Nebras Power IPP1 Jordan

Owned by Nebras Power, Mitsui, and AES Corp

Operated by Nebras Power IPP1 Jordan

400 MW, gas fired with diesel-oil backup, 2 × 1 combined cycle powered by AE94.2 gas turbines, located in Al Manakher, Jordan

Plant manager: Feras Hammad

Removing moisture from steam-turbine lube oil

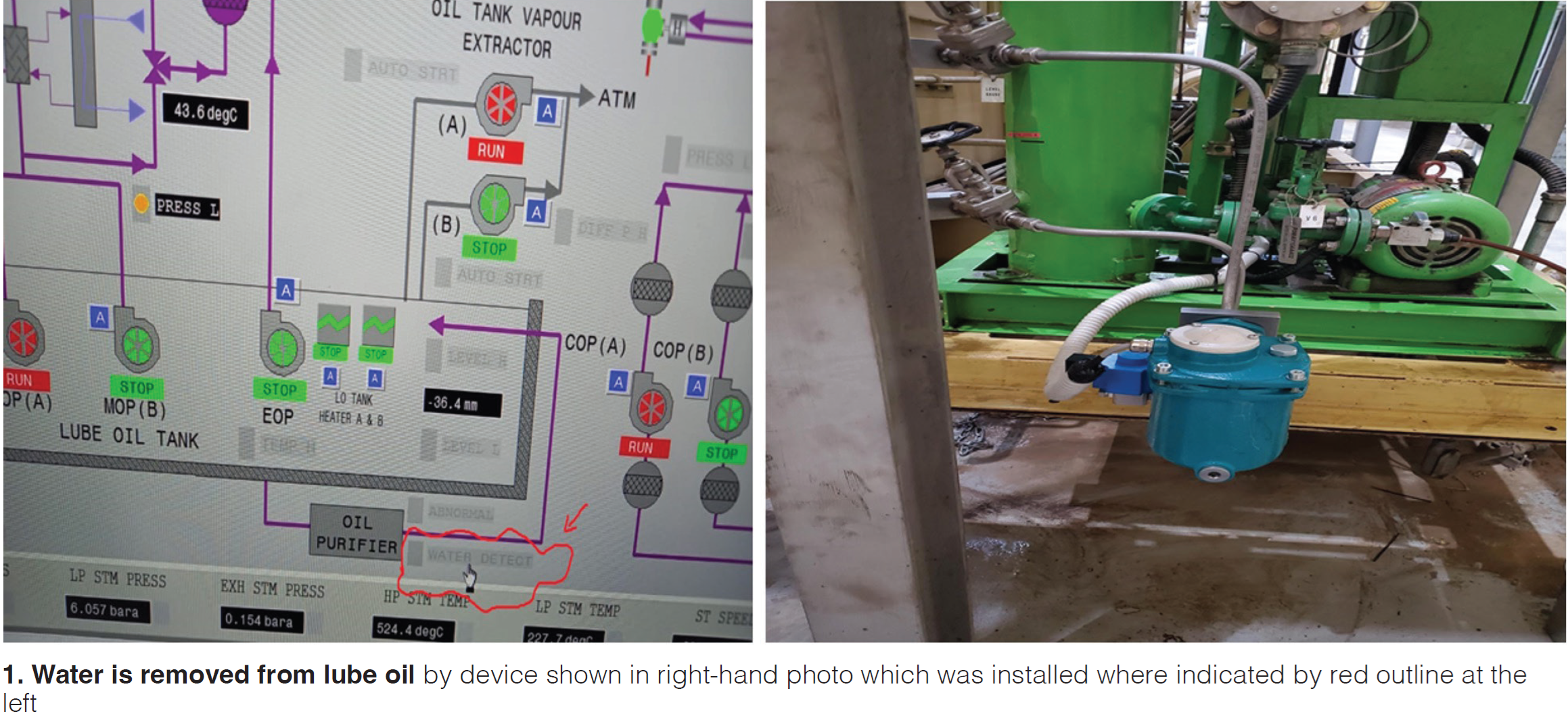

Background. Lube-oil quality is a major concern of O&M departments because of the fluid’s importance in promoting long life of rotating parts and safety. Severe oil/water dilution occurred in IPP1’s steam-turbine (ST) lube-oil system, the absence of continuous monitoring instrumentation and an alarm function on the LO system’s console making it difficult to identify in the early stages of contamination.

