Empire Generating LLC

Owned by Empire Acquisitions LLC

Operated by NAES Corp

635 MW, gas-fired 2 × 1 7F.03-powered combined cycle with Alstom HRSGs and a GE D11 steam turbine, located in Rensselaer, NY

Plant manager: Chet Szymanski

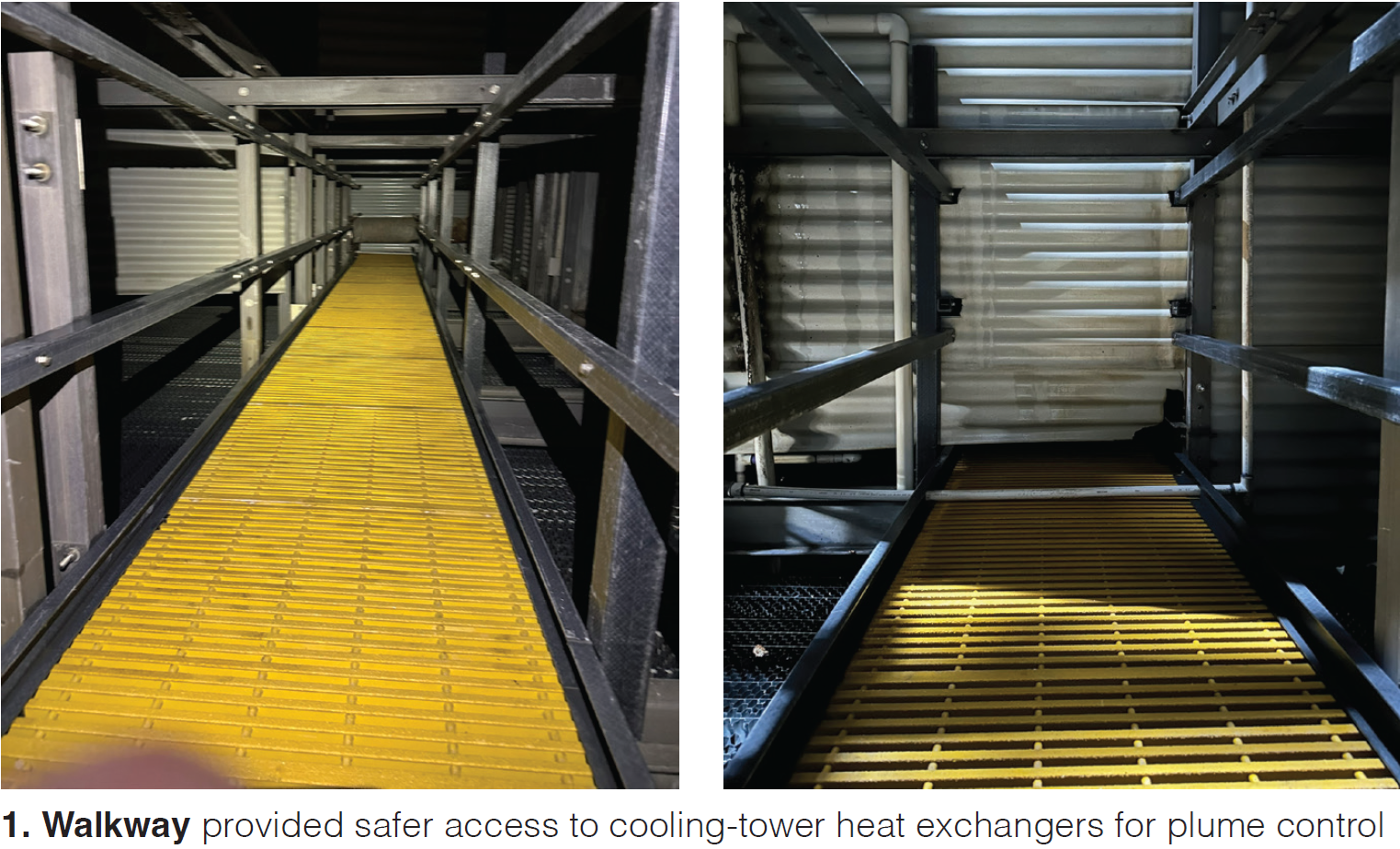

Cooling-tower mod improves maintenance access

Challenge. Empire Generating’s cooling tower is designed with a dry section that contains heat exchangers to assist in plume abatement. Because of their location, age, and duty cycle these heat exchangers routinely develop leaks that require tubes to be plugged and pipes repaired.

