The almost incalculable value of a great user’s conference presentation is learning about a forced outage or safety event that happened at someone else’s plant and making sure it doesn’t happen at yours. In that category is surely one from the Steam Turbine Users Group (STUG 2022) on turning-gear reliability. The utility presenter was a steam-turbine expert with decades of experience.

The almost incalculable value of a great user’s conference presentation is learning about a forced outage or safety event that happened at someone else’s plant and making sure it doesn’t happen at yours. In that category is surely one from the Steam Turbine Users Group (STUG 2022) on turning-gear reliability. The utility presenter was a steam-turbine expert with decades of experience.

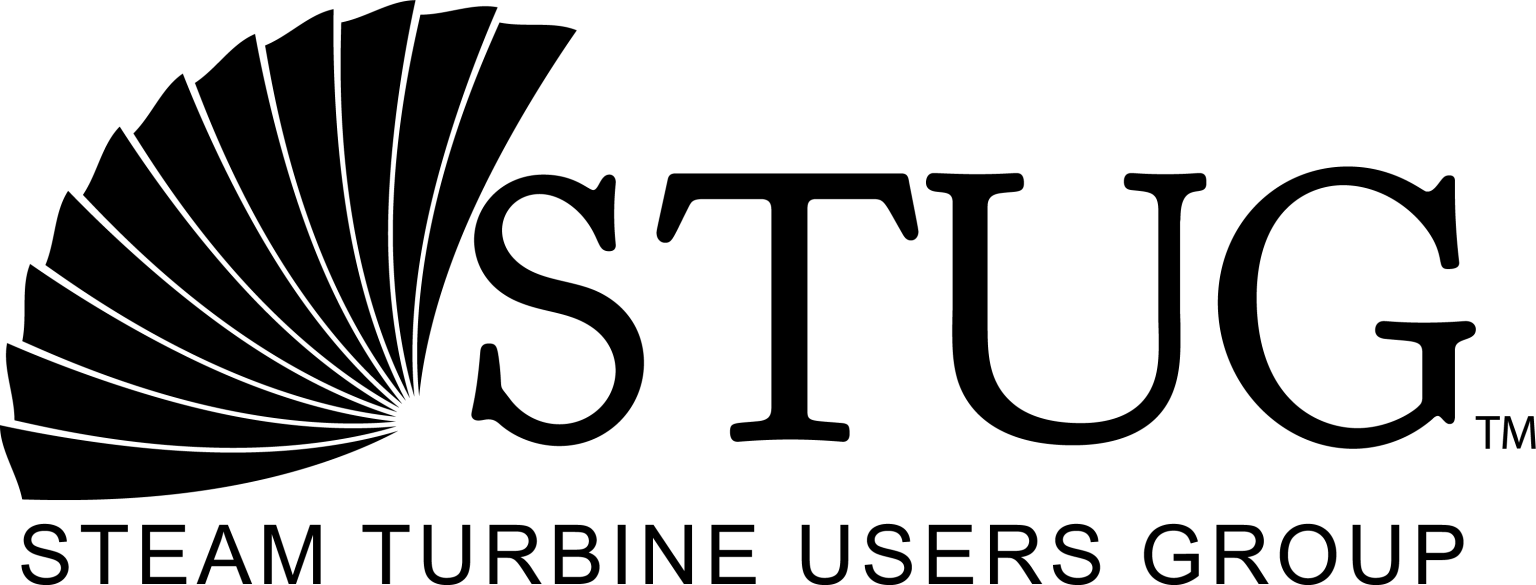

There were two important threads woven together in this talk: (1) A description of a catastrophic failure of a TG motor (Fig 1) at one of his utility’s plants, and (2) the larger implications for maintenance, sparing, and even the impact on the industry as a whole.

Regarding the second, the presenter noted that the TG (Fig 2) could be a “pinch point” for ST/G reliability in plants that are, or will be, starting and stopping much more frequently to follow renewables. It’s easy to forget, he added, that the TG probably was designed to operate perhaps 10 times a year, but under future operating scenarios that could increase to 500 or more (multiple starts per day).

