Natural-gas fuel composition has considerable influence on gas-turbine emissions and operability. This might not have been a concern to you previously, but the possible impacts on your engines of increasing reliance on non-traditional pipeline gas—in particular, shale gas, but also LNG, and byproduct fuels from industrial processes—suggests you might want to read on.

Even if you have “good gas,” be aware that the negative impacts of gas-constituent variability can be magnified by the high firing temperatures of today’s most advanced gas turbines, Scott Sheppard, Ben Emerson, and Tim Lieuwen of Turbine Logic told the editors. Reason is that these machines must “work harder” to achieve low-NOx emissions and thus have fewer “knobs” to mitigate fuel-composition impacts, the trio added.

The Wobbe and Modified Wobbe indices are two standard properties used in practice to determine the effects of fuel variability. But they only indicate the changes in heating value and usually cannot describe how changing fuel composition will affect emissions and some potentially damaging operability issues.

Aside from NOx and CO emissions, there are four operability issues of importance to plant personnel. They are:

-

-

- Blowout, or when the flame physically exits the combustor; also referred to as blowoff.

- Flashback, or when the flame moves upstream into premixing sections not designed to withstand high temperatures.

- Combustion dynamics, or the damaging pressure oscillations associated with oscillations in the combustion heat release.

- Autoignition, or the spontaneous ignition of a reactive mixture of fuel and air in the premixing section of the combustion chamber. The effects of autoignition and flashback are the same, but the underlying reasons and fuel sensitivities are completely different.

-

These four issues, which the Turbine Logic team routinely observes when performing root cause analyses, pose risks to gas turbines and are closely tied to operating conditions and fuel composition.

Before discussing the impacts of fuel variability on gas turbines, Sheppard, Emerson, and Lieuwen said it is important to understand the composition of natural gas, which in North America typically contains 85% or more of methane. The next most common constituent is ethane at about 7% or less, followed by propane at about 1.5% or less. Other components include other higher hydrocarbons, nitrogen, carbon dioxide, and hydrogen. From an operability point of view, it is convenient to divide the fuel constituents into three buckets: higher hydrocarbons, hydrogen, and diluents.

As previously mentioned, the Wobbe Index and Modified Wobbe Index both describe the effect of fuel composition on fuel heating value, with the Modified Wobbe Index also accounting for fuel temperature. In addition to Wobbe Index recommendations, OEMs typically include a fuel specification for their gas turbines on levels of higher hydrocarbons and hydrogen. By operating within these recommendations, operators generally can avoid some of the operational issues mentioned earlier. However, the combustion-dynamics issue is particularly sensitive and difficult and is an issue that must be actively monitored and managed by operators, the trio stressed.

There is a relationship between some of these operability issues and Wobbe Index—for example, higher ethane and propane contents in fuel leads to a higher fuel heating value, which also increases autoignition risks. Nonetheless, two fuels with the same Wobbe can have substantially different blowout, flashback, combustion-dynamics, and autoignition tendencies. Thus, Wobbe Index alone cannot be used to ensure safe, reliable operation.

Effects of fuel composition on operability

The operability concerns described below by Sheppard, Emerson, and Lieuwen apply mostly to dry-low-NOx/dry-low-emissions/ultra-low-emissions (DLN/DLE/ULN) systems. They are much more prone to these issues than diffusion systems—most notably combustion dynamics, which are a product of combustor design and the effort to keep NOx emissions as low as possible. Diffusion systems do experience some dynamics issues near blowout, but they can be avoided by operating with a sufficient blowout margin.

Blowout. One of the biggest factors impacting flame blowout—also known as blowoff or lean blowout (LBO)—is the flame speed of the different fuel mixtures. Flame speed is the speed at which the flame moves through the reactants during combustion. Hydrogen addition has particularly significant impacts on increasing blowout margin because of its much higher flame speed than methane.

Propane and ethane also have higher flame speeds, but the effect is much less significant than hydrogen. By contrast, diluents (particularly CO2) reduce blowout margins as they act to reduce the fuel’s flame speed.

