Black Point Power Station

Owned by Castle Peak Power Co Ltd

Operated by CLP Power Hong Kong Ltd

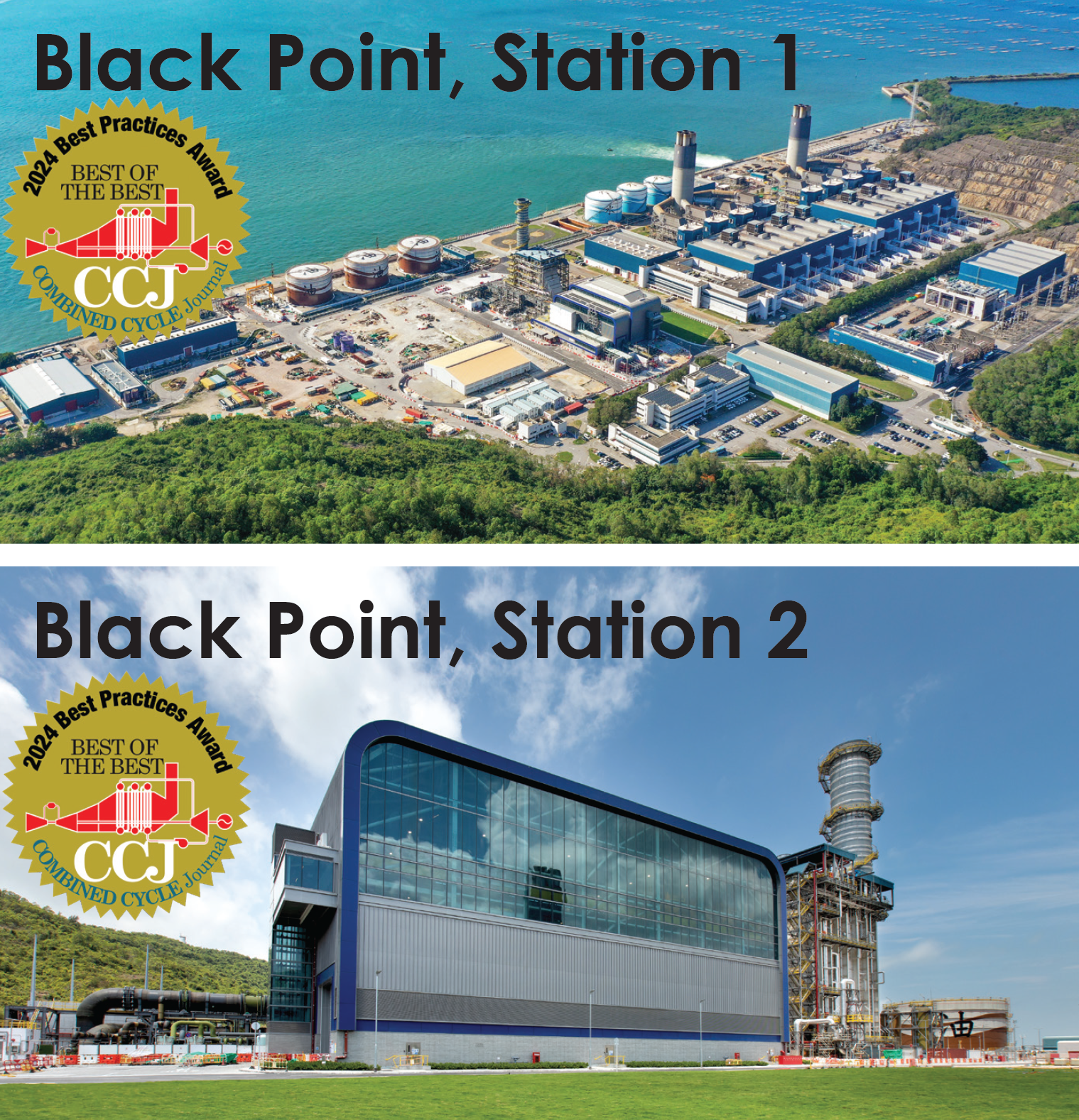

3850 MW, gas-fired with ultra-low-sulfur diesel backup, eight 337.5-MW 1 × 1 combined cycles powered by GE 9FA.03 gas turbines (a/k/a C units), plus one 550-MW and one 600-MW 1 × 1 combined cycle powered by Siemens-Energy 8000H gas turbines (a/k/a D units). The units were installed in phases from 1996 to 2024. Location: Hong Kong’s New Territories

Plant manager: Kwok Keung Luk

Operational excellence in outage management

Background. CLP Power Hong Kong Ltd (CLP Power) operates a vertically integrated electricity supply business that serves more than 80% of Hong Kong’s population. The company is regulated under a so-called Scheme of Control (SoC) Agreement by the government of the Hong Kong Special Administrative Region (SAR), which monitors the company’s operating performance and financial affairs.

