At the 2025 CIGRE International Symposium in Montréal, Kinectrics engineers Sunny Gaidhu, Krzysztof Pyc, and Ashfak Shaikh presented a practical message for powerplant owner/operators based on the paper, “Comprehensive Off-line Diagnostic Testing and Visual Inspections for High-Voltage Turbo Generators.”

At the 2025 CIGRE International Symposium in Montréal, Kinectrics engineers Sunny Gaidhu, Krzysztof Pyc, and Ashfak Shaikh presented a practical message for powerplant owner/operators based on the paper, “Comprehensive Off-line Diagnostic Testing and Visual Inspections for High-Voltage Turbo Generators.”

Offline diagnostic testing and visual inspections remain a high-value tool for large turbo generators in combined-cycle service. The paper also explains what online monitoring does well and where it can fall short. Readers who want full test images, plots, and acceptance details can download the complete paper here.

Offline testing still belongs in the plan

Offline testing puts the machine in a controlled state, having the ability to pinpoint insulation degradation, overall quality of insulation, and even partial discharge issues well before they become dangerous and pose a risk to the machine of interest. This early detection extends the life of the machine and improves overall system reliability.All the while plant electrical noise is lower, which improves sensitivity. By conducting Offline PD testing at low frequency, more of the winding is visible, including neutral-end coils that sit at low potential during operation, allowing for deeper penetration into the stator winding for greater enhanced condition assessment. Offline does require an outage window, so Kinectrics positions online and offline as complements. Use online partial discharge trends to decide when to act. Use offline tests to decide what to fix and to confirm results before return to service.

Practical offline program

A standard package covers the main insulation risks and gives fast guidance to maintenance planning, including:

- Insulation resistance and polarization index. Quick view of cleanliness and dryness. Also a gate to safe high-voltage work.

- Capacitance and dissipation factor. Tracks dielectric loss and flags aging, voids, or delamination in the groundwall.

- Offline partial discharge. Higher sensitivity than online in most plants because background noise is low. Captures activity across the entire winding.

- Slot survey with a TVA probe. Walks the slots to localize discharge sources under wedges and side-packing.

- Ultraviolet corona camera. Visual check for surface discharge at end windings and grading interfaces.

- DC ramp with current monitoring. Proves withstand and reveals abnormal leakage behavior as stress rises.

- ELCID core test. Low-flux screen for interlaminar faults before loading the unit.

Online vs offline plainly

Online monitoring shows how the generator behaves under real thermal and mechanical loads. It does not require an outage. Coverage is limited by sensor placement and signal attenuation, so absolute comparisons across units are difficult. Offline testing provides better coverage and signal to noise, but it does not include operating vibration and temperature gradients. Read the two together. Use online for drift and duty effects. Use offline for coverage, sensitivity, and acceptance before return to service.

