In recent years, winterization has become a hot topic for user groups, and this year’s CCUG was no exception. One reason is that the next extreme weather event seems to challenge everything done to address the last one.

During the “Extreme Weather Operation” roundtable, the user facilitator noted that “bomb cyclone weather forced us to think differently about freeze protection because our existing systems didn’t work well.” He tagged thermostats as a prime example.

During another event, the facilitator noted that a lightning strike had taken out all their instruments. In a show of hands, seven in the audience indicated they had experienced trips from lightning. He also asked the audience about their lightning policy for venturing out into the plant, and most people raised their hands indicating that they had one. One guideline is if the lightning is ten miles out, everyone comes off the top decks. When two miles out, no one is allowed outside.

Some general tips from the discussion:

- Get a critical transmitter list together. Where and when possible, transmit data into the control room via blue tooth

- Try to eliminate having to get to the upper decks while things are freezing up

- Monitor heat tracing from the control room

- Make sure heat trace lines have not been inadvertently disconnected because of a closed electrical circuit

- Using open flames to defrost lines may require a hot work permit in areas where stray flammable gas may be present

- Red chicken coop lights are good for heating “hooches”

- Insulation should be part of your heat trace audit

- Develop quick drain guidelines for the HRSG

- Review alarm points and operational permissives which may be impacted by cold weather

- Review work orders that could identify leaking equipment

Suggestions for longer term investments from the slide deck include replacing heat trace (mineral insulation cable is only good for 10-15 years), replace sample lines with tube bundles, insulate drum enclosures and add cladding, and reinsulate and clad interior walls and ceilings. One slide has a convenient check list for both cold and hot weather operations.

“HP Steam Turbine Door Leaks” reveals how users at a 1997-vintage 1×1 baseloaded CC facility with a bottom-supported HRSG handled diagnosis and repair of a drum door leak which was causing forced outages on a unit expected to run without interruption eleven months out of the year (Fig 2).

The leakage pathway proved to be pitted drum and door seating surfaces but bent and worn door hinge hardware and misalignment of door-to-drum sealing was also discovered. Because the leveling blocks did not work well for centering the door to the opening, plant staff resorted to workarounds which damaged key components. Worn bolts also led to workers over-torqueing to tighten and seal.

Overall solution involved phonograph-groove machining of the drum and door sealing surface, replacing internal hinge hardware and strongbacks, upgrading the leveling block and the bolting and nuts, as well as revising door closing procedures. Presenter noted that “putting the sealing gasket on properly” is critical. The revisions restored the plant team’s “faith” in walking by the door. Responding to an audience question, the presenter said they did not perform a root cause analysis of the pitting.

“Hot Topics for Insurance” may have been presented by an insurance company official but is a must-read for users as an alternative view of the state of the industry. Quotes like these may get you to link to the slides: “Supply chain impacts have resulted in enormous and unexpected business interruption losses,” “unprecedented amount of losses recently (with steam turbines),” [OEM] RCAs are not complete and issues may not be disclosed in a timely manner,” and “[we are] starting to consider climate change and sea level rise.”

This official argues that, in today’s climate, a CC facility needs to “objectively differentiate itself” from its peers with respect to risk reduction and its relationship with the insurer. One way to avoid negatively distinguishing your facility is to make sure you have these bases covered, for which presenter notes that, despite better practices overall in power generation, some sites are not attending to:

- Planning for worst case scenarios such as steam turbine lube oil fire combined with overspeed event

- Functional overspeed trip testing

- Sequential tripping

- DC load/overload system design and testing (including during operation)

- Fire emergency response procedures

- Valve maintenance and testing

- Frequency of maintenance vis a vis run hours vs time and load conditions

- Starts and stops, NERC GADS (Generating Availability Data System) data, and run profile

Critical items listed include updated TIL and FSB (field service bulletin) trackers, borescope inspection frequency, fire protection and enclosure tightness testing, concern with overfiring for profit by IPPs, and life extension studies.