Under this agreement, CLP Power has an obligation to supply sufficient and reliable electricity to its service areas at a reasonable price and in an environmentally responsible manner.

Black Point Power Station (BP), a gas-fired combined-cycle facility, originally comprised eight GE 9FA.03 gas turbines commissioned between 1996 and 2006. In response to supply/demand and climate-change challenges, all eight units were upgraded to increase their efficiency and capacity.

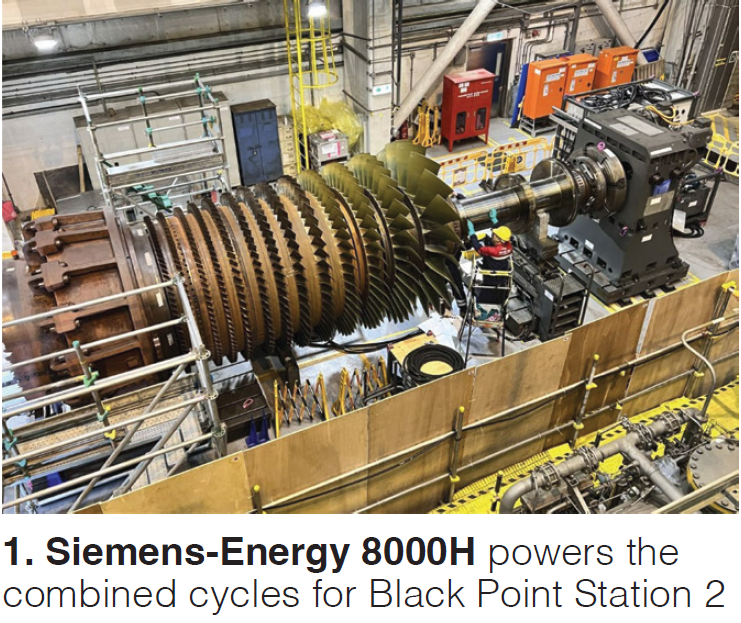

In support of the Hong Kong SAR government’s environmental policy and the transition from coal- to gas-fired generation, CLP Power added two more 1 × 1 combined cycles, one each in 2020 and 2024, increasing the proportion of gas-fired generation in its fleet to around 50%. With these Siemens-Energy 8000H machines, BP now boasts a total generating capacity of 3850 MW across 10 units.

Challenges. BP’s 10 combined cycles require about 10,000 man-days of work in a single outage season (from September to May of the following year), an effort involving around 700-800 in-house CLP O&M personnel and contractors. Managing and completing all planned outage work in a safe, effective, and timely manner presents major challenges in outage planning, execution, and management, as outlined below:

- Shortage of competent local labor. A limited local labor supply presents substantial challenges during outages requiring a skilled workforce to effectively conduct powerplant maintenance and upgrade work. The shortage of qualified workers in Hong Kong for tasks such as those requiring high-pressure welders, crane operators, scaffolders, etc, constrains resources during outage execution. The scarcity of competent labor can be attributed to several factors—including an aging workforce, cost and difficulty in arranging labor import, and heightened demand for technical expertise in the local market because of existing or future large infrastructure projects.

- Significant difference in manpower and resource requirements between peak and trough periods. Consideration must be given to the possibility of conducting outages for multiple units simultaneously. Also, given that most of the gas units have very high utilization hours, a large portion of the maintenance work can be done only during planned outages. For these reasons, a surge in manpower and resources often is experienced during outage periods compared with times when most units are operating and little maintenance work can be done. Balancing the fluctuation in manpower and resources can be quite challenging to the outage management team because CLP Power and its contractors must minimize retention cost during the low season to remain competitive. Cross training employees to handle multiple roles, and work levelization during outages, are among the ways to promote operational excellence.

