Owner/operators of 501F and 501G gas turbines co-located at Loews Ventana Canyon Resort in Tucson, Ariz, for their 2025 conferences this past February. For those looking forward to 2026, the meetings will take place from Feb 15-20 in Norfolk, Va at the Hilton Norfolk – The Main.

Sunday’s program featured social events for all attendees. The agenda for Monday—including a safety roundtable, vendor presentations (a/k/a Vendorama), reception, and vendor fair—also brought together the 501F and 501G Users Groups. The organizations met independently on Tuesday through Friday for technical presentations by users, services providers, and OEMs.

The technical meeting got underway after breakfast Monday with welcomes by the user-group chairs to the 106 registered owner/operators, acknowledgment of the 501F group’s 25th anniversary, steering-committee members, and conference sponsors.

Chairman Ivan Kush, who was key in nurturing the 501F group back to full strength after the “virtual” years, announced that long-time board member Brian Berkstresser of Liberty Utilities would assume leadership duties going forward. A review of the user website by Chad Boschert (AptCrowd) and conference instructions preceded the annual safety roundtable, which sets the tone for the event.

Half-hour vendor presentations began in mid-morning, arranged in seven sessions, with five presentations conducted in parallel during each session.

A busy first day ended with a vendor fair and reception from 4 pm until 7:30, giving owner/operators the opportunity to peruse the products and services offered by over 80 companies with interest in the 501F and 501G fleets.

501F Officers and Board of Directors

President and Chair of the Board

Brian Berkstresser, senior director of generation operations, Liberty Utilities

Vice Chair

Ivan Kush, principal CT and controls engineer, Cogentrix Energy Power Management

Secretary

Shane Short, O&M manager, Cleveland County, Southern Power

Board Members:

Blaine Gartner, principal engineer, Xcel Energy

Dave Gundry, senior engineer, fleet gas- and steam-turbine operations, Xcel Energy

Zach Wood, generation program manager, Duke Energy

Agenda highlights for the F frame’s portion of the 2025 joint meeting are summarized below. The program, developed and moderated by the steering committee, focuses on the operation, maintenance, inspection, troubleshooting, repair, and optimization of equipment in generating plants powered by 501F, 701F, and SGT6-5000 gas turbines made by Siemens Energy, Westinghouse, and Mitsubishi Power.

Tuesday: Outage execution roundtable and user presentations, Siemens Energy’s presentation to users, and Mitsubishi Power’s presentation to users.

Wednesday: Steam turbine, auxiliaries, and generator roundtables and user presentations, and PSM’s presentation to users.

Thursday: Auxiliaries, combustor, and compressor roundtables and user presentations.

Friday: HGP and rotor roundtables and user presentations.

USER-ONLY SESSIONS

The opening session centered on safety, communication, and workforce readiness across major field service providers, echoing the growing concerns of gas and steam turbine end users regardless of make or model. Users recounted several lifting and rigging incidents during recent outages, noting limited visibility and inconsistent sharing of safety lessons between sites. Many expressed concern that corrective actions are not being broadly communicated or applied across projects.

Attendees also discussed workforce experience and training gaps, citing more frequent use of less experienced field personnel and fewer veteran supervisors. Some crews reportedly lacked familiarity with standard safety practices and documentation requirements, leading to near-miss events. Participants emphasized the need to verify engineering approvals in writing and maintain clear communication throughout complex outage activities.

Conversation turned to risk management and outage planning, with users calling for stronger involvement in the OEM’s Rapid Risk Assessments and clearer documentation of engineering decisions made on site. The group urged more consistent processes, better feedback loops, and greater accountability in how OEMs share safety and procedural information across their fleets.

The session also explored the emerging role of artificial intelligence tools in plant operations and reliability analysis. Several users described pilot use of Microsoft Co-Pilot to mine years of outage and reliability data, identify regional trends, and even auto-generate management presentations within minutes. Others demonstrated internal AI setups that search company servers for equipment data while maintaining firewall protection. While participants agreed that these tools offer powerful diagnostic and benchmarking capabilities, they emphasized the continued need for human oversight, cybersecurity safeguards, and validation of AI-derived insights before operational adoption.

The following presentation summaries provide a concise look at key technical discussions shared during the 2025 501F Users Group Conference in preparation for the upcoming meeting. The full presentations—available to registered users through the 501F discussion forums (forum.501Fusers.org)—offer significantly greater technical detail, data, and field experience. Readers are encouraged to review the source materials for comprehensive insights into the engineering solutions and operational lessons exchanged by fellow end users.

