Pneumafil/Nederman

It doesn’t have to be a balance between efficiency and operating flow resistance.

Starving incoming air flow to a gas turbine forces it to consume more fuel and potentially de-rate, or force a shutdown of the turbine. Ingestion of sub-micron contaminants foul turbine blades causing compressor degradation. Many owner/operators used to think they had to choose between acceptable operating pressure drop, and high particle capture efficiency. Not anymore.

Self-cleaning filter houses, when applied in atmospheric conditions with low ambient dust concentrations and small particulate sizes, struggled when operating “online” to remove fine particulates.

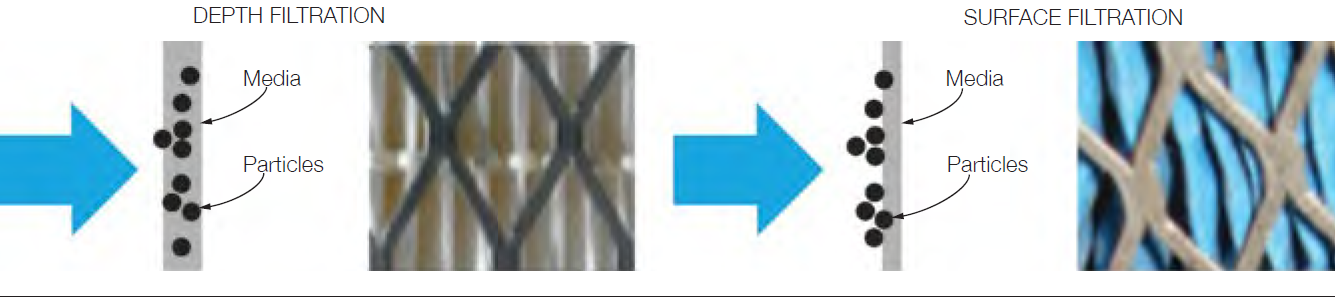

Depth-loaded static filter technology was originally developed for the HVAC marketplace, where media technology focused on dealing with the lower dust concentrations and very small dust sizes. Depth filtration typically uses a thicker layer of media, or multiple layers (also known as composites), to separate the fine particles by creating a torturous flow path. Larger particles would be captured on the surface or on pre-filter stages with progressively finer particles separated through the thickness of layers.

The higher-porosity media structure of depth-loading media combined with improved fiber and mechanical element design has an inherently lower resistance when compared to surface-loaded wet-laid pulse media. The highly engineered fibers used in composite-media structures now offer users the ability to eliminate compressed-air pulse systems. Similarly, operators save money on maintenance of the cooler skids for compressor take offs or on plant air to supply the self-cleaning systems.

If your operating conditions include low ambient dust concentrations and you haven’t seen significant reductions in DP by using pulse cleaning, you may gain a few benefits by discontinuing the use of the self-cleaning pulse system. Consider the potential advantages of how depth-loaded synthetic media can be applied to the cartridge design you use.

Although wet-laid micro-glass fibers are a proven filtration medium, synthetic fibers are more robust and durable. The combination of continuous strands and staple lengths provide loftier and more porous structure. They have better performance during humidity and moisture and recover more quickly to upset conditions. Significant reduction in fine particle ingestion to the turbine with no pressure drop penalty may provide the next step in your continuous-improvement efforts.