- Plant aging issue, given BP units are reaching mid-life. More unexpected and significant defects are being identified on critical plant equipment, indicating that the existing maintenance strategy is insufficient to maintain equipment reliability to the level expected. Plus, outage execution has become more complex because of the upgrade projects required to maintain desired reliability.

- Differences in work culture and behaviors between CLP and contractors. Multiple work parties with diverse languages and work cultures are to be expected in today’s outages. The ratio of newcomers to experienced personnel also is higher than in the past. Additional coaching, guidance, and supervision are required to ensure productive, high-quality, and safe implementation of outages.

- Very limited outage windows for BP generating units. Compressed work schedules are required to meet outage deadlines and maximize unit availability to meet summer demand. Overlapping of unit outages causes conflicts between resources required for different outages and increases the complexity of planning and coordination—especially because schedule delays are unacceptable.

Solutions and results. To ensure a successful outage, six initiatives were introduced to achieve operational excellence. They were driven through the organization’s hierarchy by management and focused on implementation of best practices and continuous-improvement initiatives to enhance outage planning and resource allocation and execution. The six initiatives are:

- Early outage preparation.

- Manpower planning.

- Pre-outage communication and engagement.

- Short-interval control.

- Communication of lessons learned.

Early outage preparation

Outage planning. An excellent unit outage starts with early and detailed planning. To ensure safe and smooth outage execution, thorough preparation of the outage program, work schedule, manpower resources, spares and materials, tools, and equipment are essential.

Driven by an initiative to achieve operational excellence, a comprehensive outage planning management system was enhanced to guide the outage team. It covers all projects and preventive maintenance (PM) and corrective maintenance (CM) work to be implemented during planned outages (PO). This management system aims to achieve the following:

- Allow early identification of potential risks in outage execution.

- Establish effective mitigation measures.

- Ensure clear communication and coordination among all stakeholders.

- Facilitate safe, smooth, and well-controlled execution of all outage work.

The outage planning management system specified a clear timetable to freeze outage work scopes and resources thusly:

- Nine months before outage start: Freeze project work list.

- Six months before outage start: Verify funding of all projects.

- Three months before outage start: Freeze PM work list; ensure resources planned for all projects are available; verify resource plan for all PM work.

- One month before outage start: Freeze CM work list; ensure the resource plan for all CM is ready.

- Two weeks before project start: Freeze outage master schedule.

Result. Effective management of outage-execution readiness is verified by use of an outage scorecard and traffic-light mechanism.

The scorecard provides comprehensive information to allow an overview of unit-outage execution readiness in terms of outage work scopes, project funding, work schedule, resource planning, and availability.

The traffic light helps to point out critical outstanding issues which may incur significant impact on outage commencement or implementation, allowing early awareness for the outage management team to take necessary mitigation measures.

Change management in outage execution. Changes in work scopes occasionally are required, even for a well-planned outage. Since the project and PM work lists have been finalized and frozen well before the outage starts, it is necessary to have a clear mechanism in place to ensure all changes to outage work scopes and/or schedules are manageable and all stakeholders are notified to allow sufficient time for coordination and adjustment of resources.

Result. The change management system helps the outage management team consolidate and evaluate resource and interfacing issues that may arise from the change. Such analysis is reported to the outage steering committee for approval with justification. This mechanism provides flexibility and the ability to align the latest outage plan, if necessary, while safeguarding the outage execution feasibility after the change. Information included: Change details, justification, proposed start/finish dates, and impact of change (material, contractor resources, equipment, funding, quality, and schedule).

Outage standard time optimization. Given the limited outage window, staff actively reviews outage standard time, especially for critical-path activities, using data collected during outage monitoring activities. Common work steps of unproductive time are identified and strategies are developed to eliminate or minimize them. Outage personnel collaborate closely with the maintenance team to reassess the work program and identify opportunities for resequencing or paralleling tasks to expedite outage completion (for example, a two-shift work arrangement for critical-path activities). These efforts help maximize resource utilization and reduce overlapping outages.