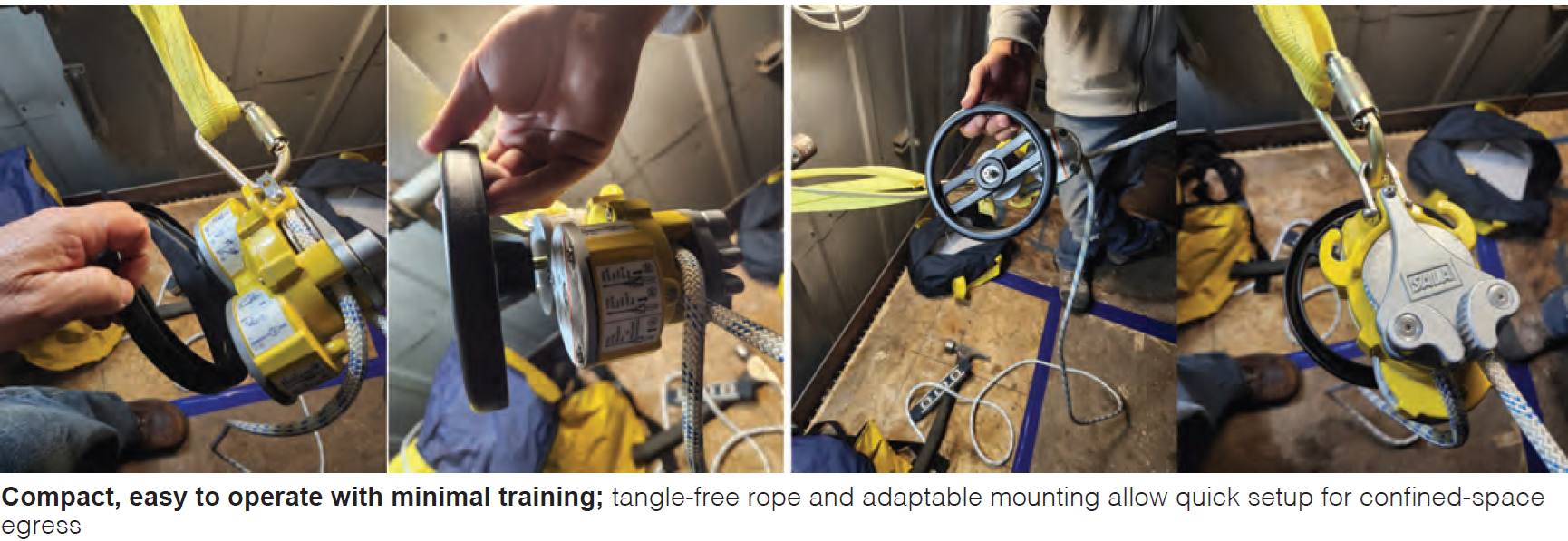

Teardrop egress device for confined space

Modifications that removed the mechanical overspeed system and revamped insulation around the exhaust teardrop have complicated safe access and exit on a 501D5. The team evaluated a 3M DBI-SALA Rollgliss R550 Rescue and Descent Device for confined-space egress.

Trained personnel operate the unit using the hand wheel, with option to convert to electric. The rope resists tangling and stores easily, and hardware accommodates multiple mounting locations. Two site rescue staff supported the exercise. The goal is to install permanent brackets or eyes to enable quick, repeatable setup and removal, improving safety and reducing time for teardrop entry and exit.

FD3 CCGT upgrades

Site upgraded its two combustion turbines from 501FC to FD3 to increase output and improve heat rate. The upgrade program required environmental permitting and multiple system studies, plus an H2 generator addition for one GT. Objectives include 198 MW at ISO, shaft-limited 215 MW, and an average 300 BTU/GT heat-rate improvement. Benefits are attributed to compressor sealing, stage-4 hardware with disc-4 change, exhaust-cylinder change, and optimized IGV settings with a 2% exhaust-flow rise at unchanged exhaust temperature.

Purge credit reduces start time, improves start-package durability, and mitigates HRSG tube thermal stress; additional modifications include a fuel-gas block-and-bleed valve, air-block system, and logic updates. GT ACO corrects exhaust-temperature control for off-reference ambient conditions. The DAIS evenly cools turbine elements post-shutdown using compressed air piped to disc cavities 2, 3, and 4. DAIS scope includes Siemens-supplied components, two 1000-CFM compressors, and two 1000-gallon surge tanks on a common header serving both turbines.

