River Road Generating Plant

Owned by Clark Public Utilities

Operated by GE Vernova O&M

248 MW, gas-fired 1 × 1 7F.02-powered combined cycle (STAG configuration) equipped with a Foster Wheeler HRSG, GE A12 steam turbine, and GE 324 generator, located in Vancouver, Wash

Plant manager: Robert Mash

Safer handling of chemical totes

Challenge. Gravity feeding the contents of a chemical tote into a stationary tank by strapping the tote to a forklift and tilting the forks to flow chemical directly from the tote into the stationary tank presented a safety risk to personnel.

Solution. Purchased a portable chemical containment vessel (Fig 1) and placed it next to the concrete containment where the stationary chemical tank is located. The portable containment is a secondary vessel that allows access for a forklift to stage and remove the totes.

Next, a flexible hose was installed, as shown in the photo, so a pump placed in the tote could transfer the chemical from the tote to the stationary chemical tank. A shutoff valve on the flex hose enables draining the hose into the tank when the transfer is completed.

Results. River Road personnel installed all components required to implement their proposed solution and conducted a test to demonstrate its viability by offloading the chemical from the tote to the stationary chemical tank. The entire process was completed within 20 minutes without incident—including moving the chemical tote from the storage area to the portable containment—proving the new process is safer, and easier for team members to handle.

Project participants:

Justin Hartsoch, operations manager

Jake Sanderson, operator

Marjorie Brice, EHS specialist

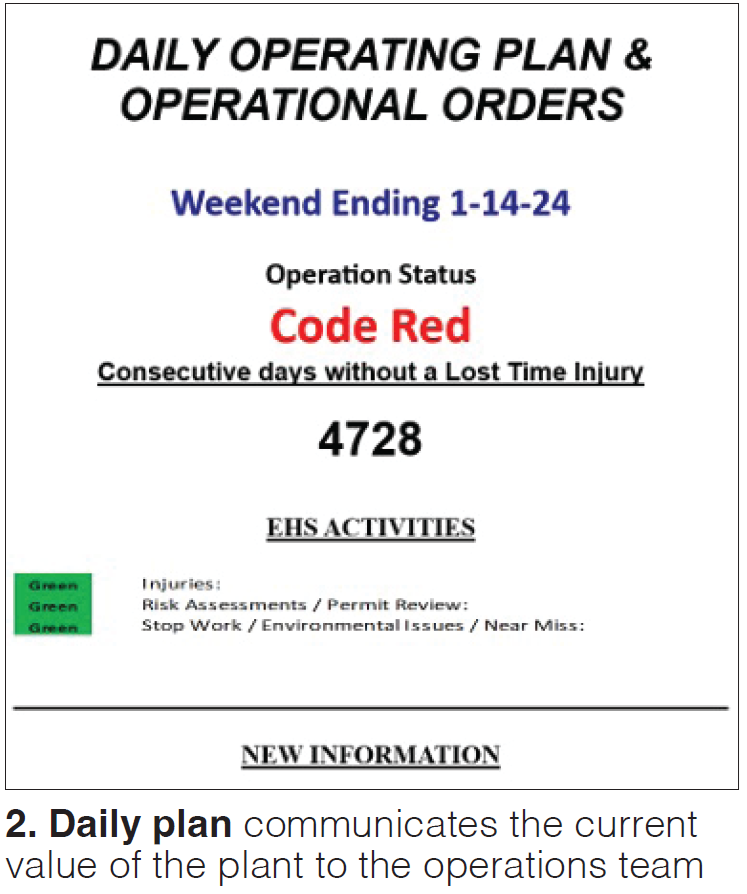

Plant’s value, calculated daily, determines operating conditions

Challenge. Maintaining reliability is the most critical aspect of plant operations at River Road. As a public utility, plant output is dedicated to its customers. If the facility goes down, the owner must procure replacement energy which is subject to volatile market prices.

