AES Levant Power Plant

Owned and operated by AES Corp

250 MW, tri-fuel peaking facility consisting of 16 diesel/generators, located in Al Manakher, Jordan

Plant manager: Feras Hammad

Charge-air-receiver crack repair: welding versus epoxy paste

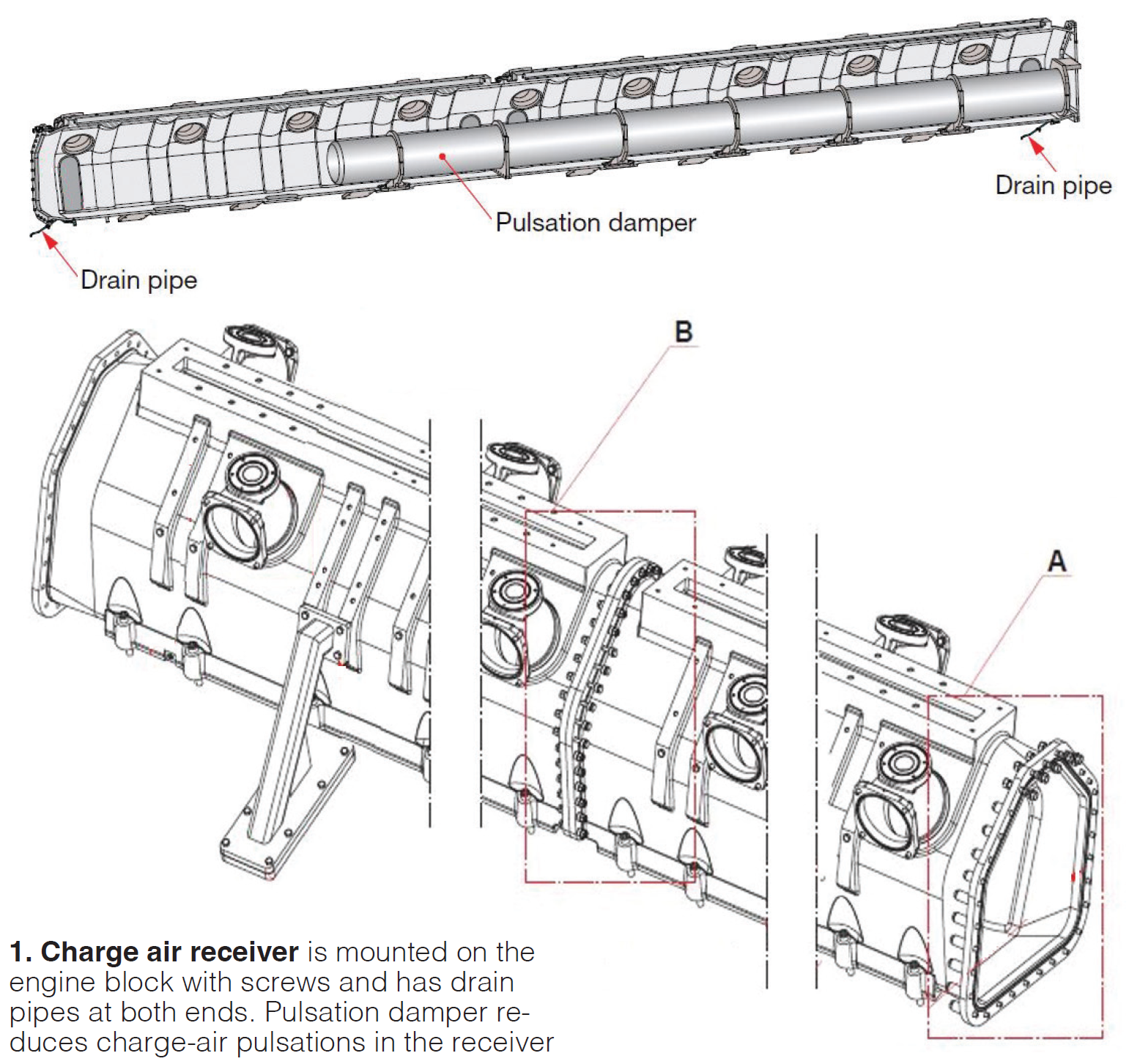

Background. Wartsila 18V50DF engines (16 in total) are the core components in the AES Levant Power Plant. The subject of this best practice, the engine charge-air receiver, is responsible for delivering and distributing intake air to all cylinders.