“Safety Valve Testing, Repair, and Programs” declares at the top that a “great testing program is essential” for ensuring safe and efficient operation of pressurized systems, but the advice at the end is no less insightful: “All inspections need to be documented or they never happened.” Keep in mind that safety relief valves are also subject to industry standards (ASME, API), your insurance carrier’s recommendations, and local jurisdictional regulations.

Slides include inspection frequency and recommendations for different classes and services of valves, examples of a work order cover sheet, repair and inspection report, and quality control guidelines.

“Outage Management, Planning, & Execution” ends with the important point that planning for the next outage begins immediately after the last one ends. Work that was not completed or needs to be revisited, and items from inspections and work orders will begin the task list for next time. Schedule your outage close-out meeting and reports deadlines as soon after the end date as possible to document lessons learned and future work when it is all top of mind.

The best of planning will not avoid discovery of emergent work scope. Don’t knee-jerk respond. Work these items into the plan, understanding that the risk of errors and accidents is twice as high when addressing emergent situations.

Balance of slides address common components of outage planning: EHS issues, building the team (owner/operator, site personnel, contractors and vendors, OEMs and CSA partners) and the small teams with the team, budgeting and schedule, building the work list from the CMMS, work package development, planning and coordination (LOTO, cranes, special movers, scaffolding, parts, tooling, etc), RFQs preparation, outage execution and verification, and others.

“Drones” explains some basics of how to set up a drone inspection program, including FAA registration, regulations, and compliance; typical applications like inspecting external and internal stack surfaces, HRSG and turbine interior components, and high voltage transformer components. Drones save money, keep workers out of high-risk areas, and are often able to access tight and confined spaces. Numerous photos of drone-inspected equipment are included, along with three types of drone units.

“Risk Management” is a basic framework used at one site for assessing various plant maladies with respect to impact on personnel safety, environmental compliance, cost, staffing/labor, and potential collateral impact on other plant components and systems.

Deciding how to address an emergent malady – whether to monitor it, attempt to mitigate it on-line, or take an outage and correct it – can challenge any risk management procedure. The detailed risk assessment and thought processes around an actual HRSG bellows leak (accompanied by key photos of damage) at the plant makes the framework actionable.

CCUG VENDOR PRESENTATIONS

“HRSG 101 and HRSG Cycling,” Greg Rueff, Vogt Power International (Babcock Power)

