What would a gas-turbine user-group meeting be without extensive participation from equipment manufacturers and solutions providers? The 501F and 501G conferences continue to demonstrate why this blend matters. User-only sessions, covered in detail here, focus on fleet experiences, common pain points, and lessons learned shared directly by owner/operators. But the meeting’s broader value emerges when this dialogue expands to include OEM and OOEM product teams, who outline hardware updates, controls evolution, reliability concerns, and long-term fleet strategies. Vendorama is a rapid-fire day, often covering topics beyond the engine, showcasing technologies and field solutions from dozens of specialized suppliers. Together, these three segments form a complete picture of the 501F and G landscapes: users identifying real-world issues, OEMs responding with guidance and upgrades, and third-party vendors offering practical tools to keep plants running safely, efficiently, and profitably.

OEM, OOEM SESSIONS

Extended presentation sessions by Siemens Energy, Mitsubishi Power, and Power Systems Manufacturing open valuable lines of communication between the end users on the front lines and various product line managers at HQ with the goal of addressing existing issues as well as pending and future solutions. Some of the key topics applicable to all of the major players follow:

- Supply-chain reliability issues, particularly delays in obtaining basic instrumentation from preferred suppliers and sub-suppliers

- Tracking and visibility of sub-supplier lead times

- Desire for updates on hardware, coatings, and component life improvements supporting fleets surpassing 40,000 EBH

- Engineering guidance for plants transitioning from baseload to cyclic operation and recommendation for inspection, modification, and monitoring recommendations across GTs, STs, and generators

Siemens Energy hosted an abbreviated session, squeezing in a lot of content and discussion into two hours. For those looking for a deeper dive into their suite of 501F upgrades and solutions, then consider blocking off an additional week midyear to attend the OEM’s LGT conference in Orlando. Enquiring end users wanted to know:

- Locations and frequency of cracking observed in compressor, combustor, and turbine cases

- T-3000 I/O card availability and planned obsolescence

- T-3000 upgrade benefits from 8.x to 9.2

- Monitoring sub-supplier performance and component availability.

- Fleet experience and design improvements enabling operation beyond 40,000 EBH

Mitsubishi Power covered a slew of topics in broad strokes over the course of their four-hour session, focusing on their own M501F and cross-fleet solutions with the W501F. Keeping outage durations within schedule is always a big talking point at user groups, and the OEM was proud to report the opening of its new Houston workshop to support critical, time-sensitive outage activities in North America. Users kept discussion going with a wide variety of topics, many of which were planned for further analysis at MPA customer webinars:

- Rotor end-of-life philosophy for both M501F and W501F machines

- Fleet experience with compressor hook-fit wear on M501F units

- R1–R4 compressor diaphragm seal-box screw liberation

- Turbine-disc scallop cracking

- Update on 9-ppm combustor rollout to the broader M501F fleet

- Rotor LTE for steamers reaching 200k hours

- Spare-parts availability for Diasys Netmation control system components

PSM, coming off the heels of its annual asset manager meeting, was already in mid-season form delivering a robust session focused on maximizing 501F output, flexibility, and durability. Their session goals were to highlight current and future 501F projects and gather user feedback on emerging technologies and impacts on operations and maintenance.

The agenda progressed from current status through validation and future outlook, with audience prompts around the roadmap beyond GTOP7, additive manufacturing (AM), FlameSheet vs DLN/ULN, materials advances, and how AutoTune/FlexSuite interact with GTOP packages.

A central theme was continuous upgrade cadence across GTOP6 Light, GTOP6, GTOP7, FlameTOP7, and “Next Gen,” targeting power increases and heat-rate improvements at a 24k-hour interval, plus sub-30% turndown (lower with ExB). The flexibility stack included IBH for roughly +10% additional turndown range, wet compression for power boost, FlameSheet for fuel flexibility, and ExB for further turndown—tied together by digital logic in GTOP7/FlameTOP7 to optimize emissions and operating modes. A field example showed IBH+ExB enabling <9-ppm NOx/CO at minimum load in hot-day conditions.

