The eleventh annual European HRSG Forum (EHF2025), held May 13–15 in Prato, Italy, drew 95 participants from 20 countries. Co-chaired by Barry Dooley of Structural Integrity and Bob Anderson of Competitive Power Resources, EHF2025 continued its mission of advancing best practices and global knowledge-sharing in combined-cycle and HRSG operations.

The event, organized by Mecca Concepts (Australia), is supported by IAPWS and held in association with HRSG Forum (US), Australasian Boiler and HRSG Forum in Brisbane (ABHUG), and the recently-launched HRSG Forum América Latina in São Paulo, Brazil.

EHF2025 offered 23 technical presentations, including a workshop on cycle chemistry, and featured strong international representation across plant operators, OEMs, engineers, consultants, and vendors. Seventeen sponsors supported the event: Precision Iceblast Corp, NEM, Dekomte, Freudenberg Flow Technologies, TÜV Rheinland, New Componit, Advanced Valve Solutions, Tuff Tube Transition, TesTex, Quest Integrity, Metroscope, OMB, Pruss, Fuel Tech, Arnold Group, IMI, and Thermic Systems.

Save the Dates. EHF2026 returns to Prato, Italy, May 19–21, 2026. Bookmark the website and check for registration and participation updates: www.europeanhrsgforum.com.

Global priorities

A consistent theme across presentations: reliable, flexible operation of aging HRSGs remains a top concern for users worldwide. Daily cycling, faster startups, and deeper turndowns are placing growing stress on pressure parts and internal components, especially in:

- Superheaters and reheaters (creep and fatigue failures).

- HP evaporators (flow-accelerated corrosion and under-deposit corrosion).

While pressure-part upgrades using modern materials are often proposed, many operators find these investments difficult to justify amid long-term plant uncertainty.

Codes and compliance

The European Pressure Equipment Directive (PED) was highlighted, especially in Germany, where HRSGs must meet stricter design and compliance requirements beyond ASME code.

Alexander Bibow, TÜV Rheinland, addressed these differences in his presentation New generation of H2-ready power plants in Germany. He noted that ASME can be used as a product standard within the scope of PED, but ASME on its own is not fully in line with certain safety requirements of the PED 2014/68/EU. “Additional requirements are mandated and must be verified,” he said. He added that these details are not easily determined. He also referenced requirements of NFPA International to highlight overall complexity.

Bibow discussed allowable stresses, material certification, welding procedures, essential task analysis and safety requirements of PED, testing methods, and variations in inspection periods.

His ultimate motivation was design developments for H2 applications.

He stressed that original ASME design philosophy focused on base-load power stations before the influx of load cycling and some operational issues including corrosion, erosion, and fatigue. This leads to current-day complications on welding and NDT approvals, risk analyses, and testing/operating instructions. He ended with discussions on inspection schedule variations.

H2 readiness analysis, he summarized, requires details in engineering, design and materials, explosion protection, operational safety, emissions awareness, organizational awareness, and corporate support.

Tube failures

HRSG tube failures (HTFs) continue to dominate reliability discussions worldwide. Key takeaways from EHF2025 include:

- Only 8% of plants globally have a formal HTF reduction program in place.

- Successful reduction programs require top-down commitment and cross-functional involvement.

- New templates and benchmarking tools for tube failures, flow-accelerated corrosion (FAC) and cycle chemistry are available.

Root cause accuracy remains vital. Case studies emphasized the need for experienced metallurgists to avoid misdiagnosing the failure mechanisms. The correct determinations of fatigue, FAC, or under-deposit corrosion (UDC) are critical to prevent repeat events.

FAC again topped the list of tube failure mechanisms. Presenters detailed:

- The role of pH control in two-phase FAC.

- Importance of oxidizing power in preventing single-phase FAC

- The linkage between UDC and poor chemistry, often worsened by corrosion product transport.

Case studies included robotic waterside inspections that now allow access to upper headers for thickness readings. Efforts are underway to enable robotic internal deposit density measurement for HP evaporators.

Tube repair/replacement

Innovative repair methods, such as tube sleeves, are gaining traction as cost-effective, short- to mid-term solutions to extend unit life.