Work on the external side of the heat exchangers (on the outside of the cooling tower) was never an issue, as there are work platforms. However, work on internal side (inside the cooling tower) proved more problematic given the lack of work platforms and the need for fall protection and to work at odd angles off tower structural-support members or scaffolding.

Solution. At the suggestion of plant personnel, the installation of an internal walkway was investigated. As envisioned, it would run the entire internal length of the cooling tower, like the existing external walkways. But to accomplish this it would be necessary to modify the internal structure of the tower, cutting “doors” between the sections, thereby reducing each section’s effectiveness.

This was not viewed as an acceptable solution. Instead, the design was modified such that internal cooling-cell integrity would be maintained and the walkway would only provide access to two cells from one ladder entry point (similar to access before the walkway was installed).

Results. The walkway was installed by Cooling Tower Depot during Empire’s 2023 fall outage (Fig 1). With improved access, Empire employees can work more comfortably on the internal side of the heat exchangers, without worrying about falling or being at odd angles and trying to hang onto slippery support cross members.

Project participants:

Project participants:

Dwayne Boyer, O&M manager

James Smith, maintenance technician

Jason Glassbrenner, safety committee

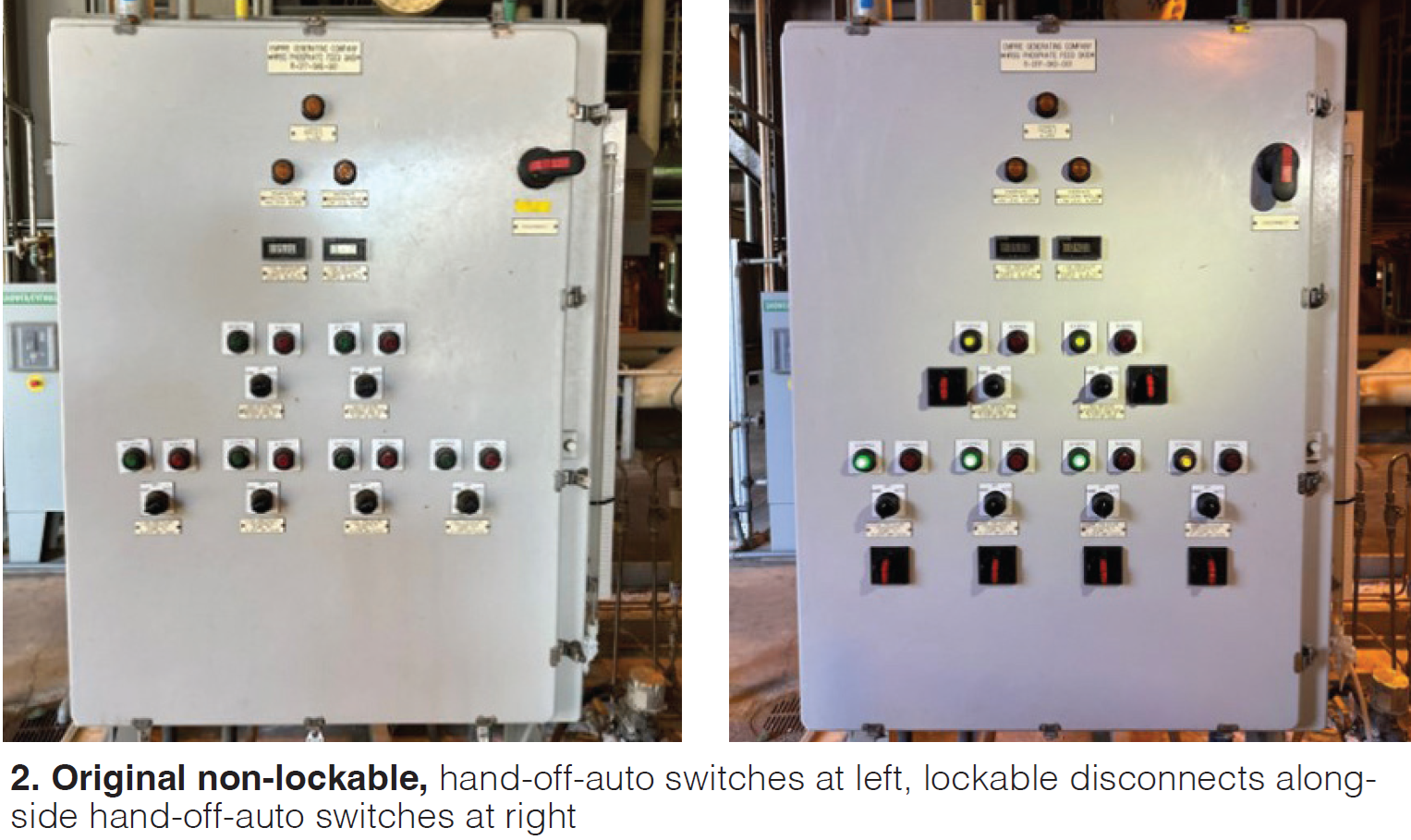

Beware local isolations on chemical pumps

Challenge. Empire has several types of chemical-pump skids that vary in pump type, size, and power requirements. Additionally, some skids are powered by multiple sources from their local power distribution panel (PDC).

As some of the older pumps hit their lifespans and required replacement/repair, staff recognized an issue that also was an opportunity. When performing LOTO on a single failed pump on the phosphate-feed-pump skid, which has four 120-V single-phase and two 480-V 3-phase power sources, techs found that each of the individual pumps fed from the PDC could be isolated only by pulling fuses after hanging a LOTO on the entire PDC. This meant taking all the associated pumps out of service.