Challenge. Leaks in the air-intake system attributed to cracks in the charge-air receivers on 13 of the plant’s engines adversely impacted performance, availability, and O&M budget (Fig 1). Plant staff participated in a brain-storming session designed to identify the optimal solution.

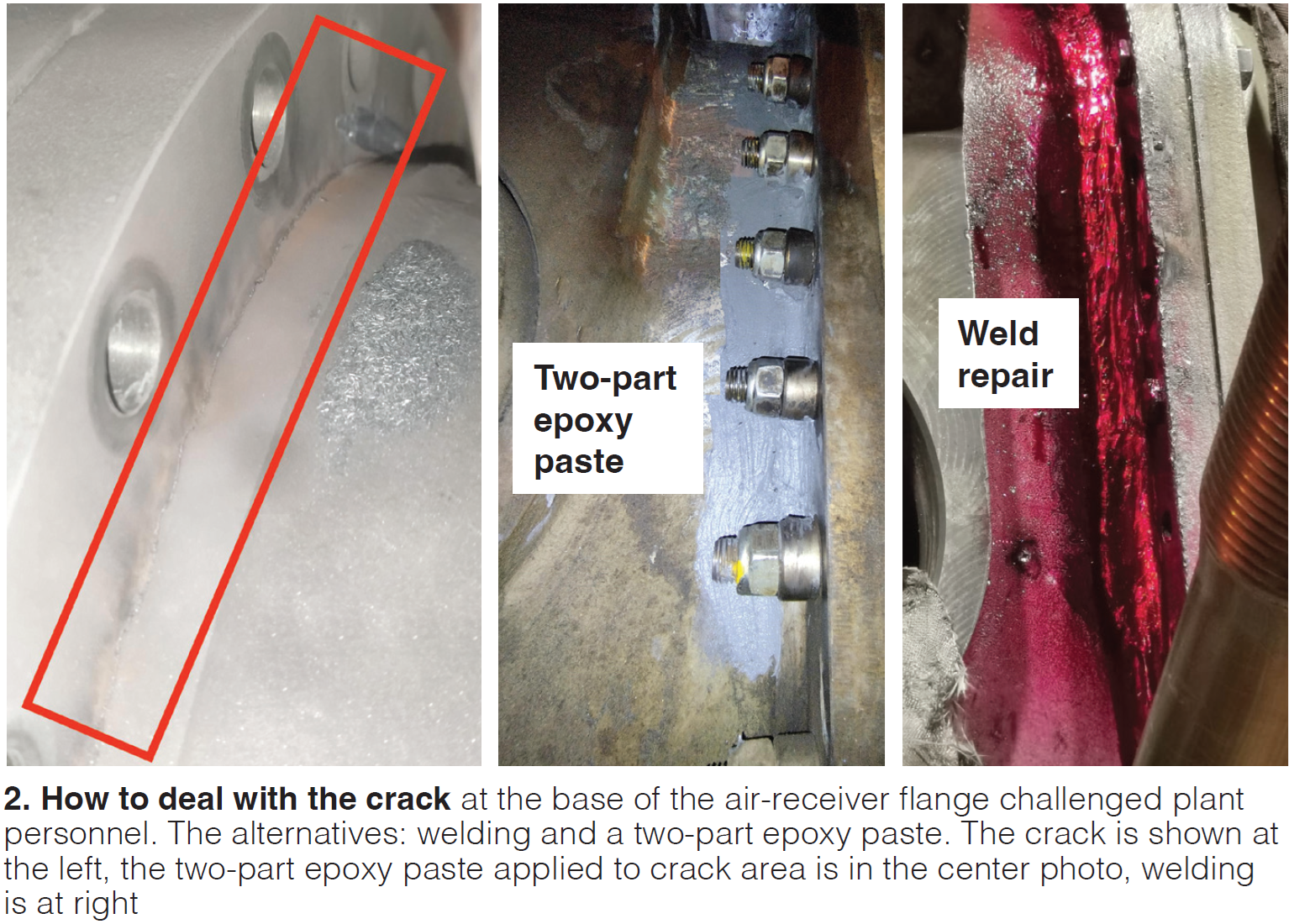

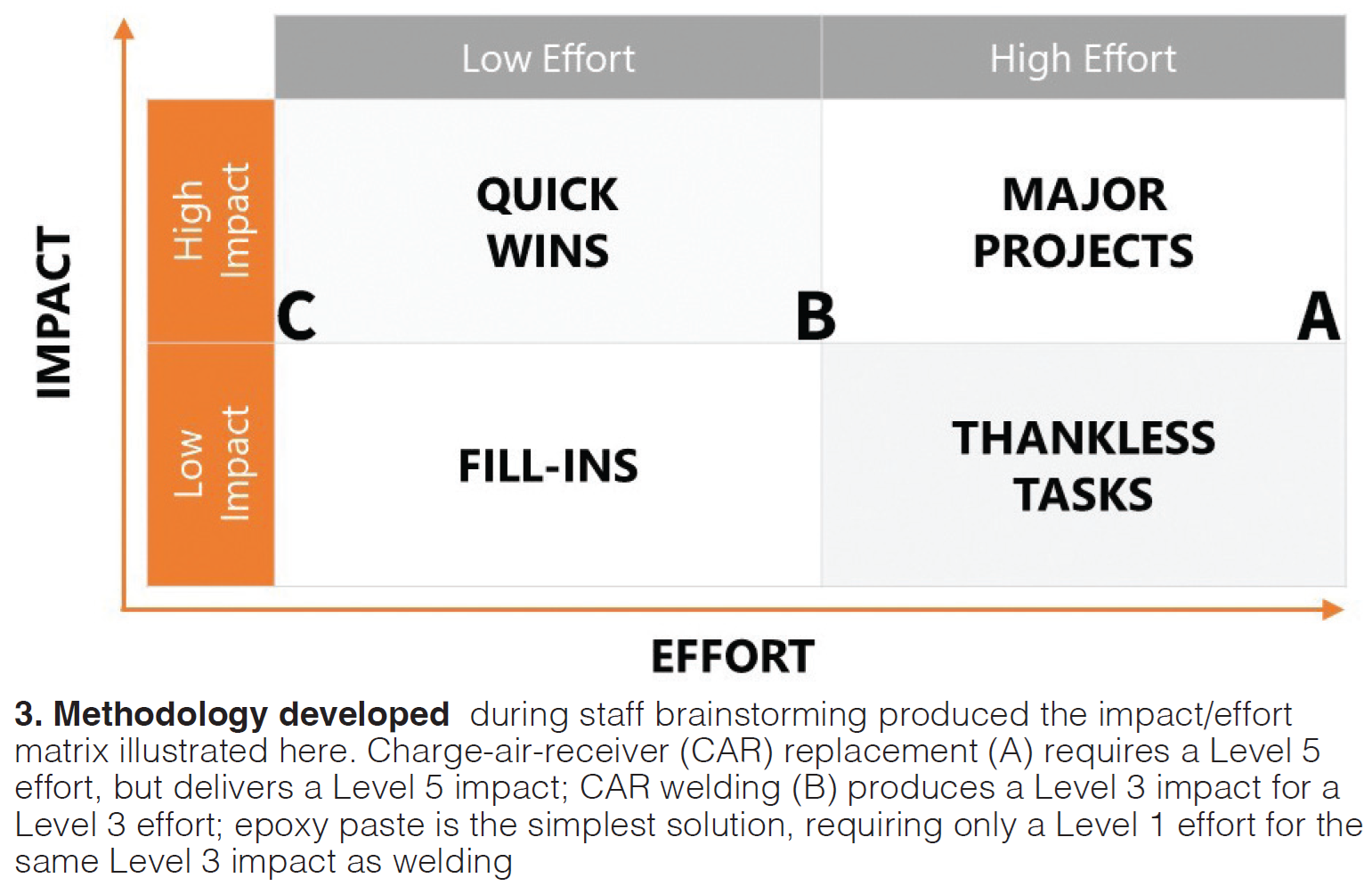

Solution. Two approaches were considered for sealing the cracks causing the leaks: welding and epoxy paste (Fig 2). The welding alternative was a relatively straightforward repair for Levant’s skilled O&M staff. However, selection of the appropriate epoxy required a technical and financial evaluation (Fig 3). The manpower requirement for performing epoxy-paste repairs on the engines was estimated at $3000 versus more than $200k for the welding solution.

