Challenge. The annual cost of providing casualty and property insurance to protect facility owners from significant financial hardship in case of a loss event can reach into the millions of dollars. Annual insurance inspections help “rheostat” this cost in either direction. The more areas of concern the insurance engineers and the inspectors have, the more the annual cost to maintain coverage. Being a relatively new facility, CPV Towantic had a typical initial list of recommendations and data requests open from these insurance site visits and inspections.

Solution. The site team set out to complete as many of the open hazard/loss-prevention recommendations that it could. While prior-year efforts focused primarily on non-financial, mainly administrative improvements, the site moved to budget the more cost-intensive recommended efforts this year. CPV Towantic worked closely with the owner to establish a proper budget to achieve these goals.

Specifically, these efforts included the following:

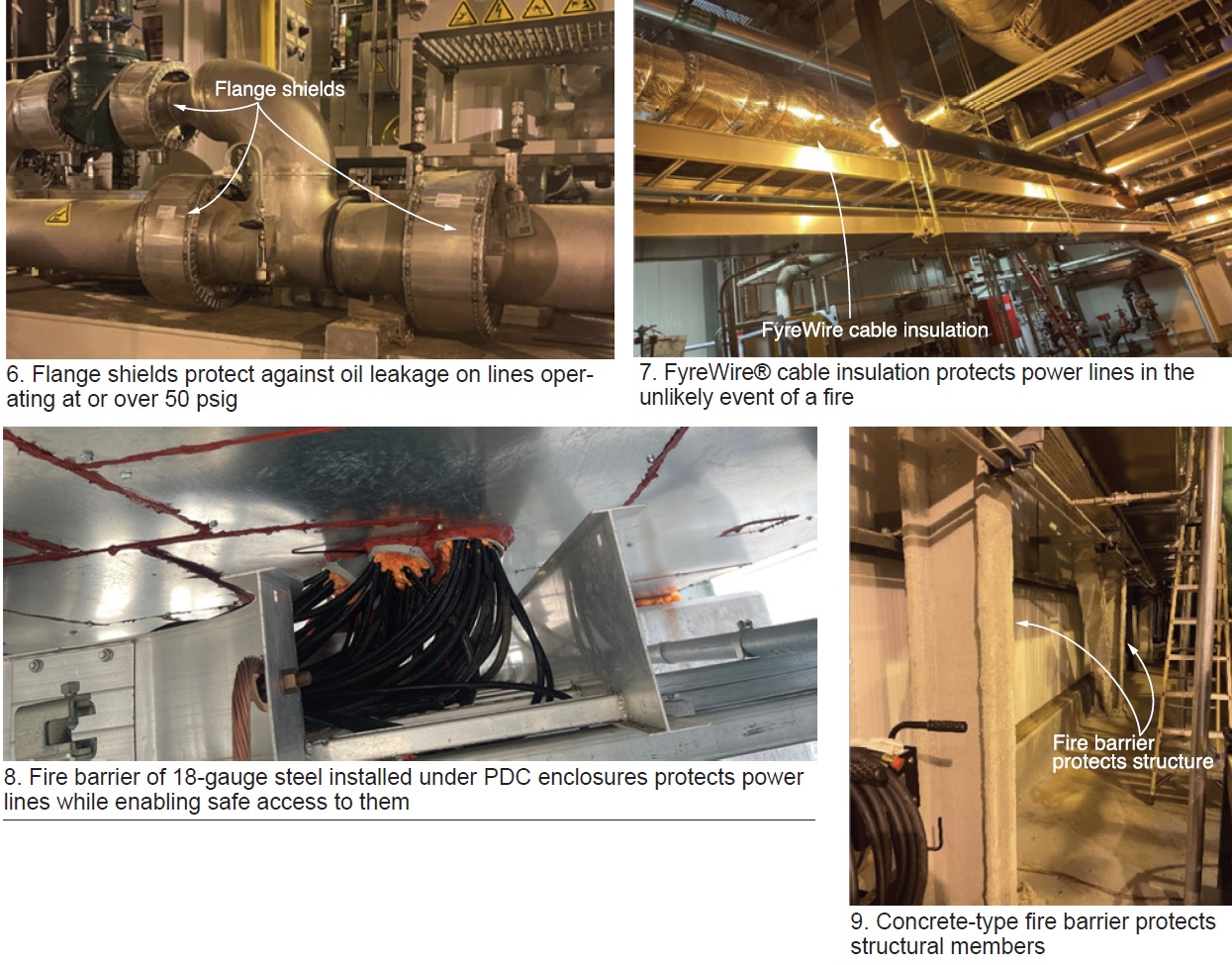

- Installation of insurance-company-approved flange shields in pressurized oil systems (lube oil, for example) serving the two gas turbines and the steam turbine (Fig 6). The site procured, and staff installed, over 200 Ramco flange shields targeting any oil-containing equipment operating at 50 psig and above.

- Protection of power cables to the steam-turbine lube- and seal-oil pumps (Fig 7). Personnel worked with insurance-company-approved vendors and products (in this case, Unifax FyreWrap®) to install a fire barrier around the dc pumps to prevent loss of operation in the event of a fire in the area.

- Installation of an insurance-company-approved, and CPV Towantic designed and installed, 18-gauge-steel thermal barrier under the PDC enclosures serving both gas turbines (Fig 8). This to satisfy the insurance company’s concern that the exposed foam-type insulation could catch fire from an arc caused by the incoming electrical lines.

- Installation of protection for structural-steel columns within the steam-turbine lube-oil containment area. The plant worked with insurance-company-approved vendors to install a 1.125-in.-thick Carobine Pyrocrete fire barrier (Fig 9) around structural steel located inside the steam-turbine’s lube-oil-skid secondary containment to minimize the risk of a fire in this space, possibly weakening the steel and causing a building collapse.

- Improve the existing hot-work permit system or implement the insurance carrier’s hot-work permit system. CPV Towantic improved its hot-work permit to incorporate the updated OSHA protocol on post-activity fire watch. Note that the site, operations company, and insurance carrier worked together to isolate the areas of the OSHA matrix that applied and simplified the process for better adherence out in the field.

- Initiate annual operational testing of the water-mist fire protection systems for the gas turbines. Plant personnel worked with the system vendor to create a preventive-maintenance program which the supplier would use to perform annual system checks. Plus, staff worked with the insurance carrier to allow an air-only system check—one not involving the release of the water mist. The system supplier was tasked with providing documentation for future records review and insurance inspections.

Results. Through the efforts described above, the insurance company acknowledged the facility’s diligence in completing numerous open-action items, stating the following:

“As you can see, there are a large number of recommendations that have been completed. . . . I think this is one of the largest single-year lists of completed recommendations that I have seen during my 20-year career. . . . The recommendations were not only completed, but completed well. I really like the job that was done on the thermal protection on the dc pump power supplies and the sheet metal that was installed under the PDCs.”

Although insurance premiums recently have been increasing for electric generating facilities, CPV Towantic’s owners acknowledge that they have seen less of an increase because of the collective efforts of the operations team and owners to undertake the insurance company’s recommendations. More importantly, the insurance carrier’s recommendation initiatives serve to continue to reduce risks at the facility.