Faribault Energy Park

Owned by Minnesota Municipal Power Agency (MMPA)

Operated by NAES Corp

265 MW, 1 × 1 7F.03-powered combined cycle equipped with a GE A10 steam turbine and CMI HRSGs, located in Faribault, Minn

Plant manager: Shawn Flake

Challenge. Accurate and complete gathering of data during abnormal plant operations can be difficult and lead to ill-advised decisions by management and engineers.

One of the most extreme events that can occur in an electric generating station is the dreaded “black plant” event, which can result from a protective-relay tripping scheme opening the main feed breaker at the plant interconnection to a substation. The electrical fault can be either internal or external to the plant.

Plant managers, O&M techs, and/or engineers have the challenging task of trying to understand what caused the event. Reacting expediently often can mitigate further operational casualties by returning ac power to necessary equipment—including safety systems. Coincidentally, the desire to react quickly has the potential to lead to either acquiring partial or inaccurate information from protective relays.

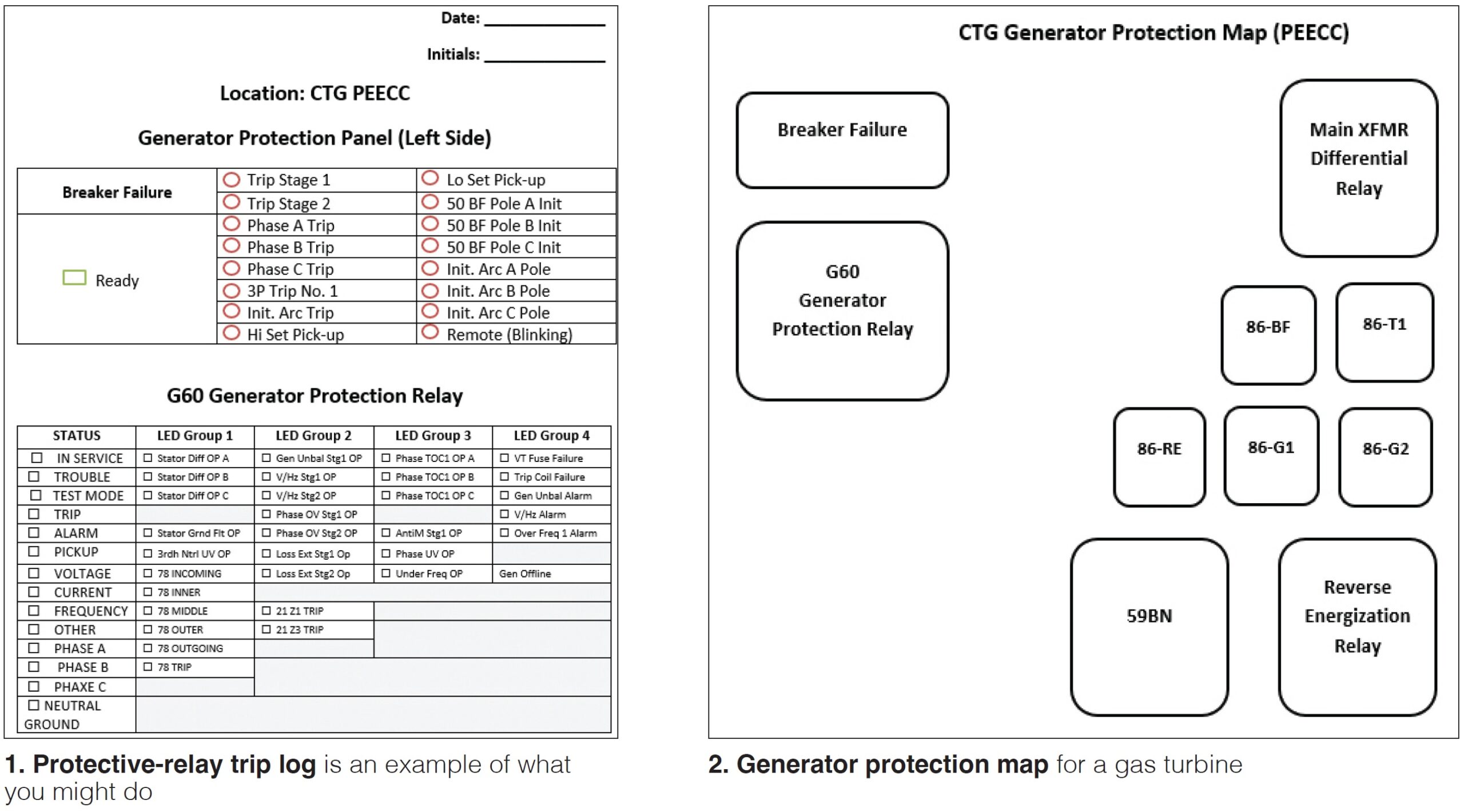

Solution. Faribault Energy Park implemented protective-relay trip logs to identify the state of all relay outputs and flags accurately and quickly (Figs 1 and 2).

Physical copies of the trip logs hang on clipboards at each relay station in the plant. The logs are configured identical to the physical location, lights, and flags on the protective relays. This allows O&M techs to quickly transpose all information from the relay station to a paper document that can be used to troubleshoot electrical faults.

Results. Quick and accurate relay trip information has minimized impacts to plant equipment during electrical-fault events. During each fault event, O&M techs were able to accurately provide fault information to management. The data sets allowed managers to make quick, sound, and effective decisions—including switching orders and initiation of electrical restoration procedures.

Project participants:

Shawn Flake, plant manager

Scott Lowe, operations manager

Tim Mallinger, lead operator