Increasing demand from data centers and extreme weather continues to push utilities and independent producers to find dispatchable megawatts fast. New-build capacity is on order, but lead times stretch years.

For owners of GE Vernova 7F units, one of the largest installed gas turbine fleets in the world, the near-term opportunity lies in upgrading the machines already in service. Two recent GE Vernova webinars outline complementary paths: a performance leap with the 7F.04-200 upgrade, and a package of reliability solutions addressing the most common trip and start challenges identified across three decades of operation.

The F-class fleet has logged more than 1.6 million starts across more than 1,350 units worldwide. That volume provides a rich dataset on what limits availability, efficiency, and start reliability. Upgrading and hardening existing 7F (and 9F) units can add capacity within months instead of years, helping balance renewables and meet near-term peak demand.

Welcome to the advanced class

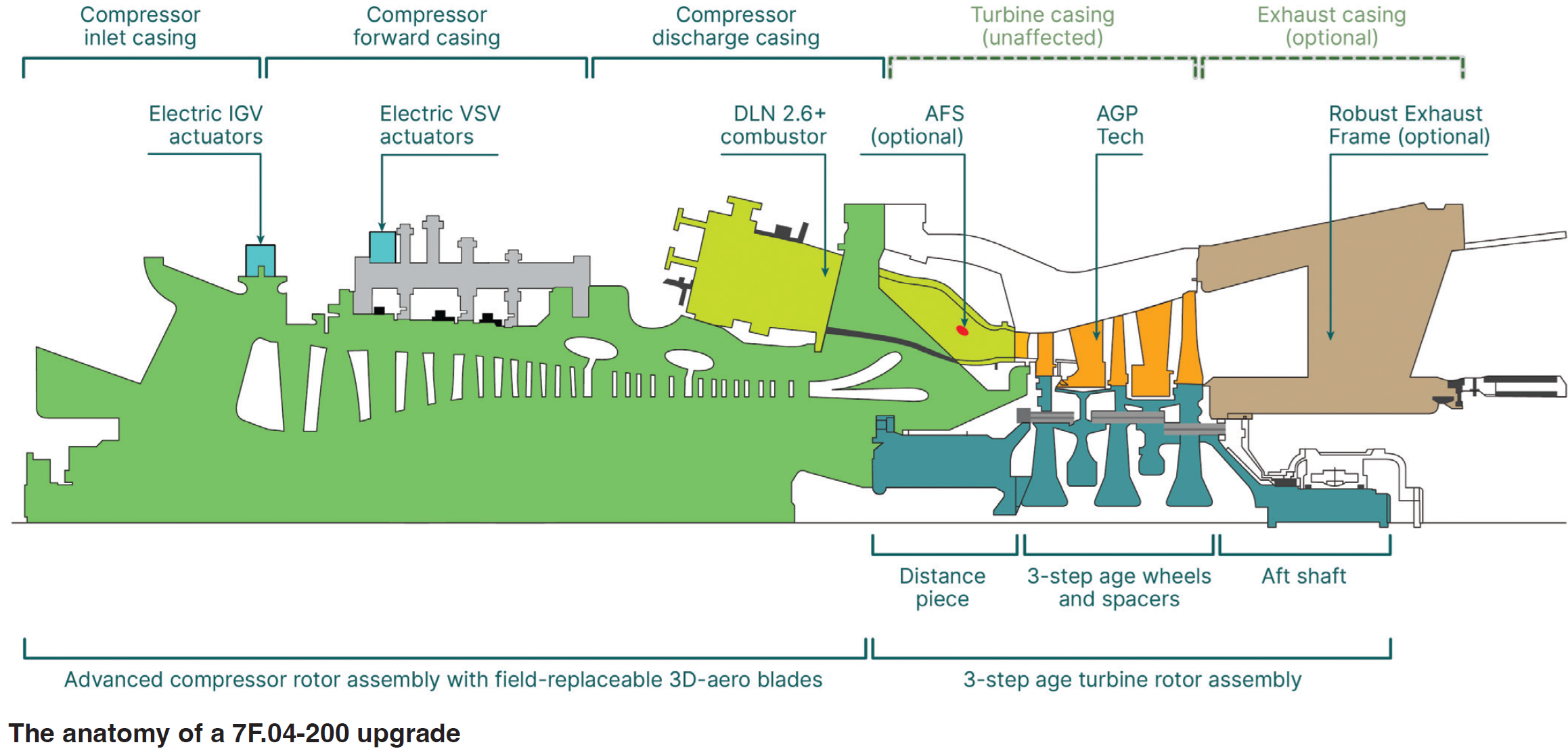

7F upgrades sales leader Robert Campbell and 7F product manager Jason Shaffer described the 7F.04-200 upgrade as a coordinated set of advancements across the compressor, combustion, and turbine sections. These upgrades extract more output, reduce heat rate, and expand turndown without changing the basic machine footprint. The scope also modernizes actuation and controls, enhancing part-load flexibility and simplifying maintenance. Access “7F.04-200” to watch the presentation and Q&A session.