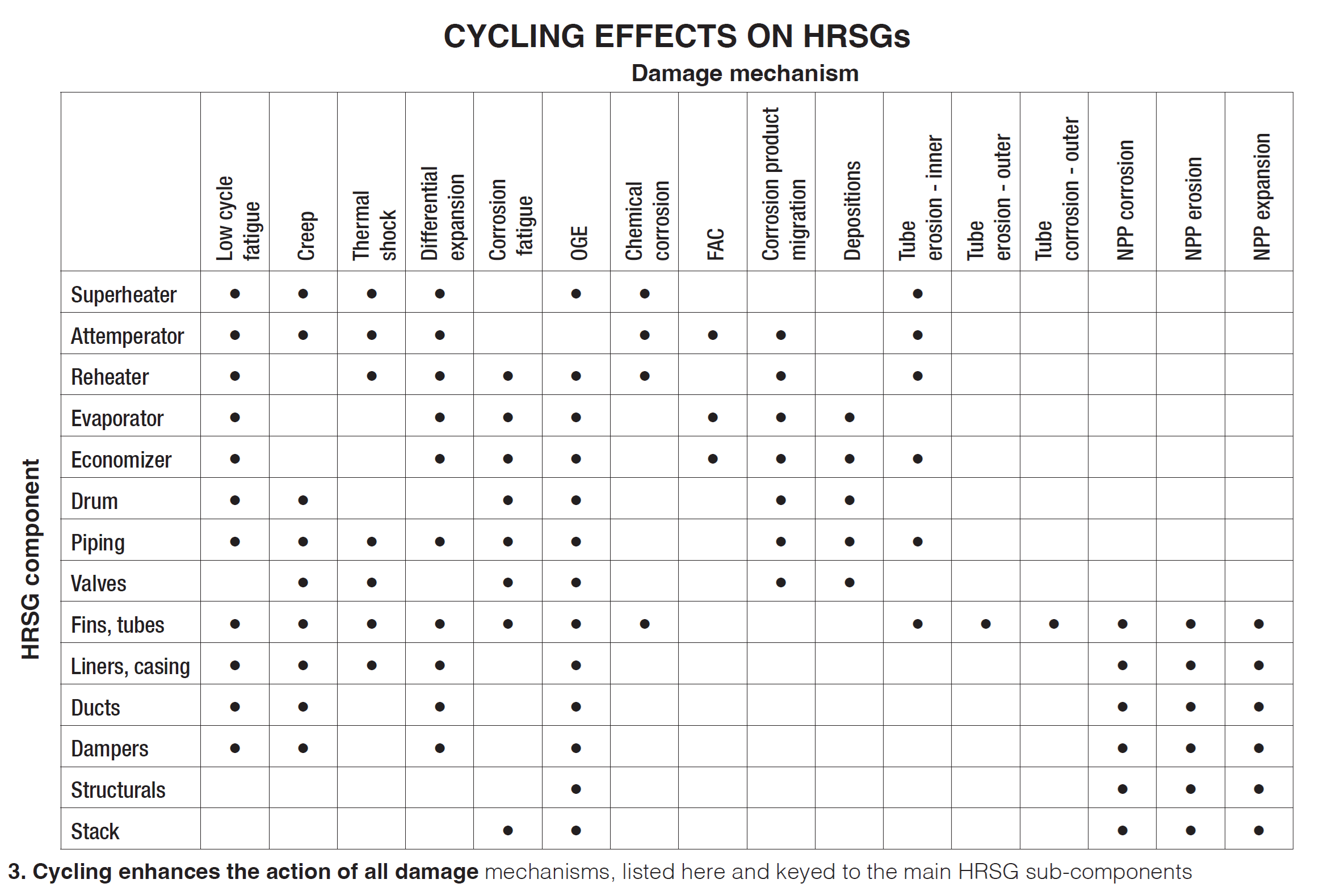

Comprehensive 64-slide primer on HRSG design features and cycling impacts covers everything in the footprint, including duct burners, attemperators, catalyst and ammonia grid, insulation, liners, bellows, and casing seals. Those familiar with HRSGs may find the last few slides – covering cycling damage mechanisms (Fig 3), calculating damage factors, and maintenance planning – most relevant. It’s always good to be reminded that “cycling enhances the action of all existing damage mechanisms.”

“Condenser Troubleshooting and Restoring Condenser Health,” Geoffrey Greenberg, TEI Babcock (Babcock Power)

Slides on troubleshooting are suitable for conversion into posters displayed by the unit. Later slides in the deck offer maintenance guidelines, best practices, diagrams and photos of typical issues, and case studies of recent projects undertaken by this vendor to address issues and restore performance.

“Turbine Oil Life Cycle Management,” Chris Knapp, Shell Oil Products

Everything you need to know about lubricating oils in power plants, with a focus on testing and analysis, understanding and mitigating varnish issues, and why/how PAG-type fluids avoid varnish formation. Words of wisdom: “Not all lube oil products are created equal even if they meet the specs.

“The Importance of Testing and Cycling Your Electrical System,” Nathaniel Smith, TEMS

You probably are not cycling (testing that they work) your electrical components frequently enough, according to this presenter, nor is following NERC PRC-005 sufficient. Any electrical coil that actuates a mechanical device should be “operated” as frequently as possible. Guidelines are included for protection relays, lockout relays, AC sensing devices (e.g., current transmitters), and breakers.

“Safety Differently: A Story About How Your Organization Could Learn Differently,” Matt Barnes, MD&A

Message here is that team performance improves when you work through a safety event with positives instead of the absence of negatives. Positives include the capacity to be successful under varying conditions, the ethical responsibility to the organization which has to handle messy, risky work, and making sure the people perceived to be part of the problem (those involved in the safety mishap) become part of the solution.