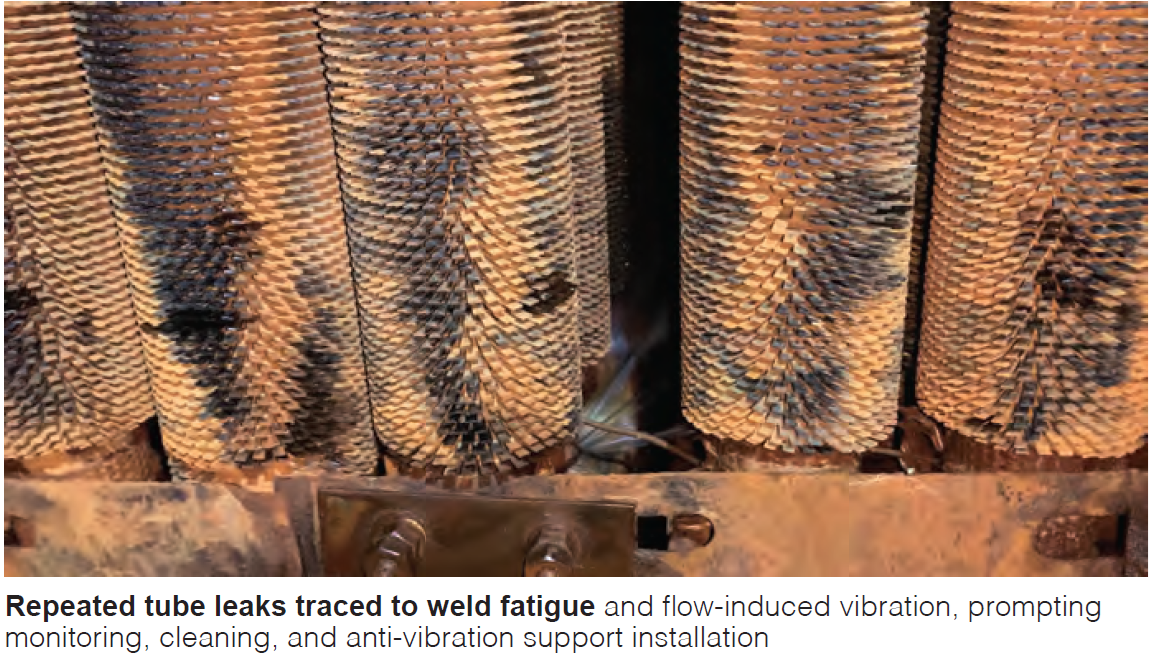

HRSG impacts after GT upgrade

A 330 MW 1 x 1 plant with reported HRSG impacts after upgrading its 501FD2 with a hybrid rotor and thermal performance upgrade.

Following the 2022 turbine upgrade, maximum CT output reached 224.92 MW at minus 13°C with evaporative cooling, but HRSG issues emerged in 2023–2024. Repeated leaks occurred on an LP feedwater heater, with toe-weld cracks at the bottom header and heavy fin deposits.

Chemistry results were normal. Lab analysis identified high cycle fatigue, likely from flow-induced vibration. Field testing showed tube natural frequencies near 5 Hz, peak vibration over 10 in/s, and mid-span motion of 0.5 in peak-to-peak. Initial mitigations included winter derates, keeping overall vibration below 6 in/s peak, avoiding PAG and duct burners below 0°C, targeted ice-blast cleaning, and shimming or repairing anti-vibration braces.

In October 2024, the team completed deeper cleaning and installed new lower mid-span supports. Results show overall vibration below 0.8 in/s peak across conditions, no derates, and no subsequent tube leaks. Long-term actions include comprehensive cleaning during major outages and reweld options at the lower header to reduce stress concentrations.

Control system replacement considerations

An end user shared practical lessons from multiple control retrofits and upgrades, focusing on specifications, reliability and lifecycle planning for 501F assets and a diverse GT fleet serving a major metropolitan area.

Past projects span MkV to Ovation, ABB to MkVIe, MHC to Foxboro, MkVI to Triconex, and later Triconex to MkVIe, illustrating that technology choices evolve and documentation must keep pace. A written, standardized control specification is stressed. Time and materials contracts are discouraged. Owners should leverage large awards for spares pricing, require training on factory-approved software, and secure service and support agreements.

Technical expectations include proven turbine or CCGT experience, human factors requirements, redundancy and room for expansion. The program calls for RFI hardening at excitation systems, load rejection survivability, sequence of events recorders, and HART I/O to future-proof instrumentation. Keep communication links but hardwire cross trips. Retag and re-ferrule every touched circuit.

Other program elements include using EPRI resources, eliminating vendor obfuscation, stocking spare hardware by cabinet and I/O type, and managing obsolescence through proactive drawing creation and updates. Many of these points can be mandated in the specification or used as bid evaluation criteria. Must read slide deck.

Bushing inspection and isolation findings

Review of generator bushing conditions, focusing on suspected first-fault locations around the manway, neutral and ISO leads, and a B-phase interface that transitions from the air side to the H2-side isolator.