FlameSheet Gen V was presented as a drop-in combustor delivering sub-9-ppm NOx with <40% turndown and HRSG-friendly exhaust temperatures. The system bolts directly to the CDC, uses existing fuel headers, and works with common plant control systems with new scheduling/logic. Under the hood: a “combustor-within-a-combustor” with two aerodynamic stages, four gas circuits, trapped-vortex stabilization, and high premixer exit velocities to accommodate reactive fuels like hydrogen, all at low pressure drop for heat-rate benefit.

Validation highlights included AM modular hardware: 13 sets installed as of September 2024, >145k operating hours and ~2200 fired starts across the fleet, with leaders exceeding 31k operating hours and 483 starts since early 2020. The roadmap charted more than 15 years of 501F upgrades, aiming for sub-30% turndown and lower in 2025.

Bottom line: PSM’s 501F path concentrates on flexible turndown, fuel flexibility (including H2 readiness), emissions control at minimum load, and validated lifecycle gains via AM and integrated digital controls, all packaged to fit existing plant interfaces.

VENDORAMA

With supply-chain challenges a persistent issue in the CCGT industry, end users are faced with the growing need to find alternative solutions to keep their units humming. This unique segment at the annual 501F and 501G Users Groups conferences offers a rapid-fire, must-attend day for owner/operators to gain a direct view of the latest third-party equipment and service offerings before the evening vendor fair.

The Vendorama day on Monday features concise, vendor-led technical presentations that are vetted by the steering committee to ensure substance and relevance, rather than pure promotion. With parallel tracks of several presentations, there’s always a learning experience to be had. Below are brief recaps from presentations in 2025 where slide decks are available to registered attendees via the users-group website.