Result. As of April 2024, optimization progress was positive with three-quarters of the major work having been reviewed during the 2023/2024 outage season. This resulted in an 83-day reduction in outage time for 2024/2025 compared to the previously approved work plan, which, in turn, was 25% less than the next earlier approved version.

Manpower planning

Because an overlapping of unit outages in 2023-2024 was foreseeable, an early review of operational manpower was conducted in October 2022 to ensure sufficient competent personnel would be available to support unit isolation, de-isolation, restoration, testing, and commissioning activities.

Result. The critical, most manpower-intensive period was identified, and an assessment conducted to determine the corresponding operational manpower requirement. As a solution, a team of outage operating engineers was established to support parallel unit outages by using a “flexible-team” arrangement across the BP units and Castle Peak Power Station, another CLP generating plant. Additionally, an early start to on-the-job training was arranged to increase the technical competence of young engineers.

The staffing requirement for each C unit (GE 9FA) was one senior shift engineer and two shift engineers at outage start and outage end, and two shift engineers in the middle of the outage; for each D unit (Siemens-Energy 8000H), one senior shift engineer and four shift engineers at outage start and outage end, and one senior shift engineer and three shift engineers in the middle of the outage.

During overlap periods—D unit start and C unit end—two senior shift engineers and four shift engineers are required; plus, one Castle Peak trainee and one graduate trainee on shift. Note that Castle Peak has coal-fired units in addition to gas/oil-fired gas turbines.

During the manpower planning stage, personnel requirements for different work scopes are reviewed (for example, high-pressure welder, crane operator, rigger, etc) to ensure outage progress will not be compromised by a shortage of staff with a particular skillset.

Additionally, project managers are responsible for reporting the status of work-permit applications in case onsite support by a foreign expert or advisor is required. This review assures sufficient manpower to complete the outage, and if gaps are identified, there’s sufficient time for making adjustments.

Result. During planning for the Unit D1 outage, management identified the need for more shift engineers. The issue was resolved by arranging three engineers from the outage management team to support in nighttime shift-work supervision.

In addition to alleviating the stringent manpower resources, this arrangement provided a good opportunity for honing the skills of outage team members regarding the 8000H gas turbine (Fig 1). Through hands-on experience and inspection of daily tasks, team members were able to expand their knowledge and provide timely updates on outage progress.

Pre-outage communication, engagement

Prior to the outage, it is essential to coordinate with the main contractor and relevant stakeholders to review and acknowledge the safety measures and job arrangements on major activities and critical tasks. This helps to align expectations of various work forces within the outage for both the site management team and the frontline workers.

Result. Several training sessions were provided for engineers and workers to deliver SHE (safety, health, and environment) standards and requirements for working in unit outage areas (Fig 2). This training was designed especially for newcomers who had no prior work experience and were not familiar with the SHE requirements for CLP Power stations. The goal was to improve safety awareness prior to outage start.

