The “Diaphragm Dishing Issues” presentation by Steampath Engineer Jeff Newton in MD&A’s Spring 2021 Webinar Series (February 18) addressed permanent axial distortion of steam-turbine diaphragms, commonly known as dishing. The effect is usually caused by deficiencies in main weld depths, weld materials, welding processes and/or steampath design with the maximum movement at the horizontal joint where the diaphragm is weakest, according to Newton.

Unless you are already an expert on steam-turbine condition, you’ll want to see the photos shown during the presentation to get a good sense of dishing (not to be confused with thermal distortion) indicators, including: outer-ring distortion, evidence of main structural weld failure, reduced axial clearance at inner setback face, rubbing, packing high teeth out of location, horizontal-joint gaps larger on the discharge side, and packing bore diameters larger on the discharge side.

If you think you have a weld failure, get a second opinion quickly; that will require immediate repair, says Newton.

Steam turbines of 1950s to mid-1960s vintage typically experience the worst dishing in the third reheat stage. That’s because it is the highest-temperature stage with carbon steel used as the seal weld material between the partitions and spacer bands, notes the steampath engineer. The condition is more prevalent after 40 years of operation; the expected design life of turbines from that vintage was 30 years. There also was a better pool of data because steam turbines underwent major inspections and outages every five or six years.

However, it is important to note none of the diaphragms from this time period actually failed, stresses Newton.

Things get dicier beginning in the 1990s. At least one manufacturer began to replace submerged arc welding in these areas with electron beam and MIG welding, which led to less consistency in weld quality; the CrMoV (chromium, molybdenum, vanadium) metallurgy was changed to just CrMo; dense-pack designs led to more stages with less axial space; and diaphragms were not as thick. Main weld depths as a percentage of partition axial height also were reduced. Furthermore, the time between major outages was extended to more than 10 years.

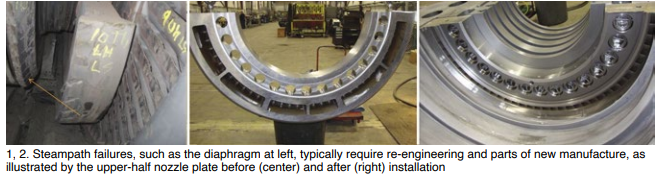

These units have experienced diaphragm failures (Fig 1). One Toshiba unit failed within five years at the first IP stage. In fact, the three examples Newton reviews are all Toshiba. A second unit also failed at the first IP stage; bucket and rotor material were found missing at disassembly.

Three of the ways to proceed if you have evidence of dishing are do nothing and monitor, install offset packing rings, and/or shift the diaphragm upstream with a steam seal face insert. However, Newton stresses, these do not address the cause of the dishing. The component has to be reconstructed, or reverse engineered with design changes to address the cause (Fig 2). Newton illustrates this for users with a photo montage sequence that drives home the as-found versus repair comparison.