Gas Turbines

Heat rate improving insulation for GTs

Arnold Group

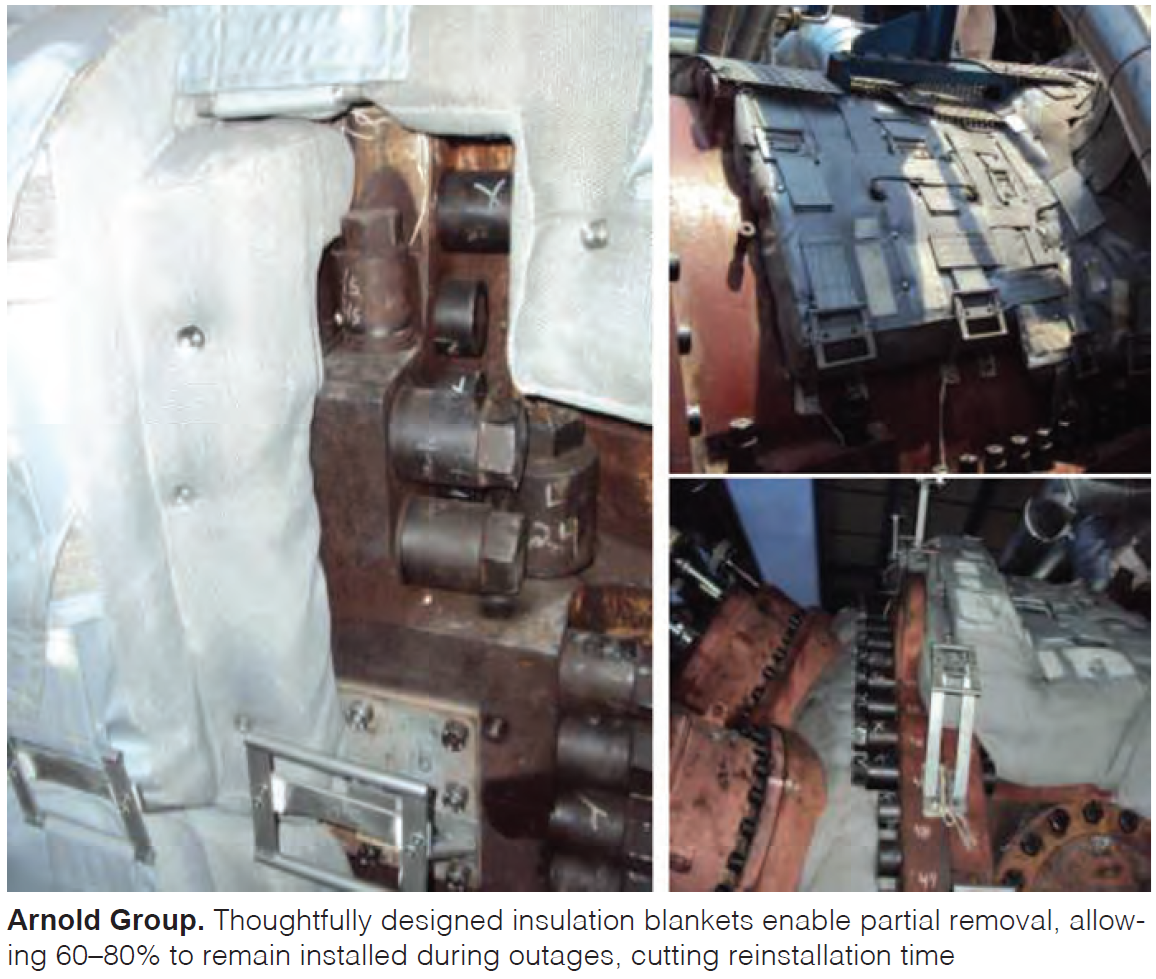

Pierre Ansmann presented a high-performance insulation system for gas turbines designed to reduce heat loss, improve plant efficiency, and extend component life across W501, M501, and M701 frames. The 3D single-layer insulation system replaces conventional multi-layer or pin-mounted designs that often suffer from sagging, hot spots, and material degradation after a few cycles. Each blanket is individually shaped and calculated for consistent surface temperature, maintaining a maximum of 15°C above ambient across the turbine casing.

The system features interlocking 45° interfaces between blankets to accommodate thermal expansion without creating gaps, eliminating hot spots that can damage nearby components. A stainless-steel substructure fixed by stud welding provides permanent support and safer access for maintenance, while high-temp Velcro fasteners allow selective removal during outages without disturbing adjacent sections. This approach enables up to 60–80% of insulation to remain installed, saving one to three days in outage reassembly time.

Field installations show significant gains in enclosure temperature uniformity and measurable heat rate improvement. Comparative testing demonstrates up to a threefold reduction in heat loss versus standard systems, along with surface temperature reductions exceeding 40%. The result is a robust, maintenance-efficient insulation solution that supports long-term reliability and performance.

Gas turbine cooling and wet compression

Mee Industries

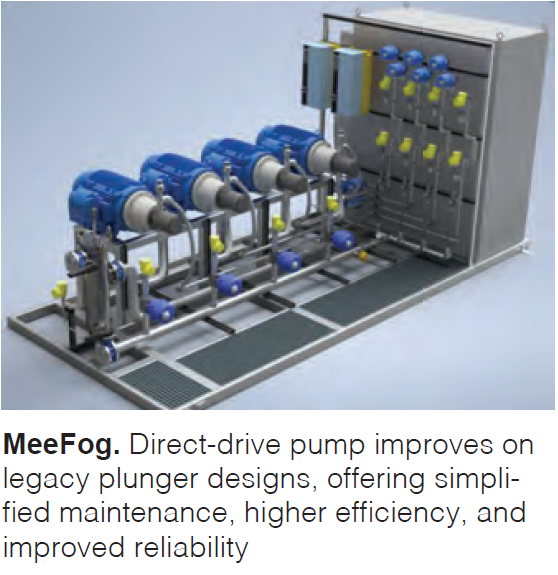

Slides review the design, reliability, and maintenance considerations of high-pressure fogging and wet compression systems for gas turbines. The technology provides 22 to 28 MW of additional power output at a cost below $50 per kW/hr, achieved through fine atomization and controlled droplet size to maximize evaporative cooling efficiency.

Approximately 90% of MeeFog droplets measure under 20 microns, promoting faster evaporation and minimizing compressor erosion compared to OEM nozzles, which typically produce droplets 3.4 times larger in mass.

