After opening drum doors for inspection, replacing manway gaskets typically calls for plant staff to tighten the manway bolts to a given torque to hold the manway cover in place while the drum is below operating pressure. The seal around the manway is formed when the pressure from the steam inside the drum provides enough force to compress the gasket between the sealing surfaces on the door and drum.

After opening drum doors for inspection, replacing manway gaskets typically calls for plant staff to tighten the manway bolts to a given torque to hold the manway cover in place while the drum is below operating pressure. The seal around the manway is formed when the pressure from the steam inside the drum provides enough force to compress the gasket between the sealing surfaces on the door and drum.

Once the drum has been brought up to operating conditions, retorqueing (a/k/a hot torqueing) the bolts is required to ensure that slack in drum door hardware from thermal growth gets taken up and the gasket remains compressed when the plant is cycled. Hot torqueing places plant staff directly in harm’s way if something were to go amiss during this process.

Safety concerns, driven by events at other facilities, encouraged Dogwood Energy Facility personnel, led by Plant Manager Steve Hilger, to investigate possible alternative procedures for tightening the steam-drum manway bolts without putting personnel in a potentially unsafe position.

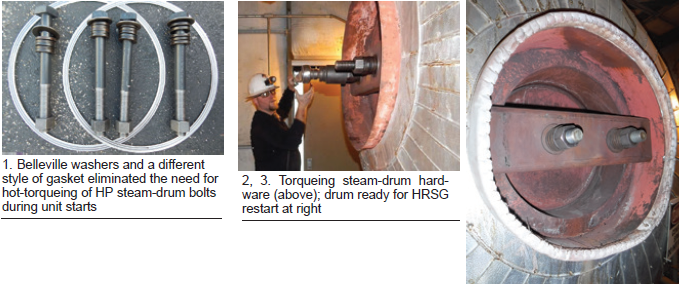

Dogwood worked with an engineering firm that was in the process of developing a solution using Belleville washers and a different style of gasket to eliminate the need for hot torqueing (Fig 1). Dogwood removed the existing studs and washers and replaced them with longer studs to accommodate the Belleville washers.

In addition, the engineering firm recommended use of a graphite ring gasket that does not liberate like the spiral-wound gaskets typically selected for drum doors. This design relies on the spring pressure of the Belleville washers to hold the gasket sealing surface tight as drums go from atmospheric to normal operating conditions (Figs 2 and 3). Note that the gasket has a spring-wave feature that allows it to accommodate thermal growth.

Dogwood Energy’s HP drums have round manways, not the elliptical ones found on most steam drums. Personnel confirmed that the recommended gasket was flexible enough to install through the drum door opening without distorting or damaging it.

Dogwood offered to be the beta test site for the Belleville washer and gasket arrangement in an effort to validate the engineered solution on its HP drums. The new assembly was installed on one of the HP drums during the fall 2017 outage and followed a test plan to validate the assembly.

Success. Dogwood completed installation of hardware on the Unit 1 HP drum in November 2017 and the following criteria were established to validate the design over a three-month test period:

-

- Conduct 1000 hours of cycling operations and/or a minimum of 12 unit starts during the test period.

- No additional torqueing of the manway hardware allowed.

- The measure of a successful test would be zero gasket leakage.

During the three-month test window, Dogwood operated for approximately 800 hours with the new gaskets and completed 23 unit starts. While the plant did not achieve 1000 hours of operation, management believed the new design had proven itself.

Dogwood did not hot torque the manway doors and did not experience any gasket leaks during the test period, when HP steam-drum conditions ranged from atmospheric to 2225 psig/645F (average HP drum metal temperature).

At the beginning of 2019, Dogwood had approximately 4400 operating hours and 200 starts on Unit 1 without any gasket leaks on the HP drum. The same system was installed on the Unit 2 HP steam-drum doors in May 2018 without any indication of a leak after approximately 3100 operating hours and 140 starts.

Given the good results, Dogwood plans to install a similar system on the IP and LP steam drums in the future.

Finally, Dogwood’s Engineering Manager Chuck Berg reminds that before modifying a drum door or other equipment in the plant, it is best to consult with the OEM or an engineering firm to ensure staff doesn’t miss anything in its evaluation of an issue concerning the recommended design change. This step also helps minimize potential issues in the future.

Dogwood, a 650-MW, 2 × 1 combined cycle powered by 501F engines, is owned by Dogwood Energy, City of Independence, Missouri Joint Municipal Electric Utility Commission, Kansas City Board of Public Utilities, and the Kansas Power Pool. The Pleasant Hill (Mo) facility is operated by NAES Corp.