Report from the Australasian Boiler and HRSG Users Group

Update: Join us in November…

2025 Annual Conference

Brisbane, Australia

November 25-27

www.abhug.com

The Australasian Boiler and HRSG Users Group Conference and Workshops (ABHUG 24) was held December 3-5, 2024, in Brisbane, Queensland, Australia. ABHUG is supported by the International Association for the Properties of Water and Steam (IAPWS) together with the local National Committees in Australia (AUSAPWS) and New Zealand (NZAPWS). This annual event is held in association with the European HRSG Forum and the HRSG Forum (US). Beginning in 2025, this collective will be joined by HRSG Forum América Latina, September 23-25, in São Paulo, Brazil (www.hrsgamericalatina.com).

The Brisbane event, organized by Mecca Concepts Pty Ltd, Australia, was co-chaired by Barry Dooley (Structural Integrity, UK) and Bob Anderson (Competitive Power Resources, US) and sponsored by HRL, Swan Analytical Instruments, and TLG Engineering. Combined Cycle Journal is the media partner.

ABHUG 24 attracted 90 participants from Australia, New Zealand, Canada, UK, Germany, and US. There were 26 prepared presentations.

All HRSG events are designed for users to communicate openly with each other, key component suppliers, consultants and international experts. Exhibitors are also invited and in 2024 delegates were joined by experts from Duff and Macintosh/Sentry, Flotech Controls, HMA Instrumentation, Intertek, Precision Iceblast Corporation, RTR, and Swan Analytical Instruments.

The first Australasian HRSG event was held in 2009.

Below are selected highlights from 2024.

Thermal transients

Bob Anderson, Competitive Power Resources, opened the discussions with his in-depth, informative and global Update and statistics on HRSG thermal transients. Detailed insights into operational issues with attemperators, condensate, superheater/reheater drain management and steam turbine bypass operation are always a highlight of these conferences. Anderson’s research pinpoints common problems and areas needing improvement based on international data.

This update is based on 70 surveys conducted globally between 2009 and 2024. Surveyed plants feature various HRSG/steam turbine configurations, and a wide range of operating hours and starts. Plants surveyed include 24 HRSG OEMs, 5 gas turbine OEMs, 11 steam turbine OEMs, and every possible type of cooling and water chemistry. Hours of operation varied from 4000 to 160,000 with up to 2400 starts.

Anderson first focused on tube failures, noting that causes are not tied to any particular HRSG OEM.

“Causes identified as far back as 2008 remain active, and the ranking of failures has not changed,” he explained. “Very few tube failures are due to creep damage,” he said, “and most are associated with low-cycle fatigue from repeated startup and shutdown.” The solution is to identify and eliminate the events causing the incremental damage.

“But low-cycle fatigue is not a root cause,” he explained. “And very few are caused by a one-off event.”

His emphatic statement: “We know all we need to know to avoid HRSG tube failures! But many plants do not apply this knowledge!”

Effective owner/operator actions should focus here:

- Look early for symptoms of known causes and take corrective actions.

- If a failure occurs, remove the failure site for metallurgical analysis and determine the exact failure mechanism.

- Then conduct precise root cause analysis and take corrective actions promptly. He repeated here that “fatigue is not a root cause.”

Anderson’s analysis showed that very few plants have a Tube Failure Root Cause Program in place (improved from 0 percent in 2008 to only 9 percent in 2023). The stumbling block is most often management approval to take the time to remove the failure location for analysis, agreed to before the failures occur.

