The energy sector is undergoing a transformative shift, driven by the growing need for cleaner, more flexible, and more efficient generation technologies. As renewable energy sources such as wind and solar continue to grow—projected to account for 80% of global net capacity additions by 2050—gas-fired power plants remain essential in ensuring grid reliability and stability.

In this evolving landscape, HRSG technology plays a critical role, particularly in combined cycle power plants (CCGTs) that demand high efficiency and operational flexibility. A recently published paper by GE Vernova (GEV), accessible by clicking this link, presents a comparative study of water chemistry performance in once-through (OT) and drum-type HRSGs, highlighting key operational findings derived from commissioning and fleet data collected from the GEV global fleet.

As the power generation industry integrates increasing levels of intermittent renewables, the demand for flexible, fast-ramping thermal generation remains strong. OT HRSGs offer high efficiency and startup responsiveness suited to dynamic grid conditions, while drum HRSGs remain a reliable alternative for applications prioritizing simplicity and robustness.

This comprehensive study, compiled by Maneka Roger, Mariah Couzzi-Carneiro, Markus Heitzmann, and Mirco Colombo, compares water chemistry behavior and steam purity in GEV’s OT and drum HRSGs, using real-world operational data from multiple global H-Class (HA) plants over a 10-year period.

The focus is on degassed cation conductivity (DCC) as a key measure of steam purity during start-up and long-term operation. Results show both HRSG types consistently meet GEV’s DCC targets, with OT HRSGs achieving startup DCC thresholds more rapidly, offering enhanced responsiveness without compromising steam purity.

These findings reinforce the suitability of OT HRSGs for high-cycling applications and validate their water chemistry performance as equivalent or superior to traditional drum HRSGs under proper feedwater conditions.