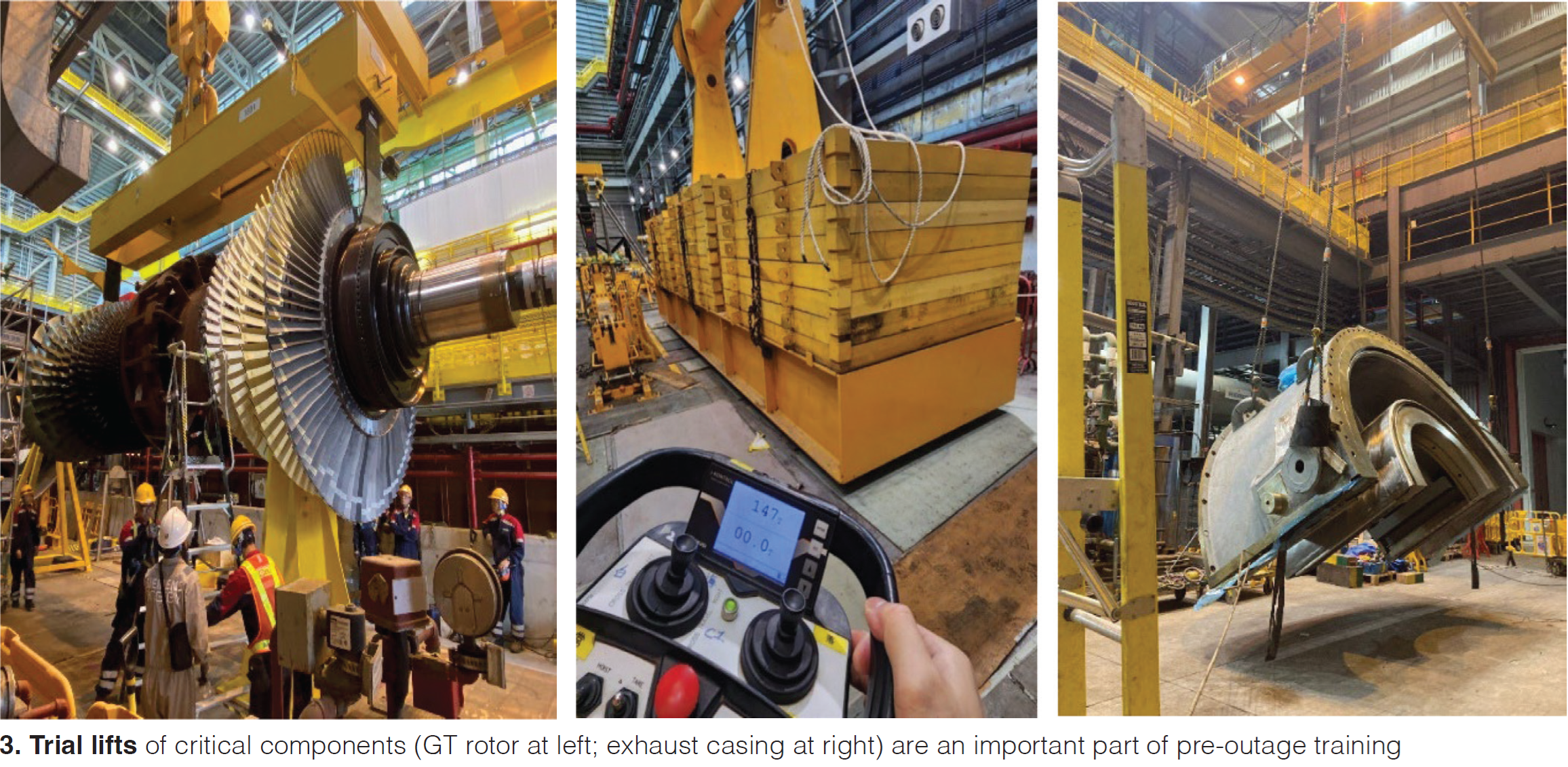

To ensure the safety message was well received by the personnel involved, some critical work packages were selected to test their understanding. For example, the gas-turbine upgrade project requires frequent heavy lifting of engine components, which involves complex handling operations.

Trial lifting of the gas-turbine rotor (Fig 3 left) and flipping of the exhaust casing (Fig 3 right) were performed to review the effectiveness of the lift plan and ensure all safety measures are being observed. A post-trial briefing was conducted for findings observed during the trial to ensure understanding and the drive for improvement.

Pre-outage inspection to fine-tune outage scope

To ensure all units can perform with high availability after a planned outage, and to minimize the forced-outage rate, it is important to identify hidden defects beforehand—thereby minimizing unexpected work during the outage which might delay the unit’s return to service. Through operational excellence, the pre-outage inspections drive and enable early assessment of the unit to achieve the following:

- Enhance understanding of current plant condition and facilitate earl decision-making of the planning and preparation for necessary maintenance work.

- Reduce work-scope uncertainties during outage execution (for example, unexpected critical plant defects or equipment failures identified).

- Ensure readiness of tools, materials, and manpower for maintenance work—preventing undesirable extension of the outage period due to resource unavailability.

Result. Two 17-day planned outages were scheduled for Units C3 and C4 in March and April (2023), respectively. The major activities in these outages focus on HRSG statutory inspection. Based on experience, it is common to identify unexpected defects in the HRSG during the inspection process. Staff encountered difficulties in preparing sufficient materials, tools, and manpower to fix those unexpected defects.

To mitigate these issues, two pre-outage inspection and maintenance outages (MO) were arranged and a boiler internal inspection by drone was conducted. During the pre-outage inspection, several internal defects were revealed.

