A distinguishing characteristic of annual meetings hosted by the Alstom Owners Group is its training workshops. The AOG has a full day of in-depth workshops planned for the upcoming 2023 meeting, March 20-24, at EPRI’s corporate offices and training facility in Charlotte, NC. A preliminary 2023 conference agenda is posted at www.aogusers.com, where you’ll also find registration, lodging, and other pertinent information. Contact ashley@aogusers.com with any questions. The 2022 program featured three two-hour training sessions during the second week of the virtual event—one in Spanish language. The three sessions were conducted by these well-respected presenters with deep technical experience:

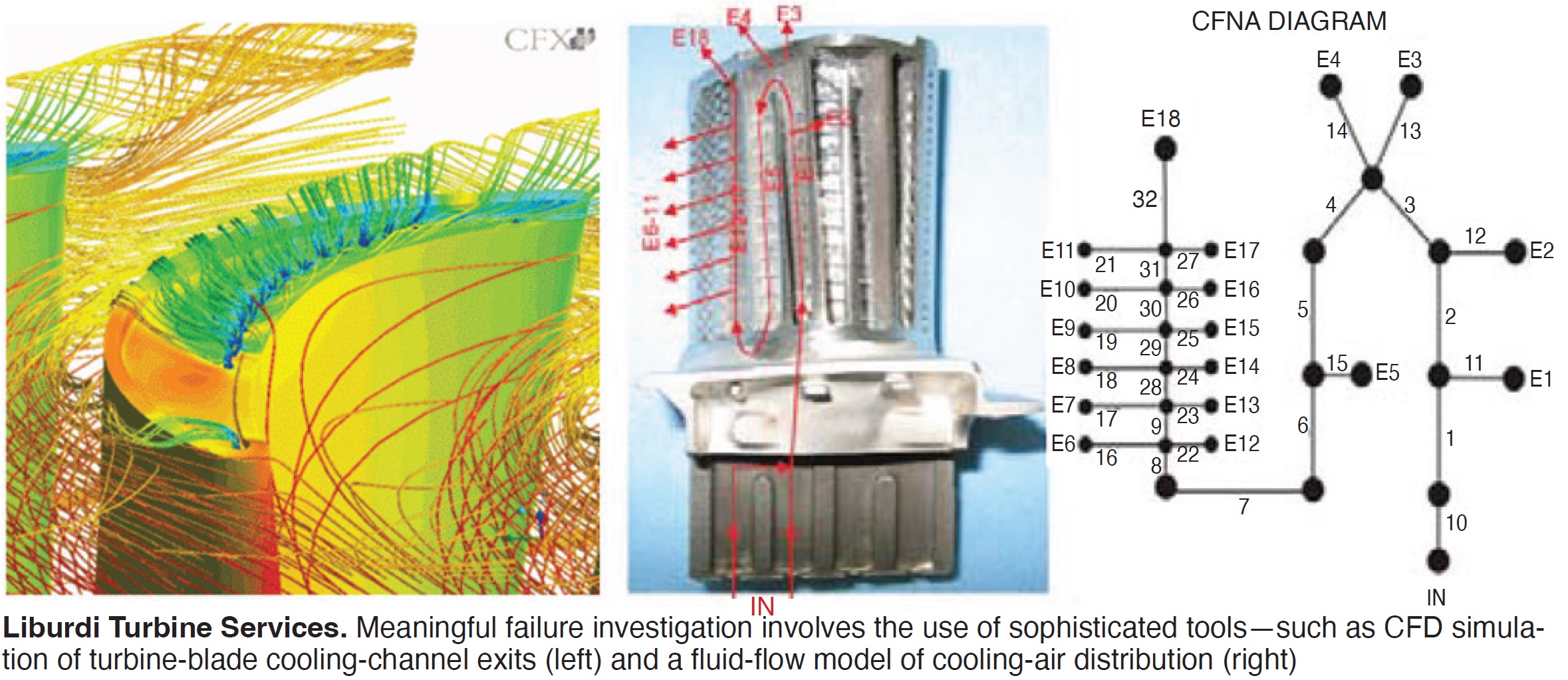

- Doug Nagy, manager of gas-turbine component repair at Liburdi Turbine Services.

- Miguelina Curcio, manager of gas-turbine component repair at Liburdi Turbine Services.

- W Howard Moudy, director of operations, National Electric Coil.

Both presentations are worthy of consideration for lunch-and-learns in the plant break room. It’s easy to divide both workshops into two one-hour sessions. For example, Nagy’s lends well to segments on failure-analysis techniques and causes of gas-turbine failures; Moudy’s to a session on stators and another on rotors.

Gas-turbine component repairs (English and Spanish)

Nagy began by saying failure analysis is a strong learning opportunity and that all failure analyses should lead to one or more corrective actions. Failure analysis, he says, encompasses root-cause determination, investigative frameworks (such as fishbone diagrams), methods, and testing, and mechanical analysis.

First steps include gathering accurate reports and evidence on the affected components, plus conducting mechanical and metallurgical examinations. The importance of visual and dimensional inspections is covered, along with a review of nondestructive testing methods (liquid penetrant, magnetic particle, eddy current, ultrasonic, x-ray, and microhardness). All this is both a good refresher for experienced staff and a primer for newcomers. Slide format is conducive to input from attendees for sharing experiences; it is not textbook style with lots of words.

Causes of gas-turbine failures are explained and well-illustrated in more than half of the slides. The outline of that content below might encourage your review of the presentation:

- Design factors—design basis of components, system design deficiencies, economic and environmental constraints.

- Operational factors—procedural errors, common operational mistakes, and monitoring and data analysis.

- Maintenance factors—maintenance plan and schedule flaws, and design migration.