Field notes identify several inspection nodes: neutral leads, ISO leads, and manway access for internal confirmation. The most credible issue presents on B-phase at the air to H2 isolator, where insulation and sealing integrity are scrutinized. Technicians document hardware condition, cleanliness, and lead routing to rule out abrasion or contact at supports. Temporary actions prioritize safety and containment, including controlled depressurization, isolating the suspect section, and verifying hydrogen purity and pressure stability before further work. Post-stabilization checks include visual inspections, torque verification on terminations, and seal assessment at the isolator interface.

Planned corrective maintenance scopes replacement or refurbishment of the affected bushing components, inspection of neutral and ISO lead insulation, and rework of gaskets or barriers at the air to H2 boundary. Return-to-service criteria include successful pressure hold, leak verification, and stable temperature indications on all three phases during ramp. The site will trend alarms, hydrogen parameters, and any condition-monitor data to confirm that vibration, thermal cycling, or aging insulation are not driving recurrence.

Steam turbine insulation improvement

For those exploring a replacement of “original style” ST insulation with an upgraded, in this case, Arnold insulation system on a BB machine, check these well-organized slides out.

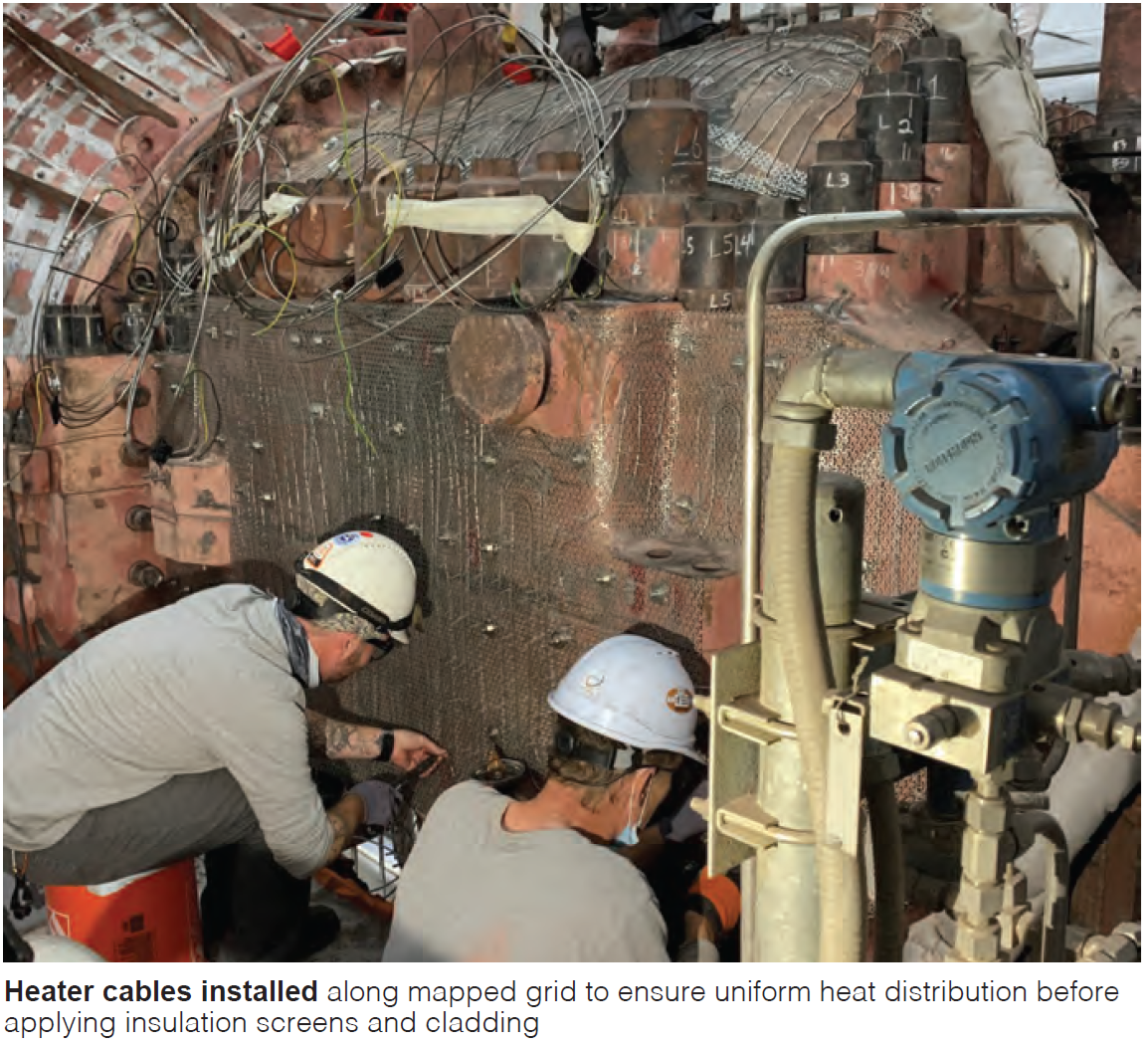

The scope begins with safe removal controls, including scaffolding, a temporary enclosure, air filtration and compliant disposal of legacy materials. These steps protect adjacent equipment and maintain housekeeping while exposing surfaces for inspection and prep. Preparatory work includes heater mapping to define the grid and termination points before new components are staged. This ensures cable routing, spacing and coverage align with thermal requirements and access limitations.