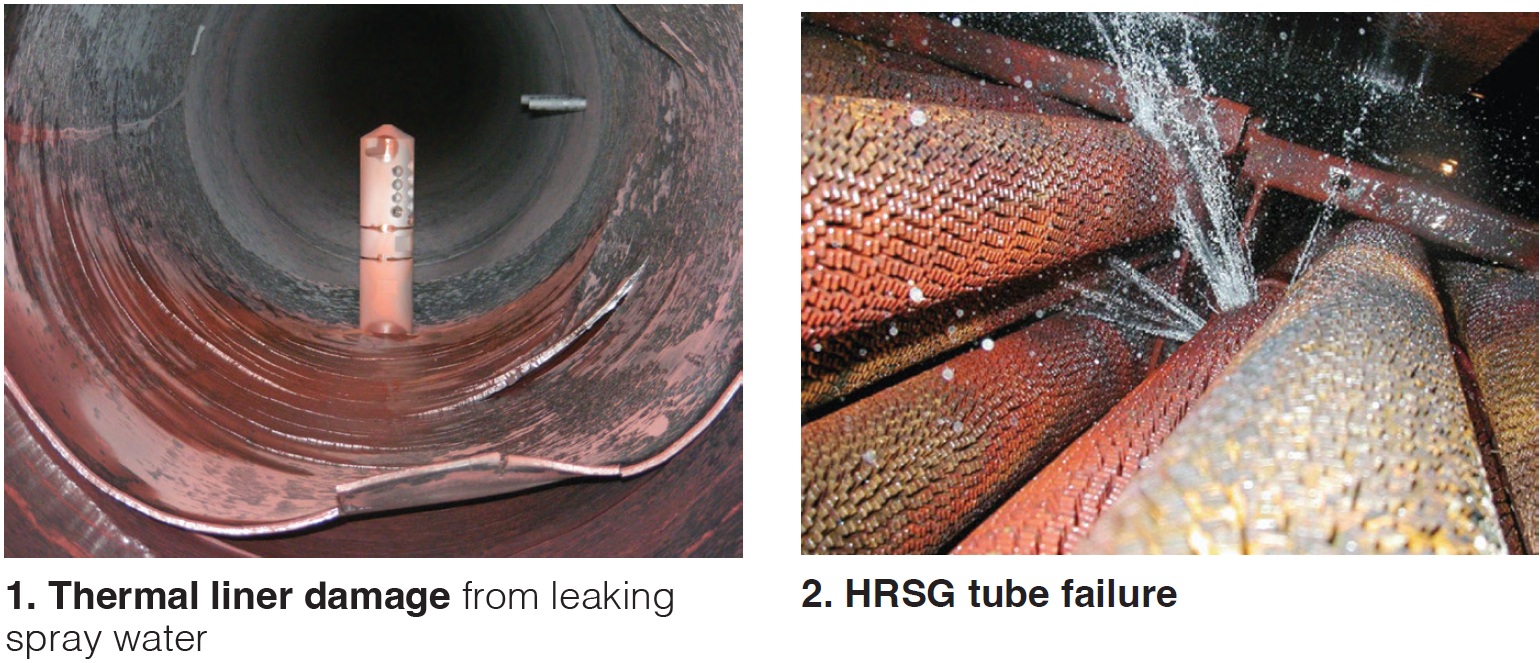

He then discussed basic attemperator issues and hardware inspections. The most damaging issues are leaking spray water causing cracks in thermal liners (Fig 1) and steam pipework (aggravated by incorrect spray valve sequence logic) and by master control/martyr block valve logic which quickly causes leak-through in both valves. Changing to master block/martyr control logic can prevent this leaking, he explained. His cautionary note: “The control valve is also expensive to purchase and costly to repair.”

Anderson also noted that overspray will be apparent in the DCS data.

He then covered HPSH/RH drain design issues, the primary optimum being:

- Drain pipe size should be large enough.

- Drain pipes should slope continuously downward.

- Blowdown vessel should be below the SH/RH elevation.