Takeaway 1: Increases in diluents pose the greatest blowout risk.

Flashback. As previously mentioned, the presence of hydrogen and higher hydrocarbons can move a flame upstream into premixing passages. Swirlers, fuel lances, and premixing passages are not designed to withstand the high temperatures that would occur with a flame in the premixing section and can quickly sustain damage.

In some events, this hardware may liberate and travel downstream through the power turbine, causing catastrophic damage. Loosely speaking, flashback can be thought of as the “opposite” of blowout; for this reason, the H2 level limits in DLN system fuel specs are set by flashback margin.

Takeaway 2: Increases in hydrogen content pose the greatest flashback risk.

Combustion dynamics. Fuel composition directly affects combustion dynamics. However, in contrast to other operability concerns, the effect is non-monotonic with operational parameters which make it particularly difficult to predict. For example, while increasing H2 levels always will decrease flashback margin, combustion-dynamics amplitude can either increase or decrease, depending upon other operating conditions.

Takeaway 3: Changes in fuel composition may decrease combustion dynamics, increase combustion dynamics, or have no effect at all.

Combustion dynamics pose a direct threat to combustion liners, transition pieces, and cross-fire tubes. If the combustion-dynamics amplitudes are severe, liberation of these parts may occur, with hardware travelling downstream through the power turbine. Combustion instabilities can also lead to blowout and flashback.

Because of the sensitivity of combustion dynamics to the details of the flame configuration inside the combustor, dynamics are sensitive to all changes in fuel composition—that is, changes in higher-hydrocarbon, hydrogen, or diluent content. Note: In this case, the risk is changes rather than increase. The Turbine Logic combustion dynamics monitoring group has observed increased challenges with dynamics, and the need for more frequent tuning because of gas composition issues.

Autoignition. Hydrogen and higher hydrocarbons also significantly decrease autoignition temperature and times, leading to increased autoignition risks. While symptomatically similar to flashback, the physics of autoignition is different. In this case, if the autoignition time of the fuel mixture falls below its residence time in the premixing tubes, the fuel mixture may spontaneously ignite in the premixing zone.

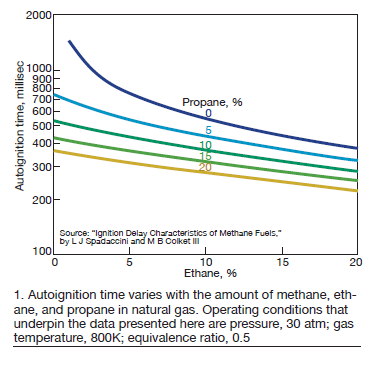

Similar to flashback, autoignition can damage premixing passages, swirlers, and fuel lances. As with any of these other operability issues, liberation of any of these parts poses a threat to the power turbine. Fig 1 shows the how quickly autoignition times decrease with increasing amounts of ethane and propane in natural-gas fuel.

Takeaway 4: Higher hydrocarbons (especially when coupled with the higher compressor discharge temperatures of aeroderivatives) pose the greatest autoignition risk.

Nitrogen oxides. There are two main NOx formation pathways:

-

-

- NOx produced in the flame, which generally is a few ppm and heavily influenced by fuel composition.

- NOx produced post-flame, which really only depends on flame temperature.

-

Thus fuel composition influences on NOx emissions are somewhat dependent on the nominal NOx emissions of the gas turbine. Assuming the firing temperature stays fixed as fuel composition varies, for units with relatively high NOx emissions (nominally 15 ppm and higher), NOx production is dictated mostly by the firing temperature and is largely insensitive to fuel composition.

