Indeck Niles Energy Center

Owned by Indeck Energy, KOSPO USA, and DL Energy

Operated by PIC Group Inc

1085 MW, gas-fired 2 × 1 7HA.02-powered combined cycle with a GE 602 steam turbine and Doosan heat-recovery steam generators, located in Niles, Mich

Plant manager: Kevin Kringle

Challenge: Indeck Niles Energy Center was not equipped with an emergency notification system to alert individuals onsite during a system-wide event. The number of plant personnel onsite averages 14 or fewer daily, with contractors adding perhaps more than 100 individuals per day during outage maintenance events. Given the plant’s size and the number of contractors onsite, staff is not able to issue radio equipment for each individual.

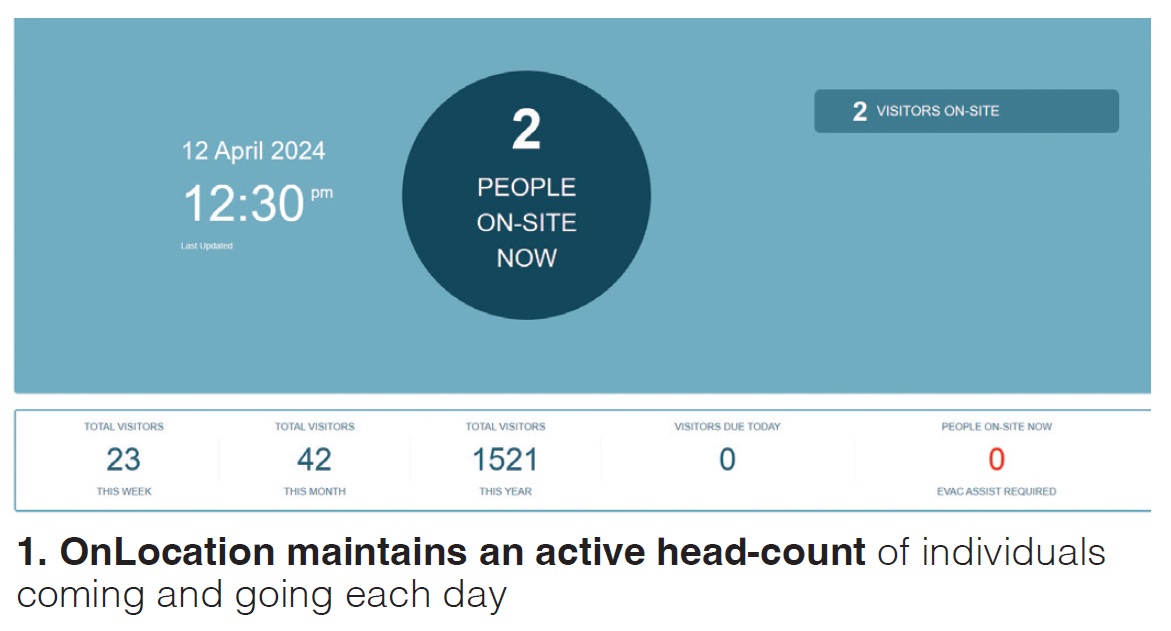

There is added difficulty in managing multiple types of documentation for site visitor logs, Covid-19 screening questionnaires, completion of site safety orientation, facility blacklist of banned personnel, and maintaining an active head-count of individuals coming and going each day (Fig 1).

Solution. MRI OnLocation, a flexible software solution for managing visitor information in real time, allows for site-specific screening questionnaires, tracking of facility head-counts for muster emergencies or evacuations, completion tracking of facility safety orientation, and blacklist of people banned from the site.

Most notably, the platform sends out live SMS notifications to all personnel on the property in the event of an emergency and provides instructions/protocols simultaneously for the facility. The platform’s OnEvac mobile app is configured for use in the event of an evacuation for a manual roll call of personnel onsite via SMS or phone call. Platform administrators send out automated “Are you safe” requests to all users with cell-phone numbers saved to their profile.

Use of this system allowed for safe social distancing practices during Covid-19 mitigation efforts sitewide. The OnLocation platform offered touchless entry and exit, and pre-screening questionnaires as needed.

The platform is web-based, and it provides constant traffic counting for entry and exit points assigned to the facility.

Plus, the platform maintains an indefinite digital log for the facility, which can be referred to for contact tracing, labor timesheets, and incident reporting at any time. This aids to manage the health and safety of both site employees and contractors/visitors from a single platform.