Advanced tools and drones

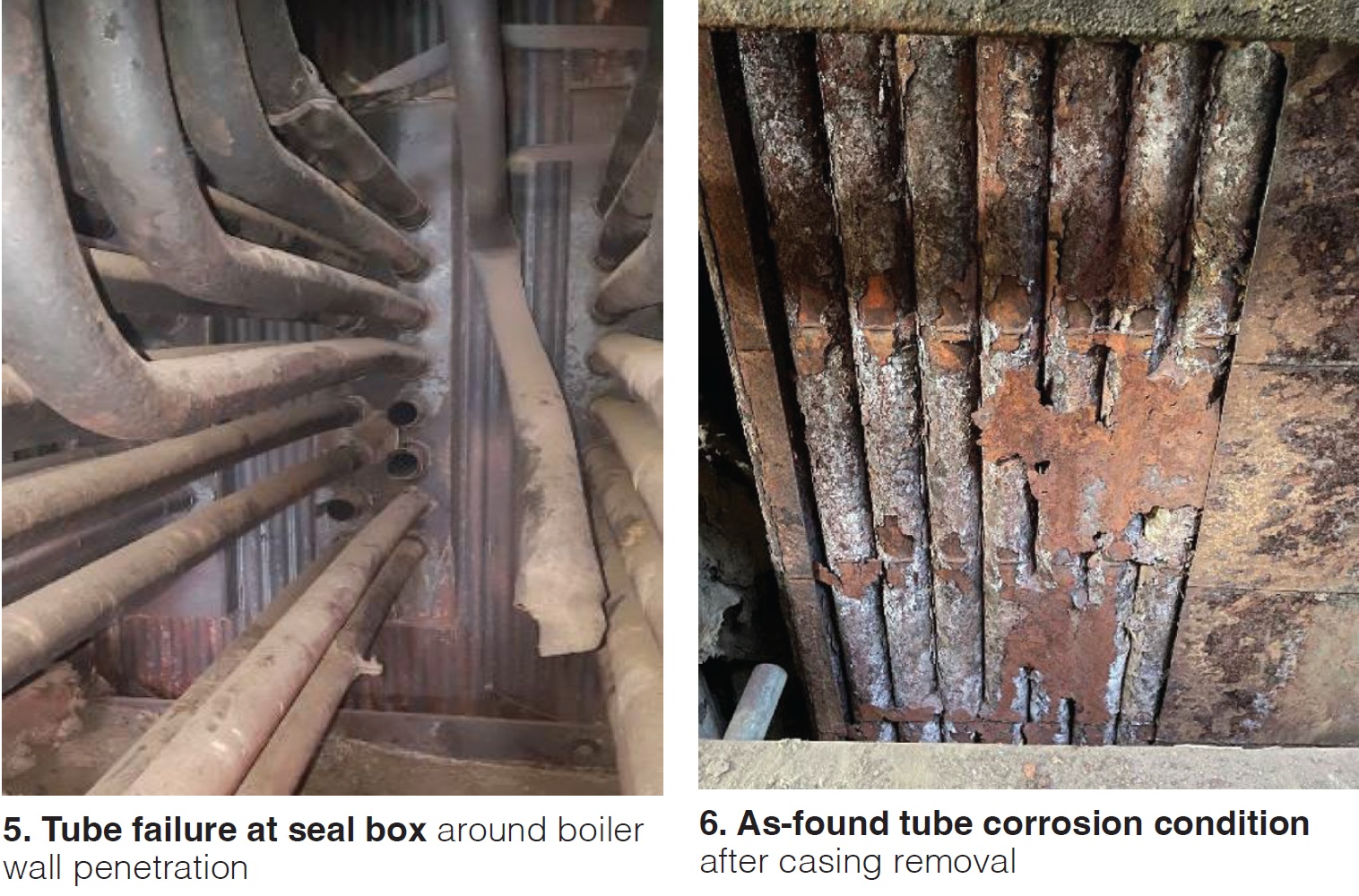

Graeme Gordon, Altrad Babcock (UK), presented HRSG Inspection tool – a novel remote visual inspection approach. His case history focused on EDF combined-cycle gas turbine power plants in France and the operator’s desire to:

- Gain access to tubes previously unable to inspect.

- Inspect a particular tube if indications are detected.

- Justify relevance of pressure inspection plans to French authorities.