Installation proceeds in layers. Crews first install heater cables and an insulation screen to manage heat distribution and mechanical protection. Subsequent phases add precut pads and cladding, tying into the mapped heater grid and sealing interfaces to minimize convection paths. The sequence supports repeatable quality, improves fit around complex geometries and standardizes future maintenance touch points.

The end user emphasizes a structured approach, from containment and removal through heater mapping and staged installation, to deliver consistent insulation performance on the BB platform. The staged method also clarifies future outage planning by breaking the work into predictable work packets: removal, mapping, cable and screen installation, then pads and cladding.

CCGT inlet and exhaust upgrades

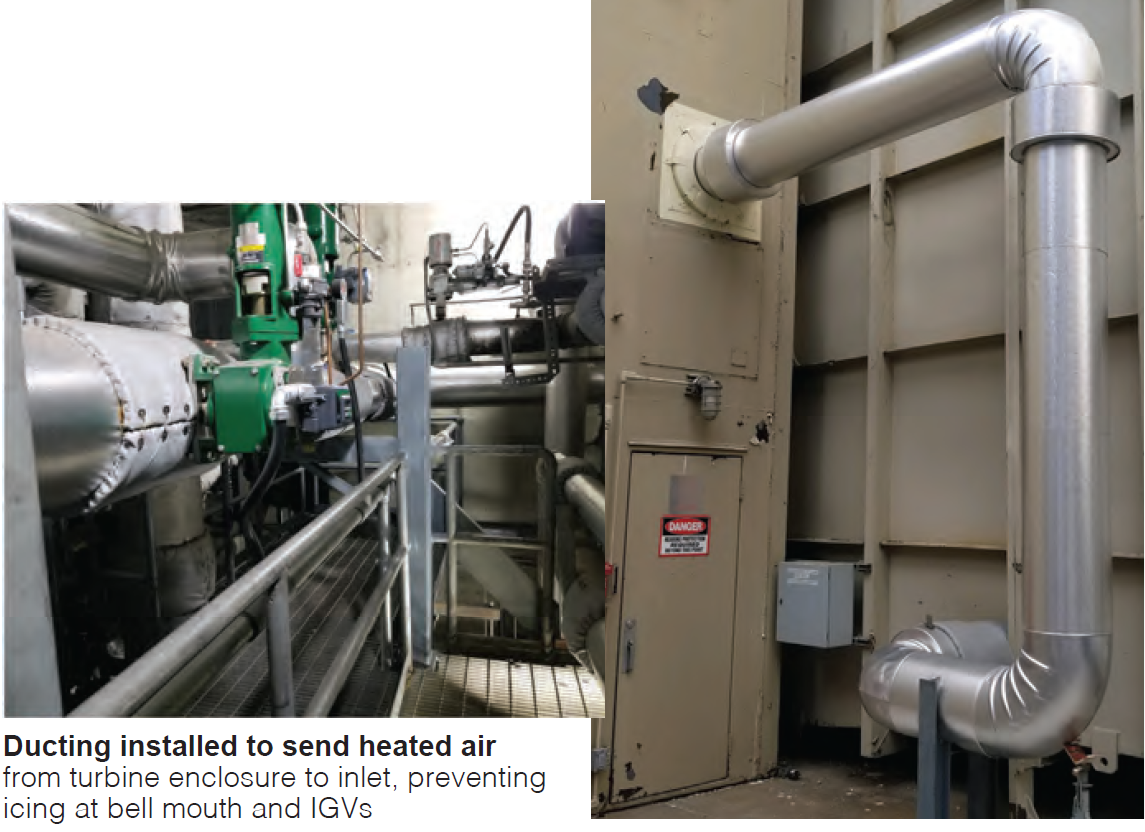

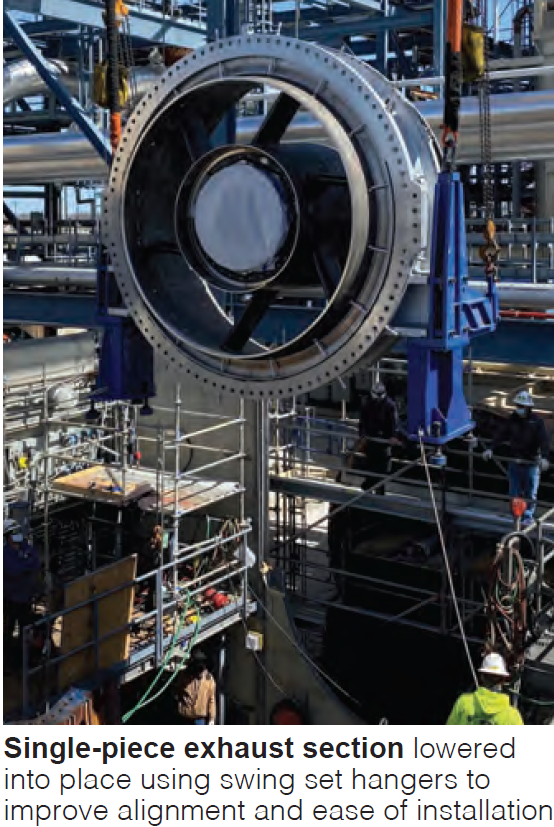

The project covers two reliability improvements increasing in commonality in aging F-class CCGTs: an inlet-air heating system to mitigate icing and a Single Piece Exhaust (SPEX) retrofit with new supports and expansion joint.

The inlet heating system extracts warm air from the compressor discharge or combustor shell and injects it into the inlet airstream immediately downstream of the silencer. Targeted protection areas include the bellmouth, inlet guide vanes, and struts, where ice formation can restrict flow or damage hardware. The routing runs from the turbine enclosure to the air inlet, enabling on-unit heat use without external heaters. The objective is consistent winter availability and reduced IGV icing events during cold, humid conditions.

On the exhaust side, the site implemented a SPEX arrangement with a swing-set hanger, upper and lower assemblies, to simplify alignment and support. An upgraded expansion joint was also installed following a failure of the original EJ. New joint and hanger system aims to control movement, maintain sealing at the turbine-to-stack interface, and reduce maintenance driven by thermal cycling.

