By Steve Seachman, Electric Power Research Institute (EPRI)

Many combined-cycle units originally designed for baseload operation are now required to cycle frequently, with still more starts and more rapid ramping over a wider range when in automatic generation control (AGC) mode. As a result, a significant number of heat recovery steam generator (HRSG) failures experienced worldwide have been at least partly attributed to inadequate steam attemperator control.

To avoid HRSG damage caused by poor control of steam temperature, some combined cycles operate at reduced steam temperatures and pay a penalty in reduced thermal performance. Inadequate temperature control also can result in excessive spray flow reactions, risking damage from saturated steam and large variations in steam temperature at the attemperator outlet.

The two major objectives in the control of steam temperature are minimizing both the extent and periods of high temperature, and avoiding spraying to saturation temperature.

The former reduces component life because of thermal creep; the latter often is associated with cracking in downstream piping and in uneven tube heating and cracking.

To improve thermal performance and reduce damage industrywide, a need exists to demonstrate better process control of combined-cycle attemperation.

The temperature control design typically installed in HRSG systems is very similar to that used in baseload drum boilers, and it has been the standard control structure for several decades. Improvements to distributed control system (DCS) technology have allowed enhancements—such as the calculation of steam properties, inclusion of nonlinear parameter adaption, and improved filtering and dynamic feedforwards.

Nonetheless, the operating strategies demanded of many combined-cycle units—including very fast startups and V-style load ramp profiles—have brought steam temperature control to the fore as an operational limiting factor.

By introducing an advanced steam temperature control strategy, HRSG operators might avoid periods of high temperature through the anticipatory action of sprays that can operate over a smaller flow range and have complementary influences to the main-steam temperature and pressure setpoints to reduce heat uptake disturbances. Benefits might include reduced temperature deviations, improved stability, and reduced actuator activity—all of which provide support for more flexible operation.

Testing of advanced strategies for steam temperature control. A study by EPRI surveyed advanced control system strategies for combined-cycle units. The project then selected two approaches for testing through simulation, subsequently testing one on a 2 × 1 combined cycle. The study and its findings are described in the EPRI report “Steam Temperature Control for Combined-Cycle Units: Survey and Testing of Advanced Strategies (3002106316).”

The following five performance criteria were considered:

- Temperature deviations during ramps and disturbances—measured as peak deviation from setpoint. This is an indication of creep-life cost and the ability of the control to respond quickly to large disturbances—such as fast start, load ramping, frequency response, and duct-burner operation.

- Time in temperature ranges above and below design. Temperatures above design produce a creep-life cost; temperatures below design produce a thermal-efficiency cost.

- Stability is determined as time to settle following a load ramp or setpoint change. Settling time is commonly defined as the time to fall and stay within defined steady-state deviation limits.

- Operation at or near saturation. The controls should successfully steer the attemperator outlet temperature away from saturation by holding to a set margin above saturation, without causing instability or large excursions.

- Actuator activity. Excessive activity of motorized actuators can cause overheating and early wearing of bearings and gearboxes. Pneumatic actuators can also suffer premature wear and loss of accuracy with high levels of activity. In both cases, valve glands can wear and leak if operated more than the design duty.

The typical design of steam temperature control on HRSGs is a cascade configuration, whereby a primary (outer loop) PID (proportional, integral, derivative) controller regulates the superheater (SH) outlet temperature by generating a setpoint for the attemperator outlet temperature. The attemperator outlet temperature then is controlled by a fast secondary (inner loop) PI (proportional plus integral) controller that modulates the spray-water valve opening to attenuate any upstream disturbances (such as duct-burner operation) and to track the setpoint generated by the primary controller.

The computational capability of modern DCS processors has enabled the introduction of advanced algorithms to improve the control of complex, high-order, and interactive processes. A feature of all these algorithms is a model of the process and associated influences (either implicit, as an approximate inversion, or explicit) that direct the controller’s corrective actions with greater accuracy than a conventional PID controller, provided an appropriate set of process and influencing models has been determined.