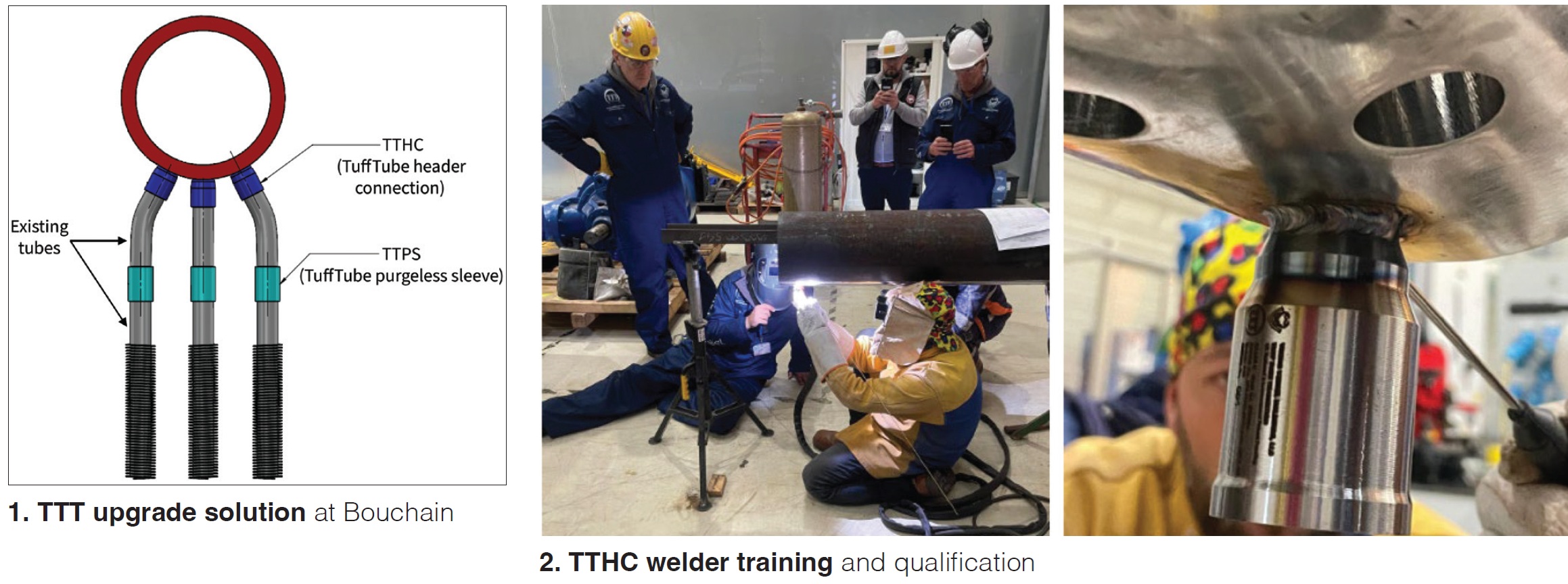

Guillaume Grognet, EDF France, presented Repair of inaccessible economizer: replacement of tube-to-header welds with reinforced sleeves.

The project: Bouchain CCGT in Lille, France, a 604 MW plant with 9HA.01 and D650 steam turbine, commissioned in 2016. The HRSG is a CMI horizontal design with reheat.

This HRSG experienced several technical issues since commissioning, primarily: HP interstage attemperator replacement, desuperheater/attemperator thermal liner cracks, DMW weld bead machining, drum manhole leaks, LP economizer fouling, HRSG inlet expansion joint failure, among others.

Grognet focused on the HP 4-1 economizer upgrade, a project undertaken after several tube leaks and forced outages. Root cause analysis showed that thermal fatigue lifetime had been reached after only seven years of operation.

