree and repair the fence, thereby preventing wildlife and unauthorized personnel from entering the premises.

Harnessing the power of technology, through the versatile use of drone applications, St. Charles has recognized tangible improvements in workflow efficiency, safety, and cost-effectiveness.

Project participants:

Nick Ruscillo, operations manager

Nick Bohl, plant manager