Ventanilla Combined Cycle Power Plant

Owned and operated by ENEL Generacíon Perú

427 MW, 2 × 1 SGT6-4000F-powered dual-fuel powerplant, located in Callao, Perú

Plant manager: Dany Alcantara

Plant background. Endesa SA, Spain’s largest electric utility, won a tender in December 1995 to take control of Empresa de Generación Termoeléctrica de Ventanilla (Etevensa), the genco operating the Ventanilla thermal plant in Perú’s Callao Province, Lima Region. Etevensa had been spun off from Electroperu SA.

Endesa was the lead company in Consorcio Generalima, which also included two Peruvian companies. According to Christopher Bergesen, a Maryland-based consultant with deep knowledge of the global electric power business, the consortium bid $US120 million and agreed to modernize the plant.

The plant was upgraded in 1997 when the OEM of record supplied and installed a pair of 170-MW gas turbines, replacing the 110-MW 501D5 engines installed in 1993.

Endesa took full control of Etevensa in August 2003 and the following year converted Ventanilla to combined-cycle operation by adding a supplementary-fired HRSG downstream of each GT and a 184-MW steam turbine.

In September 2004, Ventanilla, now owned and operated by Endesa successor company Enel Generación Perú, began burning Peruvian gas and producing power for distribution via the national grid. In January 2021, Enel commissioned a 14.6-MW battery energy storage system—Perú’s first—using lithium-ion technology.

Challenge. The water source for Ventanilla’s cooling towers is relatively poor-quality well water, requiring continuous blowdown and a high consumption of chemicals to maintain the recommended water chemistry. Cooling-water treatment in the plant’s early years consisted of the following:

- 98% sulfuric-acid for control of scaling.

- 10% sodium hypochlorite for microbiological control.

- Internal water treatment for scaling control involved:

- Automatic sulfuric acid dosing system.

- Manual dosing system for anti-scalant with regulation based on residual grab analysis in the plant laboratory.

- Manual water purge system with regulation based on periodic field measurement of specific conductivity in makeup and recirculation water.

The operator only measured online the pH to control sulfuric-acid dosage; the other systems were based on periodic measurements in the lab. They did not allow action to be taken in real time to optimize the chemical treatment without putting the condenser at risk of scaling problems.

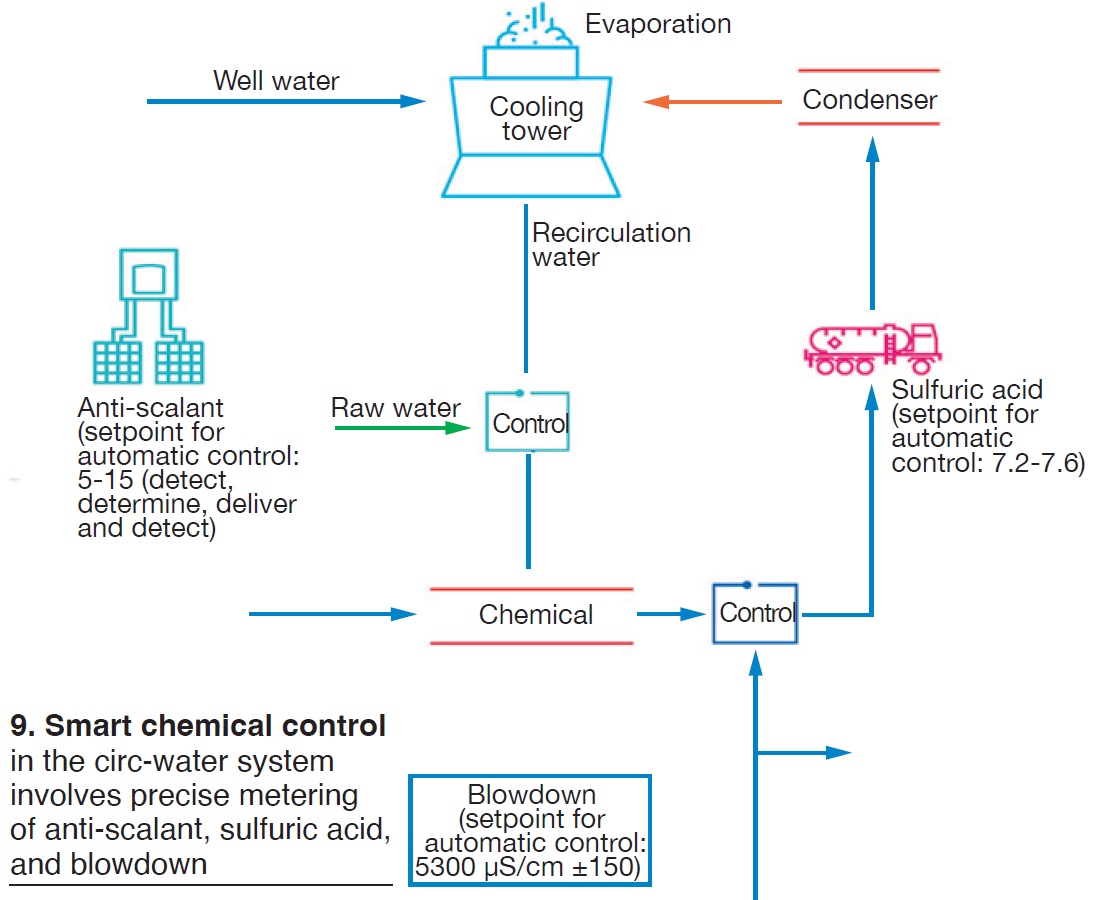

Solution. The Smart Chemical Control system described in Fig 9 integrated and enhanced the internal chemical treatment in the cooling tower thusly:

- Dosage of sulfuric acid at 98%, with the pH setpoint determined by the new chemical treatment, which controls starting and stopping of the acid pumps.

- Automatic cooling-tower blowdown control, with a recirculating-water conductivity setpoint determined by the new chemical treatment, which controls the opening and closing of the blowdown valve.

- Automatic dosage of the Nalco anti-scalant relies on a tracer in the recirculating water to control operation of the dosing pumps. This new treatment integrates and enhances the original treatment.

The three blocks and their controls are independent, making it possible to eliminate a type of failure that affects more than one unit. Water samples are taken weekly and physiochemical analyses conducted of hardness, sulfates, chlorides, pH, and specific conductivity.

Result. In the 2021-2022 period, Ventanilla saved $650,000 with its Smart Chemical Control program. The details: Reductions of 12% in makeup consumption, 7% in sulfuric acid, and 70% in anti-scaling chemicals, and a 25% saving in chemical handling time.

Enel project participants:

Jorge Tuya Rodriguez, chemical specialist and project manager

Juan Arteaga, chemical supervisor

Jose Gomez, I&C maintenance supervisor

Ventanilla 2023 Best Practices

- Online monitoring alerts to transformer issues, protecting against a forced outage at Ventanilla

- HRSG deep cleaning with dry ice pellets at high pressure meets Ventanilla’s expectations

- Cooling-tower upgrade increases electric generation at Ventanilla

- Tighter control of circ-water chemistry improves economics, safety at Ventanilla