This is the second segment of CCJ’s three-part report on PSM’s 2024 Asset Management Conference, conducted at the Westin Beach Resort in Fort Lauderdale, Fla, January 29-February 1. The first segment was published earlier this year, the third installment will appear in CCJ later this year.

The focus here is fourfold:

- FlameSheet™ keeps getting better (below).

- Benefits of additive manufacturing (AM) in the production of R1 vanes.

- Technical presentations by industry partners on (1) generator field rewinds, (2) impacts of GT upgrades on heat-recovery steam generators (HRSGs), (3) exhaust-frame mods and improvements.

- Shop tour at the Jupiter center of excellence.

FlameSheet™ platform broadens its reach for machines, fuels

It has been two decades since PSM specialists patented the FlameSheet™ combustor (https://patents.google.com/patent/US6935116B2/en). Soon after, in 2005, the first prototype was tested in a 501F machine. Commercial installations began in 2015 for a variety of F-class gas turbines.

By 2021, the technology was operating in seven 7Fs and one 501F, the latter as part of the first-of-its-kind FlameTop7 installation at Salt River Project’s Desert Basin Generation Station. More recently, the technology has racked up an impressive list of milestones, including the first application to an E-class unit last year, and the first Frame 5 commissioning this year.

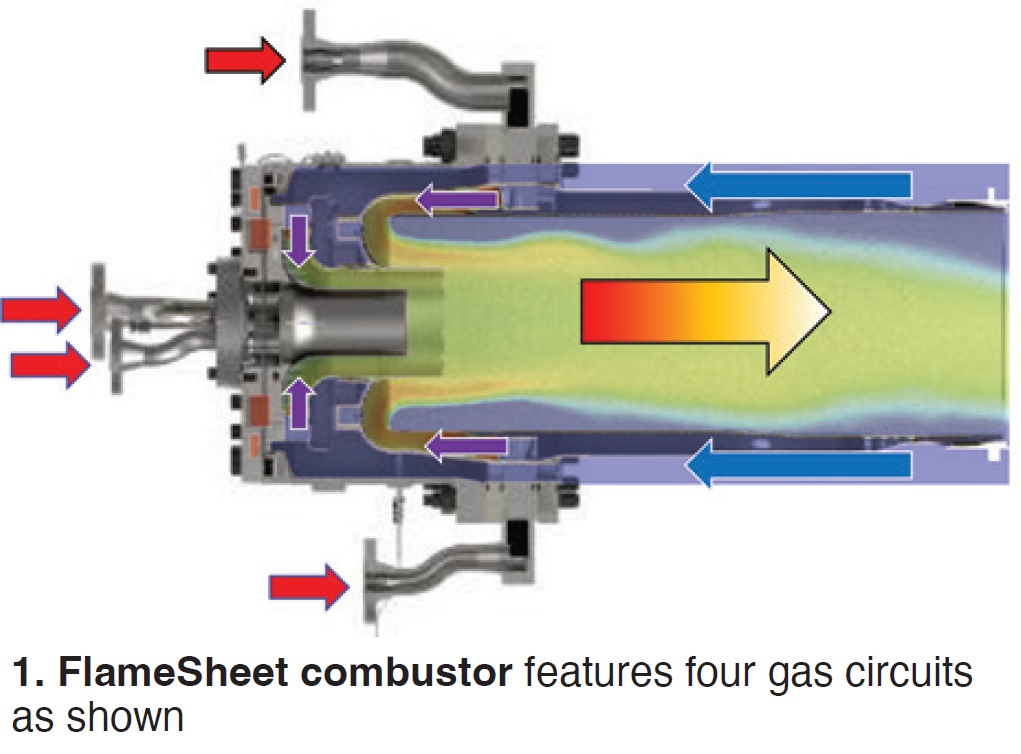

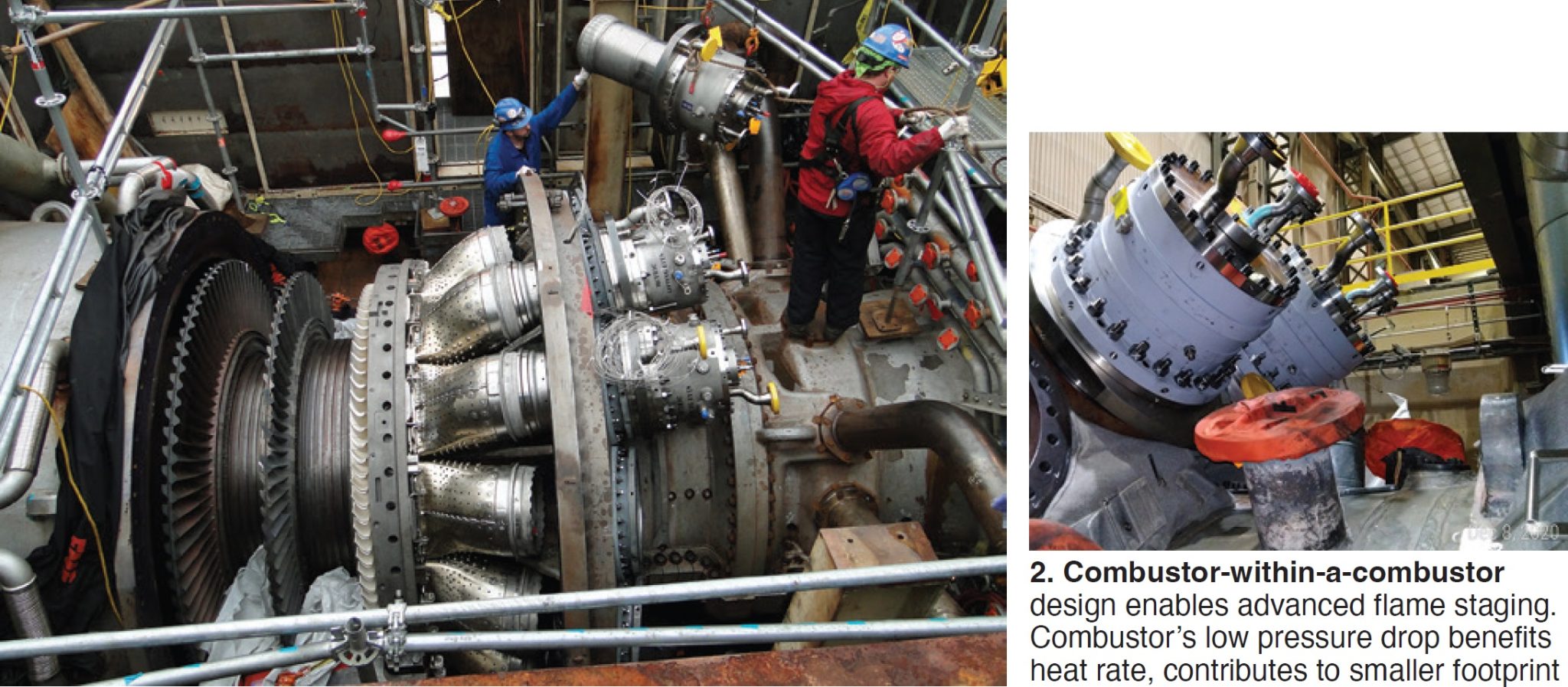

Recall that FlameSheet™ was originally developed for general operational and fuel flexibility. Simply, the concept includes four fuel circuits (Fig 1) to enable a “combustor within a combustor” design for advanced flame staging. This arrangement has two unique aerodynamic stages and relies on a trapped vortex flame to provide a wide stability margin. The pilot and main stages are effectively two independent combustors, each with its own robust flame stabilization mechanisms, allowing either combustor to operate with the other one off, enhancing operational flexibility (Fig 2).

When FlameSheet™ was coupled with PSM’s AutoTune and inlet bleed heat, turndown was improved from the 65% to 70% range of the OEM’s standard combustion system to 25% to 30 % for 7F and 35% to 40% for 501F from baseload. Adding the company’s exhaust bleed system extends turndown an additional 5% to 10%.

Lately, FlameSheet™ demonstrated up to 80% hydrogen firing (depending on GT model) in high pressure rig testing, turndown to under 30% with no sacrifice in emissions compliance, 60% H₂ firing for a 7EA unit, and a 32k operating-hour/1250 start inspection schedule.

