Hydrogen remains the cooling medium of choice for large turbine generators because of its superior heat-transfer efficiency and low windage losses. Yet that same efficiency creates a narrow safety margin. During outages or emergencies, operators must replace hydrogen with carbon dioxide and, if necessary, with air before personnel can enter the generator enclosure.

Each transition introduces risk when done manually. Differences in operator skill, changing plant layouts, or equipment condition can create delays and, in worst cases, unsafe sequencing.

A recent CCJ webinar, “Automating Hydrogen Purge to Maximize Power Plant Safety,” presented by E/One and J3 Engineering & Construction, described a system that eliminates much of this variability. For those looking for greater details, access both the recording (below) and slides.

The session, presented by Mark Williams (LinkedIn, email) and Jason Justice (LinkedIn, email), outlined an operator-initiated purge system designed to execute an interlocked, validated sequence directly from the control room. The concept is simple but powerful: the same steps, the same checks, and the same confirmation of success every time, regardless of who is on shift.

Not fully automatic

Williams emphasized that the purge begins only when the operator commands it. The human still decides whether to conduct maintenance or an emergency purge. Once initiated, the system performs a controlled sequence that closes hydrogen supply valves, opens vents, admits CO2, and verifies purity and flow conditions. The goal is to preserve operator judgment while automating the mechanical execution, ensuring the purge happens quickly and safely even under pressure.

Operators can select among several modes: hydrogen-to-CO2, CO2-to-hydrogen, or a full emergency purge. Each mode uses logic permissive tied to generator pressure, seal-oil differential pressure, gas concentration readings, and turning-gear speed. These built-in safeguards prevent premature transitions that could lead to static discharge or incomplete gas removal.

Standardizing a best practice

Many generating stations still rely on legacy procedures that vary by technician. Inconsistent training, aging manifolds, and missing instrumentation often produce purge cycles lasting from six to sixteen hours.

Bottled CO2 gas feed frequently freezes during the CO2 purge process, vent analyzers fail to verify the amount of CO2 that has flowed to the generator, and only a handful of staff know the full sequence. The system targets these deficiencies by creating a standardized approach that can be replicated across multiple plants.

The program’s priorities are straightforward:

- Repeatability. Every purge follows the same defined steps and timing.

- Verification. Continuous feedback from analyzers and flow transmitters confirms real gas movement.

- Isolation. Two motor-operated valves (MOVs) close the hydrogen line before venting pressure down and the admission of CO2.

- Ergonomics. Purges are executed safely from the control room, minimizing field exposure while keeping manual backup available.

Hardware and integration

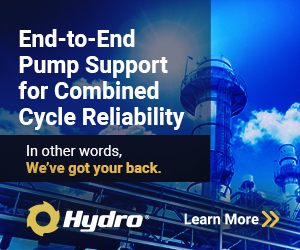

The automation package centers on three main elements: an upgraded gas-handling manifold, a non-powered CO2 vaporizer, and software integration within the existing plant control system. The manifold includes MOV hydrogen shutoff valves with feedback, dedicated CO2 supply and vent MOVs for top and bottom headers, and a pair of solenoids that direct analyzer samples from either header (Fig 1).

Dual explosion-proof analyzers measure hydrogen, carbon dioxide, and air concentrations with remote range-change capability. The operator can switch measurement ranges from the control room without accessing the analyzer cabinet. A differential-pressure transmitter verifies that the analyzer is sampling live flow rather than a stagnant pocket of gas. CO2 flow meters and totalizers record the actual amount used, helping plants confirm the purge was completed.

Dual explosion-proof analyzers measure hydrogen, carbon dioxide, and air concentrations with remote range-change capability. The operator can switch measurement ranges from the control room without accessing the analyzer cabinet. A differential-pressure transmitter verifies that the analyzer is sampling live flow rather than a stagnant pocket of gas. CO2 flow meters and totalizers record the actual amount used, helping plants confirm the purge was completed.

Integration is designed for major distributed control systems such as GEV Mark VIe, Ovation, and Siemens T3000. This eliminates the need for an auxiliary PLC and allows purge records, alarms, and analyzer data to be stored in the plant historian for future audits.