The utility in question has many 40- to 55-year-old ST/Gs from a variety of OEMs. Unfortunately, all four of the utility’s steam-turbine experts, each with 40+ years of experience, left under an early-out program. Now the utility is planning to have 16 GW of solar and 5 GW of wind over the coming years. These are conditions familiar to many utilities. But the catastrophic failure of a TG motor caused by imbalance set off alarm bells, especially since a spare motor was not available and the unit was out for an extended period.

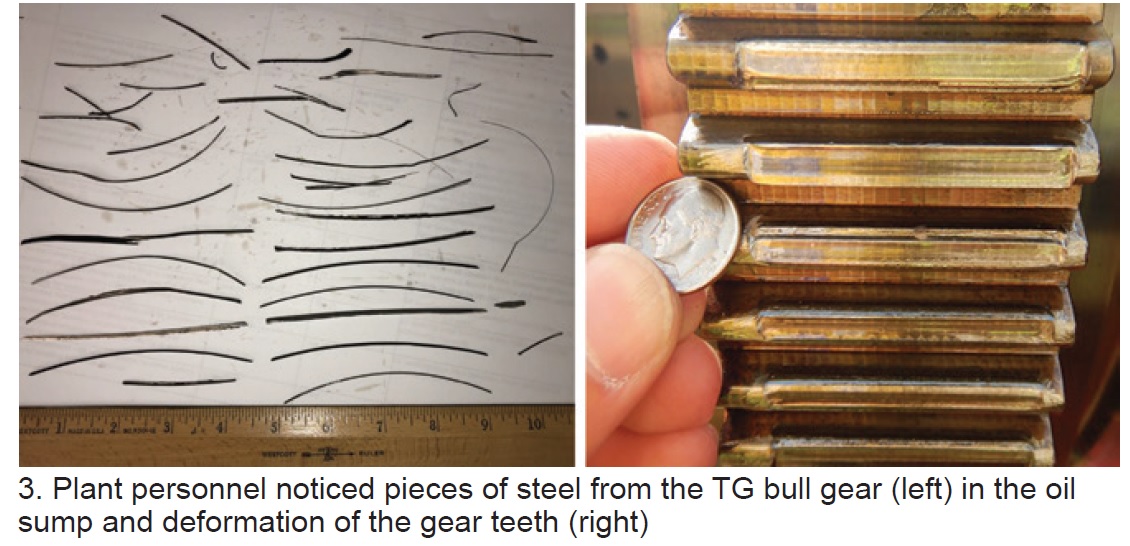

In spring 2019, plant personnel noticed pieces of steel from the TG bull gear in the oil sump (Fig 3 left), and deformation of the gear teeth (Fig 3 right). The root cause was determined to be an attempted engagement of the TG by the control system during full-speed operation resulting from the failure of a solid-state relay.

With this event as a backdrop, the presenter then turned to a tutorial of sorts on the function of the TG, basic nomenclature, different types of gearing and motors, motor interlocks, the importance of the air or hydraulic supply in the lock out/tag out (LOTO) boundary, proper tools for rigging a bull gear, and other topics.

Some of the recommendations for adjusting TG maintenance and sparing include:

- Have a spare motor, ideally one that could serve several different ST/Gs; spare bull (ring) and pinion (clash) gear; chain (if your unit has one); and several solenoids, even a complete assembly.

- Install a black-start unit with permanent reaction arm.

- Identify proper tools and their location so they can be available quickly in the event of an unexpected outage.

- Discuss issues with operations and visually inspect at least once a year prior to an outage.

- Measure and set correct backlash during outage.

- Inspect the lubrication system during outages or more frequently.

- Pull the TG out during major outages for a complete test.

- Have a battery pack to turn the rotor as backup.

To dive deeper into keeping your TG reliable, the presenter suggests obtaining a copy of EPRI Report No. 1019645, “Turbine Generator Auxiliary Systems, Volume 6: Turning Gear Maintenance Guide,” published in 2010.