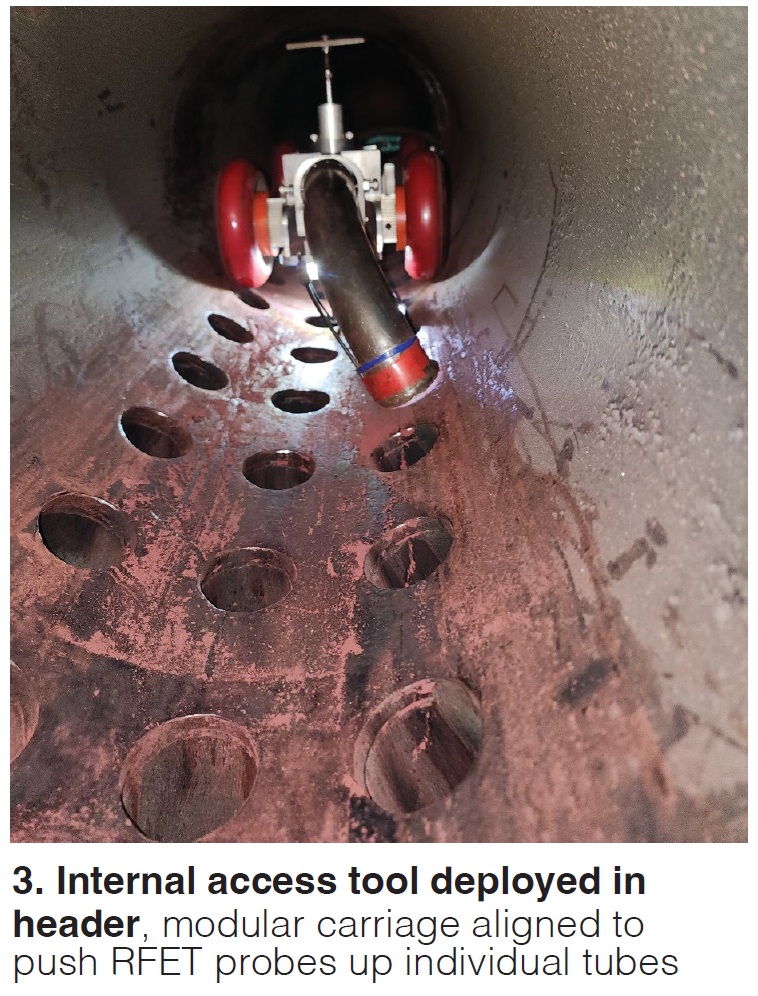

With the site down for unrelated extended maintenance, a window of opportunity presented itself for HRSG work, and Tuff Tube Transition (TTT) was selected for repairs on short order (Fig 1). Grognet walked through the steps of working alongside TTT’s Marcus Hutchinson for planning and implementation, stressing a compressed lead time, to complete over 200 upgraded, purgeless tube-to-header weld connections (TTHC).

After dealing with the ins and outs of accessing the bundle, a temporary hanging system was installed to lift the harp safely without modifying the original supports. Installation steps featured a dummy header for welder qualification (Fig 2), sequenced tube cutting one-third at a time to control stresses, TTHC fit-up and welding, followed by 100% PT and a hydrotest.

Post-work, EDF added tube temperature sensors and set a follow-up inspection plan to validate the fatigue relief. The reinforced sleeves provide a fast, engineered path to reduce local stresses, avoid a long replacement lead, and stabilize an economizer subjected to high cycling.

For a more detailed report, see Case studies on HP economizer tube leaks at Bouchain CCGT

Tube/header inspection

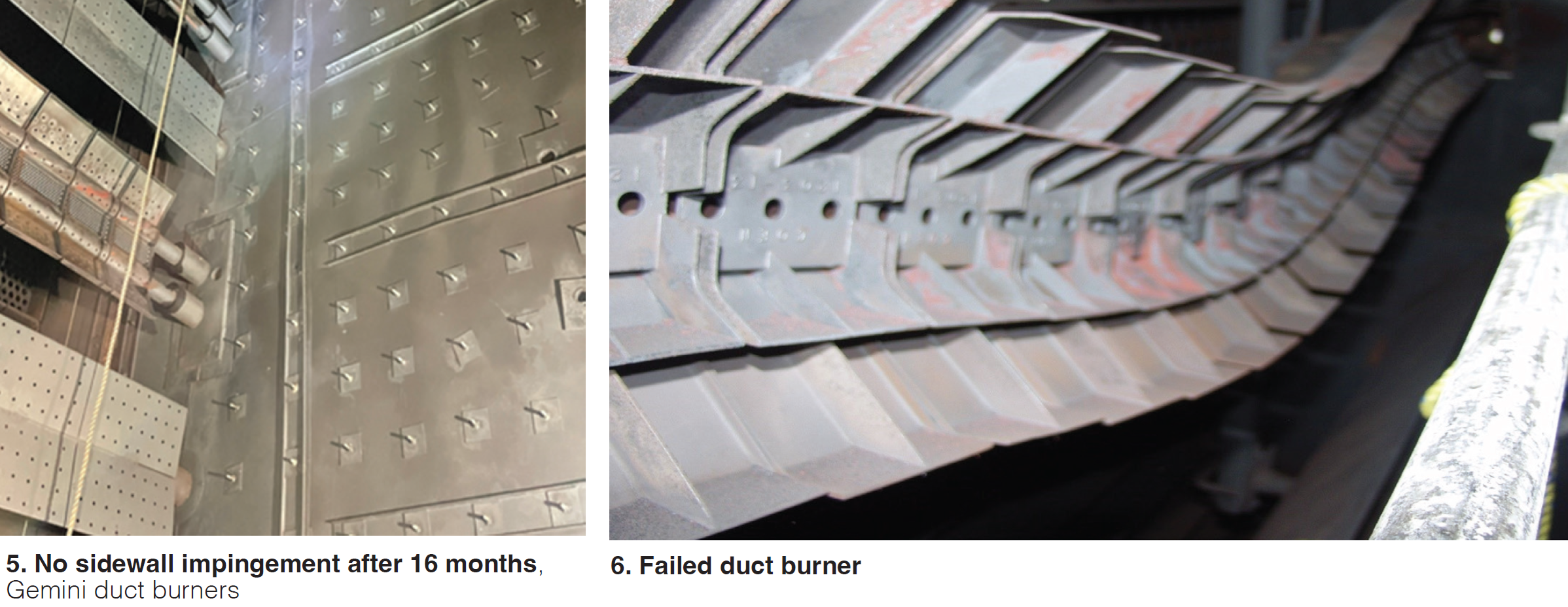

Shawn Gowatski, TesTex (US), presented an HRSG inspection update focused on faster coverage and better access to problem areas using electromagnetic techniques and purpose-built tooling. Highlights for cycling fleets and short outages:

- Finned tubes. External scans through fins to find pitting and wall thinning on evaporator and economizer tubes (Fig 3). Typical productivity about 1,250 linear feet per shift, with defect sizing by calibration standards.

