The 15th annual meeting of the Air-Cooled Condensers Users Group (ACCUG) was held at the University of East London (UK) July 23-25, 2024. Principal content categories were chemistry and corrosion, air-cooled condenser (ACC) design and performance, and system operation and maintenance.

The event was chaired by Andy Howell, EPRI; Barry Dooley, Structural Integrity (UK); and Riad Dandan, Dominion Energy. What follows is a recap of the key takeaways and a pathway to source materials for more in-depth examination of the subject matter. Presentations from all ACCUG conferences are freely and readily available to anyone willing to visit the group’s archive.

For those searching for human touch points and networking opportunities, the 2025 Annual Conference of the ACCUG will be held in Granbury, Texas from July 29-31. Details, agenda, and registration available here.

Chemistry and corrosion

Barry Dooley began the sessions with Corrosion and cycle chemistry, reviewing a 20-year global history of data from fossil, combined-cycle and industrial power plants. He noted that ACC systems come in various sizes, but the flow-accelerated corrosion (FAC) damage is the same worldwide with all system chemistries and plant types.

His comments covered:

- Reminder of ACC damage and how it is normally addressed.

- The Dooley Howell Air-Cooled Condenser Corrosion Index (DHACI) for uniformity for inspections worldwide.

His review of film-forming substances (FFS) focused on international experiences and the ongoing need for information and site trials.

He included a detailed listing and discussion of IAPWS Technical Guidance Documents for combined cycle plants with ACCs, all freely available at www.iapws.org.

Durgesh Lohiya, NTPC Limited, India, then offered Design details of condensate polishing unit (CPU) systems of NTPC ACC-based projects. He addressed CPU design, major chemistry issues, and cycle chemistry parameters. He noted that CPU design and operation for very high influent (flow) ammonia is a new challenge to NTPC.

He discussed the NTPC deep mixed bed design with external regeneration system for existing supercritical and ultra-supercritical units, for 150 to 1500 ppb influent ammonia.

Lohiya reviewed various large plants, and operating challenges and maintenance issues.

Manfred Jansen, Anodamine Incorporated, then outlined Experience of Anodamine in plants with ACCs. He stated that Anodamine is:

- Non-amine-based film forming technology added to the plant’s conventional chemistry.

- Thermally stable above 1050 F with no effect on conductivity after cation exchange (CACE) and no effect on cycle pH.

Jansen reviewed several cycle chemistry challenges (solid particle corrosion, FAC in LP turbine ducts, oxide deposits, decomposition of oxide products, insufficient passivation, etc.). He also noted extensive plant experience and studies coordinated with the Electric Power Research Institute (EPRI).

Design and performance

John De Winter, John Cockerill Hamon, began the session with Alternative induced draft ACC solution, first discussing induced-draft benefits and challenges. He then focused on a case history in Belgium featuring a modular ACC riser supported (MARS) design with the gearbox/motor at the bottom of the cold air stream for improved maintenance and reduced vibration.

Sean Cusick, SPG Dry Cooling, offered Unlocking efficiency: overcoming subcooling challenges in ACCs.