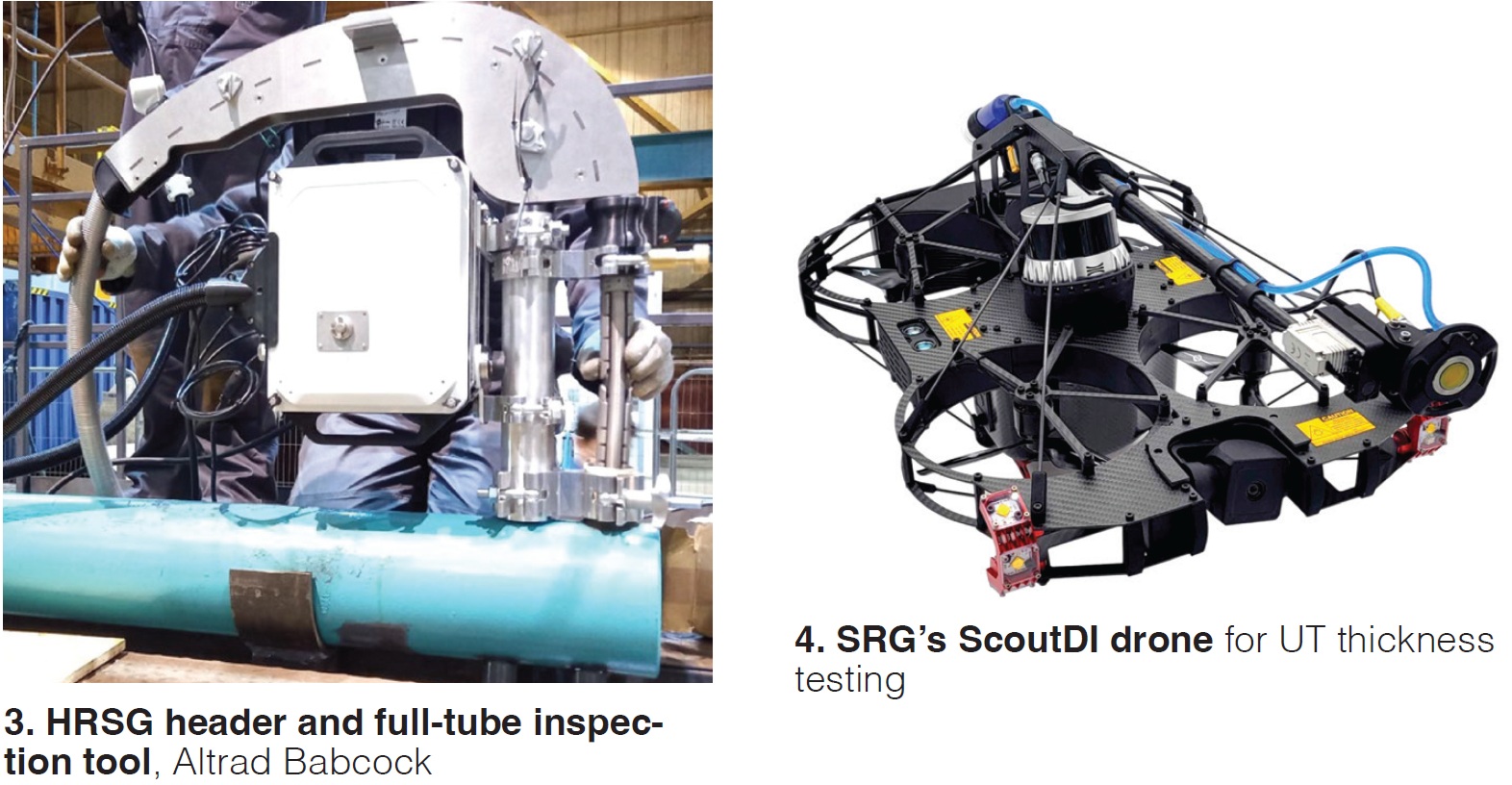

Known damage mechanisms at these plants are flow-accelerated corrosion (FAC), pitting corrosion, and fatigue cracking. The typical maintenance approach has been “reactive” (Fig 2).