From blanket flow to pressure-purge

The system replaces the old “blanket purge” method, in which operators slowly bled gas through the generator to avoid freezing, with a pressure-purge cycle that is faster and more effective. The process involves several pressurization and venting steps:

- Close hydrogen valves.

- Vent the generator to approximately 10 psig.

- Admit CO2 to raise internal pressure to roughly 28 psig.

- Vent again from the upper header to expel displaced hydrogen.

- This sequence repeats three times; a fourth cycle can be initiated if the operator is not satisfied with the purge or if the analyzer readings show an incomplete purge.

Each step is timed and interlocked. The control system records case pressure, flow, purity, and analyzer DP readings. Operators can view both turbine-end and collector-end analyzer outputs reading from the top or bottom header pipes based on the gas that is being read to confirm full displacement before declaring completion.

Solving the CO2 bottleneck

The bottleneck in many purges is CO2 delivery. When gas is drawn from the top of storage cylinders, the temperature drops, forming dry ice and choking flow. E/One’s solution uses liquid-withdrawal cylinders or micro-bulk storage combined with a passive vaporizer that converts liquid CO2 into gas using ambient heat. This approach provides stable flow of 6-7k standard cubic feet per hour at 50 to 65 psig without requiring electrical power.

Because the vaporizer is non-powered, it continues operating during a total station blackout. The only component that must remain energized is the flow totalizer, which can be tied to the plant’s uninterruptible power supply (Fig 2).

The design not only prevents dry-ice formation but also reduces CO2 consumption by roughly thirty percent, saving cost and shortening purge time to as little as one to two hours.