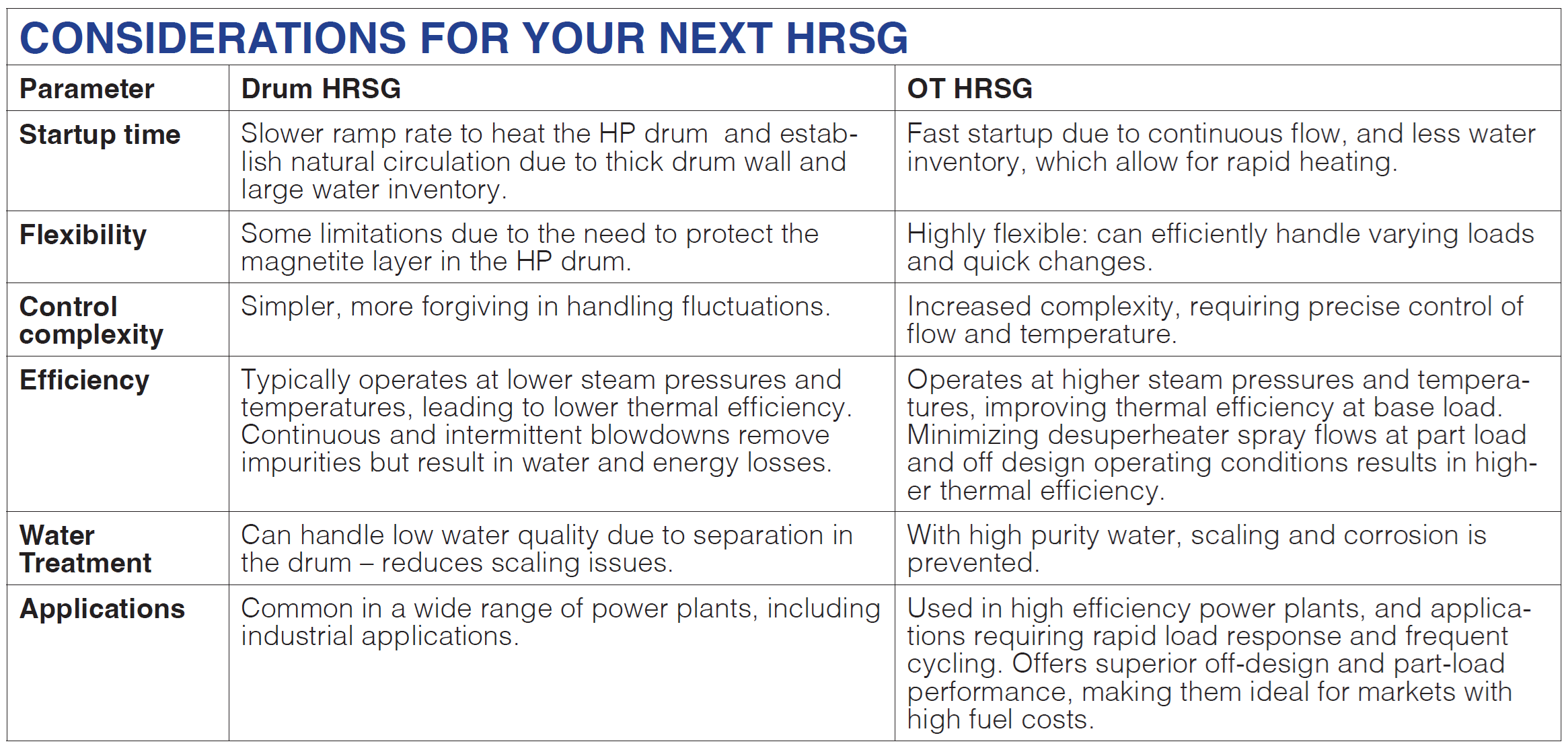

The GEV OT HRSG is highly advantageous for new plants where operational flexibility, rapid response, and efficiency are critical, though it demands rigorous water quality management and advanced controls. Drum HRSGs remain a reliable and simpler alternative, suitable for plants with less dynamic operational requirements, prioritizing robustness and operational simplicity (Table).

OT HRSGs offer several operational advantages, particularly for facilities needing rapid startup and high operational flexibility. They feature faster ramp-up times due to continuous water flow and minimal water inventory, which significantly cuts down startup durations. Their ability to handle varying loads without concerns about thermal stress on drum components provides excellent operational agility. Furthermore, OT HRSGs operate at higher steam pressures and temperatures, resulting in enhanced thermal efficiency, especially noticeable at partial loads where desuperheater spray flows are minimized.

Water chemistry management is simplified in OT HRSGs because steam purity directly correlates to feedwater quality, eliminating the need for additional chemical treatment or blowdown at steady-state operations. Consequently, OT HRSGs consistently produce higher-quality steam and achieve desired steam turbine admission criteria more swiftly. Their design proves particularly beneficial for high-cycling operations, such as plants supporting renewable energy integration, where frequent starts and stops are common.

However, the OT design does present certain drawbacks, including increased complexity in system control, necessitating precise instrumentation and advanced automation. Moreover, due to the lack of impurity separation by a drum, the feedwater quality must remain consistently high, imposing stricter demands on water treatment systems. This operational precision can potentially raise maintenance complexity and frequency, particularly related to control systems and critical instrumentation.

Conversely, drum HRSGs offer a robust, reliable alternative. Their large water inventory and inherent natural recirculation make them tolerant of operational fluctuations, providing a forgiving and stable environment. Control and operation are generally simpler and less demanding, which can reduce initial investment and complexity. Drum HRSGs are also more forgiving regarding feedwater quality variations due to their effective impurity removal through blowdown procedures.

Nonetheless, drum HRSGs have limitations in rapidly changing operational environments. Their larger thermal mass results in longer startup times and lower responsiveness to load changes. Operational efficiency is generally lower due to the need for regular blowdowns to manage water purity, leading to higher energy losses. Furthermore, the thermal stresses imposed on drum components can restrict operational flexibility and rapid load variations, potentially making them less suitable for plants requiring frequent cycling. CCJ