Over the past few years, the energy market has been much more volatile than it had been historically. Fluctuations in fuel and power prices can change dramatically in a day, possibly less. Last winter there were days that would have cost the utility upwards of $1.6 million in replacement energy had the plant tripped.

Sometimes the information that flowed from the power analyst to the plant was not passed on until the day that was impacted. This presented problems when contractors were scheduled to be onsite for repairs and also interfered with work planned by the O&M team.

The plant and the power manager needed a way to communicate the daily value of the plant to staff in a timely manner. Ultimately, the goal evolved into creating an “operational color code.” This code would then be linked to maintenance tasks based on the plant trip risk inherent with each of the tasks.

Solution. Clark Public Utilities collaborated with River Road’s O&M team to develop a process to communicate the daily value of the plant to the operations team. The power manager created a spreadsheet that calculates the daily value of the plant. The calculations use the value of selling already-purchased gas and buying replacement energy at market prices.

The utility’s internal risk group established these three levels of value and assigned each a color:

- Low-value day, GREEN.

- Intermediate-value day, ORANGE.

- High-value day, RED.

Results of the daily-value calculations are delivered to the operations team daily for the following day, or days (Fig 2).

With the color code in place, the O&M team worked collaboratively with craft, operations, and managers to assign maintenance risk values to typical work categories. The goal was to complete only high-risk maintenance during GREEN days and to limit high-risk maintenance on ORANGE days. Maintenance on RED days was limited to low-risk activities (Sidebar below).

What the operational color codes mean

RED examples.

- Calibration or tasks associated with air-permit maintenance/linearity testing.

- NPDES equipment testing and calibration.

- Steam-turbine stop- and control-valve testing.

- Diesel/generator testing.

ORANGE examples.

- Code RED tasks.

- Swap-out of equipment.

- Motor and pump operational testing.

- Change-out of motor air filters.

GREEN examples.

- All Code RED and ORANGE tasks.

- Routine plant maintenance.

Results. Day-ahead collaboration and communication has allowed scheduling and execution of work based on plant value. The operational color codes eliminate ambiguity regarding work that can be done; plus, it has improved communication between the plant and the utility’s analysts.

The operational code is reviewed during the morning meeting to determine whether scheduled work can be performed or should be postponed.

The information communicated also is included in the daily operating plan. The operations team has a better understanding of the importance and value of the plant and how their daily work can impact utility reliability. It also demonstrates the communication and collaboration between the owner and O&M team.

Project participants:

Robert Mash, plant manager

Terry Toland, energy resources manager

Cooling-tower performance upgrades

Challenges:

- Cooling-tower efficiency had slowly decreased since the last fill replacement in 2009 because of the deposition of calcium silicate inside the media prior to installation of Flow Tech devices to mitigate the issue (Fig 3). Heat rate increased because warmer water was flowing through the condenser tubes. Warmer water also compromised the ability of the heat-rejection system to cool the generator and lube oil in summer.

- The garden screens for reducing sunlight inside the cooling tower were not sufficiently robust to handle local weather conditions for more than about a year (Fig 4). A best practice was to take down the screens before winter when accumulations of ice and snow could damage them. However, the screens often were subject to tearing when they were reinstalled in spring.

Staff wanted to continue shading the tower to reduce algae growth, thereby reducing the consumption of water-treatment chemicals and their impact on the environment. A robust, permanent solution to the algae solution was the goal.

Solutions:

- Replaced the media throughout the five-cell cooling tower (Fig 5).

- Installed ridged sunscreen media on all sides of the cooling tower to block the sunlight required for algae growth.

Results:

- Reduced heat rate by about 200 Btu/kWh; increased gross capacity factor by about 1%.

- Reduced the consumption of chemicals used for bio-growth control by 40%, saving $10k annually. Eliminated the need to purchase new garden screens annually, saving another $5k. Reduced labor hours by eliminating annual replacement of sun screens, saving $2.5k. Eliminated rental costs for the lift required for replacing screens, saving another $2.5k.