The primary difficulties to address: “The owner/operator wants to inspect the internal surfaces the full length of headers and multiple tubes.” Traditional challenges have been due to complicated HRSG geometry, inspection ports on tops of headers rather than sides, multiple tube rows per header, and inability to inspect tubes distant from the inspection ports. The goal is therefore inspection of internal surfaces the full length of headers and multiple tubes.

Gordon provided details of the HRSG inspection tool feasibility study and prototypes and gave a detailed look at tool design and trials (Fig 3). He then moved to actual site inspections.

Selected benefits include:

- Accesses entire length of header and any tube within header.

- Fitted with robust navigational camera and lighting.

- Compact and portable.

- Minimizes disruption and reduces overall downtime.

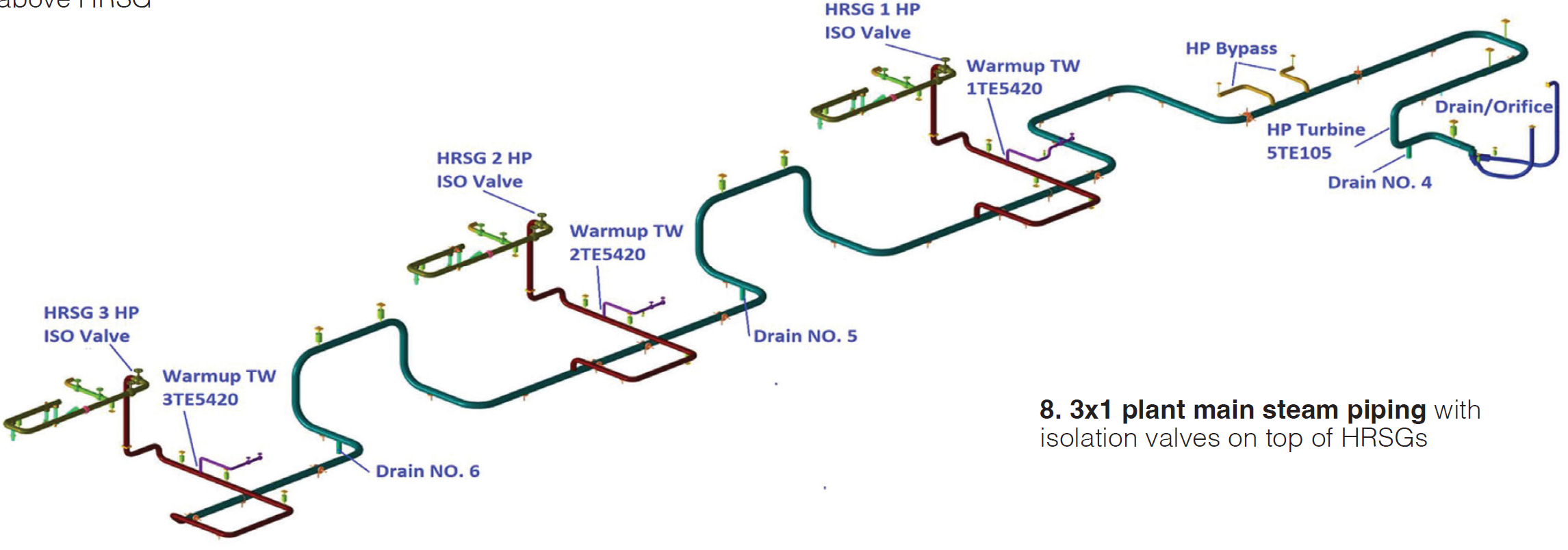

Drones. Tristan Davison, SRG Global, reviewed Utilizing drones to gain quantitative asset insights. Barry Dooley added, “In addition to video capability, drones are now capable of ultrasonic thickness testing, EMAT thickness testing, dry film thickness testing, explosive gas detection, thermography and accurate spatial measurements.”

HRSG applications are extensive. Davison pointed out that we are now “completing visual and thermographic inspections across a range of locations: burners, superheater panels, air heaters, ducts, hangers, bins and hoppers, stacks, silencers, lagging, tanks and vessels.”

One particular item discussed was the ScoutDI for internal and external NDT inspections (Fig 4).