The compressor upgrade introduces a new 14-stage configuration with redesigned inlet and casing, and field-replaceable blades. GE Vernova reports up to about 16% additional hot-day output and a ~3% heat-rate improvement. Electric variable-guide-vane actuation replaces hydraulics, enhancing reliability and reducing maintenance.

In the combustor, the DLN 2.6+ system with updated fuel nozzles and liners maintains 9/9 ppm NOx/CO compliance while extending turndown to roughly 25% of baseload with Axial Fuel Staging. The upgrade replaces legacy hydraulic valves with electric gas control valves, reducing leak points and enhancing response.

The AGP hot-gas-path kit brings advanced-material buckets, nozzles, and shrouds that raise gas turbine output by as much as 12% and enhance cooling effectiveness. A more robust rotor material further strengthens the platform for higher output and longer life.

Controls are modernized to Mark VIe with integrated BOP signaling and diagnostic capability. Across the fleet, GE Vernova cites gains of about 46 MW on hot days and 32 MW on cold days from a 7F.03 baseline.

CCGT output boost

HRSG and steam turbine upgrades sales leader Jason Bowers emphasized that more gas-turbine exhaust energy must be matched by downstream capabilities. Before committing to a performance upgrade, owners should conduct a balance of plant (BOP) impact study to evaluate plant limitations such as HRSG pressure-part limits, steam-valve sizing, pump capacity, and generator ratings.

Pairing the gas-turbine scope with an Advanced Steam Path (ASP) upgrade often multiplies the combined-cycle benefit. ASP enhancements to blade and seal configurations can add roughly 2% more output and nearly 0.7% combined cycle heat-rate improvement from the steam turbine alone. When combined with the gas turbine uprate and additional exhaust energy, plants have reported greater than 10% more output from the bottoming cycle.

Lead times for the upgrade are about 30 months from engineering release to site delivery, with on-site installation typically completed within a 45-day major-inspection window. As of mid-2025, GE Vernova has completed upgrades in more than 30 units, totaling about 1.4 million operating hours and 25,000 starts. Aligning the project with rotor maintenance or life-extension intervals helps contain outage time and cost.

Reliability enhancements: lessons from 91 million hours

Complementing the performance program, Mohamed Sayed, Houssem Zoghmar, and Noora AlAmiri reviewed recurring reliability challenges across the 7F and 9F fleet and offered practical solutions that can be completed in a single outage. The trio of engineers focuses on four areas that repeatedly drive forced outages and failed starts: flame-detection systems, exhaust thermocouples, compressor bleed valves, and control-system logic. Access “F-class Reliability Solutions” to view the recording.

Flame detectors. Cooling-water leaks and sensor drift in legacy flame scanners cause nuisance trips and maintenance challenges. GE Vernova’s software-based Non-Optical Flame Detection (NOFD) removes the UV/IR hardware entirely by using pressure and combustion dynamics algorithms within the Mark VIe system. The modification can be performed in a weekend-length outage.

For sites preferring hardware replacement, the company offers a robust dry flame detector with fiber-optic probes and remote electronics, typically installed within one week and compatible with multiple control architectures.

Exhaust thermocouples. False high exhaust spreads are often traced to vibration-fatigued thermocouples or worn connectors. New thermocouples, adopted from HA technology, feature thicker sheaths, stiffer probes, and simplified junctions—roughly half the number of replaceable parts—reducing noise and enhancing accuracy. Fleet data show more than 100 installations with significantly lower false-trip rates.

Compressor bleed valves (CBV). Sticking bleed valves are another common trip source, caused by corrosion, weak springs, and degraded solenoids. The stainless-steel CBV package replaces vulnerable components, adds limit switches, and updates control logic. GE Vernova estimates over 100 unplanned outages have been prevented in the past five years through this modification alone.

Control-system and sensor hygiene. Many dynamics or scanner alarms stem from wiring and logic aging rather than true combustion challenges. Modernized control logic prioritizes safety and diagnostic transparency, using triple-modular-redundant voting on critical signals so a single-sensor failure results in an alarm rather than a trip.

Planning a coordinated approach

Sayed advised owners to bundle reliability scopes within their next scheduled inspection to reduce downtime. Completing scanner modernization, thermocouple replacement, and CBV upgrades together delivers a noticeable reduction in start-related delays and unplanned maintenance.

With those reliability gains in place, plants can then plan for the larger 7F.04-200 performance scope during the next major inspection, preceded by a BOP study to confirm steam-cycle readiness.

Access the on-demand webinars for detailed scope definitions, fleet applicability, and lead-time guidance.