Shoreham Energy LLC

Owned by J-Power USA

Operated by NAES Corp

90-MW, two-unit, peaking facility located in Shoreham, NY

Plant manager: Kenneth Ford

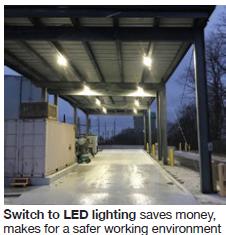

Challenge. The high-pressure sodium lighting in the fuel oil (FO) offloading area at Shoreham was dim and existing light fixtures were heavy and prone to failure. Whenever one did fail, it was a challenging task requiring complete removal of the fixture from the underside of the roof in order to replace any failed components (starter, ballast, wiring, etc) The frequency with which these older, heavier fixtures were failing suggested that a more permanent solution was necessary.

Solution. Plant staff engaged a vendor whose core business is to provide LED retrofit assemblies for most commercially available standard lighting fixtures. The aim was to replace the existing fixtures with LED retrofits that offer a much lower profile, thus preventing the bases from being impacted by the wind (the most common cause of failure of the older style models.)

Solution. Plant staff engaged a vendor whose core business is to provide LED retrofit assemblies for most commercially available standard lighting fixtures. The aim was to replace the existing fixtures with LED retrofits that offer a much lower profile, thus preventing the bases from being impacted by the wind (the most common cause of failure of the older style models.)

Cost also was an important consideration because replacement parts for the existing light fixtures were proving more and more expensive, and harder to come by.

Results. Since replacing all the fixtures within the FO offload area with LED retrofit kits, there has not been any unexpected maintenance. The low profile of these lights secures tightly to the box mounts, so wind is no longer a factor. Plus, the area is dramatically brighter, providing much safer walking and working surfaces for plant staff.

From a financial view, the LED retrofit kits, on average, were less than half the cost of replacement incandescent fixtures.

Project participants:

Eddie Lozada, I&C technician

Anthony Angieri, chief engineer

John Lawton, O&M manager