Project participants:

Terry Toland, energy resources manager

Ken Roach, maintenance manager

Justin Hartsoch, operations manager

Steve Ellsworth, shift supervisor

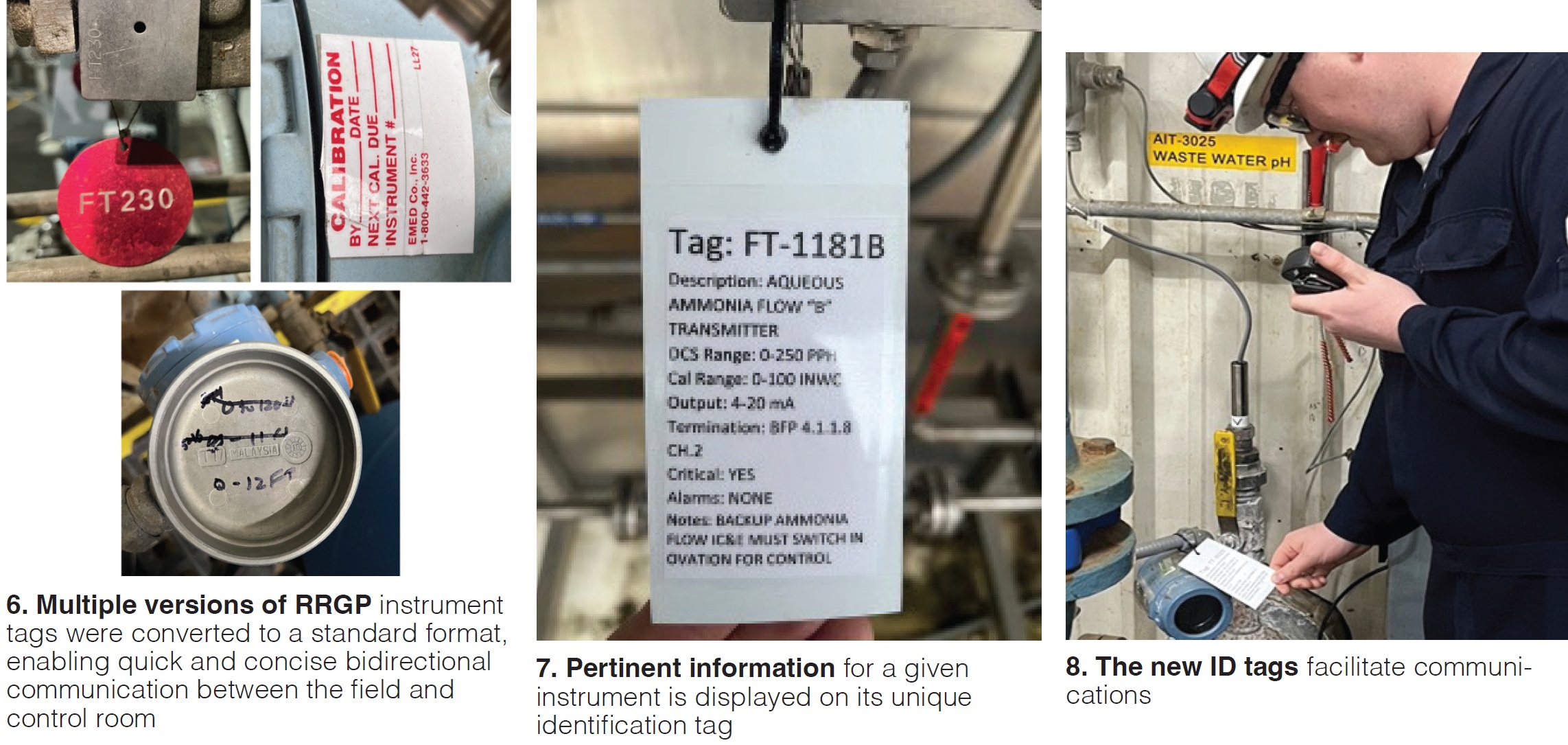

Improved instrumentation identification tags

Challenge. Over time, and with turnover of personnel at River Road Generating Plant (RRGP), instrumentation tags plantwide came to have various non-standard variations of tagging and markings. It became confusing for plant personnel to correctly identify instruments and the processes being controlled.

