Reduce startup time with condenser vacuum pump

Challenge. A goal of management at the Aureliano Chaves Power Plant was to improve starting reliability and reduce the time to breaker close, both important to the facility’s financial success.

As designed, the plant’s hogging steam-jet ejector was expected to pull vacuum to enable fast starting. However, it took approximately 2.5 hours to reach the desired vacuum. Plus, the starting steam ejector required a high level of operator intervention. In sum, Chaves startups using the supplied steam ejectors were too long, starting reliability was poor, and resources (fuel, cooling water, personnel time, etc) were wasted.

Solution. Chaves technical staff analyzed the available technologies to identify the best alternative for pulling vacuum on startup. It was to install a vacuum pump in parallel with the existing starting steam ejector (Fig 1). Note that the vacuum pump is operated only during startup; the more-efficient steam-jet evacuation system is used during normal plant operation to hold vacuum.

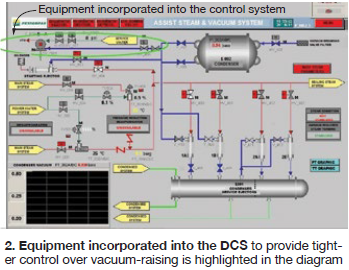

To implement the project, electricity supply was provided through an MCC panel, sealing water to the pump through a service water line, and operational control through the plant’s DCS (Fig 2).

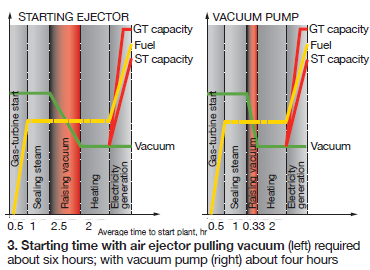

Results. The proposed solution to install a vacuum pump and significantly reduce the time for unit startup resulted in a two-hour saving plus other benefits (Fig 3). The details:

- Plant starts before installing the vacuum pump took about six hours; after, four hours.

- It took 2.5 hours to pull vacuum before modifying the air-evacuation system, 20 minutes after.

- Fuel gas required for vacuum-raising during startup was reduced by more than 90%.

- Demin water consumption was nearly 90% lower.

- Cooling-water requirements were 20% of what they were for the as-designed system.

Additional project benefits: Automation of vacuum raising and maintenance was improved; operator intervention was reduced; starting reliability and safety were improved significantly.

Project participants:

Eduardo Lúcio Nahass de Alcântara, electrical engineer

João Victor Santos Miranda, electrical engineer

Jaime Roberto Gapski, automation engineer

Eldon Zica Mendonça, mechanical engineer

Aureliano Chaves Power Plant

Owned by Ibiritermo SA

Operated by Petrobras

226-MW, gas-fired, 1 × 1 combined cycle located in Ibirité, MG, Brazil

Plant manager: Eloisia Barbosa de Almeida Pinto Coelho