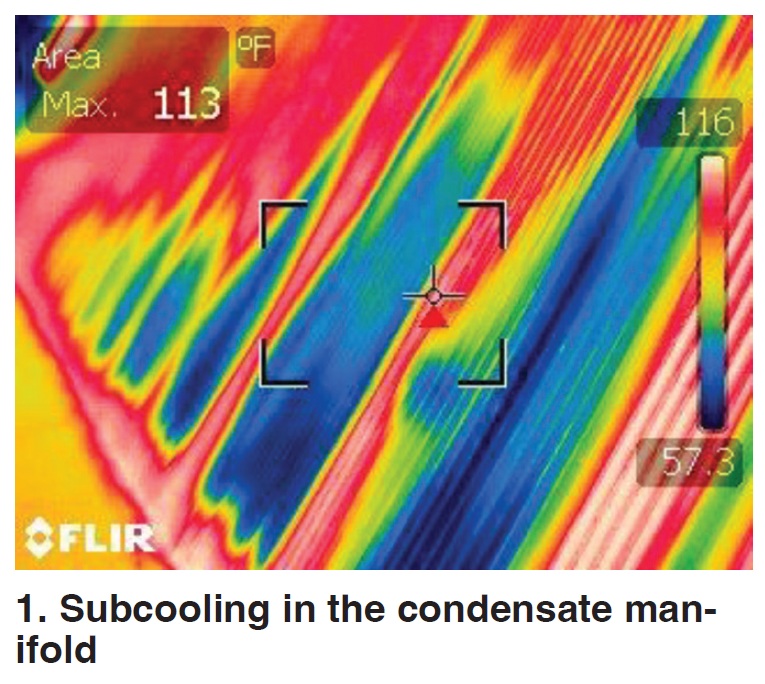

He began with ACC fundamentals and focused on subcooling: “the difference between the calculated saturation temperature and the actual condensate or non-condensable temperature.” This is illustrated in Fig 1.

He outlined the sources of subcooling:

- Uneven steam distribution.

- Air flow (too much from fan or wind).

- Steam surface availability.

- Vacuum system issues.

- Air ingress.

Subcooling, he said, leads to:

- Freezing and a loss of efficiency.

- Air ingress.

- higher backpressure.

- Increased fuel consumption and auxiliary load.

A fundamental: “Where there is air there is not steam; where there is steam there is not air. Condensate subcooling increases when the condensate passes through air within the heat exchanger.”

His bottom line: ACC performance matters; it impacts steam turbine output.

Cusick referenced a case study of the CPV (Competitive Power Ventures) Valley Energy Center in New York. To address negative impacts of continuous subcooling, even after a number of leaks were repaired, CPV implemented SPG’s remote performance monitoring system (ACC360), a “cloud-based solution that provides unprecedented insight into the performance and health of any ACC” through data analytics and modeling. For more on this plant, access this CCJ article.

Huub Hubregtse, ACC-Team Technology, ACC performance improvement, discussed ideas of narrower tubes, louvers in fins to improve heat transfer, fan modifications for air flow improvement, wind walls, losses through hot air recirculation, fouling, and use of adiabatic cooling (fogging) to reduce ambient temperature.

Jason Dehem, AX Systems, then offered More performance with optimized resources. He reviewed causes for decreased ACC performance and potential solutions, focusing on airflow underperformance.

His talk looked at tube cleaning options, fouling’s impact on fans’ electric consumption (increased fan speed), benefits of fogging, and fan upgrades. His theme: “cleaning, fogging and fan upgrades are significant and complementary drivers for increased ACC performance.”

Jeff Ebert, Galebreaker Industrial, looked at Mitigating wind effects from high seasonal winds. He first addressed how wind and turbulence impact blade loading and ACC performance, followed by the benefits of wind screens to reduce wind effects.

Ebert discussed the 350 MW gas-fired project in Saskatchewan, Canada, with its innovative- structure ACC. See Fig 2.

Results show improved ACC thermal performance at a variety of wind speeds and ambient temperatures.