Results. OnLocation eliminated the need to manage multiple programs for each person coming and going from the site. The system is entirely cloud-based, so it does not take up any additional memory space on facility network computers or hardware.

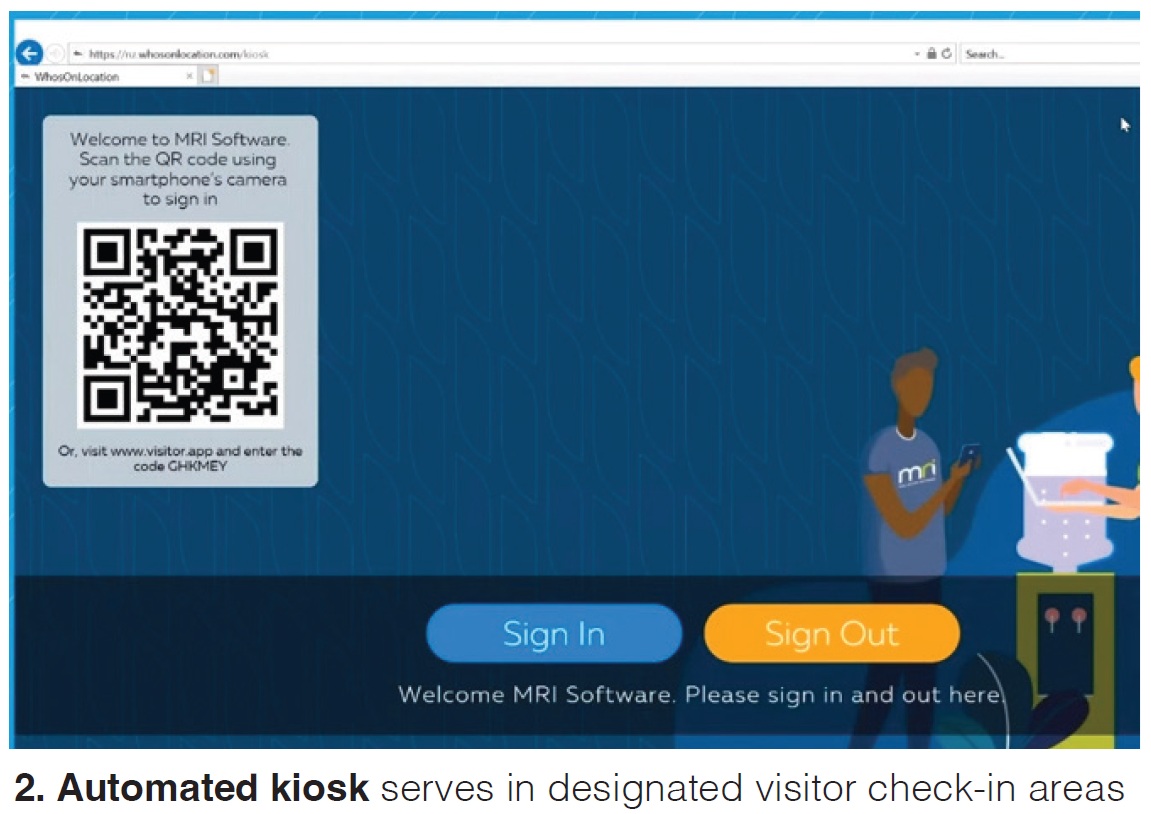

A site-specific QR code generated by OnLocation is printed and posted at facility entry points and replicated as needed. An automated kiosk can also be used via laptop, tablet, etc, for designated visitor check-in areas (Fig 2).

Multiple entry and exit points can be configured without any limitations on quantity for each facility. QR codes can be updated and regenerated as often as desired for an added layer of security. QR code posters are highly customizable to include site-specific logos, colors, or labels as required.

Employees hosting a visitor automatically receive a notification of the visitor’s arrival, once he or she has completed facility check-in. Notifications are sent directly to employees via email or mobile phone number. After initial visitor entry, OnLocation will remember and store that individual’s profile for future check-ins.

OnLocation also generates reports of people present for administrators, which can be exported via pdf or csv files. Additional features include grant/deny access, acknowledgement notices, and printing of badge passes upon arrival for a visual verification of sign-in process completion status. Facility administrators also can set maximum occupancy rules for automatic notification of thresholds reached.

Installation time for OnLocation was minimal, with significant cost saving as opposed to purchase of a site-wide PA system or radio rental contract. This has greatly contributed to overall workplace safety, security, and communications at Indeck Niles.

Project participants:

Cora Cook

Kevin Keiper

Gregory Winters