The system integrates multiple protective and diagnostic features, including continuous water-quality monitoring through conductivity meters that trigger alarms and automatic shutdowns when conductivity exceeds turbine safety limits. Additional safeguards include drain activation interlocks to prevent large water droplets from entering the compressor.

Recent installations feature direct-drive pump designs and variable frequency drives in climate-controlled or NEMA 4-rated enclosures for improved control and reliability. Over 22,000 operating hours of field data demonstrate stable performance with no reported erosion issues. The presentation emphasizes precise droplet control, automated protection systems, and modular upgrades as key factors sustaining long-term operational reliability in fogging and wet compression applications.

Better filtration pays for itself

EMW Filtertechnik

The presentation examines how advanced (H)EPA-grade gas turbine filters improve compressor cleanliness, maintain output, and reduce fuel consumption. EMW demonstrates that upgrading from F-class or E10 filtration to higher-efficiency E12 filters significantly reduces fouling and extends maintenance intervals, even in high-humidity or dust-laden environments. Testing follows ISO 29461 and ISO 29463 standards, measuring pressure drop, efficiency, and dust-holding capacity under both dry and mist conditions.

Field comparisons after 5,000 operating hours show that E12 filters maintain cleaner compressor surfaces, reducing the need for on- and offline washing. Lower pressure loss and stabilized compressor efficiency translate directly to better heat rate and availability. EMW concludes that E12 filtration delivers measurable financial return through sustained performance and reduced degradation across the turbine’s lifecycle.

Root cause analysis process and case studies

Entrust Solutions Group

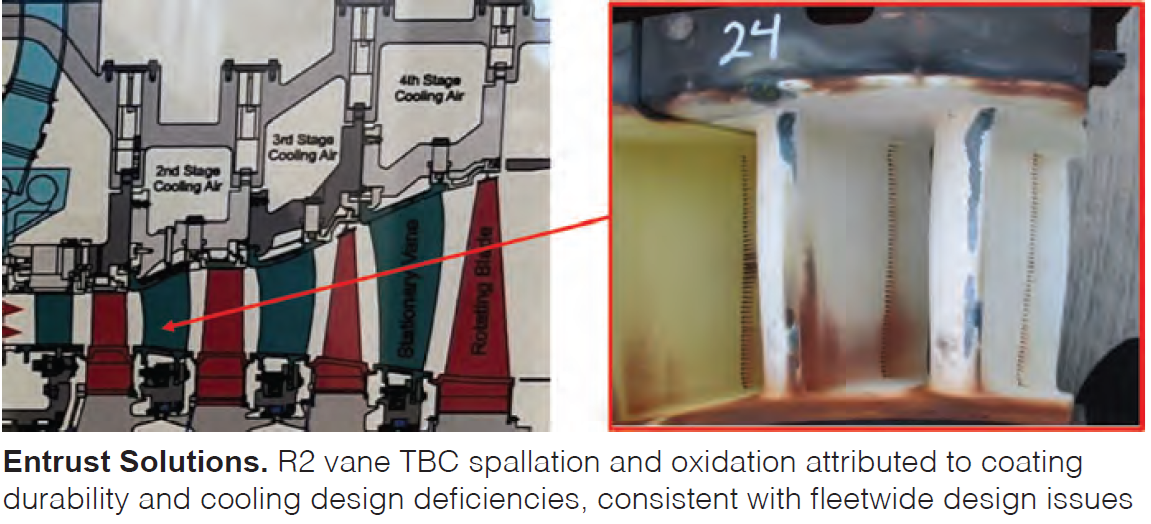

This presentation outlines Entrust’s structured, data-driven approach to root cause analysis (RCA) for turbine and generator failures, applying the Kepner-Tregoe method to distinguish probable mechanical, metallurgical, and operational contributors. The process integrates field inspection, finite element analysis, life assessment, and metallurgical evaluation to verify failure mechanisms and guide corrective actions.