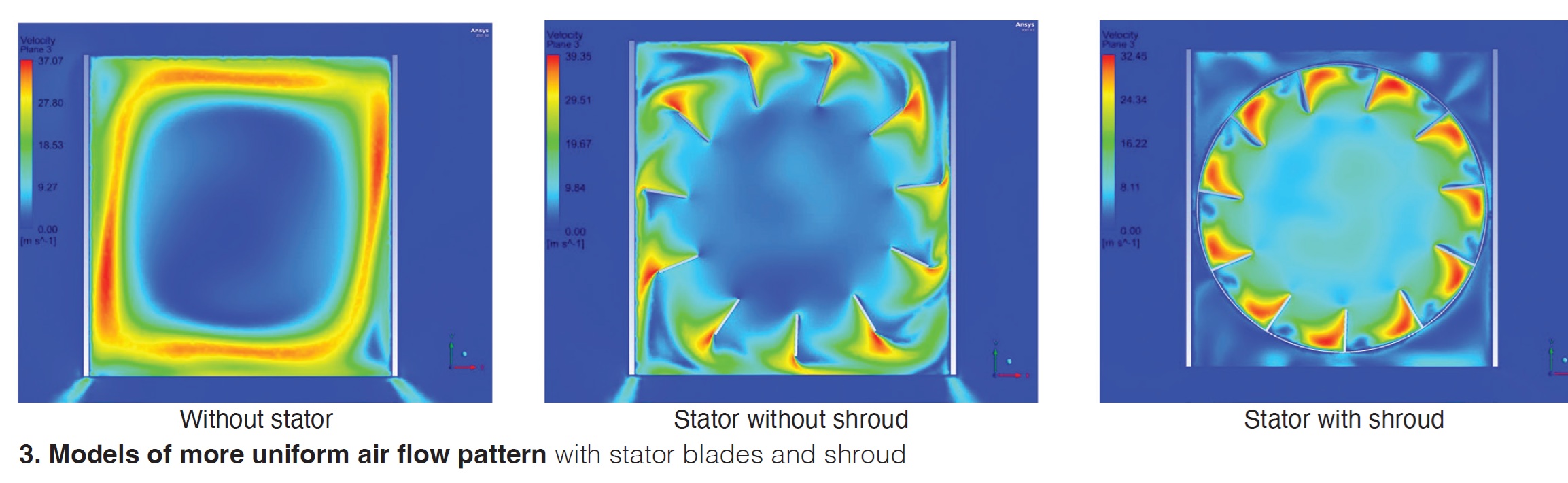

Mohammadreza Vaghar, Mapna Development Company, Iran, offered an Investigation of air flow over ACC tube bundles to improve cooling system efficiency.

This reviewed ACC module geometry, numerical modeling strategies (ACC and fans), fan stator blades and shrouds, data gathering methods and future studies. See Fig 3.

György Budik, MVM EGI, Hungary, covered Medium- to large-size hybrid cooling systems.

The hybrid wet/dry system combines some advantages including good performance in summer, low power consumption, limited water consumption, reduced plume, reduced chemical dosing and reasonable maintenance cost (among others). He reviewed both separate-circuit and single-circuit systems. He also reviewed Heller indirect dry cooling with supplemental spraying.

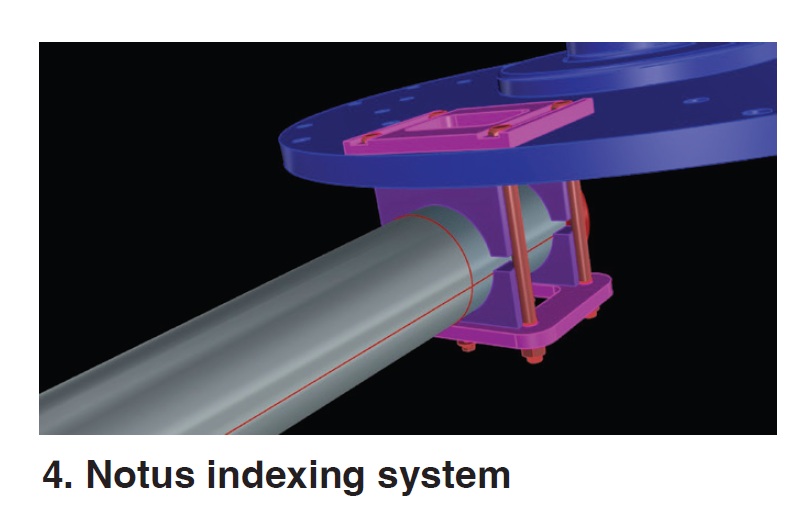

Chris Meyer, Notus Fan Engineering/Stellenbosch University, outlined From academia to industry (advanced fan technology). This presentation reviewed innovations in design based on aerodynamics, structural design, strength testing, and fan blade manufacturing. Field examples covered vibration testing, torque, power reduction, and an indexing system for blade strength. See Fig 4. Meyer, Stellenbosch University (South Africa), would follow later with Latest ACC research at Stellenbosch University.

Cosimo Bainchini, Ergon Research (Italy), updated Recent progress in modeling of wind effects. Details included high-fidelity CFD, high performance computing, and wind screen layout validations.

Eleanor Baimbridge, Suez UK, followed with Live performance modeling of energy-from-waste plant ACCs. Examples focused on recycling and resource recovery plants in the UK. Suez, a resource management company, is the fleet/plant operator of 11 UK energy-from-waste plants with a total generating capacity of 233 MW.

