It only takes 2-3% steam overflow to trigger a steam turbine/generator (ST/G) overspeed event, cautioned Dean Casey, project manager for machining services at MD&A, to stress the importance of main-steam-valve inspections and timely repairs. During his presentation in MD&A’s fall series of webinars, “Steam Turbine Valve Outage Common Issues,” Casey went on to say that the failure of the main-steam stop valve to close is the most frequent cause of ST/G overspeed events.

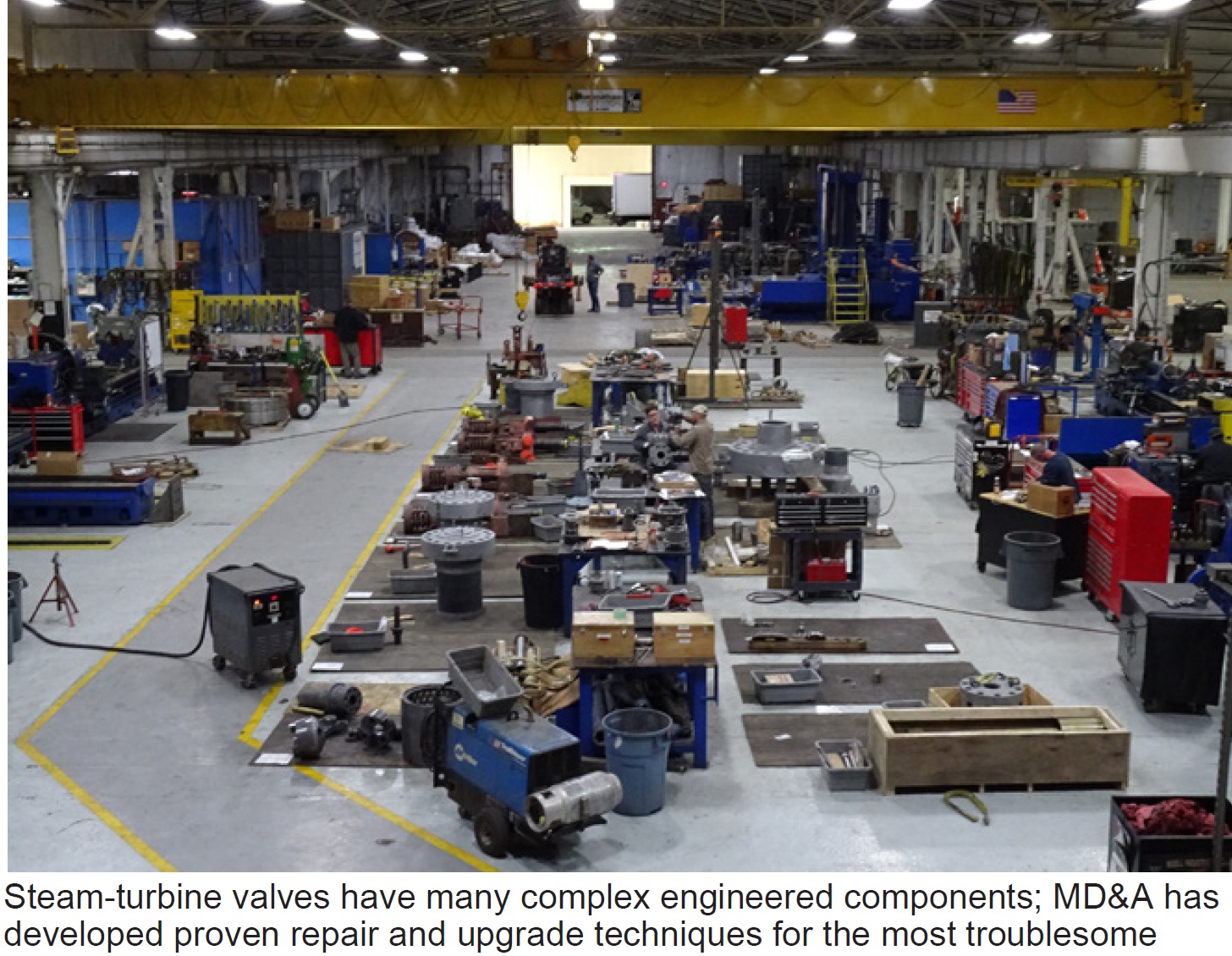

Casey then led his audience through the often-arcane repair process details associated with these complex engineered components.

If you have main-steam valves approaching three to five years, or 25,000 hours, of operation, MD&A’s minimum recommendation for inspection and repair, you owe it to yourself to listen to the webinar. This is especially true if you are past the first five years of plant operations, when valve issues begin to rise. There are no industry or independent maintenance practices for these valves, outside of nuclear plants, only OEM guidelines, making webinars like this one even more valuable.

Generally, inspection and repair are targeted at: restoring clearances to OEM specs, such as bushing removal and replacement, hardened inserts, and scale removal; achieving concentricity, so that the valve operates precisely on its centerline; sealing and resurfacing to ensure no steam cutting; and attending to foreign object barriers, such as strainer baskets.

More specific topics and case studies Casey addressed include these:

- A bent stem which had to be replaced, along with the valve-stem bushings, and inserted into a re-machined casing fit.

- Solid particle erosion (SPE), which can cut stem life in half if not addressed. MD&A has developed a laser-cladding process for some valve stems. Seats, discs, and pressure seal heads are also affected by SPE.

- Control-valve seat replacement. Casey noted that MD&A has replaced 40-50 of these seats in one OEM’s valves over the last 10 years.

- Strainer basket replacement.

- Specific repairs for spindles and sleeves in Alstom valves, and disbonding and liberation of Stellite hardfacing of Siemens KN valve seats and plugs.

- Indications (cracks, for example) in steam chests and repair options.

With supply-chain issues affecting short-term delivery to all sites, Casey urged users to identify parts for rebuilds well ahead of the outage. Around 90% of MD&A’s parts come through its Parts Div facility in Danvers, Mass, but some can be manufactured in its St. Louis shop, which Casey described as the largest non-OEM gas-turbine repair shop in the US. Examples of the latter include non-hardened bushings, inserts, and sleeves.

Capabilities in the St. Louis shop include (1) a deep-bore TIG (tungsten inert gas) welding machine designed to handle internal diameters from 4 to 30 in. and depths to 50 in.; (2) automated MIG (metal inert gas) welder for IDs from 0.88 to 27 in.; and (3) an induction machine for uniform temperature during post-weld heat treatment.

Access this recording @ https://www.mdaturbines.com/webinar-archive/