Thus, to work on a single chemical pump without interrupting normal plant operations, multiple LOTOs had to be hung for an IC&E tech to open the associated PDC and remove and reinstall the applicable fuses.

Solution. After some deliberation at a management-of-change meeting, staff determined a better solution for servicing the phosphate feed pumps. Rather than having to use multiple LOTOs to remove and reinstall fuses, Empire management approved installation of individual, lockable, door-mounted disconnects for each pump within the PDC (Fig 2). This would eliminate the need for an IC&E tech to open the panel and pull fuses and shut down power to the whole system.

The individual disconnects would enable any qualified Empire employee to LOTO individual pumps on the skid, which also would simplify the LOTO process while the phosphate system is in use.

Results. The design upgrades worked as planned and the modifications ensure a safer, more efficient LOTO and repair process. Given this success, the same upgrades are planned for other chemical-feed-pump PDCs during upcoming outages.

Project participants:

Chester Szymanski, plant manager

Dwayne Boyer, O&M manager

Patrick Riley, operations supervisor

Rob O’Connell, EH&S manager

Ben Graham, IC&E technician

Empire plant safety committee

Multiple-skills training pays dividends

Challenge. Energy facilities have multiple departments, each requiring qualifications to meet their own specific responsibilities. Empire’s org chart shows two departments: operations and maintenance, each with its own sub-departments. Both departments are crucial to plant functionality: Operations focuses on the operation of the plant, while maintenance performs preventive or corrective maintenance on all plant systems.

Over time, and with each staff focusing solely on its own specific roles and functions, a knowledge gap between the departments became apparent. Having each department perform its specific tasks only could create a scenario in which Empire might be in real trouble should one of the departments find itself short-handed for an extended period.