Together, the inlet heating and SPEX upgrades address weather-related risk at the front end and mechanical integrity at the back end of the GT train, improving reliability across changing ambient conditions.

M501F3 compressor diaphragm set screw retention enhancement

Comprehensive presentation reviews field evidence and mitigations for liberated compressor diaphragm seal-box set screws on M501F3 units, tied to Service Bulletin GTB-21014 for Rows 1-4. A 2023 major uncovered foreign object damage on the seal-box ID and rotor discs, traced to a missing R3 set screw that never reached the blade path and escaped standard borescope routes. The unit received a new diaphragm, rotor repairs, and GTB-21014 implementation during the outage.

In 2024, a sister unit experienced liberated R2 and R3 set screws at 68k fired hours, with R2 especially concerning near the compressor spindle nuts. Limited parts forced blend repairs to diaphragms and disc cavities and deferred bulletin work to align with a GT upgrade. The end user strongly recommends proactive GTB-21014 installation across R1-R4 and targeted inspections of seal-box regions beyond conventional borescope paths. This is a must-read for any owner/operator with units affected by this service bulletin.

FlameSheet™ implementation and improvements

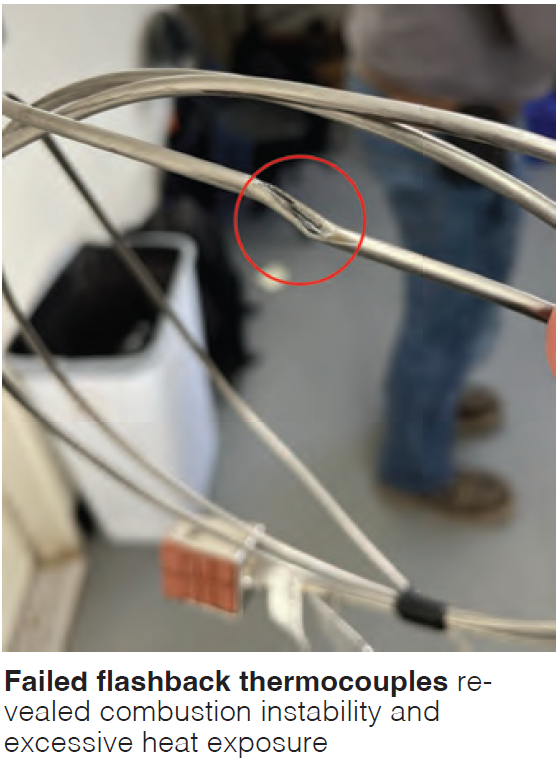

In two follow-up presentations from the 2024 meeting on early FlameSheet experience on a 2×1 CCGT with two W501FD2s and a KN steam turbine, the end users initially reported controls, performance, and hardware challenges following install on both CTs in 2023. Scope included 16 new combustors, modified gas-stage valves, expanded instrumentation, OCR controller upgrades, new modes and alarms, and Autotune 3.0.