It also created a conflict of understanding between control-room and outside operators when referring to field instruments. CROs know the instruments by description of what they control; outside operators usually see an instrument tag number without a description.

RRGP has instrument racks where three to 12 instruments can be mounted together in a central location. Thus, it can be time-consuming to identify a specific instrument without proper tags, or a mix of tag types.

To illustrate: There may be one tag with the instrument number on the device and a faded/smeared calibration sticker, and permanent pen markings on the outside or inside of the device lids. Inconsistent markings have included multiple ranges for the devices, as well as other changes that have been made over the years (Fig 6).

The O&M team needed a way to standardize the instrument details for all plant personnel to assure proper identification of instrumentation quickly and efficiently, particularly during emergencies or other critical times.

Solution. The I&C team created a weatherproof instrument tag that provides the following information:

- Instrument tag number (matches nomenclature on the P&ID).

- Description of device. Identifies the process the device is measuring and serves as a secondary form of verification with the CRO—such as HP drum level “A” transmitter.

- Control-system range as displayed in the control room.

- Calibration range of the device.

- Output range of the device.

- Location of wires landed—input or output—on the control system.

- Specifies if the device is critical to operate the plant safely and efficiently.

- Alarm/trip points. They can be useful when comparing to a local gauge for outside-operator rounds.

- Any additional information that would be helpful to personnel in the field.

The foregoing information is placed on a 3 × 6 in. tag to provide all information needed for quick and concise bidirectional communication between the field operator and the control room or technician (Fig 7).

Results. The new tags reduce the risk of misidentification of instrumentation. Personnel confidence improved after their installation (Fig 8). Plus, staff knowledge increased with regard to field instrumentation. And communications regarding reference to instrumentation has improved during troubleshooting and normal operations.

Work-order details now are more complete, allowing personnel to correct issues often in less time than previously.

Others have been impressed with the RRGP tags and have adapted them to suit their facilities.

Project participants:

Steve Dahl, IC&E technician

Jack Blair, IC&E technician

Dealing with an outage parking challenge with safety in mind

Challenge. Depending on the amount of work being performed during an outage, the space for plant personnel and contractor parking becomes a challenge. Some sites do not have the real estate to support the capacity necessary for component laydown areas, contractor trailers, and personal vehicles. Safety is a priority and insufficient parking creates several hazards.

River Road personnel identified an unused lot on the property adjacent to the plant. It had been used during construction but had remained vacant for many years. The lot was overgrown with vegetation and weeds. The ground was soft as well.

Solution. Staff developed a plan to prepare the lot for safe parking. Overgrown vegetation, weeds, berry vines, and small trees were removed. The soft gravel surface was compacted, and new gravel was added and compacted for stability (Fig 9). Portable lighting, temporary parking barriers, and ingress/egress stairs were added to allow access to the higher-elevation parking area. The space was now safe for personnel, visitor, and contractor parking.

Results. The vacant lot was successfully used as a safe parking space for the duration of the month-long outage. The location of the parking area outside the plant eliminated unnecessary vehicles from entering the plant roadway. This dramatically reduced traffic inside the plant making it safer for all personnel walking on the roadway (Fig 10).

It also provided ample room for large equipment and component staging in close proximity to work locations. Delivery of tooling and specialized equipment was made safer and more efficient with no traffic on the plant roadway.

The new lot is now the plant’s standard parking area for RRGP personnel, visitors, and contractors during outages.

Project participants:

Margie Brice, EHS supervisor

Mike Buhman, mechanic

Steve Ellsworth, shift supervisor