- Tube-to-header welds. CLAW locates cracking around the full 360 degrees of the weld. Current heads cover common HRSG tube sizes and can examine up to about 150 welds in a shift. Modified “mini” heads and extension links improve reach in tight header nests.

- Internal Access Tool. Access via endcap removal or an 8-in header hole to push probes up individual tubes (Fig 3). Waveforms and video document localized FAC and pitting at multiple elevations. A crew can clear a header in 3 to 4 shifts when access is favorable.

- Case pattern. Internal inspections frequently show highest FAC near upper headers, with ranges from 20 to 65 percent wall loss on selected tubes. Video often correlates wall loss with deposit accumulations. Findings guide selective retube plans when full drum internals removal is not possible in a short outage.

- Development items. Ongoing work with EPRI includes methods to measure internal deposit thickness in HP evaporator tubes, downsized crawlers to detect tube-to-header weld cracking from inside small headers, and phased-array follow-up for the CLAW.

Fireside cleaning and plant performance

Gas-side fouling remains a primary performance issue for HRSGs. Two cleaning technologies received attention:

- Ice blasting.

- Pressure waves.

For HRSGs with badly fouled finned tubes, cleaning remains one of the fastest return-on-investment solutions for recovering generating capacity loss due to gas-side pressure drop. New developments in pressure wave cleaning were discussed, including improved performance when used while deposits are still hot, before moisture absorption increases adhesion.

Markus Bürgin, Bang & Clean Technologies AG, focused on Swiss innovation and technology for gas-path cleaning, beginning with PressureWave+ mobile cleaning in 2001. He covered developments and experience in Italy, the Benelux region, and France.

A recent innovative development, he noted, is CloudEx, a stationary installation designed for keeping a boiler clean. (Fig 4).

Special application of HRSG deep cleaning was also highlighted by Bürgin for two projects in Italy. One installation was a syngas-fueled 166 MW gas turbine, horizontal flow HRSG and 115 MW steam turbine. The project purpose was reduced backpressure and increased plant efficiency. The other was a 262 MW gas turbine, horizontal flow HRSG and 122 MW steam turbine, with similar goals and positive results.