Bainbridge explained the variations and challenges of operating ACCs within a fleet with various ACC OEMs and site-specific cooling requirements. ACC performance modeling is used by Suez to improve cleaning schedules, identify unit defects, and increase MW output.

Case studies were presented on the effects of unit fouling, cold weather operation, cleaning requirements, ambient environment, impact of turbine modifications, and predictive monitoring for ongoing operations.

Kris Herijgers and Rob Green, Sumitomo Drive Technologies, presented ACC cooling technology gearbox evolution, offering first a history from generic to dedicated fan drives (Sumitomo and Hansen) with operating examples in the UK and US.

The presentation then focused on the advantages of a “dedicated” design with rigid housing, strong foot base, extended bearing span, cooling fins, and flexible cooling options. Also presented was a unique conditioning monitoring system for gearbox life cycle improvement.

Operation and maintenance

Lee Rhodes, Enfinium/Ferrybridge Power Station offered Ferrybridge performance improvement.

Ferrybridge is an 85 MW waste-to-energy facility in the UK (Fig 5), on line in 2015, with two boilers and one steam turbine processing 750,000 t/d of municipal waste. Gross power output is 86 MW.

The site installed Galebreaker wind screens on one unit based on CFD modeling in a cruciform and perimeter screen layout. Rhodes then showed comparative results of the units, with positive results on ACC vacuum vs ambient temperature following wind screen installation.

Mohammad Asim, ENGIE-Fadhili, Saudi Arabia, discussed ACC wind mitigation project experience. The subject plant features 4 GTs and 2 ACCs (24 cells each), facing high vacuum issues since commissioning.

Vacuum issues are based on high wind speed, high summer ambient temperatures, and high dust (sand), all leading to plant load reduction. An adiabatic cooling system installed for increased ACC performance led to unacceptable water consumption.

The solution was CFD modeling and Galebreaker wind screens. Load reduction events were reduced, and plant availability and reliability improved.

