Pre-job briefing card promotes safer workplace

Challenge, solution, and results. NRG Energy has developed a safety process called “Hurt Search” to keep plant personnel from falling victim to hazards that could be easily overlooked. We perform “Hurt Searches” on all work requiring lockout/tagout as well as on random daily work activities.

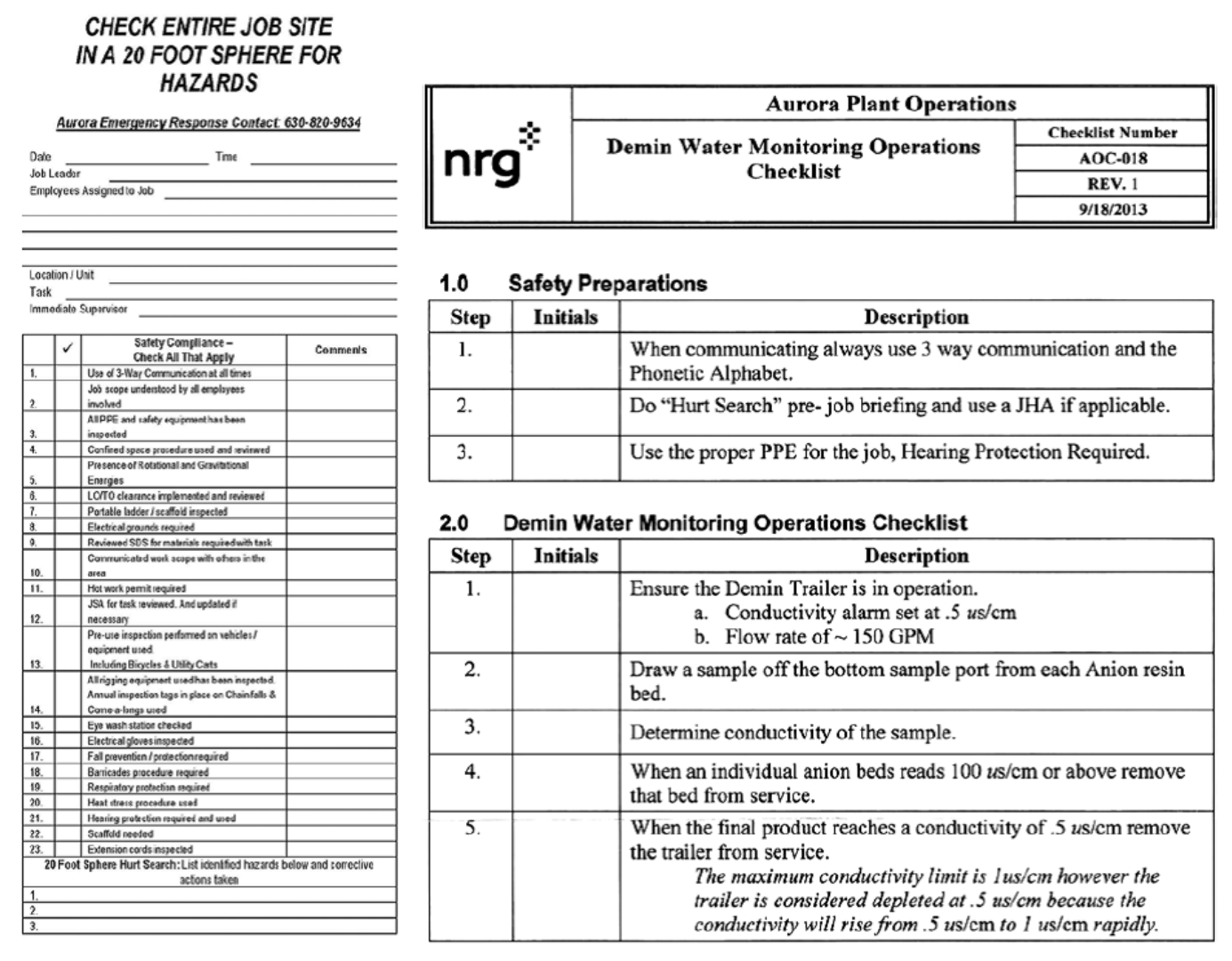

Prior to performing work, a second or third party performs a safety review (card, left). These “Hurt Searches” consist of viewing and considering all hazards within a 20-ft radius of where the work is being performed. The safety review has been a great success with zero recordable injuries, zero loss time injuries, zero minor injuries in over four years.

Demin-water checklist

Challenge, solution, and results. Plant operators perform continuous conductivity monitoring of the demineralized-water produced during operations. A checklist is used (below) as a guide to test and track the conductivity of individual anion beds. Once an anion bed reaches a point of being depleted, it is isolated from the process.

This practice has proven to increase the throughput of the demin trailers by more than 10,000 gallons. This increase has generated a cost savings on average of $20,000 per year for the plant.

Project participants:

Jim Brown, plant manager

Robert Isaac, O&M supervisor

Aurora Generating Station

NRG Energy Inc

946-MW, gas-fired, 10-unit, simple-cycle peaking facility located in Aurora, Ill

Plant manager: Jim Brown