Duct burners

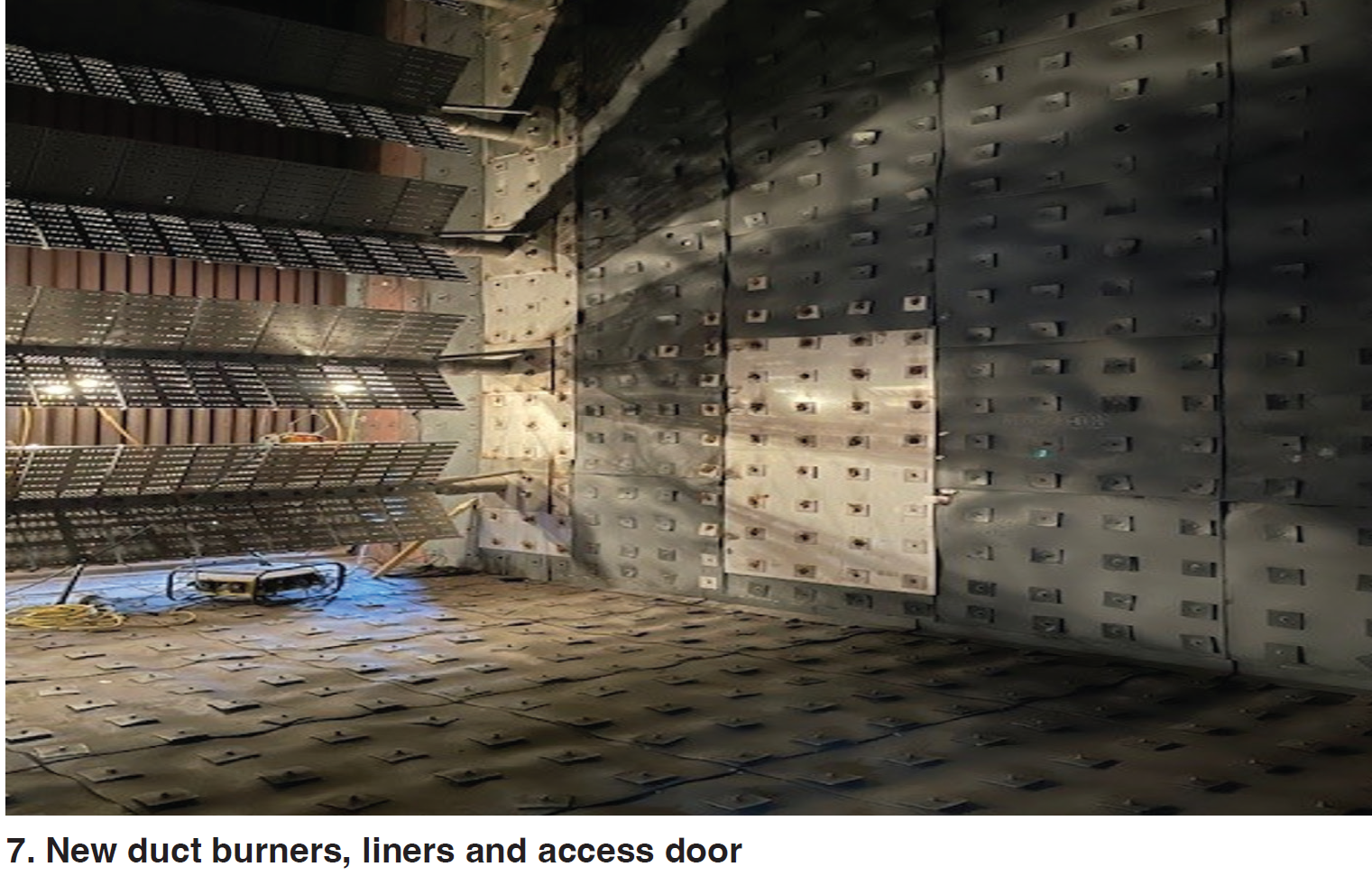

A new short-flame-length, self-supporting duct burner design was presented as a retrofit option for older HRSGs and a design advancement for new builds.

Scott Baumann, Thermic Systems, introduced the new Gemini tandem duct burner design featuring compact flames (50 percent shorter) to eliminate flame impingement on tubes and liners. These burners showed a 2.4 m flame length as opposed to the original 5.5 m length. Gemini burners and baffles had been installed on a unit and after 16 months run time there were no signs of side wall impingement (Fig 5).

Baumann discussed other innovations including an HRSG intelligent recirculation system to reduce dew point, innovations for rethinking dilution air thermal energy, optimizing ammonia vaporization, and examples of an induced-flow heat exchanger.

Bill Kitterman, SVI Bremco, offered two distinct projects for HRSG duct burner replacement.

One case was a Frame 5 modification from vertically fired to horizontally fired, including gas piping and controls.

He first showed the existing vertical system and existing piping system. Explaining access points, Kitterman then showed the horizontal arrangement during construction.

Next was a 7FA HRSG retrofit involving runner replacement (Fig 6) as well as small piping (ignitor, etc.). The unit had also suffered severe liner damage.

Scope included removing existing burner runners and header and modifying support sleeves.

New burners were then installed, piping was replaced, and new liners were secured (Fig 7).

The project was completed in 14 days (28 shifts).

Cycle chemistry

Barry Dooley presented global chemistry benchmarking results and the latest IAPWS guidance. New data show:

- 86% of plants lack effective corrosion product monitoring.

- 80% operate with substandard instrumentation.

- 78% do not monitor drum carryover.

- 73% do not question legacy chemistry practices.

A new IAPWS decay map and corrosion product monitoring procedure now allow operators to evaluate the effectiveness of chemistry during operation and shutdown. For more on this, see Corrosion monitoring in flexible and fast-starting plants

Updates on film-forming substances (FFS) noted some key status items:

- Documented reductions in corrosion product transport in water-touched circuits.

- Limited or questionable protection in steam circuits.

- Risk of under-deposit corrosion and “gunk” formation when pre-application steps are skipped.

- Reports of increased HP evaporator fouling and deposit load when FFS are misapplied.

Attendees also received updates on IAPWS Technical Guidance Documents (TGDs) for combined-cycle plants.

Kenneth Hutchinson, GE Vernova, presented Water chemistry: GE Vernova’s once-through HRSG vs. drum HRSG. He first walked through features of the two designs, noting the same arrangement but without the HP drum for the once-through unit.

This led to a detailed discussion comparing the HP steam purity of GEV’s once-through and drum HRSGs during startup and continuous operation, and methods of controlling HP steam purity.

He offered a case study of various operating plants during the first decade of commercial operation. Details of startup and long-term operating reliability were reviewed.

His conclusions:

- Steam purity – both drum and once-through HRSGs have comparable performance and consistently achieve degassed cation conductivity (DCC) values below 0.2 µS/cm.

- Startup performance – DCC decay time during startup is within specifications for both HRSG types.

- Operational efficiency – The enhancements done on plants for limiting impurity ingress during operation and standstill maintain healthy chemistry for both startup and long-term operations.