The potential advantages of advanced HRSG steam-temperature control lie with the ability to reduce temperature deviations during startups and load ramping and other disturbances and to reduce overspray events by beginning to act earlier.

These four controller options were considered for the study:

- Smith Predictor. A well-proven, dead-time compensation design that would use a standard block in the DCS to augment the PID controller.

- Modified Smith Predictor a/k/a Advanced PID (A-PID). Similar in design to the Smith Predictor but with a plant model that also reduces the time of the response presented to the PID controller. The model compensation block is built up from existing DCS blocks. It has been applied successfully on several coal-fired plants.

- Model Predictive Control (MPC) is well-proven in process-industry applications and already applied on some thermal plants. The controller has a concise response-model definition capable of capturing high-order response dynamics, with inherent capabilities to include limits and cost metrics in the control design. MPC control of combined-cycle plants and HRSGs has been the subject of modeling and research, but little exists in the way of published test methods and results from practical plant applications.

- State Feedback with Disturbance Observer, which is offered as a module by some DCS vendors. It has been demonstrated on SH temperature controls for drum and supercritical units. It could be built up from standard DCS blocks, but no published procedures exist for setup and tuning.

A-PID, MPC. The project team selected two controller designs for the study: A-PID and MPC. The former was chosen because of its successful application on coal-fired boilers and because it required no advanced control modules (provided the DCS has a delay function block). A-PID is an extension of the well-known Smith Predictor, a model-based controller that effectively eliminates process response dead time, enabling controllers to be tuned with higher gain.

This is achieved by estimating the expected response to a controller output change, but with the dead time removed. The resulting signal is added to the process feedback so the controller “sees” a response to its output actions very quickly and responds appropriately. Then, after the dead time has elapsed, and the actual process begins to respond, the Smith model’s output is progressively removed with the same time constant as the process. This mechanism gives a smooth crossover from model to actual process input.

The MPC was selected for its potential to model and reject two independent disturbances, because it is capable of modeling “inverse” SH outlet temperature dynamics seen during load ramps. Plus, MPC modules were available for testing at the host site’s DCS, provided as part of an advanced control suite.

MPC has been growing as a powerful control concept, with many applications over the last three decades. The most prevalent application has been in chemical, refinery, and other process industries, but its capability to deal with interactive processes and its inherent ability to compensate for dead time and high-order processes lead naturally to powerplant control applications—such as steam temperature, sream pressure, and drum level control.

Simulation tests. Both the A-PID and MPC designs initially were tested with a PC-based plant/controller simulation (with Simulink™ modeling environment) to ensure the control structures functioned as expected and potential implementation issues were identified. The advantage of PC-based simulations is having unrestricted access to the models and enabling scenario testing faster than in real time. Success of this phase to test the controllers depends on the level of process model static and dynamic accuracy and controller emulation fidelity.

Subsequently, the two designs were configured on virtual DCS controllers and tested at the host site’s replica operator training simulator. Goals of the onsite simulator tests were the following:

- Compare the control performance of the options.

- Check practical aspects of the implementation (signal tracking, override functions, bumpless controller switching, etc).

- Establish procedures and methods for process model identification and controller tuning.

Following extensive testing, the MPC design was selected for deployment at the plant. The design was installed and commissioned on one HRSG reheater temperature control loop. This arrangement enabled a comparison between the performance of the MPC (A-HRSG controls) and the original PID (B-HRSG controls).

A control switching facility also enabled a comparison to be made between a retuned PID control and the new MPC design on the same HRSG. Wide-range load-ramp tuning and benchmark tests were performed, providing data for a quantitative performance comparison.

Results

Following MPC tuning, A-HRSG reheater MPC performance was demonstrated as significantly superior to the existing PID control still operating on the B-HRSG. It was also shown to be more stable and faster responding than the retuned and optimized PID control of the A-HRSG.