The technology comes equipped with what is claimed to be an industry-leading combustor hardware protection system. An active flashback monitor/fast runback technique protects against slugs of poor-quality fuel on premix combustors. By cutting fuel to the affected circuit, emissions compliance can be restored within 40 seconds, according to PSM. The protection system has been demonstrated for the 7F and 501F. It also avoids hardware damage, outages, and trips from poor-quality fuel.

Today’s FlameSheet™ Gen VI incorporates “micro-mixer” technology to better handle highly reactive fuels like H₂. Generically, micro-mixing refers to the goal of decreasing the “scale” of the fuel/air mixture, reducing flame length and resonance time (for combustion reactions to take place), and making the mixture as uniform as possible. This is accomplished by replacing the pilot in each can with a pilot utilizing this technology. PSM’s micro-mixing technology achieved sub-30% turndown in the 7F machine.

The four FlameSheet™ fuel circuits are called the pilot, pilot tune, main 1, and main 2. Subsystems include proprietary flashback monitoring and ignition designs. AutoTune is also part of every installation. Other salient features include these:

- Aerodynamic trapped vortex for wide stability margins.

- High pre-mixer exit velocities to tolerate highly reactive fuels.

- Robust mixing techniques for tolerance to Fuel Wobbe Index variations.

- Low-pressure-drop combustor for improved heat rate and smaller footprint.

FlameSheet™ with exhaust bleed also addresses steam-cycle attemperation issues. It allows a reduction in exhaust temperature while maintaining low turndown levels, improving attemperation margins.

Today’s scorecard for FlameSheet™ includes the following highlights:

- 33 units operating and under contract through 2026.

- 320,000 operating hours since 2015.

- 60,000 operating hours for the fleet leader, with over 400 starts.

- Four units burning hydrogen.

As one example of FlameSheet™ plus GTOP benefits, the customer’s goals were to raise unit output, improve heat rate, and burn shale gas with up to 10-12% C₂ compounds. The results from a low Δp FlameSheet™ install were 10% higher output, 2.2% better heat rate, 40% turndown with CO emissions in compliance (on reduced exhaust-temperature isotherm), NOₓ emissions below 9 ppm under a +50F baseload firing temperature, and reduced start time of 30 minutes.