In the control room

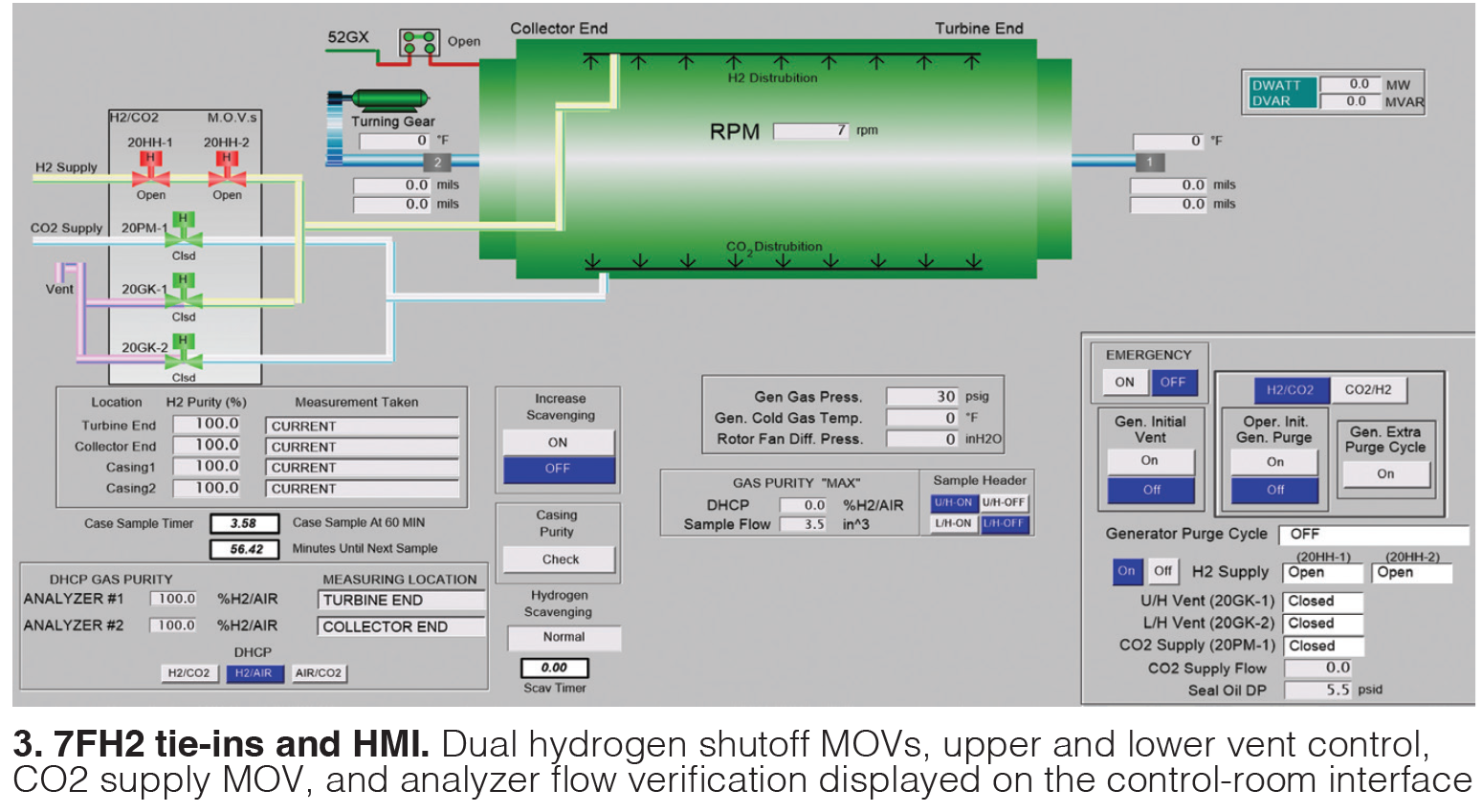

Justice, a seasoned controls expert, walked the audience through a series of simulations for each purge modality. The operator interface consolidates all purge information onto a single screen. It displays hydrogen purity for both ends of the generator, MOV positions, analyzer-flow DP, seal-oil DP, generator case pressure, and CO2 flow totals (Fig 3).

In maintenance mode, the logic pauses the sequence if seal-oil DP falls too low, allowing operators to correct oil-system conditions before continuing.

In emergency mode, the system prioritizes hydrogen removal and finishes by holding the generator pressure to about ten psig with CO2 to maintain seal oil system integrity preventing seal oil back flow into the generator.

Manual valves remain in place for contingency. If an MOV fails or loses power, operators can complete the purge by hand. MOVs are designed to fail in position to prevent unintended motion during outages.

Safety logic and fail behaviors

Safety functions are embedded throughout the sequence. The control logic requires verified closure of both hydrogen isolation valves before any venting or CO2 introduction. Analyzer ranges shift automatically to the appropriate gas pair, preventing operators from viewing misleading values.

Analyzer DP transmitter ensures that purity readings reflect actual flow across the analyzer cell. During an emergency purge timing safeguards guarantee that CO2 flows for a minimum period with acceptable purity readings before the system ends the emergency purge.

In a total power loss, the vaporizer continues functioning, and the analyzers and MOVs can operate on UPS power long enough to complete a safe purge. Plants may also add conditional logic to initiate purging automatically if seal-oil DP collapses during a blackout.

Implementation steps

For facilities evaluating automation, the presenters recommended the following actions:

- Survey existing manifolds, hoses, and regulators, and replace outdated hardware

- Review P&IDs to identify tie-in points for hydrogen, CO2, vent lines, top header, and bottom header

- Determine generator case volume to calculate proper CO2 gas flow rates and volumes

- Verify analyzer condition and upgrade analyzers with remote range change capability

- Size an ambient vaporizer rated for local climate conditions

- Integrate the new sequence within the main DCS and historian rather than a separate controller

- Train operators on the purge HMI and conduct dry runs before field deployment

The benefits

Plants that have implemented the operator-initiated purge report shorter purge durations, reduced CO2 consumption, and improved procedural consistency. The ability to conduct the entire operation from the control room eliminates the need to send staff into harms way during storms or equipment emergencies.

Automation also allows logging and a verifiable record of each step, reinforcing the safety culture expected in modern combined-cycle and fossil-steam plants.

Hydrogen management is an area where discipline pays dividends. A repeatable purge process reduces both risk and uncertainty, providing operators with confidence that hydrogen has been completely removed before maintenance begins.

Watch and share with your team

The webinar recording and slide deck explain each purge mode in detail and include demonstrations of analyzer range changes, seal-oil protections, and field installations. Operations, I&C, and safety departments are encouraged to review the recording together and discuss how similar improvements could be applied to their own generators.

Williams and Justice concluded that automation does not replace skilled people; it enables them to perform a critical safety task with consistency and confidence.