- Repair factors—design basis for repairs, effect of refurbishment on potential integrity, and inspection during the repair process.

Generators 101 essential for plant operators

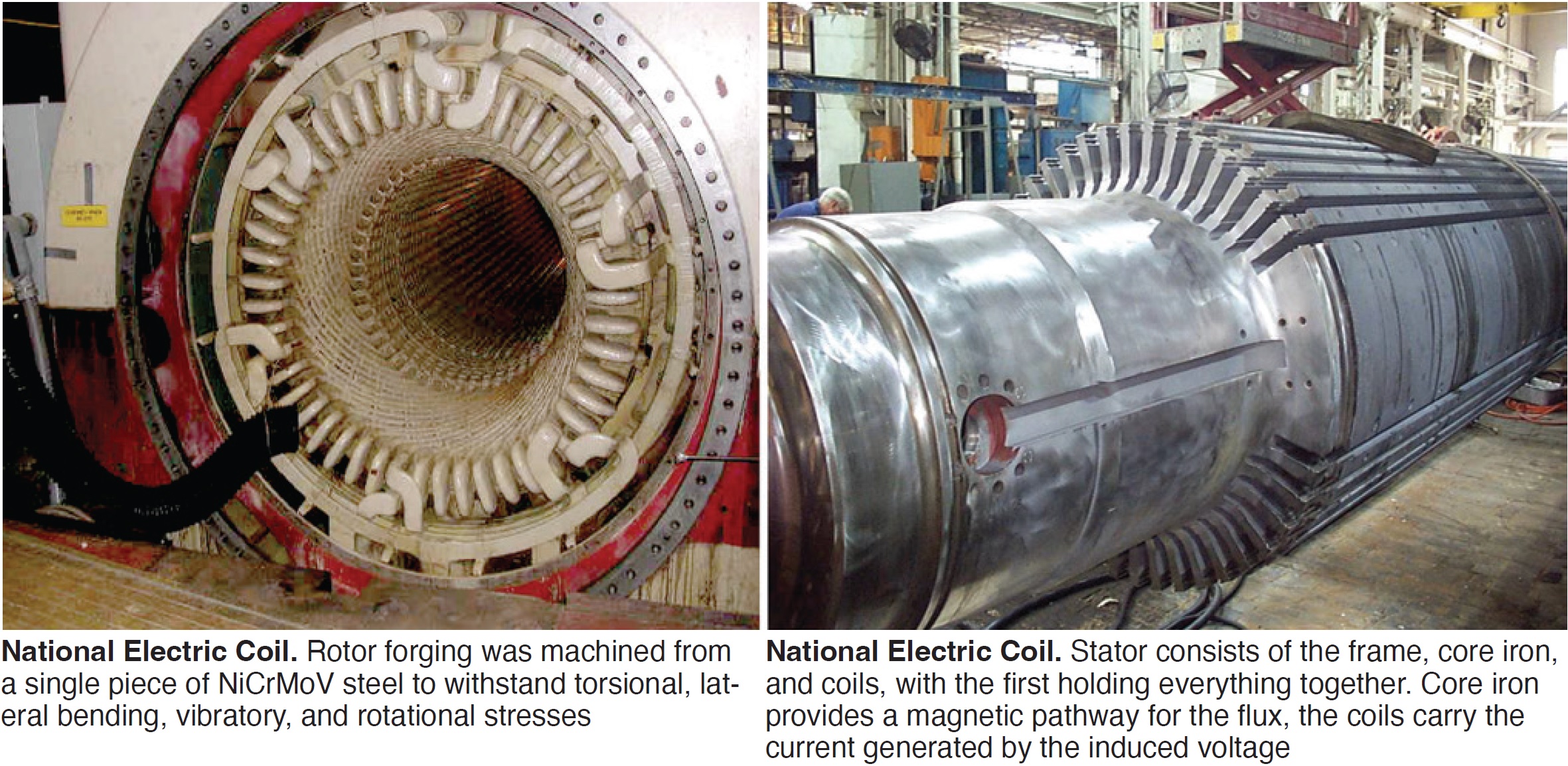

Moudy’s stator tutorial resembles a medical text showing all the body parts. The illustrations will benefit greatly O&M personnel who never have seen a generator apart. The stator, Moudy said, consists of the frame, core iron, and coils, the first “holding everything together.” The core iron provides a magnetic path for the flux, while the coils carry the current generated by the induced voltage.

Illustrations of proper core clamping and the types of core laminations follow. Spark erosion then is explained and described with photos showing the progression of a failure. Side ripple filler was touted as a cure for SE.

Final topics in this portion of the program included the following: stator slot wedges, stator coil bracing, coil design, endwinding stability, and phase leads and phase rings.

In his rotor tutorial, Moudy began at the beginning—with William Sturgeon’s finding in 1823 that current running through copper wire wound around a piece of iron produces a magnetic field. He reviewed the basic components of rotors and their purposes. For example, the shaft, retaining rings, and wedges are of forged steel, the winding of copper. Then there’s the insulation.

The photo nearby shows the slots machined in the rotor forging to hold the winding’s copper turns. Wedge grooves, “fir tree-” or “T-” shaped allow wedges to hold copper turns in place during rotation. He went on to describe the various types/designs of retaining rings and the material preferred for them for holding the windings in place.

Cooling was Moudy’s next topic. He covered conventional indirect cooled, inner-cooled conductors, inner-cooled coils and insulation, and GE’s diagonal cooled windings. Details on coil-to-coil and pole-to-pole connectors for a variety of machines followed.

Remaining segments of the presentation included end-turn blocking, rotor slot wedges, slip rings/collector rings, radial and axial connections, J-strap leads, rotor journals and bearings, and rotor fans/blowers.