Monitor spark-plug performance to prevent failed starts

Challenge. The ignition systems for Ferndale Generating Station’s 7EAs rely on spark plugs to initiate combustion. The engine model installed has two independent ignition circuits, each with its own spark plug. A unit will start as long as one circuit works properly. If both plugs fail to deliver an adequate spark, the unit won’t start.

Ignition-system components are inspected and refurbished during turbine inspections as a preventive-maintenance item. If degradation between inspections results in failure of both spark plugs, the telltale means of detection is an unsuccessful start resulting from a “failure to ignite,” as indicated by a control system alarm.

Although this potentially indicates a spark-plug system malfunction, it’s not an absolute indicator, as other problems can trigger a “failure to ignite”—for example, issues with fuel, air flow, crossfire, or controls.The only way to determine whether an individual spark plug is functioning properly is to remove and test it.

Dissatisfied with this reactive and tedious approach, staff looked for a means of assessing spark-plug health in-situ on an ongoing basis—this to avoid costly failed starts, reliability impacts, and impromptu repairs. After researching the possibilities, Team Ferndale found no industry solution that would achieve this objective.

Solution. In 2013, an employee theorized that the amount of current flow in the spark-plug cable during ignition should indicate whether the spark plug is functioning properly. If current flow in the cable between the ignition transformer and plug could be measured in-situ, staff could determine if each circuit was delivering an adequate spark without having to pull and test the plug. Using this diagnostic, plant personnel could be alerted to an ignition-circuit failure regardless of whether it stemmed from a shorted, open, or dead circuit.

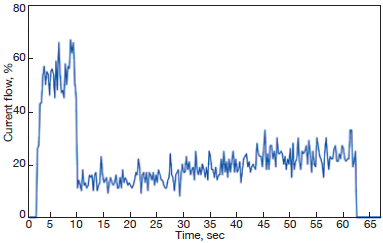

To prove the theory, staff began by bench-testing a properly functioning spark-plug system in Ferndale’s shop to ascertain the characteristics of a healthy current level during an ignition sequence. Variants of “good” spark plugs—new, rebuilt, and used—were tested and found to produce a similar spark-intensity level. From this, personnel derived the expected current of a properly functioning plug.

Next, the O&M team examined how the current changed in various failure modes of spark plugs and cables that jeopardized adequate spark generation—for example, electrode in contact with spark plug tip, broken electrode, damaged insulators—as well as numerous ways to short or kill the circuit. Result: In all cases, the current flow was significantly reduced compared to that of a healthy circuit. In the case of a short circuit, current flow quickly decays to zero following an initial increase.

Next, the O&M team examined how the current changed in various failure modes of spark plugs and cables that jeopardized adequate spark generation—for example, electrode in contact with spark plug tip, broken electrode, damaged insulators—as well as numerous ways to short or kill the circuit. Result: In all cases, the current flow was significantly reduced compared to that of a healthy circuit. In the case of a short circuit, current flow quickly decays to zero following an initial increase.

To measure spark-plug cable current flow in the installed system, the plant purchased small current transformers which provide a 4- to 20-mA current loop output proportional to current flowing in the cable. They were installed in the unit’s ignition-transformer cabinet with a spark-plug cable fed through them (Fig 1). Each transformer’s 4-20-mA output was wired to the respective GT’s Mark V control system and the input signal scale was configured thusly: 4 mA = 0%, 20 mA = 100%.

While the level remains above 8% for Ferndale’s healthy case (Fig 2), staff opted to use a low-level alarm point of 4% to allow for variations in spark intensities over time and avoid nuisance indications. The control system was configured to monitor spark-plug cable current during the ignition sequence and to generate an alarm when the current drops below the designated 4% alarm level for more than three seconds. This alarm remains uncleared until the operator performs a master reset on the respective GT’s Mark V.

When a 7EA is shutdown, the plugs are positioned with their tips penetrating into the combustion can liner ID. In the initial phase of a startup, the control system performs a purge by cranking the GT without injecting fuel. This admits fresh air into the downstream spaces (GT exhaust and HRSG) in order to remove any combustible mixtures that may have accumulated.

After the purge is complete and the unit is at firing speed, the control system energizes the ignition circuits for 60 seconds while fuel is admitted to initiate combustion. When proper ignition is achieved, the control system gradually accelerates the unit to operating speed.

During acceleration, pressure builds in the combustion cans and the spark plugs auto-retract by overcoming insertion spring pressure. They remain retracted while the unit is operating. During the subsequent unit shutdown and coastdown, the pressure in the combustion can reduces to a point where spring pressure is able to reinsert the spark plug, preparing it for the next unit start.

Staff configured the system to passively monitor spark-plug performance during every start, so no operator action is required. When it identifies a potential spark-plug malfunction and generates an alarm, the operator notifies appropriate personnel so the spark plug can be removed and replaced at the next unit shutdown opportunity.

Results. During the three years the systems have been in service, they have proven extremely effective in identifying ignition-circuit issues, generating around 10 alarms collectively. In every case, when the corresponding spark plug was removed and tested, personnel confirmed that a malfunction had occurred resulting in a degraded spark or no spark at all. Without this system alerting staff to developing issues, Ferndale could presumably have incurred several failed starts along with the associated impacts.

Participants (all NAES):

Tim Miller, plant manager

Marty Stangland, I&E technician

Ferndale staff

Ferndale Generating Station

Owned by Puget Sound Energy

Operated by NAES Corp

270-MW, gas fired 2 × 1 combined cycle located in Ferndale, Wash

Plant manager: Tim Miller