For more on this, see OT vs drum HRSGs: Selecting the right design for operational flexibility

Transients, layup risks, and valves

Thermal transients continue to drive operational issues. The latest data, based on Bob Anderson’s thermal transient surveys of 73 CCGT plants worldwide, shows:

- 85% of plants experience leaking spray water at attemperators.

- 92% use valve logic that encourages leaks.

- 37% report overspray, 30% allow manual control, and just 20% routinely inspect attemperators.

- Only 38 to 40% effectively drain the HPSH/RH during startup.

Two HRSG layup failure scenarios were flagged for potential safety impact:

- Leaking or open cold/hot reheat isolation valves, intermediate-pressure superheater (IPSH), or leaking high-pressure bypass pressure control valve on a non-operating HRSG during 2×1 operation can allow steam from the operating unit, IPSH, or HP drum to enter and flood the reheater. If undetected, this condition may lead to water hammer or even steam turbine water induction during restart. Installing an alarm to detect positive pressure in a non-operating reheater can provide critical early warning.

- During hot layup, normal condensation in the high-pressure superheater (HPSH) can accumulate at the bottom of certain harps, forming a loop seal. This trapped water can migrate upward into hot headers and pipework, posing a risk during startup if not properly drained. A differential pressure alarm between the HPSH outlet and HP drum can help detect this condition and prevent damage.

Valve-specific sessions covered high-temperature gate, globe, and check valves, of main steam stops, bypass pressure control valve selection, and the benefits of combination stop/check valves.

Paolo Tomaini, OMB Valves, Italy, discussed How to specify reliable gate, globe and check valves for 1050F and above (P91 and P92 steam lines).

He began with the impact of valve failures:

- Reduced heat rate due to steam leaking.

- Longer startup due to leaking or improper open/close functions.

- Increased maintenance requirements to monitor and repair.

- Forced shutdowns due to safety-related issues on pressure containment.

- Financial loss due to poor performance and reduced plant availability.

Tomaini covered key features and benefits of gate valves, globe valves, check valves (swing and tilting), material selection, and hard-facing issues which are becoming more prominent.

His conclusions included the importance of properly specifying valve features and designs, proper material selection, and reliance on suppliers with proven expertise.

