How Kearny personnel leak-check an operating engine without entering the package

Personnel at PSEG Fossil’s Kearny Generating Station, a 10-unit peaking facility in central New Jersey managed by Peter Van Den Houten, strive to continually improve work practices to ensure the safety of plant and contractor personnel.

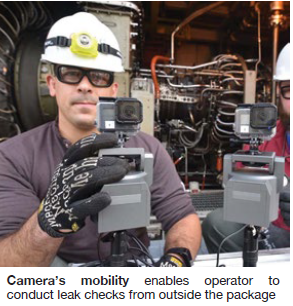

One recent example: An innovative application for GoPro cameras, to put “eyes” inside the engine package (photo). The compact camera system enables staff to capture photos and video under extreme conditions.

During post-maintenance testing or oil commissioning of the station’s peaking units, leak checks are a routine task, The ability to safely look for leaks has been greatly improved with the use of this camera system, developed in-house by the peaking team under the guidance of Al Van Hart, technical manager.

The GoPro cameras are seated on mag-base remote mounts, giving operators pan and tilt capability. The cameras can capture a live feed and send it to an operator outside the package in a safe environment. The camera’s mobility enables the operator to conduct a full set of leak checks without entering the package. Click the link to see the GoPro in action at https://vimeo.com/306229398.This has significantly improved the safety of those who perform this work.

Results. While some other peaking plants with LM6000 gas turbines use high-cost stationary cameras for leak detection, the PSEG team took the inspection task to the next level by using GoPro cameras with pan/tilt mounts to provide greater flexibility at a less cost.

Lifting hoist for Edgewood Energy’s water combination skid filter mitigates injury risk

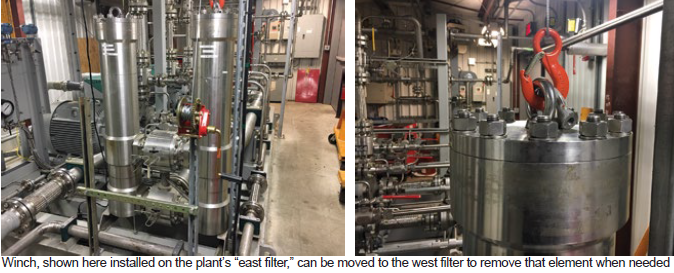

Routine replacement of the combo skid suction filter for Edgewood’s LM6000s required a technician to work in an awkward position, with both arms extended at, or above, eye level. Additionally, the filter element, which is approximately 40 in. long, would need to be manually lifted out of the filter assembly and a new filter inserted. An exhausted filter, saturated with demineralized water, is estimated to weigh between 30 and 40 lb.

The challenge in this instance was to provide an ergonomically friendly solution that would make this routine task safer by eliminating the potential for injury caused by shoulder, back, and/or neck strain.

Plant personnel, including Chief Engineer Anthony Angieri and OMT Nicholas Post designed a simple lift system, utilizing a locally purchased manual winch. The winch provides a means of lifting the filter element out of the frame by utilizing its inherent mechanical advantage (photos). The lifting hoist has been a great success, with employees happy to have a simple and effective method to perform an unpopular task.

Custom platform, I-beam facilitate maintenance, improve safety at Lawrence

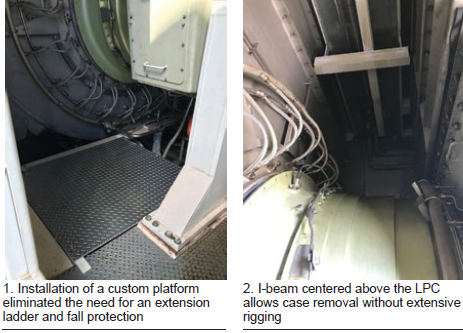

At Hoosier Energy’s Lawrence Generating Station, a peaking facility with six LM6000s, certain maintenance evolutions inside the gas-turbine packages required technicians to use an extension ladder. Example: The Kvaerner package does not have a deck at engine level so technicians had to use an extension ladder to work on the low-pressure compressor (LPC).

The ladder was lowered 4 ft from engine level so the footing could be safely secured to the package floor. This required the technician to don fall protection to complete both routine and non-routine LPC maintenance and created an ergonomically uncomfortable work environment.

Another challenge was to eliminate the rigging necessary to remove the LPC case. Rigging chains create a major safety hazard to the technicians and to the equipment. Chain-falls become a trip hazard and create several pinch points and hand traps. Chain-fall rigging requires extreme care while removing the LPC case in order to prevent airfoil damage.

The plant safety committee, including Matthew O’Hara, lead O&M technician, discussed options and decided that a custom diamond-plate platform would eliminate the need for an extension ladder and fall protection (Fig 1). It also would allow technicians to work safely from an ergonomically friendly position.

Plant Manager Robert VanDenburgh’s operations team discussed options and concluded installing an I-beam above the LPC case would allow technicians to remove the case without extensive rigging (Fig 2). One technician can comfortably work from the installed platform to complete the LPC case removal without the dangers associated with ladders and rigging.