“AIG Tuning and System Maintenance,” Andy Toback, Environex, and Kevin Perez, Groome Industrial

Ammonia injection grids can be tuned to improve NOx reduction performance and reduce ammonia consumption. Slides help you make a first order decision as to whether tuning will be beneficial for your unit(s). The procedure is described, along with sampling probe requirements, pros and cons of installing a permanent sampling grid, chemistry basics, results before and after tuning, plant preparation for “tuning day,” operating requirements, access to sampling ports (sometimes sampling ports are not accessible). Because 7F units achieve 9 ppm NOx at the GT exhaust, they are generally not good candidates for tuning, note presenters.

“Attemperator Repair and Replacements,” Bill Kitterman, SVI Bremco

Slide deck, a photo journey of removing, repairing, and re-installing a hot reheat steam bypass attemperator, high pressure steam attemperator, and a reheat attemperator will disabuse you of any notion that the process is straightforward, mostly because of the cramped, tight areas these components are located within the HRSG block, original design materials selected (P91), support structures, and welding limitations (Fig 4).

Memorable quotes from the presentation (users and presenter): “OEM that built this unit did not believe in maintenance,” “there are so many issues, it’s almost beyond planning,” and “if you have P91 units, start stocking replacement material you can use based on your line sizes”

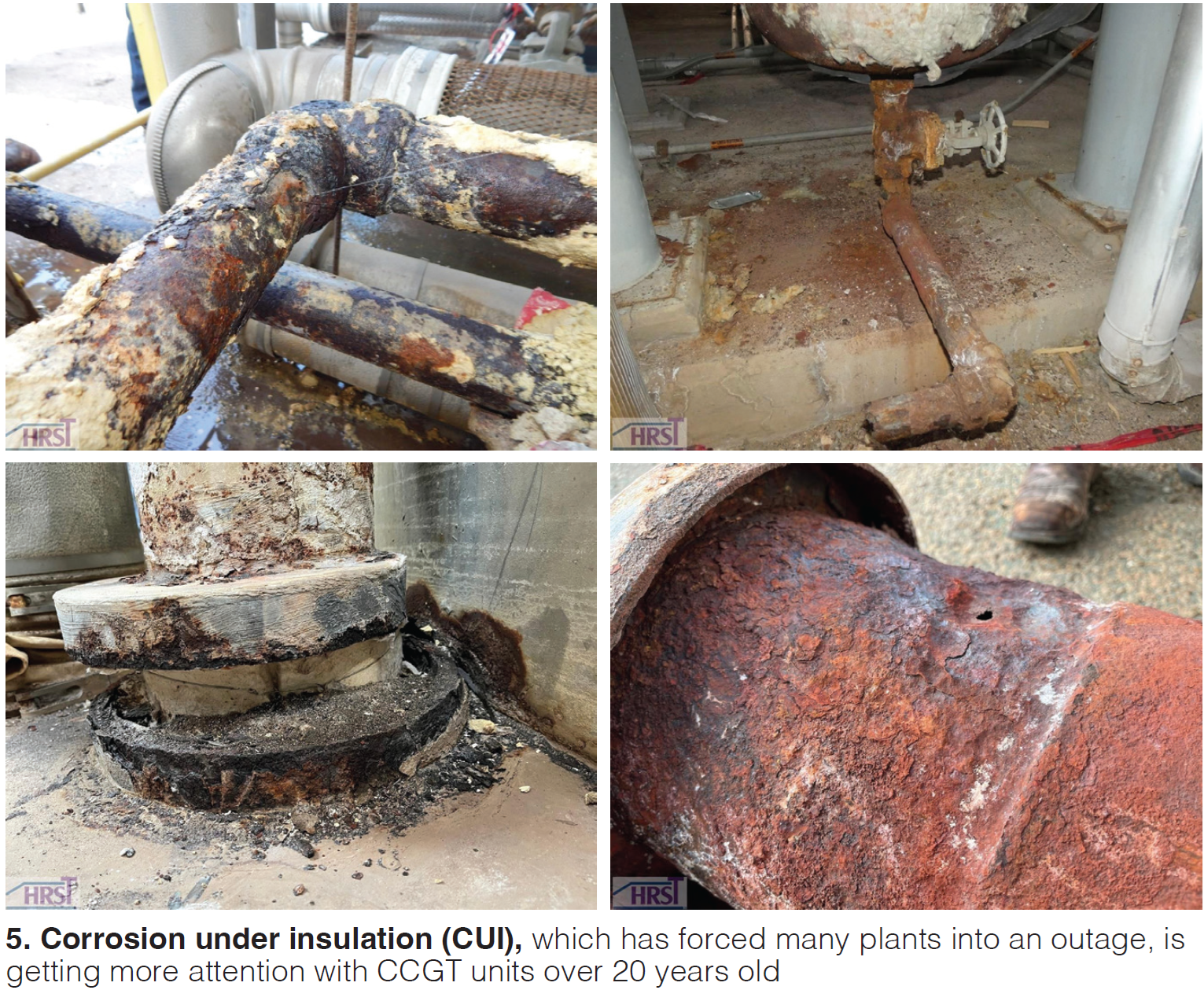

“Corrosion Under Insulation – What Lurks Below,” Jordan Bartol, HRST

If your HRSG has 20+ years operation (like many from the 1997-2003 CC boom years), these photos of corrosion under insulation (CUI) may cause you to immediately remove insulation and check the piping, especially in areas affected by exhaust gas dewpoint and ambient dewpoint (Fig 5). Examples of CUI covered are economizer drainpipes, feedwater piping, blowdown piping, LP evaporator riser, HP economizer vent, insulated stacks, and others. Cursory and advanced NDE inspection techniques are described, along with practical tips and modifications which can prevent or reduce risk of CUI.

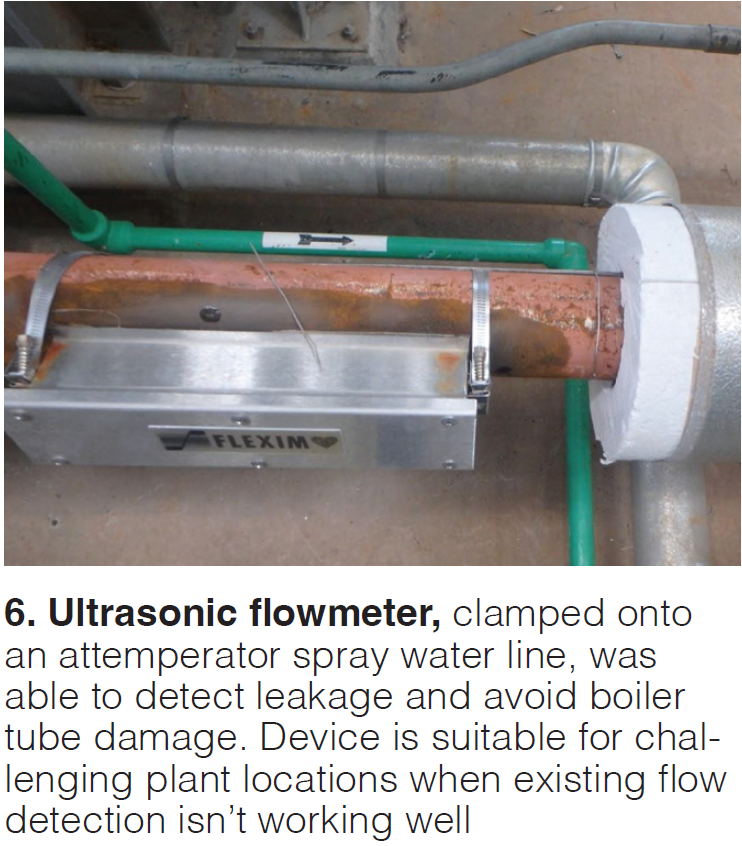

“Attemperator Leak Detection to Prevent Steam Tube Damage,” John Van Nostrand, Emerson/Flexim GmbH

Benefit from a clamp-on permanent ultrasonic flow measuring device, dubbed Fluxus, was so high in monitoring attemperator spray water leakage at one plant that the owner/operator added the devices to the reheat and high-pressure spray water lines in that plant, then applied them for flow measurement throughout the CCGT fleet (Fig 6). Technology is suitable for other applications, including natural gas flow, boiler blowdown, feedwater, cooling water, steam, and other fluids.

