EthosEnergy Group presented two complementary webinars in early fall: “Turndown or shutdown?” and “How to keep your aging GE gas turbine running longer”. Presenter and moderator for the first was Jeff Schleis, chief engineer, products and application. He was supported by Principal Engineer Chris Chandler, an expert in turbine optimization and engineered solutions for gas turbines.

Schleis noted at the outset that for a significant number of gas-turbine owners and operators today, “the unspoken question is ‘turndown or shutdown’?” Greater investment in, and prioritization of, renewables generation is reducing the capacity factors of gas-fired assets because of increased cycling operation. Result is many plants are examining the benefits of extended turndown and wondering if it can improve the bottom line.

Most likely, it was said, a bottom-line improvement will be experienced where the share of renewables in electric production exceeds 40%. According to data from S&P Global Market Intelligence, 13 states are poised to exceed the 40% threshold in 2023.

Schleis cautioned that knowing the financial impact of cycling versus the net loss to generate at off-peak times is not easy to evaluate accurately. Fewer starts, lower fuel costs, and ultimately extending the time between outages all factor into the return on investment. Enabling turndown beyond the unit’s current capability can tip the economic scales and reduce the negative impact of cycling.

The moderator identified the following steps on the path to extended-turndown profit: 1, understand turndown limits; 2, conduct testing; 3, consider modifications; 4, validate financial analysis; 5, install an integrated solution. If the stars align, you will improve the bottom line.

To get a better feel for what attendees were experiencing, Schleis asked a couple of questions:

First, concerned current operations. The takeaways included:

- Cycling more, 72%.

- Cycling less, 4%.

- Operating at different times of the day, 31%.

- Running less, 18%.

Answers to the second question revealed where attendees were on the path to extended turndown:

- Actively operating in an extended-turndown mode, 17%.

- Creating a formal business case, 9%.

- Testing turndown limits, 15%.

- Researching solutions, 31%.

- Operating profile does not benefit from extended turndown at this time, 25%.

Benefits of turndown discussed included the following:

- The switch from starts-based to hours-based maintenance provides a greater opportunity for parts (and rotor) life extensions. Plus, it decreases the severity of parts repairs.

- Decrease in midday losses attributed to renewables generation because you continue to run when large amounts of solar/wind kilowatt-hours drive down prices.

- Cogeneration plants may satisfy their contractual requirements at reduced load. When steam production is more profitable than power, turn down the unit to maximize thermal energy with minimum power generation. Another strategy: Run redundant units for reliable steam production at minimum power generation.

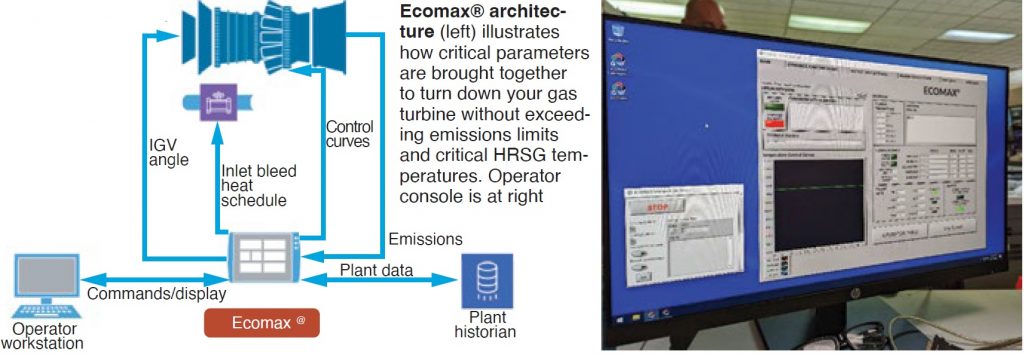

Ecomax®, an EthosEnergy solution, is discussed as a critical tool for maximizing turndown. As the diagram shows, its automatic tuning feature manipulates control curves and IGVs to keep your GT within emissions limits. Plus, automatic tuning of GT control curves reduces the isotherm. Getting down to 50% of the baseload rating, or lower, might also mean reducing air flow through the machine. Addition of inlet bleed heat and automatic adjustment of the IGV angle can contribute here.

One of the case studies presented illustrates how EthosEnergy achieves its operational goals. A cogeneration plant with three GE Frame 6B engines served as the example. Key points:

- Premix minimum load decreased from 70% to 50%.

- Testing proved turndown to 30% possible before CO limits are exceeded.

- NOₓ emissions are maintained below 25 ppm.

- Exhaust gas temperature is limited to 1022F (max isotherm of 1085F) to maintain 950F in HRSG piping, by design.

- Process steam production was maximized with minimum generation and no duct firing.