100-MW air-cooled unit

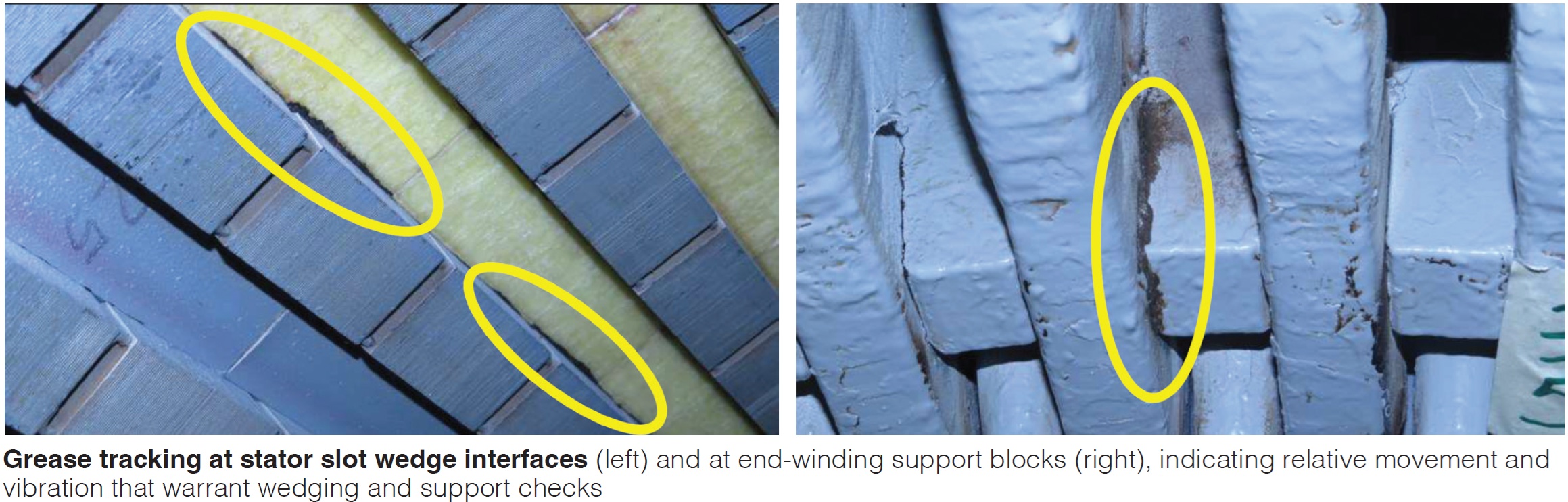

A full diagnostic suite found a fundamentally sound stator with localized issues. Insulation resistance exceeded 100 MΩ on all phases. Polarization index was roughly 3.7 to 4.7. Dissipation factor change and tip-up were less than 1 percent, which is consistent with healthy epoxy-mica insulation. Offline partial discharge identified one phase with the highest activity. The TVA probe crossed typical thresholds in three slots. The UV camera showed weak to moderate corona at two end-winding sites near grading. ELCID was clean at less than 100 mA. Visuals showed greasing at wedges and minor rub marks at end-winding supports (Figure).

Actions for the outage were direct:

- Repair the two corona sites

- Plan a wedging-tightness survey when the rotor is out

- Repeat the offline suite in five to six years

- Add semiannual online PD trending

The practical takeaway is that small, targeted fixes now prevent nuisance trips and protect against an early rewind.

540-MW hydrogen-cooled unit

Testing before and after remedial work showed how diagnostics guide the list and verify results. Initial findings included contamination in the isolated-phase bus, slot-coupler leads routed too close to end windings, and a few bent tooth corners around one slot. Insulation resistance and polarization index supported high-voltage testing. One borderline PI result was tied to moisture in the inner water system. Dissipation factor trends were stable. Offline PD on the white phase was high before cleaning. After bus cleaning and lead re-routing, PD levels dropped to acceptable values. Online phase-resolved PD plots confirmed the improvement. ELCID remained well below the 100-mA concern threshold.

Actions were to keep the new lead routing, maintain a clean bus, and continue online PD trending with periodic offline confirmation. The takeaway is that cleaning and lead management often remove false positives that mask real insulation health.

Guidance for plant personnel

The paper provides detailed thresholds and example plots. For the more mechanically inclined, a short checklist is often more useful in the field:

- Pair online PD alarms with a standing offline playbook. Run the offline suite when trends move or before heavy runs.

- Use TVA probe plus UV camera to find locations fast.

- Keep a short acceptance table in the work plan. As a rule of thumb for epoxy-mica, aim for IR above 100 MΩ, PI of 2.0 or greater, ELCID less than 100 mA, and tan-δ tip-up less than 1 percent. Trend against your own history first.

- After corrective work, repeat the same tests in the same configuration. Lock in a new baseline and archive the plots.

Offline diagnostics turn guesswork into evidence and help avoid premature failures. Online tools decide timing. Offline tools decide scope and confirm results. The two field cases show the pattern. Find the issue. Fix it. Prove the improvement. Trend it going forward. For full procedures, acceptance tables, and case study figures, download the complete paper. CCJ