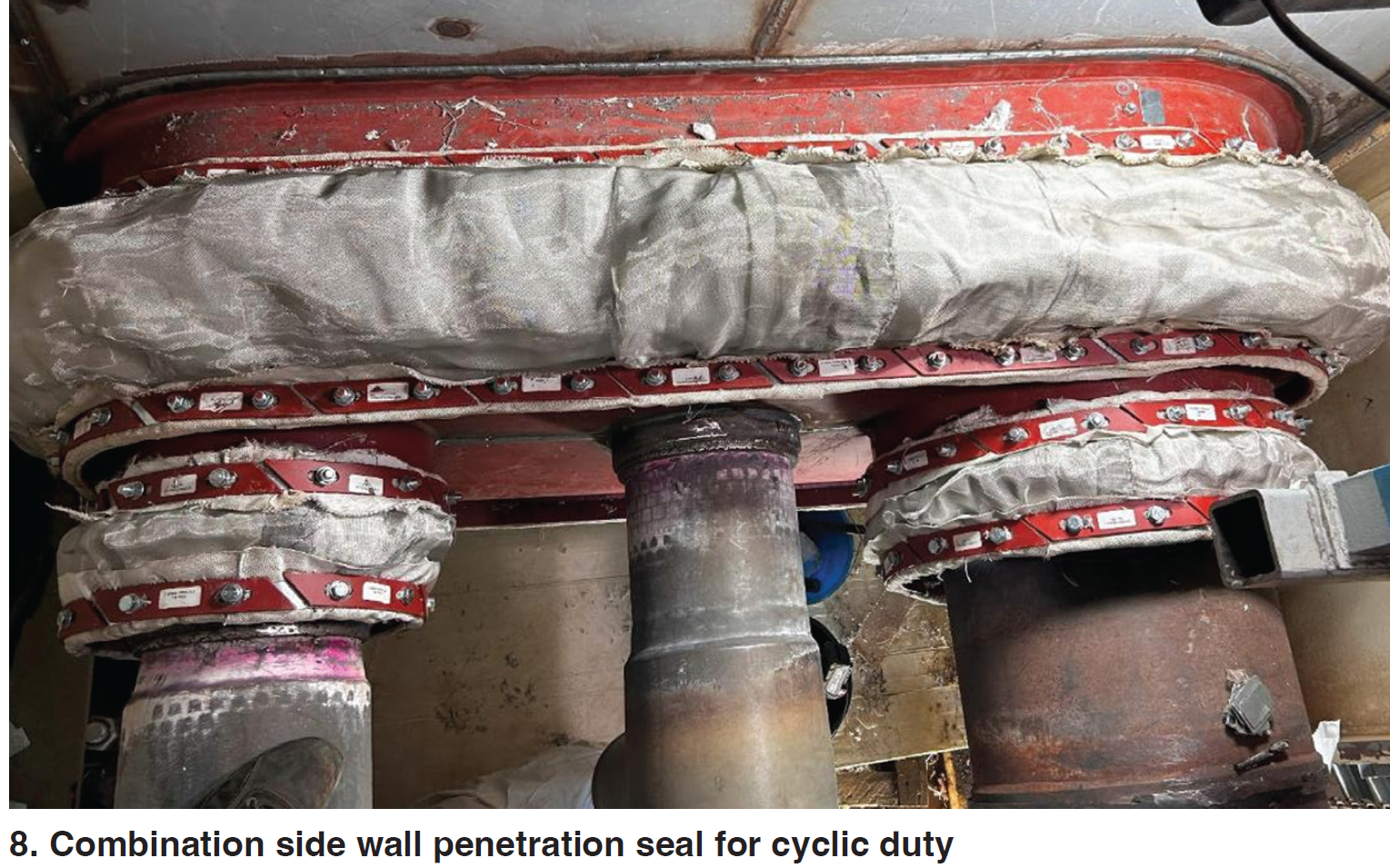

Penetration seals

Jake Waterhouse, Dekomte (UK), focused on how penetration seals and GT exhaust joints can be specified and installed for high-cycling service common at CCGT plants. The target is gas tightness, stable metal temperatures, and predictable life under frequent starts and load swings.

- Cycling classes were shown from baseload to very high cycling, with design validation using transient temperature data and analysis. Field experience indicates low fatigue usage when frames are kept at even temperature and internal flow shields calm the hot gas stream.

- Typical leaf flex seals struggle in cycling duty. Foil layers can crease, crack, and leak, and the many small parts complicate maintenance near sensitive equipment.

- Replacement concept: formed multi-layer fabric with PTFE membranes, insulated frames, and internal flow shields. The package is aimed at reducing leakage, lowering casing temperature, and shortening outage time.

- For HRSG side wall penetrations, split steel collars and fabric bolsters allow replacement without post-weld heat treatment. This supports fast installs during short cycling outages and simpler future maintenance (Fig 8).

In practice, cyclic service drives larger relative movements and thermal gradients at side wall nozzles. A combination approach was highlighted: renew casing insulation, cap and shield the liner around the nozzle, and use a staggered fabric penetration seal to limit gas circulation inside the seal cavity. Early surveys at a reference site showed low fabric and casing temperatures after one year of cycling.

- Operator notes for cycling fleets:

- Trigger a retrofit plan when there are persistent gas leaks, paint discoloration or hot spots at penetrations, frequent repacking, or degraded insulation.

- During the outage, specify internal flow shields, confirm insulation details around the nozzle, and use bolted collars where feasible.

- After return to service, trend start counts and verify low frame and casing temperatures, then plan a mid-life inspection of fabric layers and pillows at about five years for high-cycling units.