Solution. To safeguard the plant and its employees, a cross-qualification qualification program was designed and implemented, whereby specific employees from each department would be selected to train and qualify in the other. By expanding the knowledge and skillsets of these individuals, Empire would provide suitable backup support across a variety of tasks.

The first cross-qualification group involved two maintenance department employees (the water treatment technician and an IC&E tech) qualifying to become O&M techs. They were required, over a period of several months, to complete the full qualification process of an O&M tech and become approved by the plant manager to stand a shift. This provided these employees with key insights into the knowledge and daily tasks of an O&M tech.

The second step in the cross-qualification process involved sending an O&M tech to instrument calibration training alongside an IC&E Tech. The O&M tech who volunteered had prior electrical knowledge and expressed an interest in learning more about the IC&E tech’s duties. This additional training gave him an understanding of how instrumentation devices work and how to calibrate them.

Results. With implementation of the cross-qualification program, Empire is creating a well-rounded workforce—each department having the knowledge and skills to fill roles and conduct different collateral duties. With the two additional qualified O&M techs, management is able to increase the support in the operations department during outage work. Also, it is able to have extra coverage that allows other O&M techs to pursue their cross-training.

Plus, having an O&M tech qualified for IC&E tech duties provides additional support to that department during outages, and any other time the IC&E department finds itself short staffed.

As part of Empire’s drive for continuous improvement, and taking advantage of employees’ desires to learn, plant management supports the cross-qualification program to further enhance staff capabilities. Management plans to send another operations-department employee with prior electrical knowledge for instrumentation training. Additionally, based on the program’s initial success, the O&M tech qualification requirement has been implemented for all new maintenance-department hires.

Project participants:

Patrick Riley, operations supervisor

Jason Glassbrenner, water treatment technician and safety committee chair

Ben Graham, IC&E technician

Devin Spain, O&M technician

Man-down-qualified personnel make for a safer workplace

Challenge. Attrition has created a large disparity in both age and operational knowledge between our O&M leads (a/k/a control-room operators) and technicians. As a facility staffed 24/7/365, there was a concern about what an O&M tech would do should he or she encountered a situation where the CRO became incapacitated.

Solution. Management discussed ways to address this challenge, developing a solution it named the “man-down qualification.” It is designed to give the O&M tech some critical knowledge of what the CRO does in the control room and trains the technician to perform basic, yet vital, operations to keep the plant in a safe and stable condition until more-qualified help arrives. All individuals currently having O&M tech responsibilities, as well as those in the initial stages of O&M technician training, were required to complete the new qualification.

Some of the concepts within the new qualification standard include the following:

- Familiarization with navigation of both the ABB (balance-of-plant) and Mark VI (turbine) HMIs.

- Familiarization with Title V air-permit limits.

- Ability to change turbine modes of operation.

- Read/acknowledge system alarms.

- How to properly enter events in the logbook.

- Demonstrate proper three-part communication with the transmission operator (TO).

- Familiarization with emergency response procedures and the ability to implement them.

Upon completion of the man-down qualification program, an O&M tech has the ability to respond to any emergency—medical or otherwise—that the CRO may have. The tech is able to notify the TO and run the unit as directed, call Empire management and inform them of the incident, and properly log all information as required by governing authorities.

Results. Shortly after this process was implemented, staff witnessed first-hand its value: On a weekend night shift a senior CRO went down because of a known medical condition and was in and out of consciousness. Using his new training, the O&M tech called the TO, held plant load, called 911 and Empire management regarding the medical emergency, provided medical assistance to the downed CRO, and maintained a time log of the events as they occurred.

This event confirmed that man-down qualification should be an essential part of being a well-rounded O&M technician. It will continue to be a part of every new Empire O&M tech’s qualification process for the foreseeable future.

Project participants:

Patrick Riley, operations supervisor

All qualified O&M leads and technicians