With clear and sufficient information on HRSG internal condition, the CLP Power maintenance team and contractor were able to update and fine-tune the work scopes for the planned outage. The bottom line: Planned outages were completed successfully within the original planned window with all additional HRSG internal defects repaired.

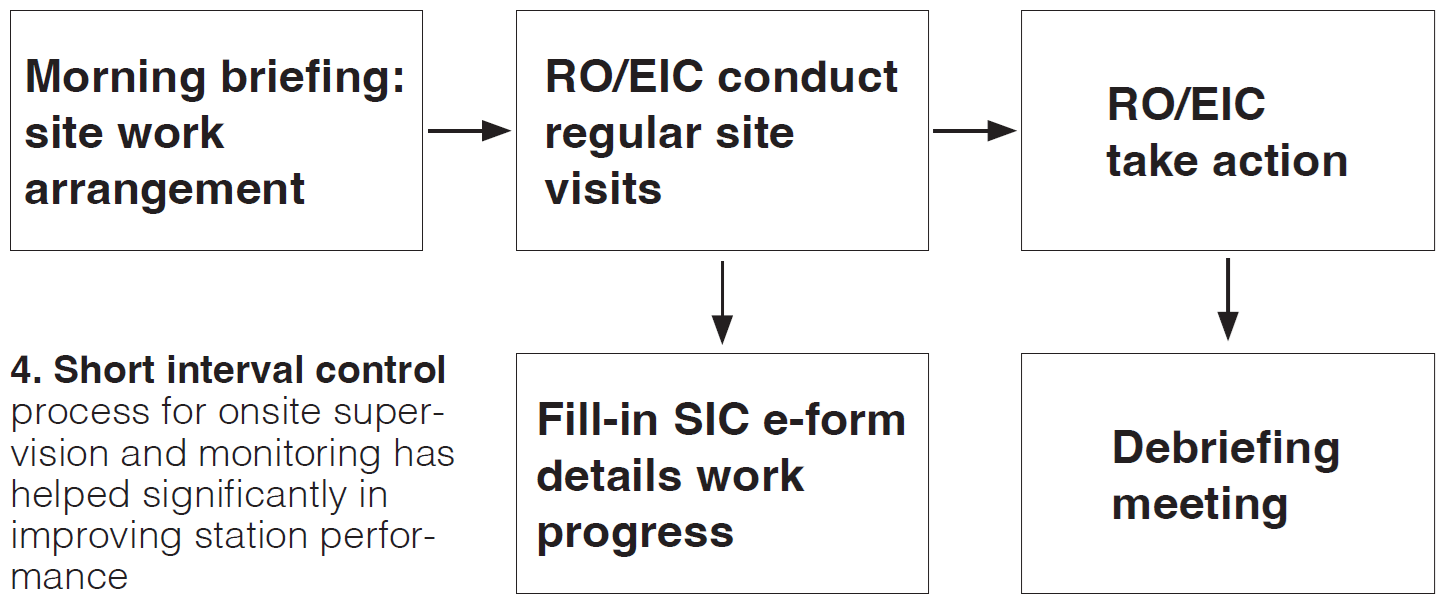

Short interval control

The first implementation of short interval control (SIC) for onsite supervision and monitoring in 2023 contributed significant improvement to site inspection and overall performance. SIC is a structured process that brings insight into identifying opportunity times for improvement and managing site safety, productivity, and quality performance—thereby enabling instantaneous actions to improve effectiveness and efficiency of activities and processes (Fig 4).

Regular site visits by CLP Power’s responsible officer (RO) and the contractor’s engineer-in-charge (EIC) can strengthen construction site management and directly instruct contractors on the owner’s requirements. Direct and timely supervision can effectively deliver the utility’s work expectations.

In each site check-in, the RO assures active supervision to provide the following:

- Timely calibration on site management.

- Seamless cooperation with contractors to address unforeseeable issues.

- Regular site performance records for analysis.

The direct benefits of SIC include empowering the RO to maintain adequate control and understanding of construction-site condition. When necessary, the RO can take immediate action to ensure effective site management. Any issues that arise during site checks are meticulously recorded and used to promote continuous improvement.

As the SIC process evolved from mere compliance to general use, it has played a crucial role in shaping the mindset of both the RO and contractors regarding effective site management. By bridging cultural and behavioral gaps that are aligned with CLP’s expectations, this process enhances the competencies of both parties.

