Long Ridge Energy Generation

Owned by Long Ridge Energy & Power

Operated by NAES Corp

485 MW, gas-fired 1 × 1 7HA.02-powered combined cycle capable of burning between 15% and 20% (vol) of hydrogen today, located in Hannibal, Ohio

Plant manager: Chris Bates

Denison survey helps improve employee morale

Background. The culture of Long Ridge Energy Generation stresses the importance of preserving employee strengths as well as continuous improvement. One area requiring consistent monitoring is that of employee morale. Management decided to gauge the overall morale of the team by administering the Denison Organizational Culture Survey and using the results to make necessary changes.

Challenge. Employee morale will always be a major contributing factor to an organization’s success. After almost three years at Long Ridge Energy Generation, the management team wanted to see what could be done to improve morale and ensure employees were satisfied with the plant’s culture.

Solution. A Denison Organizational Culture Survey was conducted to receive feedback from employees on the way the Long Ridge organization operates. Once the surveys were completed, multiple sessions were held to share the results and create an action plan to make several recommended changes.

Results. The feedback received from Long Ridge staff (Fig 1) was used to make changes in policies, alter the way daily affairs were managed, and contribute to implementing new practices. The overall morale of the plant has improved. The Denison survey will be conducted again for comparison purposes and to see if additional changes are necessary.

Project participant:

Brandi Hobbs, administrative manager

Mod improves reliability of water treatment system

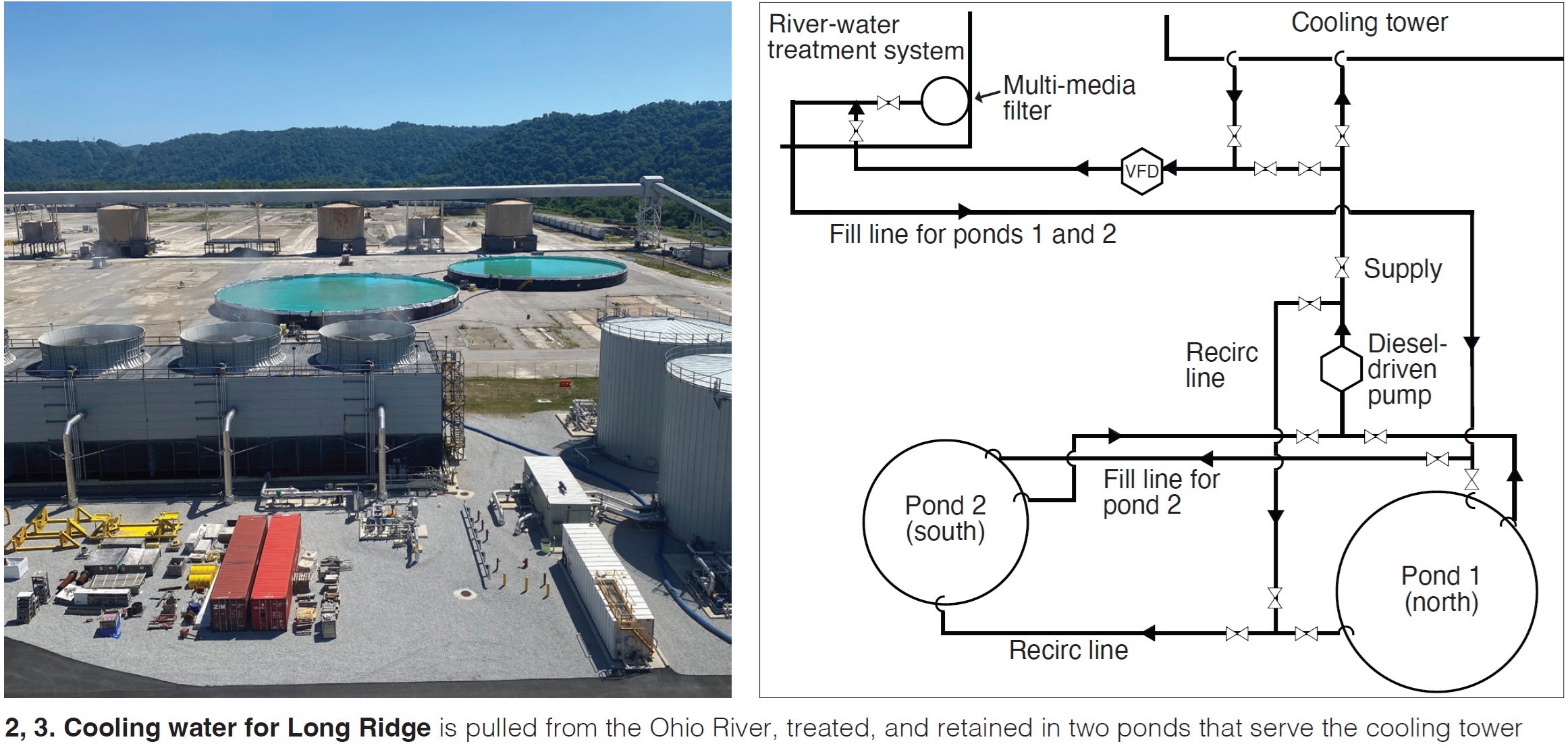

Background. Long Ridge Energy Generation uses an onsite facility to treat water pulled from the Ohio River, the plant’s primary source of cooling water. The water treatment facility must be functioning properly for the plant to operate.