Features/capabilities include surface temperatures 0 to 50C/122F, operating frequencies up to 5Mhz, and inspection thickness range in steel from 3 to 250 mm/0.12 to 9.8 in. This unit is power-tethered for unlimited flight time.

Maintenance planning. Jack Odlum, HRST (US), focused on advanced inspection techniques throughout the HRSG in his presentation Advanced inspection ahead of major outages for maintenance planning.

He included inspection methods for economizer, evaporator, steam drum, superheater, duct burner, liner and casing. For this presentation, advanced inspection means non-destructive examination and use of sophisticated camera equipment.

Advanced inspection includes ultrasonic thickness, phased array, dye penetrant and magnetic particle, pulsed eddy current, replication, hardness testing, infrared imaging, borescopes, and use of drones. All were covered in this comprehensive discussion.

His conclusions:

- Advanced inspections see what you normally do not see.

- Large-scale repairs involving pressure parts can be forecast using these techniques.

- Smaller repairs can be properly sourced ahead of the outage.

- Coordinating HRSG projects with known turbine time tables can optimize site outage time, budget, and cost of personnel.

Boiler integrity

Wayne Hill, Energy Australia, discussed his company’s Boiler integrity program. His key question: “How do we systematically improve engineering practices for boiler asset management and ensure compliance?”

He went into depth on corporate engineering standards and compliance including guidelines and technical bulletins, working groups and other published documents. The overall program involves site processes (implementing standards and guidelines), boiler inspection management systems (BIMS), tube failure reduction programs, an inspection data management system (IDMS), and audit reviews of site practices. “Periodic audits,” he explained, “reveal improvement actions to raise engineering practices on sites and ensure compliance.”

The company’s Standards are often developed through Technical Working Groups that include principal engineers, site engineers, site managers and operations personnel.

Hill highlighted the corporate boiler tube failure reduction program that features incident procedures and standards, and in-depth research into root cause analysis.

Loy Yang B is a 1200 MW coal-fired station in Victoria’s Latrobe Valley, commissioned in 1993. David Desiatov presented LYB reheater repair and lessons learned, a project coordinated with HRL.

A tube failure in Reheater 2 had forced Unit 1 off line. The failed tube “had penetrated through the Reheater 2 outlet header box,” he explained. As a result, three tubes failed (Fig 5). The failure occurred on the Cr Mo side of a dissimilar metal weld (347 stainless to 2.25 Cr 1 Mo).

Evaluations included a temperature profile (ultrasonic oxide thickness testing) and condition assessment (hardness testing and microscopy).

The solution was bend replacement including a seal weld at the seal box.

A lessons-learned outcome was determining remaining useful creep life of thin tubes. Other outcomes were discussed including reliability of thermocouple data.

One of his conclusions: “Thermocouples are an accurate way to calibrate temperature and remaining life software and can be applied anywhere in the boiler, greatly reducing conservatism in calculating remaining useful life.”

Through this case study, said Desiatov, “we discovered potential at-risk tubes that remain in service, established a detailed temperature map, and analyzed trends that are critical for future targeted tube sampling.”

Smaller outdoor coal units. Anita Zunker, PEi Group, New Zealand, discussed cases of Widespread corrosion of wall tubes in two 32 MW coal-fired boilers. Wall tube corrosion had not been considered a high risk to these units’ owner/operator, and the supplier no longer existed (commissioned in 1994 and 1996). Under-casing corrosion had not been investigated. The outside units also experienced rainwater ingress into the casing.

Eventually, heavily-pitted tube surfaces and corrosion became apparent, but areas were difficult to access and repair processes were expensive.

Detailed investigations and step-by-step assessments began. Casings were removed for assessment by visual, UT, pit depth measurement, and laser scanning (Fig 6). This included validations by destructive testing. Extensive tube corrosion was identified, and operators developed and executed a “robust inspection and analysis scope for tube corrosion.”

Fitness-for-service repair works began and results have extended the boiler retirement plans.