Insights and observations derived from SIC undergo a thorough root-cause analysis (RCA). Lessons learned and action items to address identified issues are registered and communicated to both the RO and contractors via a pre-outage communications program. This proactive approach enables the outage management team and different working parties to make necessary preparations for any foreseeable risks in upcoming work.

With SIC implemented, ROs and EICs are required to proactively supervise work and capture the safety, quality, and productivity performance of site activities. An “SIC App” using “Power Apps” has been developed using the “Power Automate” platform for users to submit site observations for every job. The application streamlines processes by recording work planning data automatically and creating a database for all observations onsite while facilitating data analysis by the outage management team.

This analysis is used to facilitate discussions in the management control system as well as with the contractor management team in its drive for work ownership and continuous improvement.

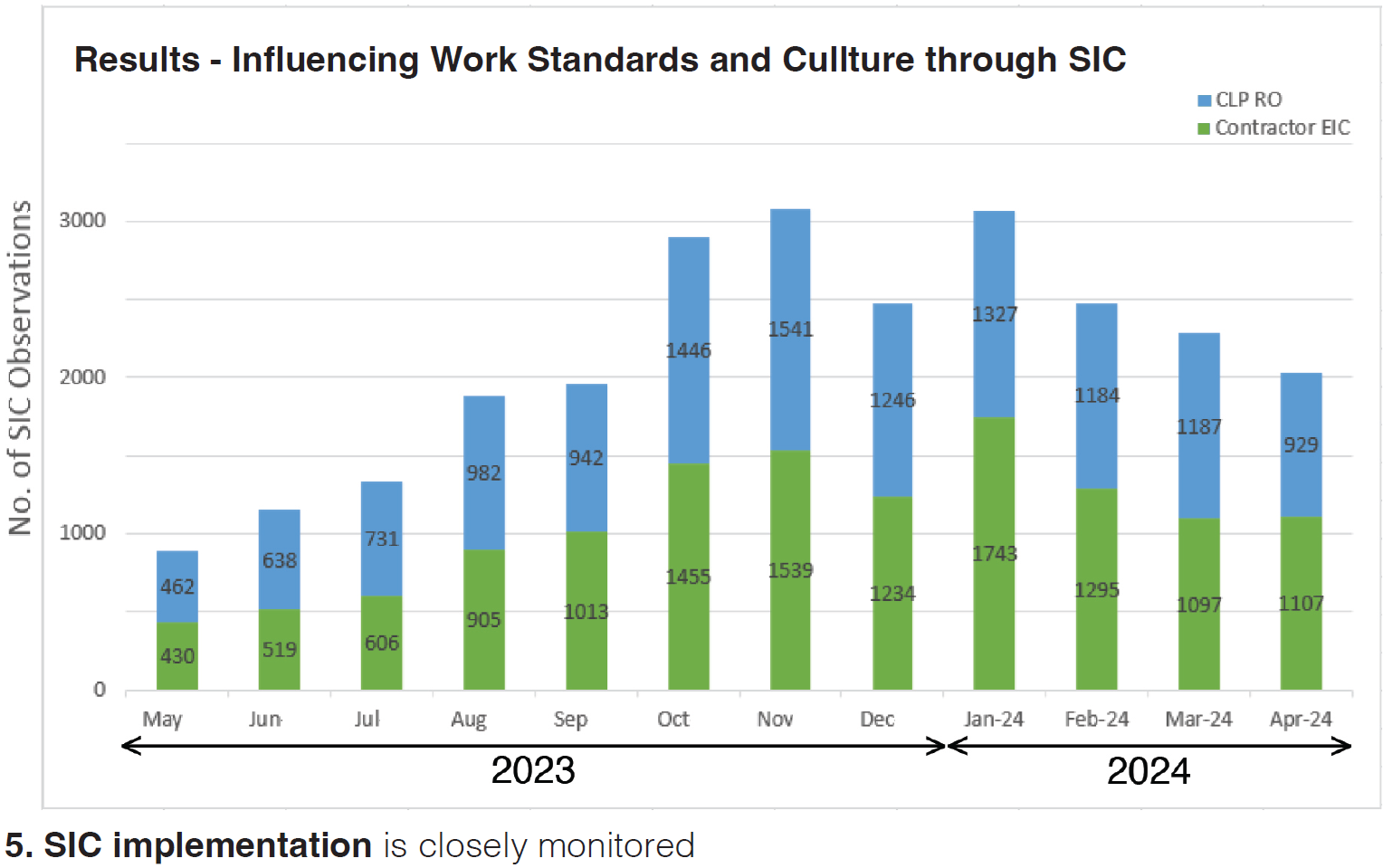

Result. The effectiveness of SIC implementation has been monitored closely since its launch. Staff has found that the quantity of SIC submissions significantly increased during the outage season (October to April), indicating a higher level of work ownership on both the CLP in-house maintenance teams and contractor teams (Fig 5).

Numerous areas of improvement, which CLP calls “opportunity time” also were identified to improve outage performance in terms of productivity, quality, and safety. Since January 2024, an increasing trend of good observations also was reported through SIC exercise, revealing a positive change in the mindset and working behaviors of different contractor teams.

To achieve operational excellence, more support, guidance, and coaching from CLP Power was provided to selected contractor EICs and site supervisors, allowing them tighter control of the workforce and the ability to address productivity issues by taking immediate actions onsite. Productivity and quality of work improved accordingly.

Result. During a recent Unit D1 outage, the day and night shifts were scheduled to speed-up progress on critical-path activities; ROs were assigned shift duties to monitor work performance and progress. Past experience had indicated that a reduction of supervisory personnel during night shifts led t more relaxed behavior and lower productivity among contractors.

SIC process observations provided valuable findings into the specific items that had to be addressed, thereby enabling follow-up to rectify issues and improve overall performance.

Example of a productivity issue identified and improved at an early stage of the outage: Multiple SIC observations by RO reported that a contractor work team was not present from 11:30 p.m. to 1:10 a.m. for its meal break and also left the site at around 6 a.m. for an 8 p.m. to 8 a.m. shift.

