End users have long treated API 653 tank inspections as necessary pain from challenges associated with fuel handling, confined-space entry, outage coordination, and weeks of operational uncertainty. A recent Electric Power Research Institute (EPRI) Incubatenergy Labs demonstration with Tennessee Valley Authority (TVA) shows there’s a safer, faster path: submersible, autonomous robots that perform phased-array UT while tanks stay online.

The system, developed by Square Robot (Westborough, Mass), was deployed on four TVA tanks across two sites to test coverage, data quality, and real-world logistics against traditional out-of-service (OOS) methods.

Why it matters

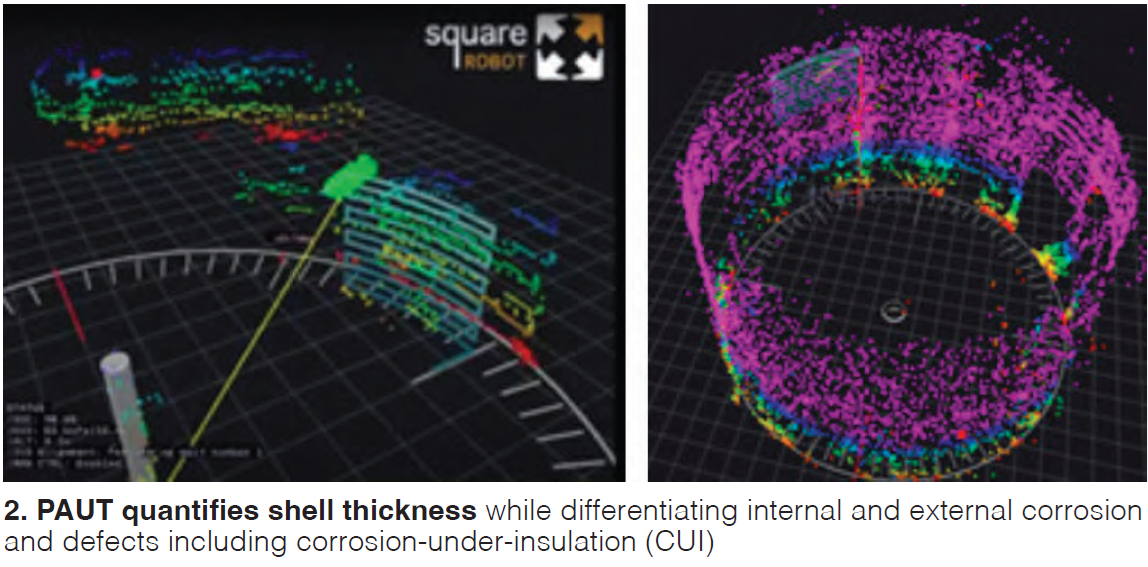

- Eliminate OOS disruptions. Robots inspect from inside the product, avoiding drain/clean/vent cycles that drive outage days and safety exposure. The platform uses proprietary navigation plus 256-element PAUT to image bottom plates, size corrosion on product and soil sides, measure coatings/linings, and track settlement patterns—with location accuracy to roughly six inches.

- Shift inspections from “project” to “activity.” Keeping tanks in service simplifies staffing, trucking, and back-up fuel planning, while preserving plant flexibility during peak or contingency periods.

Fuel oil tank results

At TVA’s Marshall Combustion Turbine site, three identical 62-ft tanks (~1,000,000 gal each) were inspected robotically in 3.5 days total—versus weeks to a month per tank for OOS. Coverage averaged ~60% of the bottoms, with ~100 GB of PAUT data per tank; by comparison, the previous OOS effort collected 28 single-point UT readings across a bottom, orders of magnitude less information.

Operational and safety impacts were equally material:

- ~6 tons of CO₂ avoided by not venting/draining.

- ~850 confined-space hours eliminated, plus no need for dedicated personnel to supervise those entries.

- Zero fuel trucking: TVA estimated OOS would have required ~130 truck movements per tank, with potential loss of a half-day of plant operations if fuel was needed mid-inspection.

Firewater tank results

At the Magnolia CCGT site, the robot tackled a 92-ft firewater tank—bolted floor, significant sediment, and flows observed up to 5,500 gpm. Compared to a prior robotic crawler (63-element spot UT) that could reach only a single plate due to bolt obstructions, the submersible robot delivered >10× the data, touching ~90+ plates, and achieved ~10% bottom coverage in ~3 days—while coordinating flow adjustments with plant staff (targeting ≤2,500 gpm during key passes).

For planning purposes, TVA estimated that a conventional OOS path here would have meant ~500 confined-space hours. API 653 reports were issued within 2-4 weeks; Marshall’s fuel tanks received 20-year intervals, while Magnolia’s firewater tank, given lower coverage and minimum thickness, received a 5.47-year extension.

Program-level takeaways

TVA’s technology scout characterized the shift succinctly: inspections proceeded while operations continued, changing how the utility thinks about tank programs going forward.

From the lab vantage point, the demonstration confirms that in-service robotics can reduce safety exposure, improve data density, and enable smarter interval decisions—without tying up people and equipment in lengthy tank outages. Project notes highlight potential six-figure cost savings, reallocation of project-management hours, and the ability to prioritize scarce outage windows for higher-value work.

Square Robot reports over 300 tanks inspected across eight countries, with 190k confined-space hours eliminated and 600k lb emissions contained.

What to look for, how to react

- Asset mix. Firewater vs fuel oil will drive coverage expectations, hydraulics coordination, and interval outcomes; Magnolia’s lower coverage still yielded a meaningful extension.

- Data density. Moving from “dozens of spot UTs” to hundreds of gigabytes of PAUT creates richer corrosion mapping and settlement insights, useful for RBI models and capital planning.

- Safety accounting. Quantify avoided entries up front; TVA’s experience shows the scale—hundreds of hours—is non-trivial for staffing and contractor budgeting.

- Fuel logistics. If your OOS plan includes significant transfer/hauling, model the operational risk case; TVA’s estimate of ~130 trucks/tank underscores schedule and HSE exposure otherwise.

Bottom line

For owner/operators, submersible robotic inspections convert a high-risk, high-disruption task into a short, in-service activity that yields better data, safer work, and more predictable schedules. TVA’s results provide a credible blueprint: compress inspection timelines from weeks to days, eliminate large blocks of confined-space work and trucking, and make interval calls on evidence not guesswork.