Results. The two-part epoxy paste selected for this application was Belzona 1161 Super UW-Metal and solidifier. Belzona has a history of successful epoxy applications in the electric power industry.

Project participants:

Laith Jara’abeh

Abdullah Al Dabaybeh

Raviarma

‘LFO filtration machine’ improves fuel quality, boosts engine availability

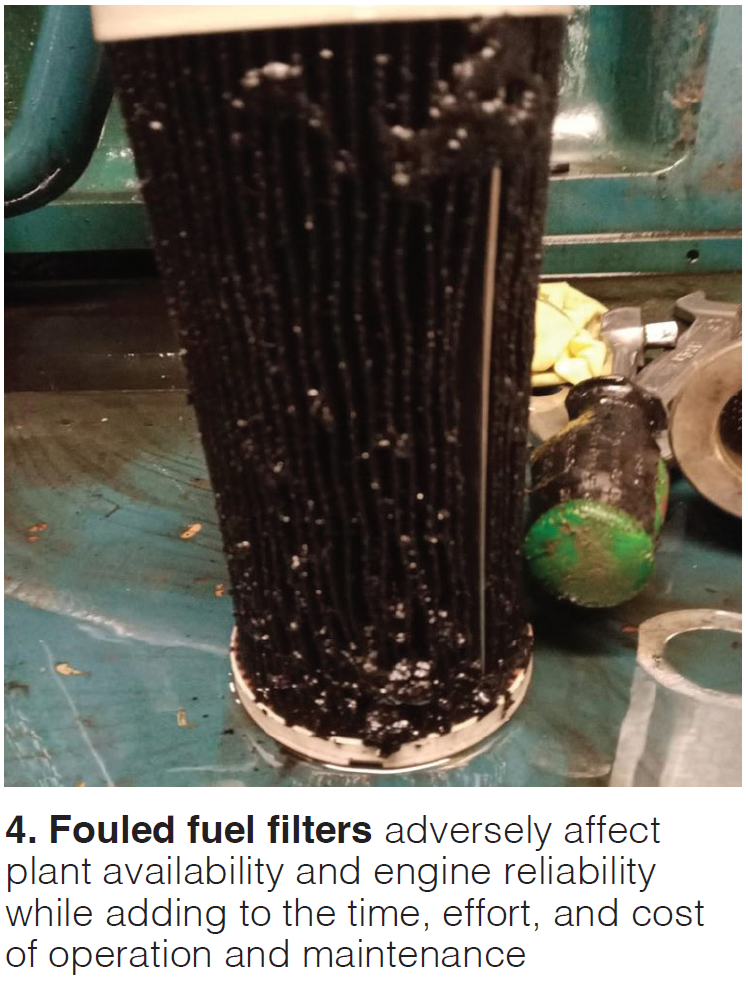

Challenge. Water and sludge accumulation in fuel filters adversely impacted plant operation when fouling was severe and the engines transferred to backup mode (Fig 4). Clumps of fuel would be in evidence and the smell difficult to bear.

Solution. O&M personnel attributed fouling of the light fuel oil to inadequate filtration and purchased a MICFIL AL/ST 600 from Germany’s MICFIL Ultra Fine Filters GmbH (Fig 5). Among its features are removal of particles over 0.5 µm, water absorption, and removal of about 98% of all bacteria. The filter is said to prevent abrasion in bearing shells, ball bearings, and all moving oil-lubricated parts in the engine as well as in the diesel exposed parts within injection pumps and single-tip nozzles—thereby promoting improved and cleaner combustion.

Results. Savings in materials costs and O&M time and effort amounted to more than $100,000 in 2023.

Project participants:

Sameer Abedrabboh

Ahmad Banihani

Osama Khamis

LED floodlights reduce O&M cost

Challenge. Reduce the power consumption and maintenance cost of plant floodlighting which suffered frequent defects.

Solution. Transition from the existing incandescent lighting to LED (Fig 6).

Results. Annual energy cost for lighting was halved, and the annual material cost was reduced by three-quarters. Data were not available regarding the saving in maintenance cost.

Project participants:

Ashraf Qasim

Ayman Mobaied