CLP Power raised the issue with the contractor’s representative in a weekly RCA meeting and requested that the company provide the work team clear instructions regarding the need to return on time after meal breaks and to remain working onsite until at least 7 a.m. The resulting improvement enabled early commissioning.

In 2023, three of seven Black Point unit outages were completed successfully in fewer days than expected thanks to SIC support. The remainder of the outages were completed on time.

Lessons learned

- Lessons-learned register. SIC findings with actual onsite work progress, deviation with work plans, and any other issues observed during the outages were captured using an application developed by in-house staff. A register also was established to track and analyze all findings. RCA meetings are conducted with working parties weekly to address issues and ensure timely improvements and immediate follow-up actions.

- Post-outage focus groups are collaborative forums that dig into significant or repetitious major outage issues or incidents. Key stakeholders are selected to review existing practices and propose improvement actions. By sharing perspectives and insights among the key parties, areas for improvement are identified and they act as a driver for systematic changes in future outages.

- Engagement sessions share the outcomes of the discussion groups. They ensure collective understanding and engagement while encouraging feedback and suggestions from the larger group. This allows for alignment of outage management practices and ensures all stakeholders are engaged to support the proposed changes in future outages. It creates an atmosphere for a learning organization and empowers all stakeholders to own and contribute to the success of future outages.

Result. The D1 outage started in late February 2024 and the critical-path activity was the hot-gas-path inspection for the Siemens-Energy gas turbine. According to the engine log, the D1 had experienced an incident during an earlier combustion inspection and boiler statutory inspection outage. The follow-up investigation team identified that the incident was caused by fuel-oil leakage during a fuel-transfer commissioning test.

As an improvement action, CLP Power established quality check sheets to verify the integrity and condition of the gas-turbine fuel-gas and fuel-oil systems after restoration from unit overhaul. Additionally, the acceptance standard for torque checks on fuel-oil and gas pipes also were reinforced to ensure high-quality outage work.

End notes

By learning from the challenges and pitfalls encountered in previous outages, plant personnel developed effective solutions to enhance outage management. Implementing comprehensive planning, emphasizing communication and coordination, and prioritizing work contribute to successful outage execution and improved performance.

Project participants:

Justina Yim, principal business manager

Dennis Chan, resources planning manager

Daniel Pong, outage manager

Kelly Chan, engineer