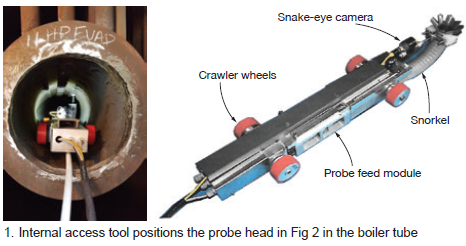

Innovations, looks forward, and disclosure of new ideas were hallmarks of the second annual HRSG Forum with Bob Anderson, held earlier this year in Houston. TesTex Inc, Pittsburgh, Pa, was there with a collection of ideas including its proprietary remote field electromagnetic technique (RFET) equipment (Fig 1).

For internal tube inspection, TesTex has developed and operates this proven method for accessing the finned tubes through the headers. Forum participants could not only see the system and watch it operate; they could touch it.

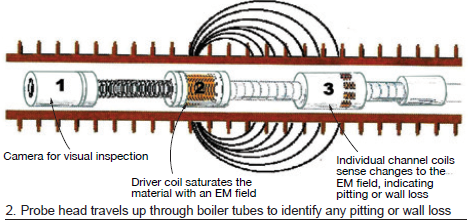

With the internal access tool inserted, a flexible RFET multichannel probe head is inserted into each tube (Fig 2). The probe includes a camera, a driver coil that saturates the material with an electromagnetic field, and eight individual pick-up coils that sense changes to the field, indicating pitting or wall loss. Results are shown both visually and graphically—and recorded.

The probe is inserted into the vertical tubes and pushed upward to the top header. It captures readings and video images as it is inserted into and retracted from each tube. The flexible multichannel system travels at 2 to 3 in./sec, collecting 480 samples per channel per second, at a frequency of 15 Hz.

“Assuming the conductivity and magnetic permeability of the tube are constant, any variations in wall thickness at the two coils cause a change in the phase and amplitude of the received signal,” explained Shawn Gowatski, manager of the company’s solutions providers group. “The multiple pickup coils allow detection of small localized anomalies.”

To enable the probe to complete the 90-deg horizontal-to-vertical bend, the current header ID minimum is 5.25 in. There is no maximum ID limit. Current header-to-header tube length limit is 70 ft.

TesTex has been working with RFET since 1987.

Also on display was the proprietary low-frequency electromagnetic technique (LFET) system. With this, TesTex personnel can examine HRSG finned tubes from the exterior to detect and quantify internal pitting, wall thinning attributed to flow-accelerated corrosion, and other damage issues. The signal penetrates the tube through the fins to identify any tube wall thinning or irregularity.

“This hand-operated system is used for the leading- and trailing-edge HRSG tubes. A two-person crew can examine approximately 1,000 linear feet of tubes in a shift,” explained Gowatski. The technology is also used on tube walls and sections of large fossil-fired utility boilers.

The hands-on demonstration at the HRSG Forum featured a 2-in.-OD carbon steel tube, 0.150-in. wall thickness, with 0.75 in. fins. Two 0.5-in.-diam pits had been machined on the inside tube surface (30% and 60% deep). Three output views were presented: side-view phase plot, top-view simulated color B-scan, and 3-D window.

LFET inspections are designed to locate and identify pitting, general wall loss, caustic and phosphate gouging, corrosion cells, hydrogen damage, microbiologically induced corrosion attack, flow-accelerated corrosion, cracking, erosion, and manufacturing defects.

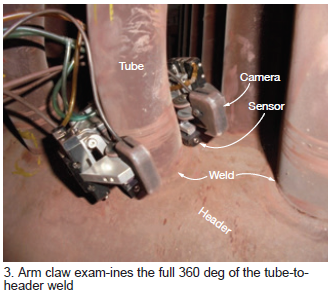

Also of interest at the HRSG Forum was the balanced field electromagnetic technique (BFET) inspection for tube-to-header welds. Customized “claws” hold sensors and cameras as the assembly moves circumferentially around the weld. Results detect and confirm any cracking, lack of fusion, porosity, or other defect.

This is used for header diameters of four in. and larger. The claws are able to examine the tube-to-header welds for tube diameters of 1.5 to 2.5 in. These claws can traverse 360 deg of the tube-to-header weld (two coils spaced 180 deg apart) and include two cameras for visual inspection and recording (Fig 3).

This is used for header diameters of four in. and larger. The claws are able to examine the tube-to-header welds for tube diameters of 1.5 to 2.5 in. These claws can traverse 360 deg of the tube-to-header weld (two coils spaced 180 deg apart) and include two cameras for visual inspection and recording (Fig 3).

The arm claw can examine the first two rows from the access point. A crew is able to inspect approximately 200 welds per shift. Electromagnetic sensors assess the tube-to-header welds in an HRSG without any surface preparation. “Our clients like the fact the claw is able to examine 360 deg around the tube to header weld and they do not have to perform any sand blasting,” said Gowatski.

TesTex provides NDT products and services for both ferrous and non-ferrous components. Clients include fossil and nuclear power generation, chemicals, and refining, among others. The company also performs corrosion-under-insulation inspections.