Challenge. Prevent moisture from contaminating ST lube oil.

Solution. First step in mitigating the moisture intrusion problem at Nebras Power was to modify, as necessary, ports on the lube-oil tank to facilitate connection of the portable purification system currently serving the gas turbines. Next step was to test the effectiveness of that purification system on ST lube oil and record data for decision-making. Also, to purchase and install water high-qualify detection instrumentation.

Water-detection effectiveness was monitored closely. Lube-oil quality was tested semi-annually and found acceptable.

In keeping with the plant’s commitment to continual improvement, staff focused on upgrading the ST insulation and resizing of the oil seals to let steam escape and condense in the oil galleries.

Note that the steam-turbine lube-oil system was provided with an oil purification system capable of removing moisture, but its capacity was insufficient for the task at hand. Plus, it did not have a moisture alarm or automatic drainage function to eliminate any water collected.

An acceptable replacement was identified, purchased, and installed by AES personnel. No major modification of the existing purification system was required to accommodate the new one (Fig 1), which collects water from the bottom of the water separator by gravity. Isolation valves are provided for operation and maintenance. A connection to the DCS allows personnel to monitor system operation.

Results. The new purification system provides greater accuracy in monitoring lube-oil water content. Plus, the need for precautionary oil drainage by operators to identify moisture has been eliminated. Finally, the area is kept clean and oily waste has been reduced.

Plant staff is confident that water in oil will not exceed acceptable levels in the future and that lube-oil quality improvement will extend the lifetime of STG bearings.

Project participants:

Sameer Ghanim

Issa Irshaid

Ali Hamed

Shaker Balawi

Replacing belt-driven fan drivers with VFDs reduces cooling-system O&M cost

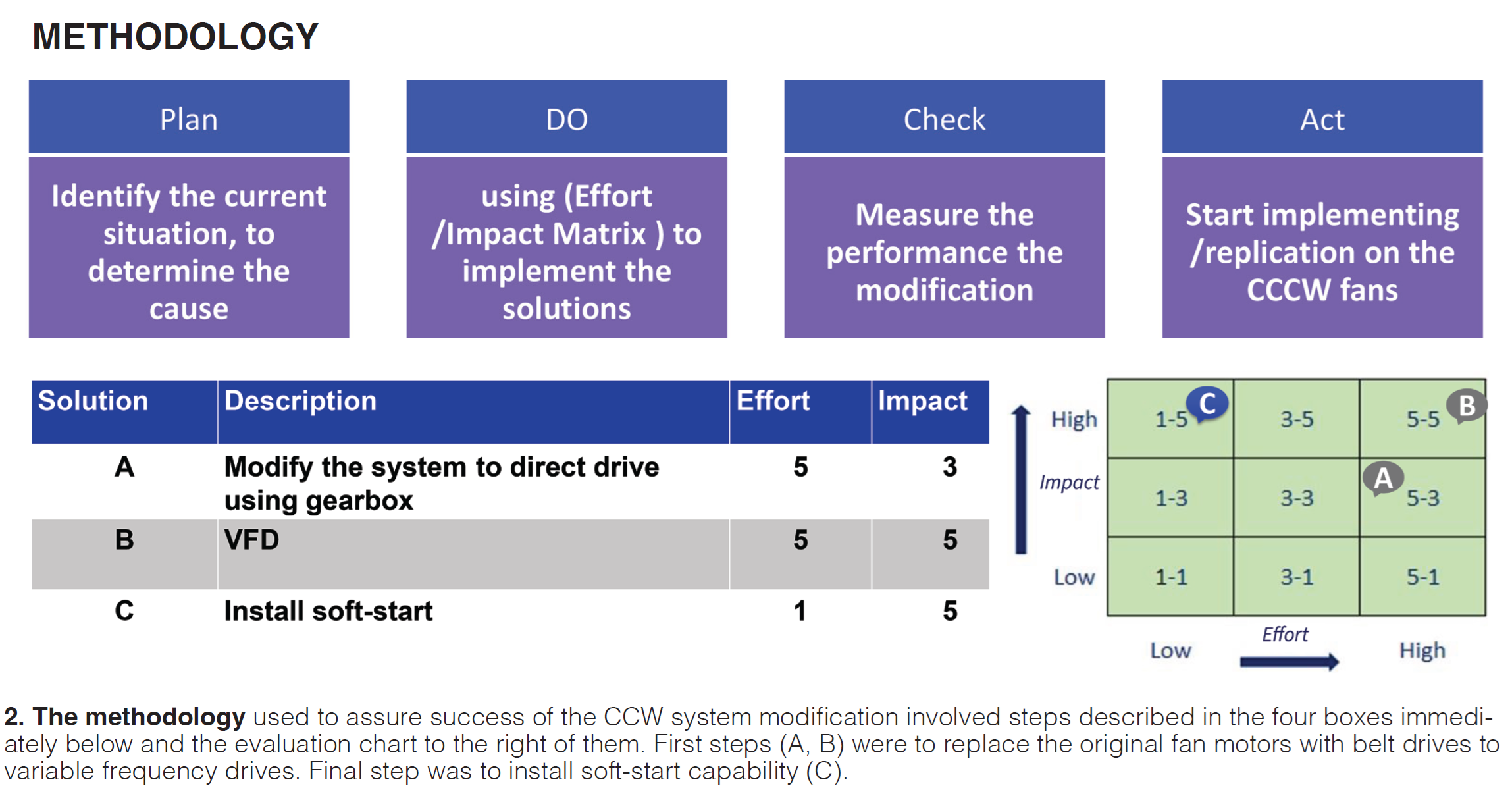

Challenge. As supplied, the four fans providing cooling air for Nebras Power’s closed cooling water (CCW) system each were powered by a 45-kW belt-driven motor. This design presented several issues when starting the fans—including these:

- High mechanical stress on both motor and fan components.

- High starting torque.

- High starting current.

Challenge was to identify a solution to reduce the noted impacts of the present starting system.

Solution. Key steps in developing the solution for improving drive-system performance and reducing O&M cost were the following:

- Technical and financial evaluation.

- Communicate with suppliers and get a quotation for the equipment and work involved.

- Issue a management of change notice.

- Execute the plan.

- Check and monitor the modification.

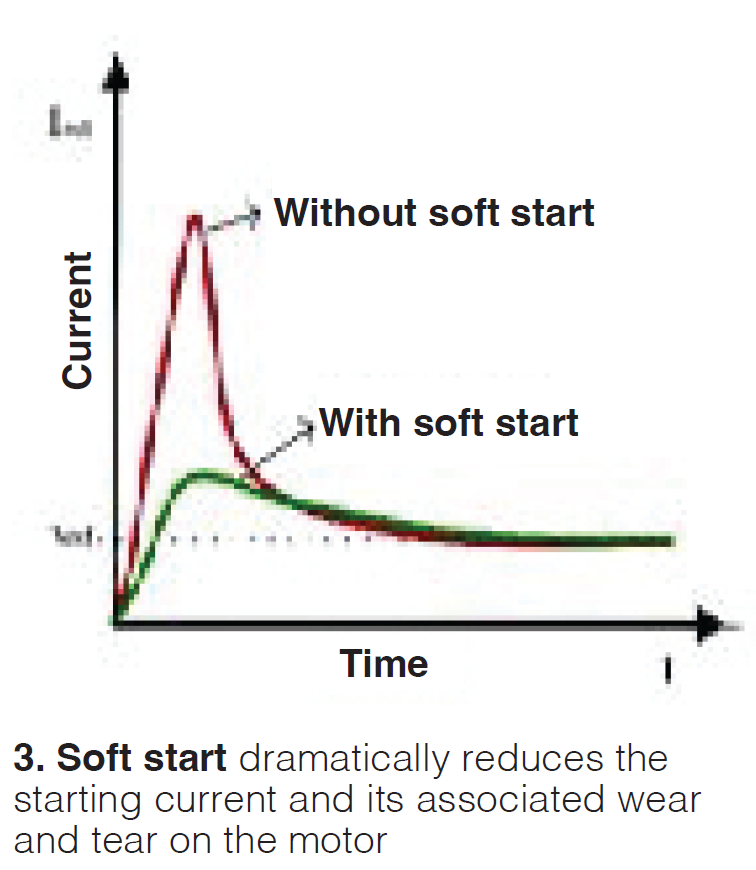

Methodology and tools used to arrive at the solution are described in Fig 2. Fig 3 illustrates the advantage of installing soft-start.

Results included the following:

- Reduced mechanical stress.

- Extended equipment lifetime.

- Reduced the inrush current.

- Increased efficiency and saved energy.

- Reduced the cost of spare parts.

- Reduced O&M cost.

Project participants:

Mohammad Alziq

Mohammad Aldaher