Callide B. Gerrie Visser, CS Energy, offered Secondary and tertiary superheater inlet header tube stub cracking and discussed stub cracking at the 700 MW fossil-fueled Callide B Power Station in Central Queensland. During a 2023 outage, inspectors found multiple defects in the SH stub tubes adjacent to the manifold-to-stub fillet weld. A comprehensive repair program began.

Highest stress had occurred during startup, believed to be due to restrained thermal expansion during startup. Movement was limited by the refractory roof.

Action options include changing the penthouse and installing membrane seals.

Steam temperatures

Steven Bond, Bond Engineering, Australia, presented CCGT HP and RH attemperator turndown and reliability improvements. His case study was an Alstom 13E2 gas turbine with duct-fired Alstom HRSG. The unit suffered reheat spray nozzle failures and Bond offered solutions including improved control philosophy, piping design/stress issues and resolutions, and general troubleshooting tips.

Stuart Mann, AGL Energy, Australia, offered Analysis of drivers of high superheater temperatures for an IHI/Foster Wheeler coal-fired boiler.

He discussed the influence of the HP heaters at various loads, and the influences of over-firing and rapid fuel cycling variations.

He discussed AGL’s projects now in place to address the issues.

Chemistry

Barry Dooley gave his update on Fossil and HRSG cycle chemistry control and FAC.

He noted that “statistics from detailed assessments of close to 300 plants worldwide indicate that monitoring corrosion products is the primary influence on availability, closely followed by deposits in waterwalls and HP evaporators, inadequate instrumentation, and challenging the status quo.”

Dooley and David Addison, Thermal Chemistry (New Zealand), also provided a review of international activities on film-forming substances. This highlighted current needs on the effect of FFS on growth mechanisms of Fe, Cu and Cr oxides in water and steam, as well as research on changing from one FFS to another.

Updates were also presented on the International, Australian and New Zealand Associations for the Properties of Water and Steam.

Summarizing, Dooley pointed out that the new IAPWS decay map provides the first indicator to validate whether a plant’s chemistry is optimized and provides a tool to quantify any benefits from an application of a film-forming substance. With the growth of renewable energy forcing conventional and CCGT plants into more and more flexible operation, the benefits to plants from understanding and then controlling the factors leading to corrosion product transport will be very significant. Dig deeper into the new IAPWS tool by accessing their newly redesigned website.

Rounding it out

A number of other specific case studies were presented and examined. One, for example, looked at damage caused by undrainable water accumulated in main steam pipework, leading to long deadhead sections upstream of isolation valves.

Tom Burnett, Intertek (US), offered a review of High energy piping dead-leg concerns for CCGTs. His examples were taken from Capital Power in Canada.

His first example was damage to a high-pressure main steam piping isolation valve on top of an HRSG (Fig 7). He then offered an overview of a typical 3 x 1 main steam piping system (Fig 8) and walked through the illustration during plant operations.

His premise: “Potential HEP quenching due to long dead-leg design in between the HP, RH and LP to the common header is a condition that is not monitored in the typical CCGT plant.”

“The challenge,” he noted,” is that the dead legs without flow can have saturated condensate accumulate with higher temperature superheated steam higher in the pipe. Also, when shut down, the pipe wall temperature will be higher, and saturated condensate will tend to be at the bottom of the pipe.’

This temperature differential “may cause the pipe to bow and create an area for saturated condensate to accumulate, significantly increasing the risk of a water hammer and pipe quenching.” He offered various plant examples.

Burnett stated, “Because most HEP systems only monitor internal steam temperature with thermal wells at midpoint or higher in the pipe, the operator will not know if there is saturated condensate in the pipe during startup, leading to potential damage. The solution is to have a minimum of top and bottom pipe surface thermocouples installed.”

And a caution: “Over long operating time, the piping will creep and will challenge the elevation depending on the support system design, especially at the bottom of risers. Elbows at long horizontal runs may lift as well.”

