By Rishi Velkar and Todd Robison, NV Energy

Combined-cycle plants built during the construction boom of the late 1990s/early 2000s are now about 70% through their 30-yr design lives. Although not originally designed to cycle, ever-increasing amounts of solar energy readily available on the grid, especially in the Southwest, make it economically prudent for these plants to cycle off completely from time to time throughout the year.

However, cycling and plant age contribute to premature equipment failure, negatively impacting reliability and increasing operating costs. It’s important for plant personnel to be proactive to properly address issues affecting availability and avoid outages of long duration.

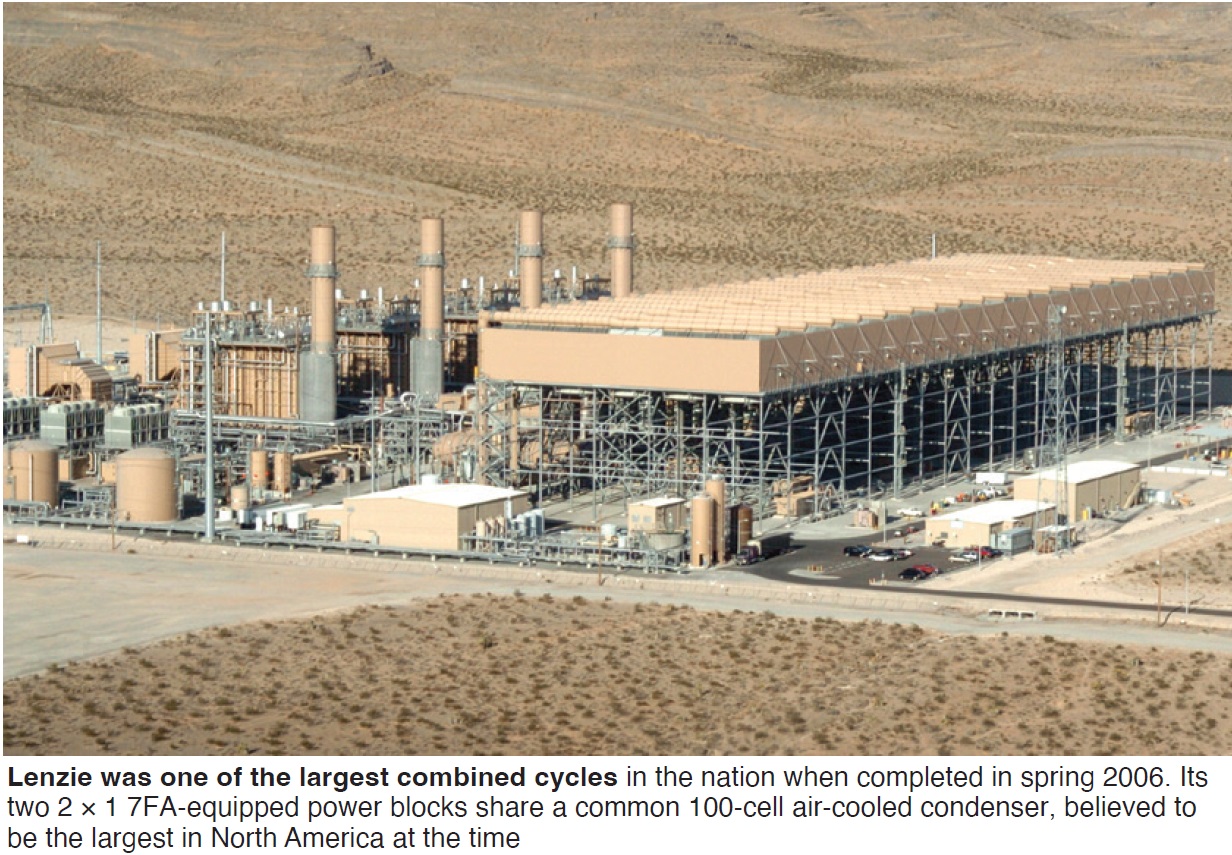

The following case history concerns NV Energy’s Chuck Lenzie Generating Station, a 2 × 1 natural-gas-fueled combined cycle located about 30 miles north of the Las Vegas Strip. The plant has two power blocks, each equipped with two 7F gas turbine/generators and one D11 steam turbine/generator.