Initial commissioning focused on BOP tuning, acceleration to FSNL, and revised hold points. Early operation featured CT1 flashbacks, high baseload NOx, failed flashback thermocouples, and suspected compressor-discharge air shortfall. Extensive diagnostics, additional instrumentation, and tuning trades between dynamics and emissions followed.

Working in concert with PSM, corrective actions in 2024 rebalanced airflow via S13 orifice reduction, meter-plate changes shifting flow from pilot to main, plug welding transition-piece cooling holes, and liner-trip modifications. By mid-2024, CT1 achieved sub-8 ppm baseload NOx, acceptable dynamics, improved power and heat rate, and turndown near 50–65 MW.

More progress on the way. At the upcoming conference, expect an update on 2025 work including borescope results, EXB commissioning to enable sub-45 MW operation, and IBH system optimization.

W501F R3 blade creep event

In late 2020 and early 2021, two units experienced abnormal vibration traced to R3 blade creep and liberation, with R3 creep features also found on one unit during a scheduled outage. OEM testing showed that at part load with LLCO enabled, exhaust temperatures were higher than expected; adjusting the OTC curve lowered LLCO temperatures and closed the immediate event.

To quantify thermal exposure, the end user and EPRI used an updated digital twin reflecting compressor bypass bleed to estimate stage temperatures before and after the OTC change. Results indicate the control change reduced estimated firing and gas-path temperatures by up to 30C at part load, while full-load service temperatures remain more than 100C higher than at 20–30% load.

Given creep’s sensitivity to temperature and time, the team recommends adding a borescope inspection at 20,000–28,000 hours rather than running to a 33,000-hour HGPI, noting that a 5% absolute temperature increase can accelerate creep roughly tenfold.

R1 vane issues

A 501FC+ in CCGT operation reports first-stage vane distress traced to iron contamination of the thermal barrier coating. Spring 2024 borescope inspection flagged four R1 vanes as high risk to the Spring 2025 HGP; a modified combustion inspection followed, replacing fourteen vanes. Offsite analysis concluded that iron contamination degraded the TBC, leading to cracking and base-metal damage on several vanes.

OEM spec sets an iron limit below 0.01 ppm. Site sampling identified probable sources: inlet-chiller water at 0.61 ppm iron, which can enter via coil leaks; NOx steam at 0.01 ppm; and water-wash fluid at 0.02 ppm, a modest contributor given short duration.

Recommended actions focus on eliminating chiller-coil leaks, further qualifying NOx-steam quality, and tightening water-wash controls. The event reinforces rigorous chemistry monitoring and rapid follow-up inspections when borescope findings indicate early coating breakdown on hot-gas-path airfoils.

R1 blade distress

W501FD1 peaking units, averaging ~150 starts/yr, continue to see recurrent first-stage blade distress. During its Fall 2022 torque-tube rotor replacement on one unit, the plant installed new R1 blades, the only non-OEM HGP parts on that machine.

By October 2024, the set had accumulated 318 starts and 2800 hours (up from 163 starts and 1082 hours the prior year) at a 900-start HGPI interval. Teardown showed clean cooling passages and no abnormal rust, yet leading-edge distress was present on nearly every blade; only one blade was unaffected prompting an RCA.

The site has historically cycled through multiple R1 designs and now plans an output-increase program with ULN combustors and a TPU/full-rotor upgrade beginning September 2025, targeting durable high-start operation with dual-fuel DLN and water injection. Details to come at February conference after initial cold-weather operations.

Air-separator fretting and replacement

End user details W501F air-separator fretting history, inspection triggers, and a successful repair path informed by fleet experience and a 2018 OEM service bulletin covering FD1-FD3 units. Early cases include one case in 2016, where fretting led to scrap, and another in 2020, where fretting was discovered during a GT upgrade, prompting rotor shipment to Sulzer.

Disassembly revealed uniform radial fretting around 360 degrees, with measurements indicating the air separator was compressed about 0.007 in more than expected. The OEM recommendation was replacement, but the end user pursued repair, requesting WFMT and FPT of the gooseneck, fretted surface and ligaments, then machining and polishing the wheel, machining the separator, building up with a 0.015 in nickel-based HVOF coating, and final machining to optimize crush. Post-repair checks found no indications before or after the work, and air-separator compression was restored to 0.033 in.

The unit has operated successfully since early 2021, with the next outage planned for late 2027. Contact information was provided for follow-up.

M501F rotor exchange/replacement timing and considerations

OEM guidance links comprehensive rotor inspections (CRIs) to even-numbered majors (or 12 years) but gives no limits for turning-gear hours or rotor EOL.