Results:

-

- The custom platform installed in the LPC work area eliminated the fall hazard. The LPC now can be accessed without the need for an extension ladder or fall protection. Plus, ergonomics of this work environment have been improved dramatically.

- The I-beam installed above LPC aft of the VBV ductwork allows for safe and level case lifts without need for extensive rigging.

Instrument relocation promotes safe, easy access to vital data at Toronto plant

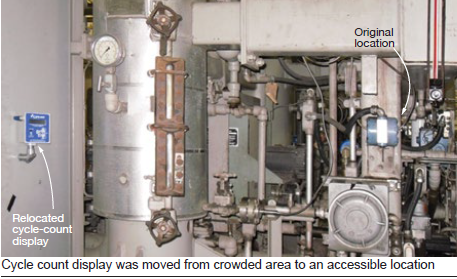

The 2 × 1 combined-cycle cogeneration plant serving the Greater Toronto Airport Authority (GTAA) has two gas compressors, one for each of the plant’s LM6000s. Proper operation of the compressors is critical for achieving high engine availability.

Each compressor is equipped with a lubricator cycle-count display. It’s important for cycle count to be relatively constant too ensure against excess oil which could mix in with the natural gas being compressed. The display was in a location difficult for personnel to access and take readings. Plus, ever-present oil mist made for a slippery deck.

The safety hazard was exposed when an operator slipped and lost his balance while gathering data, hurting his back in the process. The injury was not a major one, but the incident provoked a thought process to mitigate this risk.

Plant Manager Don Tiffney’s staff initiated measures to ensure that the area is maintained clean and also installed anti-skid strips on the floor. But this was a temporary solution. Next step was for O&M Manager Socrates Furtado’s team to examine the feasibility of relocating the cycle-count display away from the unit in a location more accessible to operators. Personnel installed a limit switch next to the lubricator and wired it to a new cycle-count display mounted on the main panel, as shown in the photo.

Relocation of the display mitigated the risk of injury to operators during their shift rounds. Also, the new location prevented oil mist from depositing on the display, making it easy to view the parameter displayed.

Mitigating hazards associated with inspection of air-inlet chiller coils at Worthington

Hoosier Energy’s 174-MW Worthington Generating Station relies on four 1800-ton chillers during summer peak operations to provide 40F water to the air inlet houses of its four LM6000s, thereby ensuring top gas-turbine performance.

To protect against freeze-up during the winter, 40% glycol is added to the chilled-water loop; a small boiler maintains loop temperature at 54F. The warm glycol/water mixture circulates through the inlet coils, heating inlet air to maintain the optimal temperature for efficient generation.

Periodic coil inspections required removal of the upper panels on the filter house which can be accomplished only from the top of the structure. This dictated an aerial lift and fall protection. The aerial lift created a safety hazard and fall protection increased the time required to complete inspections.

Among the challenges facing plant personnel were the following:

-

- How to eliminate the need for an aerial lift.

- How to engineer out the need for fall protection.

- How to remove the access panels without need for a pry bar.

- How to decrease the amount of time needed to complete coil inspections.

Plant Manager Robert VanDenburgh’s operations team concluded that the safest way to access the coils was to install a fixed ladder to the top of the filter house. The team also decided to install a guardrail on top of the filter house package to remove the fall hazard. Plus, handles were installed on each of the four coil cover plates to eliminate the need for a pry bar. The handles eliminate pinch points and hand traps which will allow the technician to remove the coil plates with increased safety and greater ease.

Results:

-

- By installing ladders and guardrails, the fall hazard associated with the coil inspections has been eliminated. Plus, the amount of time needed to perform inspections also has been reduced.

- Because many inspections are conducted during cold weather conditions, minimizing exposure to the elements also created a safer work environment. Installing handles to the coil access plates completely eliminated pinch points and hand traps, adding another layer of safety to this task.

- Plant personnel created a much safer work environment while reducing the time needed to complete inspections. The safety improvements have enabled an increase in inspection intervals, thereby boosting gas-turbine performance.

Pinelawn’s safety mod for easier filling of LM6000 hydraulic start reservoir

The challenge was to find a safer way to add fluid to the gas-turbine hydraulic starter reservoir, which is located under a system radiator and tucked away in the corner of its auxiliary enclosure. The original design situated the fill port in a cramped and hard-to-reach location, thus creating the potential for staff injury as a result of strain or from a slip/trip/fall.

Plant Manager Kenneth Ford’s team at this 1 × 1 combined cycle looked at several solutions, but in consideration of the challenging enclosure configuration, decided to relocate the fill port by simply adding several short lengths of piping. It is now in an easy-to-reach location and at a greater vertical height thus creating a much-improved ergonomic work environment.

Relocating the fill port has reduced the chance of injury from awkward body positioning. The modification generated very positive feedback from the site O&M personnel who recognize the importance of a safe workplace.