By Vaughn Watson, Vector Systems Inc

Connect with Vaughn on LinkedIn

The efficiency and long-term performance of an SCR system is largely dependent on several key design considerations for its various components. When complex NOₓ reductions on heat-recovery steam generators (HRSGs) are required, there are critical aspects of the system that must be addressed to ensure success. While the catalyst often gets all the credit, and all the blame, when performance declines, careful attention to system design can mitigate or prevent many of the top factors contributing to SCR issues.

Catalyst design itself is crucial to the effectiveness of the emissions control system. Catalyst volume, formulation, and pressure drop must consider the totality of operating scenarios the boiler will encounter. This evaluation should include all load levels, including the minimum emissions-compliant load (MECL), that the boiler will operate within.

All ambient conditions also should be considered. This is especially important for boilers firing multiple fuels or blended fuel streams. Your evaluation must include all operating cases from the HRSG OEM, but also interpolation of DCS data trends, if evaluating an existing unit for catalyst performance.

Additional testing to ascertain the NO/NO₂ ratio is important because high NO₂ speciation can be a major issue to SCR efficiency and require specific SCR catalyst formulations to achieve desired NOₓ reductions. Be sure to consider boiler turndown as well because the NOₓ produced typically is higher, and the decrease in exhaust temperature will limit catalyst efficiency.

SCR catalyst should be inspected at every outage to ensure the catalyst face is not blocked by rust or insulation (Fig 1). This can majorly affect SCR catalyst performance by masking the SCR’s active pore sites.

Bypass can greatly affect NOₓ and ammonia slip. The catalyst support structure, as well as the perimeter seals, should be inspected to ensure there is no bypass of exhaust gas and ammonia. Assure catalyst modules are well packed to prevent ammoniated exhaust gas from passing unreacted through gaps around the catalyst bed. On a high-performance SCR, small amounts of bypass can drastically add up to the inability to meet objectives.

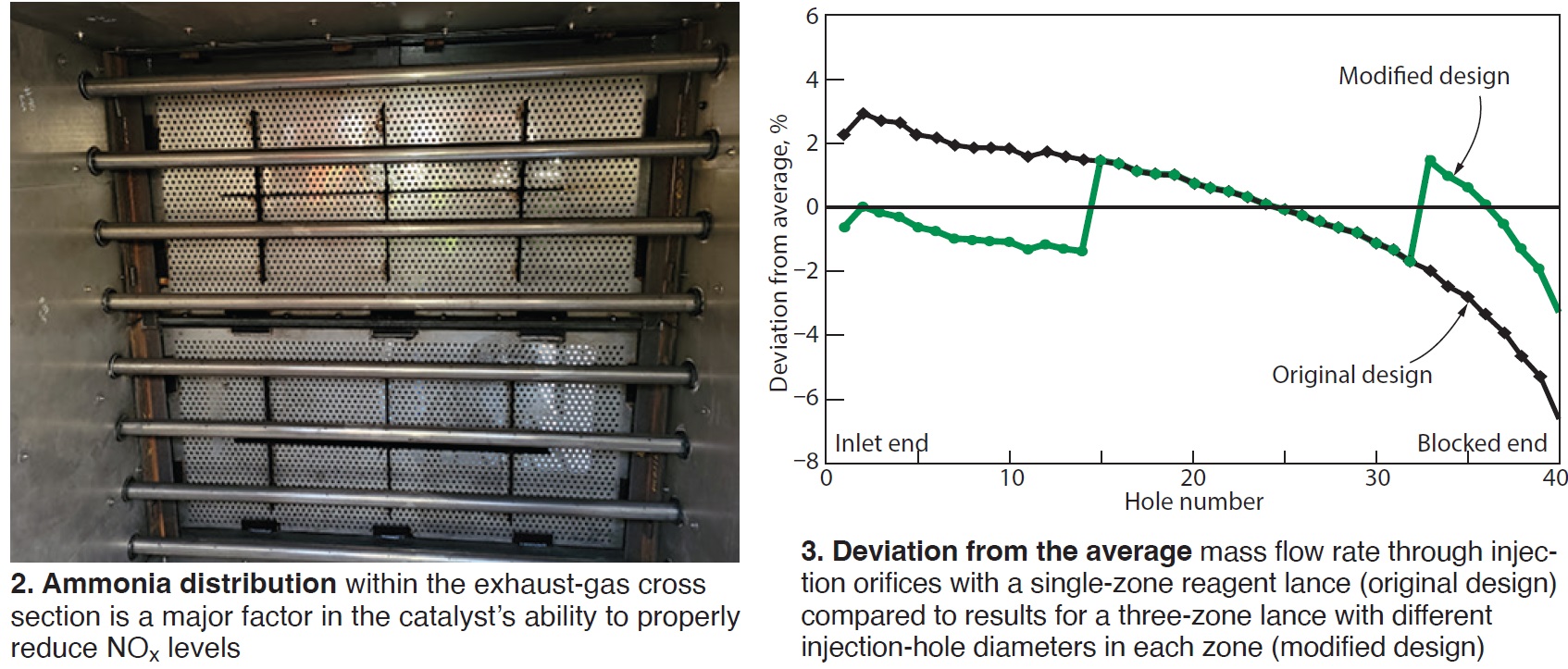

Ammonia distribution within the exhaust-gas cross section is a major factor in the catalyst’s ability to properly reduce NOₓ levels. This important part of the system falls on the design of the ammonia injection grid. AIG design must consider the amount of ammonia and diluent required for the reaction, as well as the ability to inject and mix the ammonia with the NOₓ present in the exhaust gas (Fig 2).

Give careful consideration to injection pressures, mass flow, and density change along the length of each AIG lance. Injection-grid design for advanced NOₓ control will carefully vary injection orifice sizing, spacing, and angle of injection necessary to ensure the NH₃:NOₓ distribution is matched to the volume of catalyst (Fig 3).

Inspect the AIG every outage to ensure there is no significant plugging, which could have a huge impact on catalyst performance. Clean the AIG if you find plugging, then determine the root cause. Often, the design of the AIG can be improved to achieve better performance and provide some resilience against frequent plugging issues.

Avoiding many SCR performance issues begins with the ammonia supply. Work with a reputable and accountable chemical supplier to ensure you are getting the reagent purity necessary for your system. Avoid ammonia contamination in transit to the plant by requiring dedicated trucks for each haul.

Also, require certificates and test reports before offloading to help protect the system against such contaminants like chlorides and calcium. These impurities can damage and plug the various components of the ammonia system.

Specifying the correct purity grade of ammonia is critical for aqueous ammonia systems; reagent-grade ammonia is the best option. The key differentiation is the purity of the water content of the solution which may contain soluble minerals that can plug, foul, erode, and damage SCR system components.

Such impurities in the reagent solution can lead to vaporizer fouling, AIG plugging, and potential catalyst performance problems. Keep in mind that it only takes one bad load of ammonia to experience the headaches associated with ammonia impurity.

By ensuring the foregoing factors are considered in the SCR and ammonia-system design, and addressing problems when they are discovered, are essential to an efficient SCR system capable of advanced NOₓ reduction.