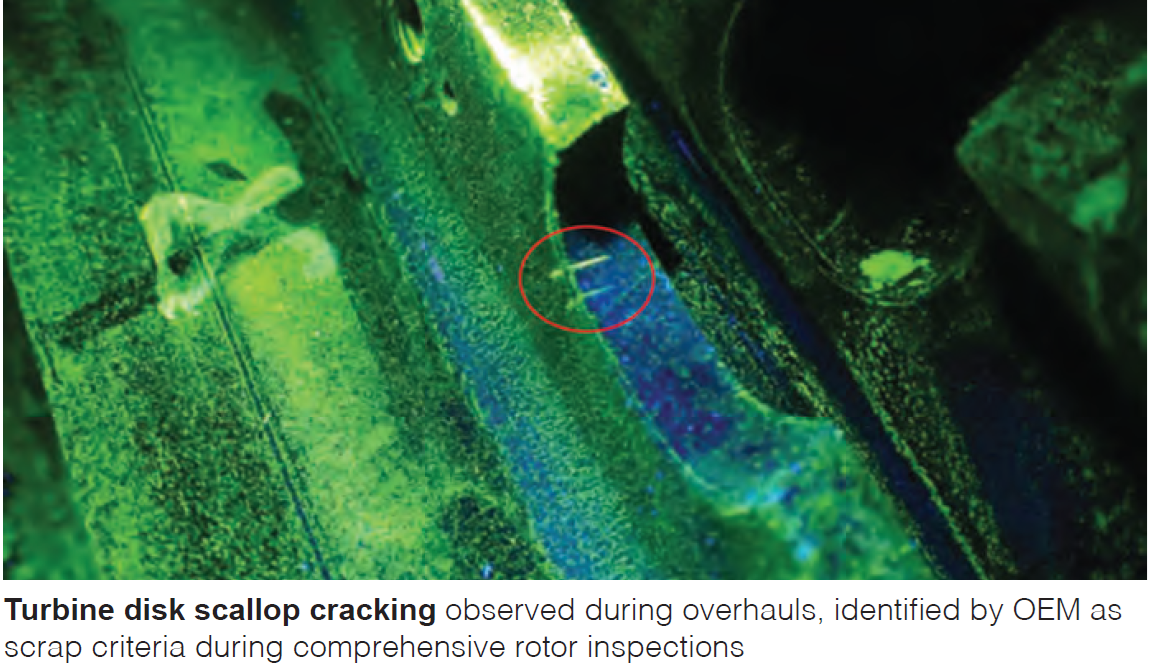

The units have high turning-gear exposure: at first majors, one unit logged ~45k fired hours, 1,170 starts, 41k TG hours; the other ~59k fired hours, 1,628 starts, 55k TG hours. Both units show turbine-disc scallop cracking risk, which would trigger rotor scrap at CRI.

CRIs are quoted at ~30 days with no findings, while rotor exchanges can shorten outages if the seed rotor includes compressor blading. After pedigree checks and HS balance review, the site chose an early rotor swap on a unit with ~83k hours and will CRI/refurbish that rotor for next major of the sister unit, stressing parts planning, supply-chain timing, and R4 root-spring installation to protect the R4 disk.

501FD1–FD4 rotor replacement and mHGPI

Peaking site outlines why Unit 2 shifted from a planned HGPI to a rotor replacement in 2024, and how that decision drives work on Units 1 and 3 in 2025 and 2026. The 2000-vintage peaking site faced known compressor damage and torque-tube failures near the 900-start interval. Comparing options, fleet engineers found a seeded-rotor swap could compress outage duration to about 30 days with parts on hand, versus uncertain timing of a torque tube failure or roughly 60 days to replace the tube without addressing compressor issues.

Execution details stress vendor selection and shop capability, coupled with fallout planning and budgeting for R1 vanes and blades, R2 ring segments, and a fraction of R2 blades, and a technical recommendation to revert from VGP to standard parts at the next HGPI. Blade-height mismatches required tipping and rework, highlighting the need for clearances verification, prebuilt blade rings, and spare bearings. Compressor modifications to support hot restarts included trimming R1 and R16 and addressing a service bulletin on seal rub risk. After installation, elevated blade-path spreads around 2000-2400 rpm were tuned out, with the unit returning to service in October 2024.

Building on lessons learned, the requirements for work on the next rotor will include refined blade measurement, handling, and reinstallation procedures to improve accuracy and balance efficiency. The same high-speed balance process will be followed, but with tighter control over sequence labeling and position tracking for R1/R2. The shop will again identify and reinstall the longest blades in each row before tip measurement. Additional focus will be placed on careful blade packaging, alignment verification after shipment, and re-establishing consistent tip clearances. CCJ