The Energy Information Administration reports that US electricity demand will increase by 25% within five years, requiring a significant increase in generating capacity, upgrades to existing assets, and improvements to grid infrastructure. But that’s only part of the solution: Maintaining the current fleet of generation assets in top condition is vital to meeting projected demand.

The editors caught up with Dürr Universal’s maintenance experts at a recent user-group vendor fair where discussion focused on the important role of gas turbines in balancing both current and future electric needs. The Dürr team noted that, in their experience, air inlet systems are among the most overlooked components in gas-turbine inspections.

This could be considered penny wise and pound foolish given that a well-maintained inlet system supports high turbine availability and efficiency while preventing costly downtime and equipment degradation. One of the most critical aspects of maintaining these systems, the Dürr experts said, is protecting against corrosion and coating failures.

Recall that the GT air inlet system typically has these five main sections:

- Dirty-air side, where unfiltered air enters.

- Clean-air side, where filtered and conditioned air moves toward the turbine.

- Conditioning system, if installed, may include evaporative cooling or fogging.

- Inlet plenum and silencer, which manage air flow to the turbine.

- Turbine inlet transition section, to ensure smooth air flow into the compressor.

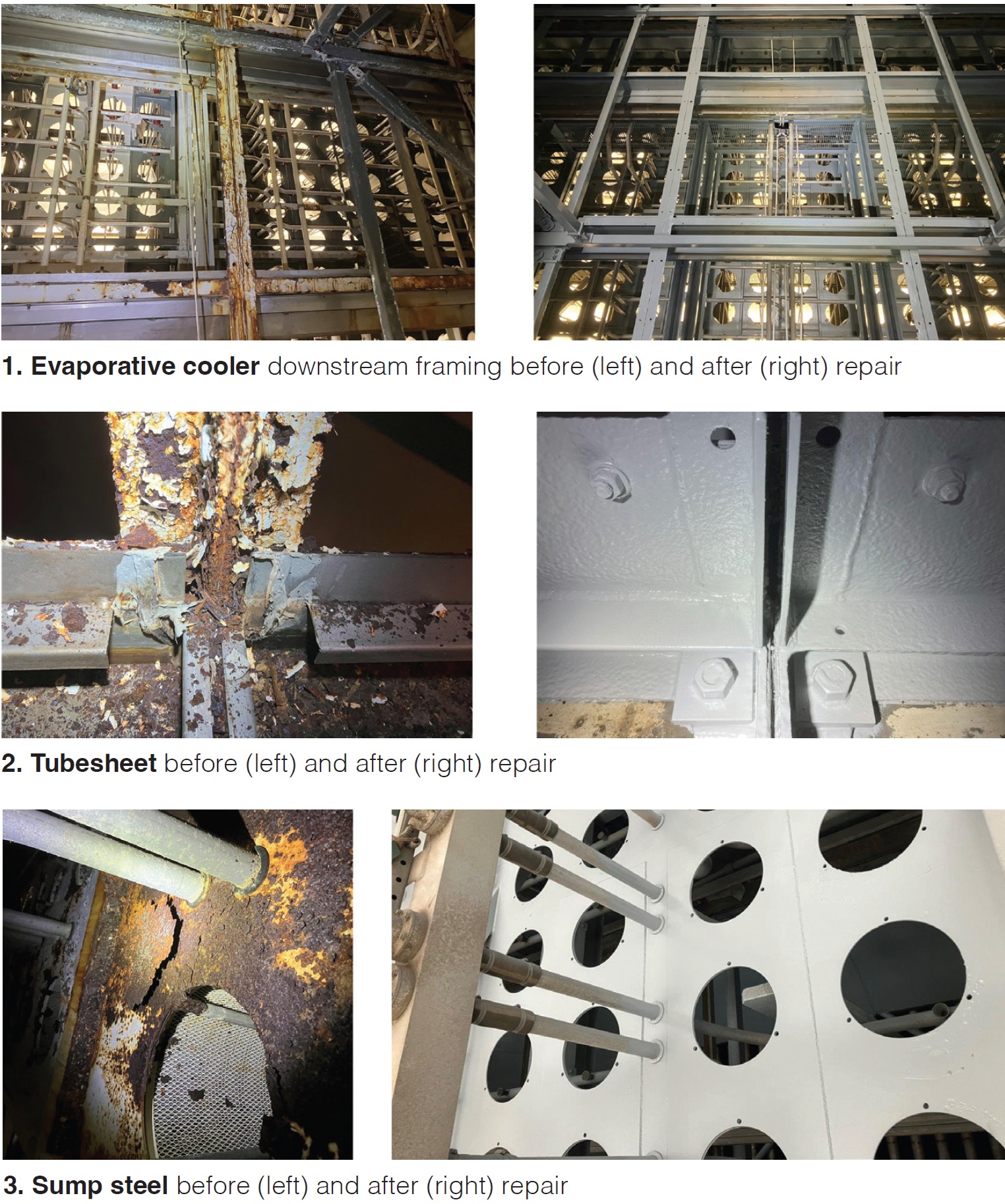

Also, remember that most turbine inlet systems are constructed using coated carbon steel. Over time, these components can degrade, leading to rust, chipping paint, and metal deterioration. And when such debris enters the clean air stream it can affect critical components within the turbine proper.

Corrosion in GT inlets is particularly common in humid climates. Systems with evaporative coolers or fogging systems introduce humidity, increasing the likelihood of corrosion—especially if coated surfaces are not properly maintained or if the conditioning equipment is not operated correctly. Exposure to corrosive cleaning agents can also damage coated surfaces and accelerate metal degradation. Once coating systems fail, the exposed steel surfaces become vulnerable, resulting in increased maintenance costs and reduced performance.

To mitigate these risks, the Dürr Universal team recommends the following best practices:

- Regular inspections and maintenance. Conduct annual inspections to identify coating failures early, preventing minor issues from escalating into major repairs. Early detection of rust, peeling paint, and/or structural weaknesses allows for timely intervention and cost saving.

- Proper surface preparation. Before applying new coatings, ensure surfaces are thoroughly prepared to maximize coating adhesion and longevity.

- High-performance coating systems. Use industry-approved multi-layer systems—such as zinc primers, epoxy intermediates, and polyurethane topcoats—for long-term durability and resistance to harsh environments.

- Filtration system maintenance. Effective inlet filtration prevents contaminants from entering the turbine, reducing the risk of corrosion and fouling. A well-maintained filtration system not only prolongs coating life but also minimizes recoverable and non-recoverable degradation.

Investing in preventive maintenance and proper coating systems significantly reduces long-term expenses. Recoating a surface is far more economical than replacing steel structures compromised by extensive corrosion. Additionally, well-maintained coatings help improve efficiency, reduce downtime, and extend the lifespan of gas-turbine components.

As gas-turbine assets are called upon to operate longer and more frequently, it’s more important than ever to partner with inlet system experts. Professionals providing comprehensive inspections, maintenance recommendations, and high-quality coating systems ensure your equipment remains in peak condition. They can tailor solutions for all inlet designs, focusing on local and environmental exposures to keep your units operating while minimizing downtime. CCJ