Worthington Generation Station

Owned by Hoosier Energy Rural Electric Co-op Inc

Operated by NAES Corp

174 MW, gas-fired facility equipped with four LM6000 simple-cycle engines for meeting member peaking-power needs, making off-system sales, and satisfying generating reserve requirements. Station is located in Green County, Ind, and connected to Hoosier’s 138-kV transmission line

Plant manager: Robert VanDenburgh

Challenge. Worthington Generation is exposed to harsh winter conditions, so plant operators are well aware of the potential for freeze-related trips. The packages have heaters installed, and heat tracing, but cold temperatures always are a concern—specifically with the NOx-water injection system. It injects demineralized water into the combustor through the fuel nozzles to regulate flame temperature, thereby helping to keep NOx emissions within regulatory limits.

The NOx-water pressure transmitter is located 25 ft from the sample location, so ¼-in. tubing is run to provide the pressure signal required by the instrument. This tubing is a major freeze-up concern because of its length, small size, and location at the bottom of the package. Challenges facing plant personnel were these:

- How to prevent water in the tubing from freezing in the package.

- How to prevent the pressure transmitter from freeze-up in the gage panel.

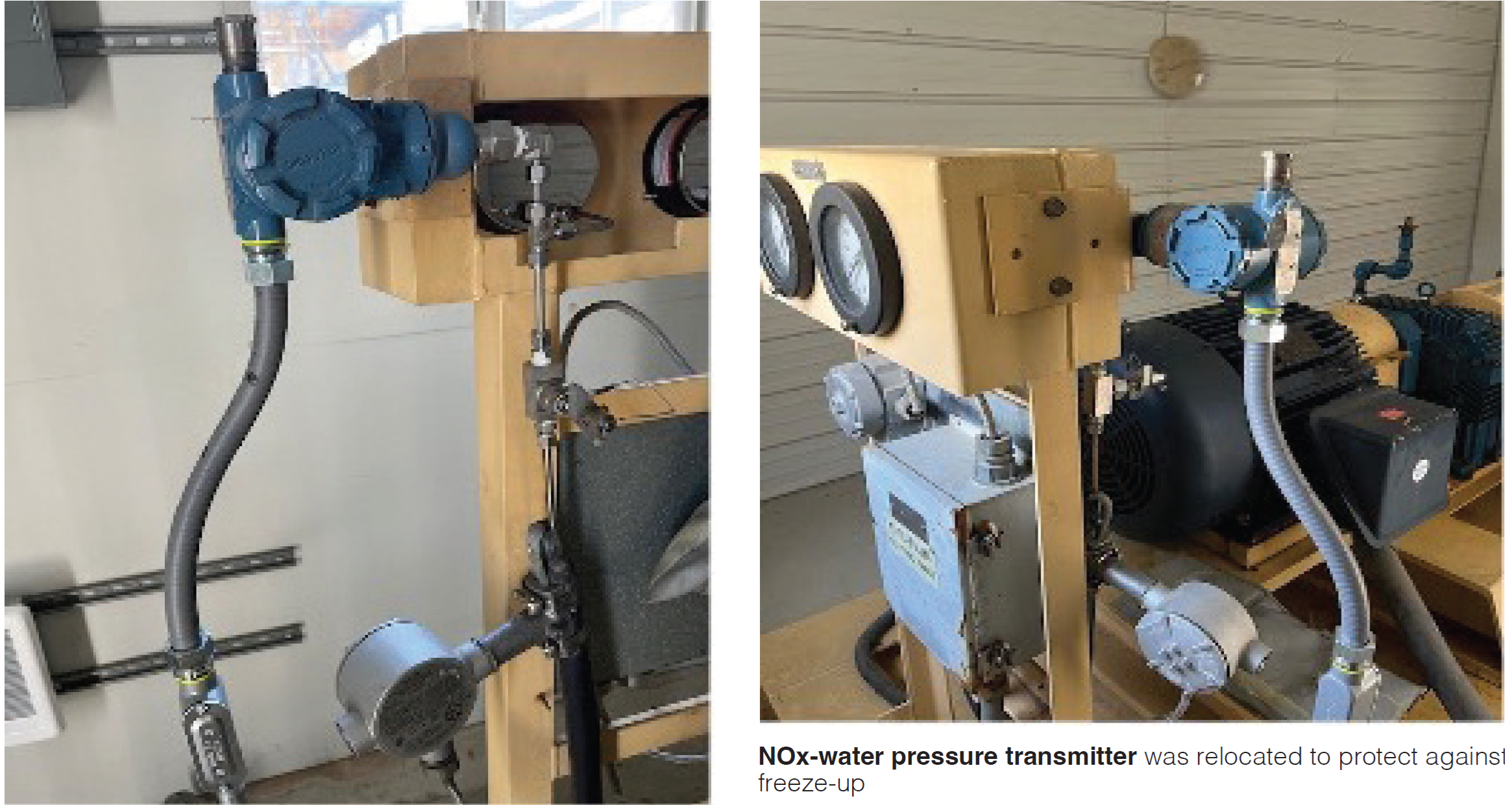

Solution. Relocate the NOx-water transmitter and ¼-in. tubing to a warm location (photos). Staff researched areas near the package and discovered that the NOx-water building was a perfect place: Temperature is above 70F year-round and the tubing can be completely removed from the package. The steps taken:

- Relocate the NOx-water pressure transmitter from the gage panel to the heated NOx-water building.

- Remove the ¼-in. sensing tube from the package and install it in the NOx-water building.

Result. All NOx-water pressure-transmitter freeze concerns were eliminated.

Project participants:

Matthew O’Hara, lead O&M technician

Jason Robertson, Worthington Generation O&M/IC&E technician

William Hooker, Worthington Generation O&M technician

Garett Ray, Worthington Generation O&M technician