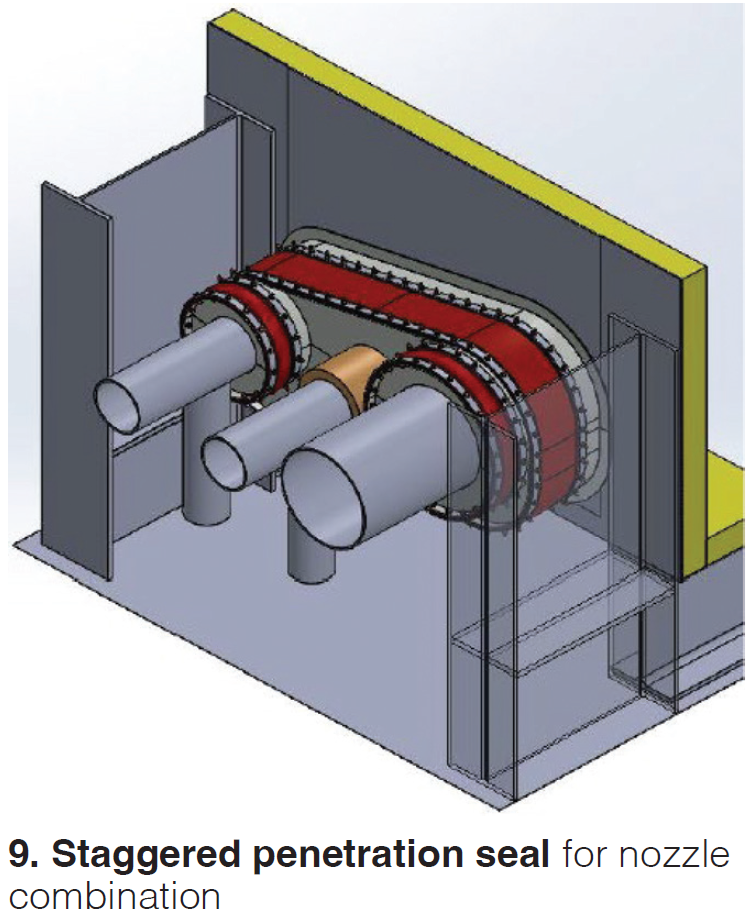

Roy Russell, Dekomte, discussed Side wall penetration seals and ash hoppers. His case studies focused on turbine exhaust expansion joints and HRSG penetration seals, a fossil boiler ash hopper, and a waste-to-energy boiler grate.

For combined cycle plants, he discussed fabric expansion joint technologies for GT exhaust/HRSG inlet hot and cold casing, variations for penetration seals, and side-wall close proximity seals. This included a new concept, a combination of nozzles into a staggered penetration seal focused on “insulation integrity in the casing and around each nozzle” as well as multi-pipe penetration seals (Fig 9).

He then moved to conventional boiler ash handling systems and waste-to-energy units.

Sam Clayton, HRL Technology, discussed Plant performance and its relationship with plant integrity noting strongly that “combustion is the least controlled process” and should be a key focus area. He also highlighted air heater performance and electrostatic precipitator performance in fossil boilers.

Stan Rosinski, EPRI, presented Evaluation of cleaning technologies for fouling removal and potential tube damage in boilers and HRSGs. His discussion focused on explosive cleaning methods and foam cleaning.

Additional ABHUG 2024 presentations covered Electric heating of HRSGs during wet layup (Anderson), a case study on inspection and assessment of Nozzle crack-like defects on a high-pressure feedwater heater (SRG Global), the Impact of FFS on heat transfer (Nalco), Non-fossil steam production in Australia (Addison), Australian standards on pressure equipment in-service inspection (HRL), Backup production of ultrapure water (Water Rentals), Corrosion-control lessons from the petrochemical industry (Quest Integrity), Addressing damage mechanisms in HRSGs (Quest Integrity), and Deaerator cracking/blowdown system erosion and early life creep damage (INPEX Australia).

Sponsor presentations were included for HRL, Precision Iceblast, Swan, Flotech, Duff & Macintosh, HMA Instrumentation, Intertek, and RTR Group.

The next meeting of ABHUG will be in Brisbane from November 25-27, 2025. Details at the group’s new website, www.abhug.com, as they become available. CCJ