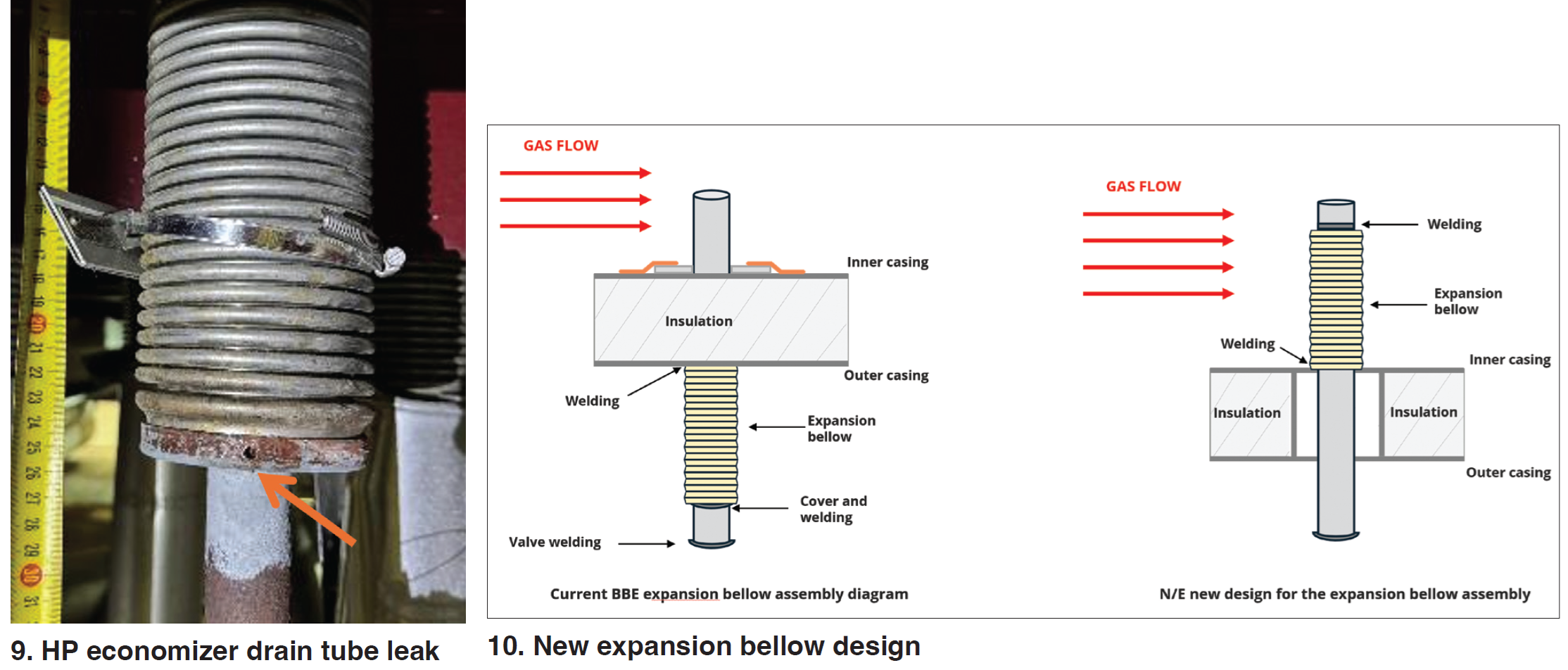

Drains

Sergio Gómez, Bahia de Bizkaia Electricidad (BBE), Spain, addressed Problems and solutions in economizer drains. BBE is an independent power plant operational since 2003, near Bilbao. This 800 MW plant features two GE 9FA+3 type gas turbines and one D11 type steam turbine. The plant is now experiencing fewer operating hours and more starts annually.

The two HRSGs are Nooter/Eriksen design manufactured by Babcock Wilcox Española.

In a case study, water below the boiler was difficult to trace. The leak was in a drain tube of the HP economizer, in the area enclosed by the expansion bellow (Fig 9).

The solution is shown in Fig 10.

Lifetime assessment

Tom Popov, Wien Energie, Austria, presented Lifetime extension of combined heat and power plants by performing life assessments.

He discussed a natural gas/oil fired Benson unit commissioned in 1992, with planned end of life in 2030. This plant is operated primarily during the cold season to supply Vienna’s district heating.

Popov focused on plant operator experiences with lifetime assessments (LTA) to extend plant operating life. Program features included long-term employees with plant knowledge, careful review of plant documentation and history, and risk-based classification of plant subsystems based on plant availability and safety. These factors were used to set priorities for any required actions.

Lifetime assessment (LTA) was used to obtain “more profound knowledge of the condition of key components for which the already accessible information was not sufficient.”

“Some previous inspections,” he added, “did not provide a full picture of the conditions.”

The plant took a “practical rather than theoretical LTA approach,” he explained. Key elements included:

- Thorough non-destructive examination of the boiler.

- Visual and remote visual inspections.

- Wet fluorescent magnetic testing.

- Replica examination.

- Hardness testing.

- Creep or fatigue calculations were not included.

- Consideration of historical operating and service data.

LTA execution was within a tight framework of five weeks.

Results showed that despite operational changes (decreasing operating hours), lifetime extension beyond the initially planned end of life is possible. “Use of auxiliary steam will be used to keep the boiler under slight overpressure during standstill hours,” he stated.

Rounding it out

Throughout this event, details and in-depth discussions on thermal transients and water chemistry issues were led by Bob Anderson and Barry Dooley.

Specific presentations not named above are listed below:

- HRSG tube failure reduction program, Stan Rosinski, EPRI (US).

- Gas turbine SCR in a changing world, Karolyn Hagan, Cormetech (US).

- Re-life on main steam stop valve, Graham Murray, Altrad Babcock (UK).

- Specifying replacement bypass valves, Ory Selzer, IMI-CCI (US).

- Innovative bypass systems, Pascal Ebbeler, NEM Energy (Germany).

- Persta combined stop check valve, Khalid Achbari, Advanced Valve Solutions (The Netherlands).

- Importance of reheater isolation and avoiding HPSH loop seal formation during layup, Anderson.

To close out the successful technical sessions, a conference dinner, hosted by Precision Ice Blast, was held at Conservatorio San Niccolò in the heart of Prato, offering delegates a scenic venue for informal exchange.

Looking ahead

The twelfth European HRSG Forum (EHF2026) will return to Prato, May 19–21, 2026. For information, contact Barry Dooley (bdooley@structint.com / bdooley@IAPWS.org) or Bob Anderson (anderson@competitivepower.us). Additional updates will be posted at www.europeanhrsgforum.com.