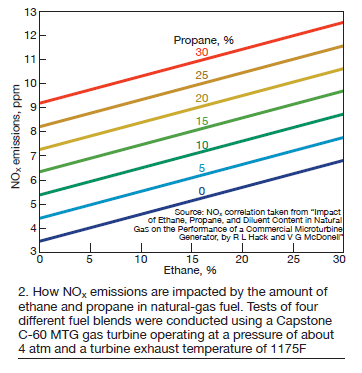

On the other hand, units that have fairly low NOx emissions (less than 5 ppm) will see a significant effect from changes in fuel composition. Data suggest that NOx concentrations may even double with changes in fuel composition for such low-NOx systems. Fig 2 shows how much NOx production can increase, in the low-NOx case, with increasing amounts of ethane and propane in natural gas.

Takeaway 5: The lower a gas turbine’s NOx emissions, the greater the impact of fuel composition on those emissions.

Carbon monoxide. The effects of fuel composition on CO production are largely controlled by whether it moves the system closer to, or farther from, lean blowout. If the unit is near LBO, CO emissions typically already are high, but can still be raised significantly by the presence of higher hydrocarbons and hydrogen in the fuel. Away from LBO, CO emissions may still rise with the addition of higher hydrocarbons and hydrogen, but the effect is quite small.

Takeaway 6: Similar to blowout, increased diluent content poses the greatest CO risk.

Recommendations

A fuel treatment system will mitigate the fuel-variability effects on each of the operability issues discussed above, Sheppard, Emerson, and Lieuwen said. These systems are equipped for removing solid particulates and higher hydrocarbons. The latter is accomplished by condensation and liquid removal.

Most OEMs also recommend some degree of fuel superheating before use in a gas turbine to ensure that no fuel condenses before reaching the fuel nozzles. Condensed fuel can cause significant autoignition issues, the trio warned. Even with a good fuel treatment system, small concentrations of liquid hydrocarbons from the fuel gas remain a risk when liquids are entrained from the liquid knockouts. This may occur with higher hydrocarbons, because the knockouts fill more quickly and require more frequent draining than experience might dictate.

Along with Wobbe Index recommendations, OEMs issue fuel specifications for their units. They are designed to accommodate blowout and flashback margins, and those phenomena should not occur when operating within the specs. However, even when operating within the recommended specs, combustion dynamics and emissions may be impacted by changes in fuel composition.

The greatest operational risk that cannot be managed by staying within OEM fuel guidelines is combustion dynamics. The Turbine Logic experts strongly recommend users have a combustion dynamics monitoring system (CDMS) to warn of impending issues, and also have protocols in place for ensuring sensors are healthy; plus, appropriate notifications if levels exceed alarms.

In their experience, every engine monitored by Turbine Logic has had multiple dynamics excursions exceeding thresholds as the ambient temperature and load varied. The need for shorter tuning intervals only can be confirmed by CDMS.

Several options are available to control loud combustion instabilities, and all are used by manual- or auto-tuning systems. These include varying the fuel temperature within the OEM spec, altering the fuel staging, increasing the non-premix pilot fuel, varying the amount of inlet air chilling, and varying the amount of steam/water injection. De-rating is the last resort.

To complicate things, because of the non-monotonic nature of combustion dynamics, a change in fuel composition can alter the unit’s response to each of these operational changes. Since combustion dynamics don’t have a one-to-one relationship for different operating conditions, installation of a CDMS can provide great insight into how your units respond to different operational changes. CDM systems provide nearly instantaneous feedback and will facilitate the building of a knowledge base around how your units behave regarding combustion dynamics.

If you continue to have combustion-dynamics issues while keeping NOx concentrations within regulatory limits, consider installing an auto-tuning system. It monitors dynamics and emissions and has control logic to minimize emissions while keeping combustion dynamics within acceptable limits to prevent hardware damage.

Auto-tuning systems typically have the ability to regulate several operational parameters— including firing temperature, fuel splits, and even fuel-split schedules. When either dynamics or an emissions excursion occurs, auto-tuning systems step in and nudge these parameters to return the gas turbine to safe and compliant operation. While seasonal tunes remain a good idea, and sometimes a necessity, the auto-tuning system will handle the day-to-day changes that gas composition variability may introduce.

Questions? Contact Sheppard, Emerson, or Lieuwen at connect@turbinelogic.com or 678-841-8420.