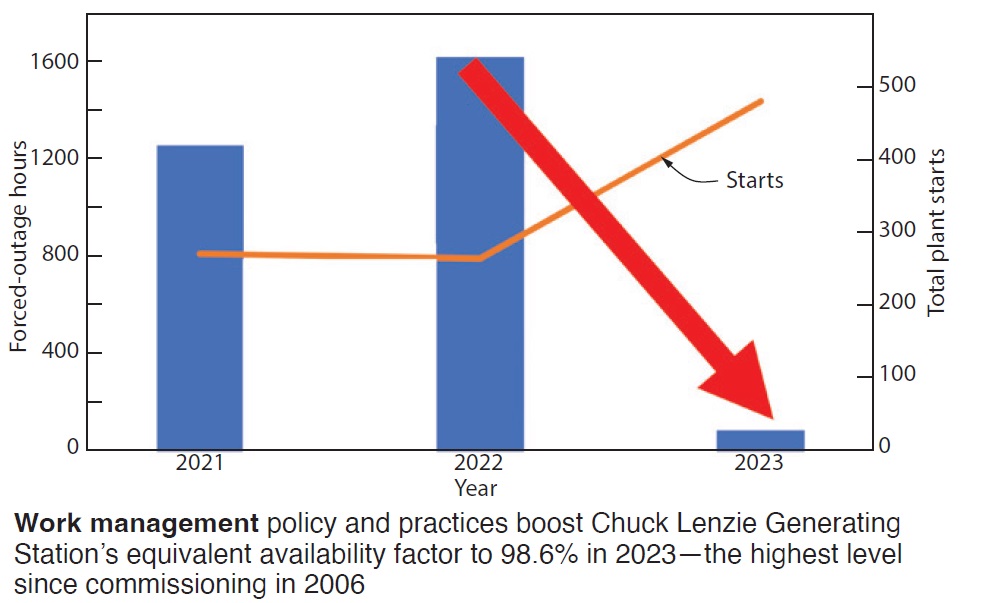

Lenzie, which went into service in 2006, achieved an equivalent availability factor (EAF) of 98.6% in 2023, its highest ever. While the number of starts doubled from about 63 per turbine in 2022 to more than 140 per turbine in 2023, the Lenzie team was able to reduce the plant’s forced-outage hours to only 153 compared to more than 1000 hours from the prior years. This was achieved primarily because of Lenzie’s strong adherence to NV Energy’s work management policy/practices (figure).

Recall that the primary purpose of work management is to recognize, define, prioritize, and document the maintenance effort required to restore and preserve system function for reliability. Work identification encompasses both reactive (corrective) and proactive (preventive) work and requires cooperation between the operation and maintenance staffs. The outcome is quality work that improves plant reliability and availability.

Process plants typically have a Computerized Maintenance Management System (CMMS) incorporating work orders that can build up over time if not properly maintained. Lenzie started 2023 by reviewing, with representatives from both operations and maintenance, each work order in backlog.

Result: The backlog of corrective maintenance orders was reduced from 600 to 120, the preventive work orders from 100 to 20. Note that NV Energy refers to a storage place for work orders that have not been closed as “The Backlog.”

An accurate Backlog is necessary to continually evaluate maintenance requirements and successfully perform work planning and scheduling activities. Duplicate work orders, and jobs that had become irrelevant or impractical, were purged from the Backlog; they divert attention from real priorities and make it impossible to accurately gauge the workload.

The next step in the work-management process is a critical one involving the work planning done by way of scheduling software. Work scheduling is the process of work management that enables the plant to improve the effectiveness and efficiency of the maintenance effort by doing the right work at the right time using the right resources.

The process of work scheduling is essentially determining the when and who of the work-management process by prioritizing the work backlog and then matching it to the available resources. This is conducted using the principle of joint prioritization—the collaborative prioritization of work among key stakeholders.

Another critical piece of the puzzle is to maintain the Short Notice Outage Workorder list (SNOW), a list of work orders that take an outage to complete. It is vital to plan the work in advance so when an opportunity presents itself during an outage, forced or planned, the work can be completed, not put off until the last minute. At Lenzie, the SNOW list is reviewed and modified/updated multiple times annually.

However, the most important practice that a powerplant should adopt is to have constant communication between its operations and maintenance organizations. Since operations is the most important customer at any plant, it is the eyes and ears in the field and the first alert to issues. But these must be communicated to maintenance and it is vital for management to provide a platform to support these discussions. At Lenzie knowledge is transferred during the morning meeting at 6:10, after the shift change. This is where operations makes maintenance aware of any issues that present a reliability risk.

Also, as power companies plan to retrofit and upgrade legacy equipment and processes as plants approach end of life, one topic often left out of the discussion is the importance of stocking critical spare parts. Having critical spares on hand can reduce downtime significantly. During 2022-2023, Lenzie personnel identified and stocked more than 200 spare parts in the warehouse.

Finally, keep in mind that Lenzie was able to exceed its EAF goal by adopting a proactive maintenance approach. Given that combined cycles likely will be cycling more in the future, this might be a good time to review your plant’s mode of operation and method of maintenance planning.