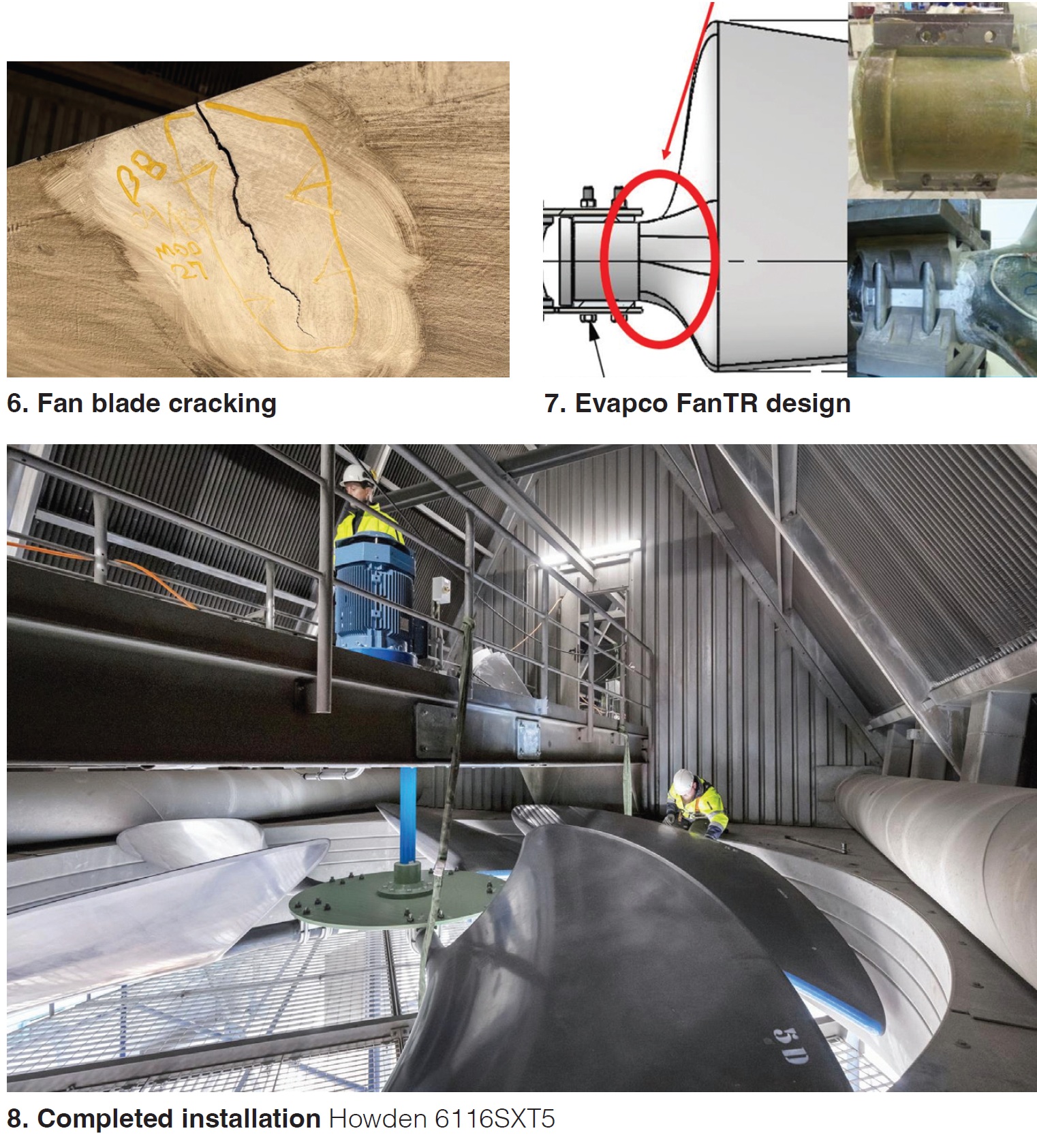

Patrick Saususs, Evapco Dry Cooling, offered Fan modification impacts on ACC vibration. His case study was the Virginia City Hybrid Energy Center, owned and operated by Dominion Energy.

This coal waste and biomass plant features 2 ACCs with 7-blade fans, 30 cells each. Blade cracking (Fig 6) has been an issue since 2016. The solution in this case was the 9-blade FanTR design (Fig 7). Installations began in 2018.

This case history covered vibration fundamentals and standards as well as gearbox mounting studies.

One lesson learned: Seemingly minor modifications can have a big impact. You must look at frequencies in multiple directions, and be cautious of multiple fan interactions.

Jacques Muiyser, Howden (Netherlands), offered a Low noise ACC retrofit case study.

In this Howden Netherlands case study, the 10 existing fans had been in operation for 20 years. The goal was to improve cooling capacity in summer with no increase in noise level. The owner/operator also wanted to implement fan speed control to reduce fan power consumption when additional cooling was not required.

The retrofit method discussed involved baseline measurements of the existing fans, new fan selection, detailed engineering of fans and other components, and safety assessments, followed by delivery and commissioning specifics.

A Howden model 6116SX15 (Fig 8) was selected to deliver 30 percent more flow than the existing fans. Although the fans would run at higher speed, a decrease in sound power level of 3 dBa was expected. VFDs for fan speed control were added.

During commissioning, a reduction in blade angle of approximately one degree resulted in a desired increase in air flow while not exceeding the maximum allowable motor power. High vibrations occurred and the solution was additional stiffening plates to the fan casing.

“Due to the implementation of VFDs and speed control, energy could be conserved during periods where additional cooling was not needed,” he said: “This was a good example of every retrofit project is unique.”

Tour information

Christian Keefe and Valerio Teducci, InterGen, presented Coryton Power Station ACC: operation, performance and engineering. A Coryton tour would conclude the 2024 conference, courtesy of InterGen and organized by plant manager Tony Wren.

Coryton’s GEA Power Cooling Systems ACC was commissioned in 2002. The plant generates 800 MW in a 2 x 1 combined cycle. Originally designed for base load, Coryton is now in two-shifting operation.

The ACC contains 40 cells in 8 rows of 5 fan bays. ACC operational control is manual (4 rows always open, 4 rows selectable).

This presentation offered details on:

- Design.

- System and plant start.

- Freeze protection.

- ACC fogging system.

- Data monitoring.

- ACC wash.

- Air ingress survey.

- Fogging system – can be used above 77F ambient.

- Galebreaker wind screens, perimeter and cruciform.

- They then offered a detailed list of equipment improvements to date, as well as future considerations.