The A-PID controller was relatively easy to tune with the system identification tuning calculation tools. The design gave a fast, stable control capability. Some tracking issues related to cascade control windup and resetting contributed to the inclusion of a saturation protection limiter were particular to the DCS and not necessarily an impairment to the design concept.

The A-PID design, based on a modified Smith Predictor, is best suited in applications with large dead time and high-order process responses, as noted earlier—such as those found on large drum boilers with a single-stage desuperheater. Investigators found that the final stages of the HRSG superheater and reheater have lower-order responses; however, they are more prone to disturbances because of their relatively lightweight tubing and rapid variations in gas temperatures during startups and load ramps.

For the SH controls, the split-range valve design performed well, but in its present form, the A-PID did not achieve significantly improved disturbance rejection on the simulator. The reheater (RH) temperature control with the A-PID was superior to the standard PID for both stability and disturbance rejection. This is because the response model of the RH was of higher order, and so some of the features of the delay and order-reduction functions came into play.

The MPC facility’s capability to input two independent disturbance variables inputs was used to advantage on the reheater to reject the disturbance caused by load changes on both the A and B gas turbines (GTs). The SH outlet and disturbance response models vary significantly over the GT load range. Because the MPC is not adaptive, two MPCs were used with a fuzzy blending (weighted average) function to slide between controllers, which were sufficient to cover the entire load range.

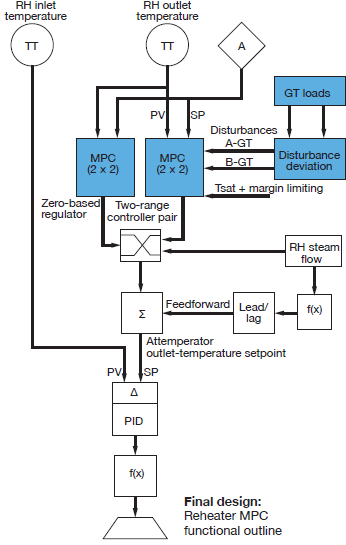

For the MPC design to provide significantly superior performance during load ramps, the structure must include an output feedforward signal predicting the expected attemperator outlet temperature. The MPC design, as implemented for the tests, provided significant improvement to temperature disturbance deviations, time to settle, periods away from setpoint, and overall stability. The final design for the reheater MPC functional outline is shown in the figure.

Benefits

- Improved temperature control. When the MPC controller is applied in a regulator configuration with attemperator outlet setpoint feedforward, and full use is made of the disturbance inputs, the MPC provides a stable and very responsive control design.

- Opportunity to improve steam-cycle efficiency. The MPC provides a significantly narrower band of temperature deviations over time. Such an outcome allows operators to raise steam temperature setpoints without decreasing creep life, thereby reducing unit heat rate and fuel consumption.

- Reduced actuator activity. The MPC can be adjusted to reduce reversals in the attemperator outlet temperature direction without compromising temperature control performance. Thus, actuator activity can be reduced, together with valve and actuator wear. For motorized modulating actuators, this capability would reduce bearing and gearbox wear as well as the risk of motor overheating.

- Supporting unit flexibility. Implementing MPC may provide an effective strategy against damage risk to both high-temperature HRSG components and field actuators. Therefore, it could play a significant role in supporting flexible operations, particularly if the need for more frequent ramping and startups increases as more unregulated generation enters the energy mix.

- Reduced saturation events. MPC provides the opportunity to increase temperature setpoints, thereby reducing the number of saturation events in steam piping and tubing and prolonging the service lives of these components.

The bottom line: The study demonstrated the application of advanced steam-temperature control strategies on a combined-cycle plant, and provided quantitative assessments by benchmarking performance against the classical cascade control structure previously applied at the host site. CCJ

About the author

Steve Seachman is principal technical leader in the Instrumentation, Controls, and Automation Program for the Generation Sector at the Electric Power Research Institute.