“Case Studies from CCGT High Energy Piping Reliability,” Peter Jackson, Tetra Engineering

First slides here review maintenance planning and implementation associated with relevant guidelines for covered piping systems, including ASME B31.1 (2008 Addenda), EPRI Guideline 1018998 (2009), and ASME B31.1 Chapter VII (2024). Following slides cover case studies of (1) hanger condition assessment, (2) water hammer cracked cold reheat (CRH) pipe weld, (3) creep failure of HP bypass to CRH, (4) quench failures of HRSG reheater interstage DRH 90 deg elbows, (5) HP steam drain manifold failure by high-speed erosive wear, (6) fatigue failure of common hot reheat welded lateral, and (7) formed Tee design issues and early life creep failures.

“IEEE C37.23-2015 Standard for Metal-Enclosed Bus,” Mohsen Tarassoly, EBI

Isolated phase bus and other bus systems (segregated, non-segregated) are among the only components without backups at a powerplant. When it fails, the plant is out of service. The referenced IEEE standard updates temperature, voltage, and current ratings; rated insulation levels; and short-circuit, momentary, and short-time withstand currents. Buses should be maintained during a scheduled shutdown, or at least every 18-24 months. Don’t rely on what you see; take advantage of EMI tests which can help identify (though not conclusively) problem areas.

“Top 5 SCR Performance Issues,” Vaughn Watson, Vector Systems Inc

Catalyst is often not the culprit in SCR mal-performance. Differential pressure across the catalyst, catalyst bypass/plugging, poor ammonia distribution and reagent quality are other factors. Slides cover these topics with a focus on the ammonia injection grid (AIG) and the importance of component manufacturing on AIG performance. Company also supplies in-situ test grids for tuning and optimization.

“Generator Outage Management – What’s Your Contingency Plan?” Jamie Clark, AGT Services Inc

Overriding message one: Get your unit’s baseline condition now! Message two: AGT (along with PSM) “has the capabilities and expertise to address virtually all OEM deficiencies.” The current availability of large-generator services for power plants is not comforting as the demand crunch (20+ year old units, other units close to their 2nd or even 3rd field rewind) converges with limited shop and field resources and specialists.

Slides offer a wealth of good material to plan inspection and repair outages, including expected schedules for major, minor, and mid-range outages, field rewinds (six months out), stator rewinds (one year out), and duration of common repair situations. Other slides cover scope document development (e.g., standard field and stator testing), robotic inspection (when, and when not, to use and why, with numerous photos), addressing OEM bulletins, and issues with brazed joints across the OEM offerings.

“Air Filtration and Extreme Weather,” Bob Reinhardt, Donaldson Filtration Solutions

Slides in bulleted outline form cover F9 vs E class filtration; extreme weather events (snow and ice, wildfire smoke, extreme heat, and high humidity and coastal locations); and preventive maintenance steps, including pulse checks, filter installation, prefilter changeout, evap tuning, and hood treatments.

Closing reminder. End users registered at www.powerusers.org are encouraged to download the full slide decks from the 2024 conference and put the shared experience and lessons learned to immediate use. The material spans everything from outage planning and controls upgrades to generator rewinds and cold-weather prep—practical, field-tested guidance that speaks directly to today’s plant challenges. And if you’re not already planning to attend the 2025 Combined Conference, set for August 25–28 in Washington DC, now’s the time. Few events offer as much actionable content, peer exchange, and expert access in one place.

Access the content specific to each of the 2024 Power Users Combined Conference tracks here: