Jackson Generation

Owned by J-Power USA

Operated by NAES Corp

1200 MW, two 1 × 1 combined cycles powered by Mitsubishi 501 JAC gas turbines and SRT40AX steam turbines with HRSGs from John Cockerill, located in Elwood, Ill

Plant manager: Scott Freese

Share current drawings plant-wide to assist operations personnel

Challenge. Plant personnel use many tools to help them operate their facilities—especially P&IDs. Virtually every powerplant has a big binder containing the drawings for the entire facility. When a question or problem arises, staff brings out the “big book” and flips through numerous pages to find the correct one.

Another way to do this is to have the P&IDs in a digital format to facilitate the searching and highlighting required. However, it can be a nuisance to find the exact drawing needed if the P&ID library was not organized properly from the beginning of operations.

Yet another challenge: Retaining the most current revision of each drawing at the plant and being able to update it across the site. Be aware that you could have multiple departments using different revisions of the same P&ID.

Solution. At least one of Jackson’s operators knew the plant’s P&IDs could be organized in a more user-friendly fashion. Using his website-building skills he started putting together a plant-only P&ID website with all the revised EPC P&IDs and vendor drawings. The P&IDs are organized by system and can be filtered by vendor. The P&IDs can be linked, enabling you, for example, to start with the condensate P&ID and follow it all the way to boiler feedwater. Heat trace, electrical, and isometrics are included.

The website also serves as a master file, holding the most current revision of each drawing—including breaker schedules and electrical one-lines. The website is a critical troubleshooting and training tool.

Results. All plant personnel have website access, saving time in preparing LOTOs and contractor work packets. The website also has proved a critical asset for conducting heat-trace audits and for repairing heat-trace circuits. All the drawings required for this effort are linked and organized. Because each P&ID is opened in Adobe so you have the ability to highlight and red-line the drawings.

Project participant:

Danil Klokov

Removing varnish and mitigating its formation

Challenge. Varnish in hydraulic systems can be triggered by a thermal event that causes the oil to start degrading. Since going commercial in May 2022, Jackson Generation has tested its control oil monthly. The control-oil skid serving the plant’s steam turbine consists of two 100% oil pumps arranged in a lead/lag configuration that sit atop a 344-gal reservoir.

The system features both discharge and return filtration—including polishing filters and three fuller’s earth filters. It protects inlet-guide-vane (IGV) and variable-guide-vane (VGV) actuators, as well as HP, IP, and LP turbine stop/control valve actuators. The trip-oil system also is supplied from the control-oil skid.

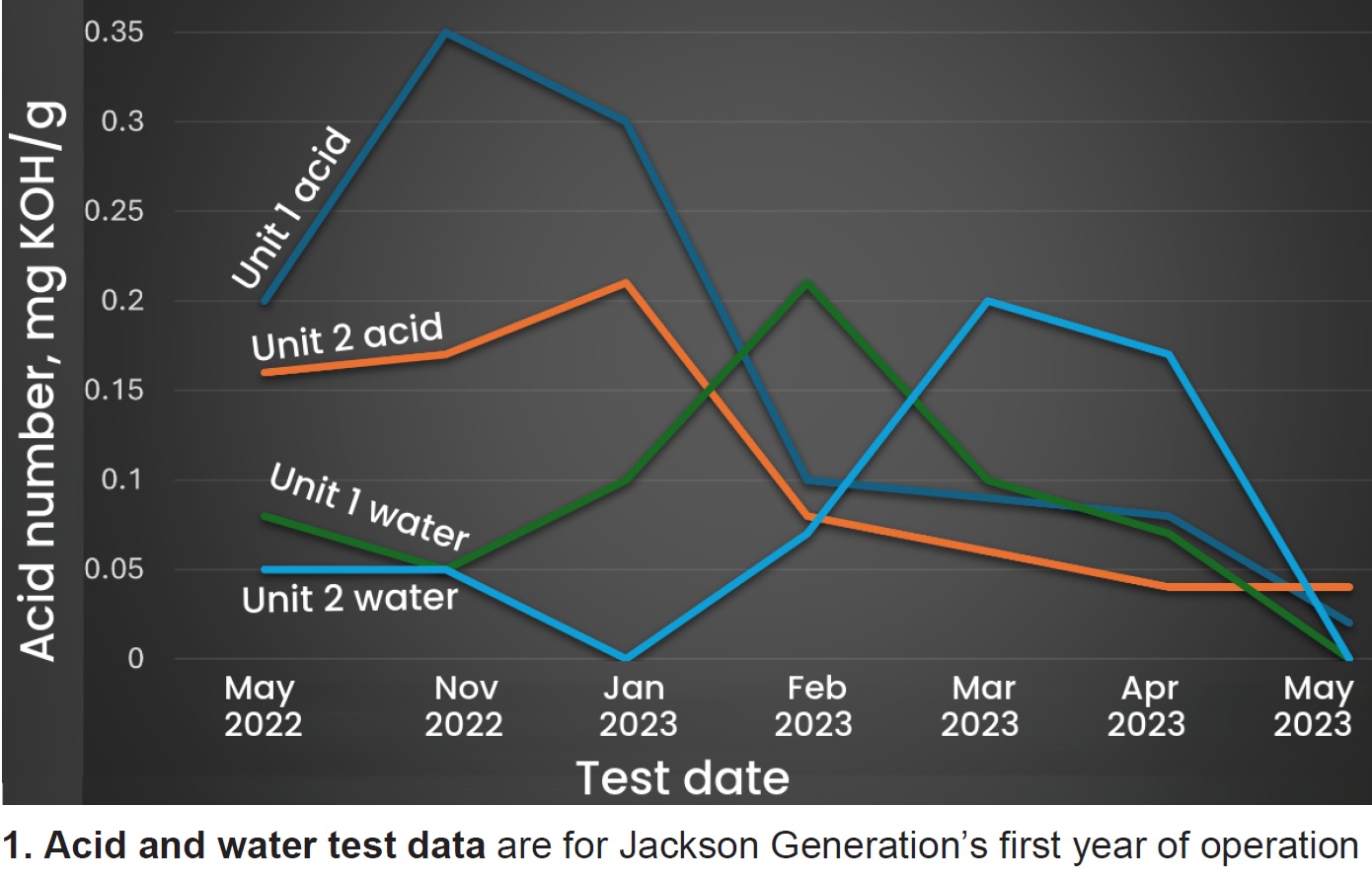

Each oil test conducted covered all the basic fluid health targets: particulates, acid, and water. The first oil analysis, in May 2022, revealed an acid number of 0.2 mg KOH/g with no water indication for Unit 1 and 0.16 mg KOH/g for Unit 2, also with no water indication.

The following month, on June 27, while attempting to start Unit 2, the startup permissive was lost because of IGV servo module deviation. This alarm is caused by the demand and the feedback of the IGVs being greater than 3%. A warranty claim was submitted and the IGVs were recalibrated.

Unit 2 tripped on July 30 because of an IGV deviation alarm. The servos for the IGVs were replaced with new ones from inventory. The old servos were sent to the OEM for inspection; signs of varnish were noted.

By November 2022, Unit 1 acid numbers had jumped from 0.2 to 0.35 mg KOH/g, Unit 2 acid numbers from 0.16 to 0.2 mg KOH/g.

Control-oil water content also had increased on both units, from no water indication on either unit to 0.1 on Unit 1 and 0.05 on Unit 2.

Varnish was affecting the IGV servos, as well as those for the turbine stop/control valves. On Jan 13, 2023 the Unit 1 turbine IP control valve started closing while at baseload because of a failed servo, which was replaced. Inspection of the failed servo revealed varnish damage.

Thus, the varnish problem affected every aspect of the control-oil system: Unit 1 had experienced five IGV servo failures, two VGV servo failures, and five steam-valve servo failures. Unit 2 had two IGV servo failures, one VGV servo failure, and four steam-valve servo failures.

Solution. Collaboration among the entire Jackson Generation team, JPower engineers, and Mitsubishi resulted in a plan determined to correct the varnish problems on both units. In January, a rental side-stream varnish filtration skid was installed on Unit 1 along with ion-exchange filters. After running the filter skid for a month, the site team inspected the fuller’s-earth filers on the main control skid, finding they never were installed during commissioning.

Fuller’s earth filters were installed along with a water removal cart, water being a byproduct of skid operation. Acid and water indicators soon began dropping on Unit 1, providing confidence to move the cart to Unit 2 (Fig 1).

During the spring 2023 outage, both control-oil reservoirs were drained to 50% and replenished with new oil. The result of this had an initial negative effect. Varnish numbers went up causing failures on both units’ trip-oil systems.

Note that each of the steam-turbine control valves for HP and IP systems has a trip-oil line going to the actuator. Each trip-oil line applies pressure to a poppet valve allowing the actuator to stroke up and down. If this poppet valve is not completely closed, then sufficient control oil pressure cannot be maintained on the steam valves to allow them to stroke open.

In May 2023 when starting to roll the Unit 2 steam turbine, the HP and IP control valves would not open. The unit was brought down to investigate. Rexroth reps for the valve actuators brought onsite to troubleshoot found that varnish had built up on the HP and IP trip-oil poppet valves, causing them to stick open (Fig 2), thereby preventing the necessary control-oil pressure to be applied to properly actuate the valve.

The poppet valves were cleaned and reinstalled, costing six days of downtime to get personnel and tooling onsite. A week after the incident on Unit 2, the same issue occurred on Unit 1. However, this time site personnel were prepared with all proper tooling onsite and able to clean and replace the poppet valves in only five hours, thereby saving the plant days of forced-outage time (Fig 3).

Results. After numerous oil analyses and different filter combinations, Jackson Generation has all control-oil parameters below recommended guidelines. The permanent set up on the control-oil skid consists of fuller’s earth filters with ion-exchange filters that are changed monthly. A nitrogen blanket system was also installed on the reservoir to eliminate any water ingress, which has the added benefit of drying out the head space of the tank. Oil samples are taken biweekly to assure varnish has not returned.

Project participants:

Corbin Shanklin and the Jackson Generation O&M departments