MD&A kicked off its fall 2022 webinar series with a presentation on rotor life extension. You’ll want to take an hour and listen in if your plant has a 7F unit approaching 5000 starts/144,000 equivalent operating hours (EOH) or a 7B through 7EA unit approaching 5000 starts/200,000 EOH. Get the background on these requirements in “Heavy-Duty Gas Turbine Operating and Maintenance Considerations,” GER 3620P, January 2021, available at no cost on the Internet.

Fred Willett explained that MD&A seeks a balance between a standard approach and one customized to address each user’s unique machine characteristics. “All new rotors are the same, but all used rotors are unique,” he said. For this reason, Willett had to answer most of the questions with “talk to our sales rep”—questions such as “What is the lead time for a 7FA rotor?” and “Can you do compressor reblading at the customer site?”

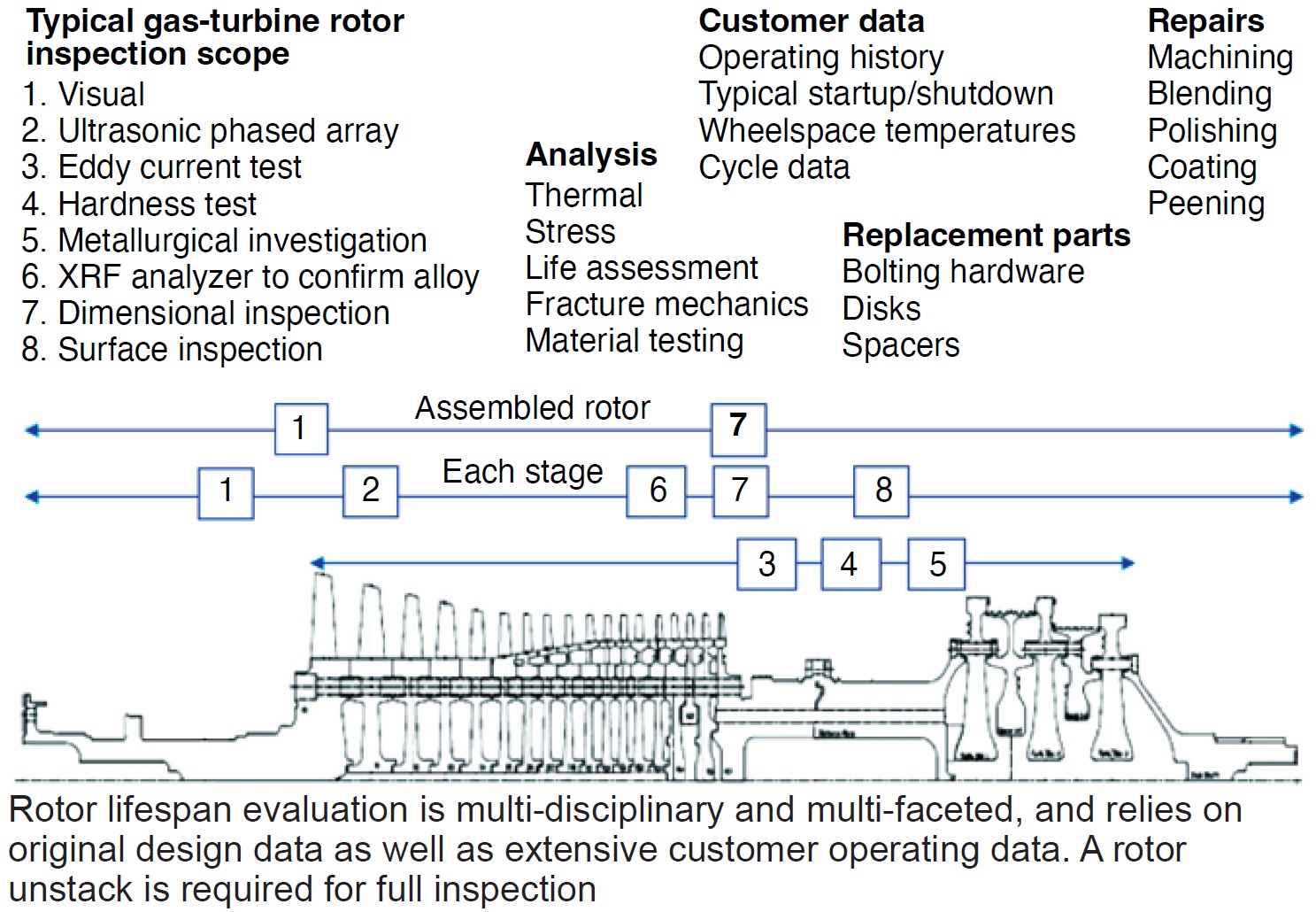

Goal of a rotor lifetime assessment (RLA) is to designate each rotor component for reuse, repair, or replace “for the continued safe and productive operation of the unit” (Fig). For example, thermal transients impact the back-end stages of a compressor far more than the early stages. In one example, Willett noted that new wheels were required for Stages 13-17 while Stages 1-12 could be repaired or reused.

Temperature obviously is the main factor in the stress concentrations in latter stage wheels but Willett also dwelled on the contribution from the “dovetail skew angle” which increases from the front-to-back stages of the compressor discs.

Regarding the turbine section, Willett noted that disks “have had their share of problems,” and in recent years, so too failures of the 1-2 spacer, for which “there is more than one machine failure known.” Importantly, MD&A offers first-stage discs with redesigned cooling slots, has patented a geometry for an upgraded 1-2 spacer, and has upgraded components for all the other rotor problem areas.

Willett touted MD&A’s parent, MHI, and, as an OEM, its “deep domain expertise” in this area. MHI has conducted over 270 comprehensive rotor inspections, with shops and labs in the US and Japan. Some of that expertise was obtained by reverse engineering and manufacturing rotors which were purchased by customers but never installed or operated. When one listener asked if MD&A’s upgraded components also have durability improvements, compared to the OEM, Willett’s answer was an unequivocal “Yes.”

The slides include some very insightful heat maps of compressor rotors during different points along the startup and shutdown sequence, as well as detailed diagrams of component stress concentration points.

Access this recording @ https://www.mdaturbines.com/webinar-archive/