Challenge. The water treatment system was unreliable and maintenance on that facility could not be performed while the plant was operational. Long Ridge was forced to find another source of water when the water treatment facility was down or needed maintenance.

Solution. An employee with prior experience in the oil and gas industry recommended using aboveground storage tanks (a/k/a ASTs) as a solution (Figs 2 and 3). Onsite equipment was used to fill the tanks with treated water and infrastructure was installed to pump it to the cooling tower.

Results. The ASTs allow the plant to continue operating if it cannot produce useable water with the treatment facility. Plus, the ASTs serve as a backup when the treatment facility requires maintenance.

Project participant:

Logan Ensinger, control room operator

Circ-water system reliability upgrade

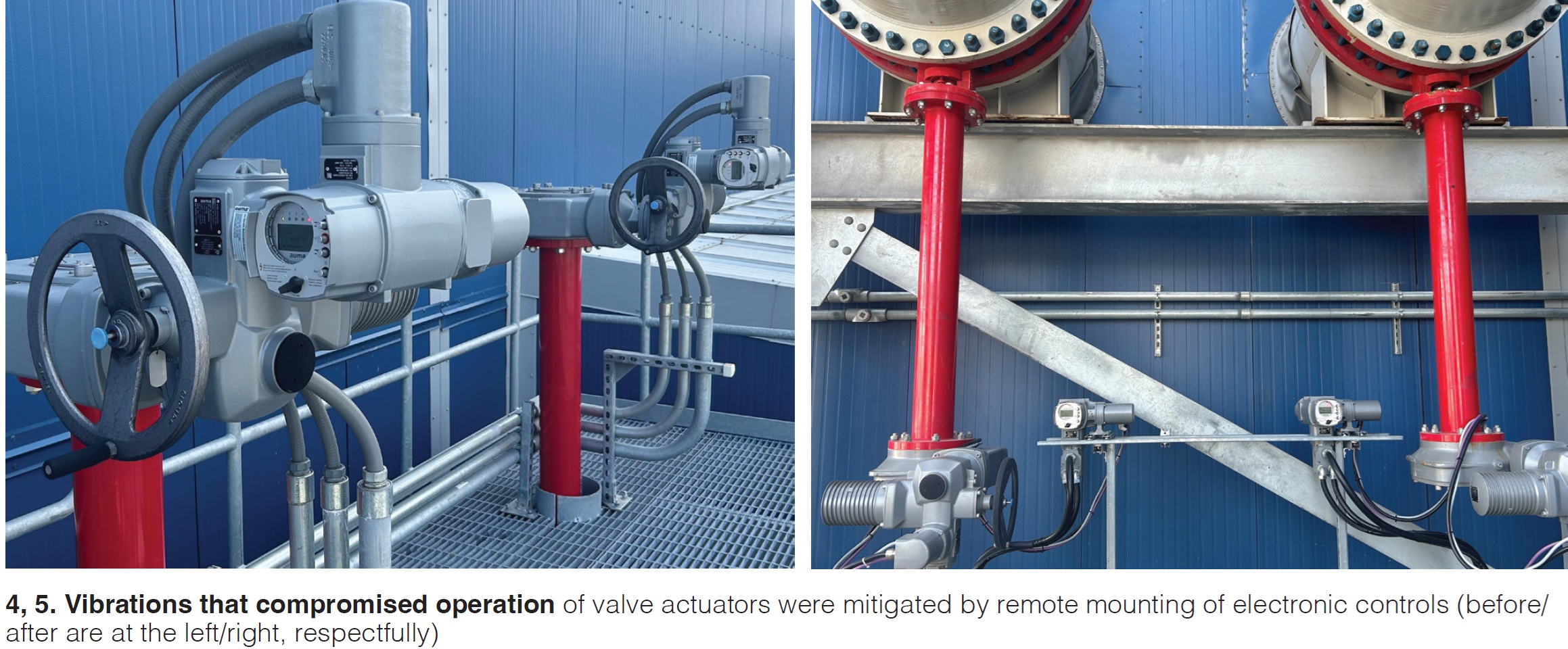

Background. Long Ridge uses a circulating water system from the cooling tower to serve both the main condenser and auxiliary equipment. It is comprised of two 50%-capacity pumps plus two inlet and two outlet valves to control flow to the condenser. These valves are used during system startup and shutdown to throttle and create backpressure to keep the pumps running on their designed operating curves.

Challenge. The inlet and discharge valve actuators were experiencing internal electrical component failures which resulted in “bad quality” for DCS and local display indication. This required the auxiliary operator to control the valves locally to establish conditions for starting the system. Staff determined these failures were caused by extreme vibrations attributed to the length of the valve stems used to interface with the valves.

Solution. Long Ridge contacted the valve manufacturer’s local rep to discuss options for remediating the issue. One option was a conversion kit that could be installed by plant technicians. It allowed remote mounting of the electronic controls that provided the same functionality as the original installation (Figs 4 and 5). The initial mod was performed on the ground-level inlet and outlet isolation valves.

Results. No failures have occurred since the first mod was completed. Plan is for the remaining valves to be modified at the next opportunity.

Project participant:

Victor Jackson