A 501FD3 air separator failure case study attributes damage to fatigue cracking and liberation of the hammerhead section, initiated by fretting and compounded by thermal and centrifugal stress. A second case involving R2 vane burn-through links coating spallation and oxidation to a design deficiency in thermal barrier coating selection and vane cooling. Together, the examples illustrate how disciplined RCA supports fleet reliability, OEM negotiation, and preventive maintenance strategy.

Fyrewash® F2 detergent development and field performance

Rochem Technical Services

Steve Egelhoff began with three important points: Faster rinsing, improved fouling removal, and no dangerous-goods label. He then went on to outline a reformulation of FYREWASH® F2, its water-based gas-turbine compressor detergent. The prior formulation used terpinolene as a grease cutter, however, transport rules later classified it as “very toxic to aquatic life.” The new formulation eliminates terpinolene, using a plant-derived grease cutter with a proprietary non-ionic surfactant/co-solvent blend.

Reported benefits include quicker rinsing from higher polarity and faster foam breakdown, smaller bubbles for longer blade contact, stable emulsions with demin water, minimal odor, and compliance with major OEM specs.

Field testing demonstrates consistent power recovery across multiple turbine types: 4–6 MW in 7FA and 7HA units, over 5 MW in SGT6-8000H models, and full conductivity recovery in under 90 minutes.

GT air filtration solutions

Faist Filters

Faist presents advanced static and pulse filtration systems for gas turbine air intakes, designed to maximize compressor protection and performance. Its double-cylinder pulse cartridge filter increases surface area by 7%, reduces pressure drop by 13%, and cuts transport costs by 50%. Hydrophobic synthetic media meeting ISO 29461-2 delivers high dirt-holding capacity, durability, and resistance to water and soluble contaminants.

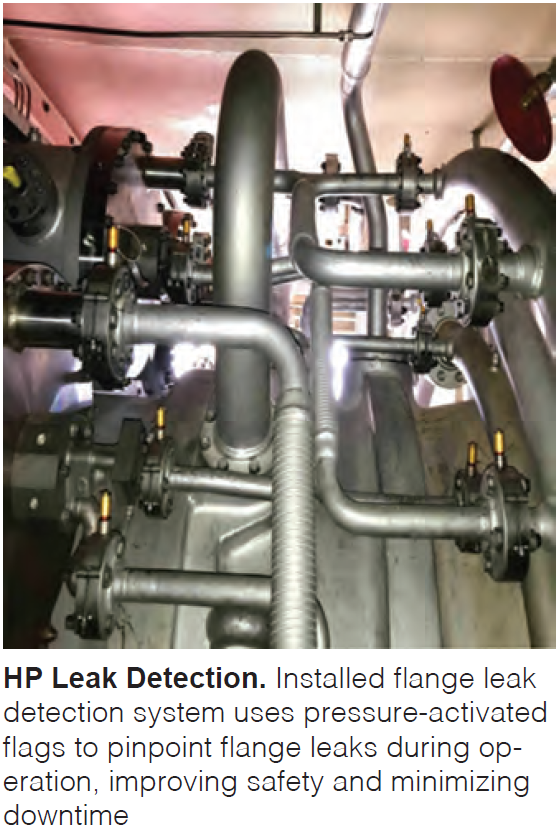

Flange gas leak detection to maximize safety at reduced cost

HP Leak Detection

Learn about a patented flange leak detection system that identifies active fuel and compressor leaks during operation using visual flag indicators that trigger at approximately 6 psi. It eliminates unsafe manual leak checks, shortens troubleshooting time, and prevents costly outages.

Solutions for legacy turbine torque converter issues

Voith US

Presentation reviews service experience and replacement options for Voith torque converters used in turbine starting systems. Field data from 2023–2024 indicate fewer catastrophic failures as operators adhere more closely to maintenance schedules and perform alignment checks more regularly. Standard overhauls and overrunning clutch replacements remain common, while actuator adjustments and coupling wear show slight increases.

Bevel gearbox issues continue to rise, prompting attention to oil level and quality and inclusion of gearboxes in torque converter maintenance programs. Flexible element couplings and solenoid valves are identified as critical spares. Voith confirms availability of replacement units and components for all 501F and 501G torque converters, including solutions for obsolete starting equipment.

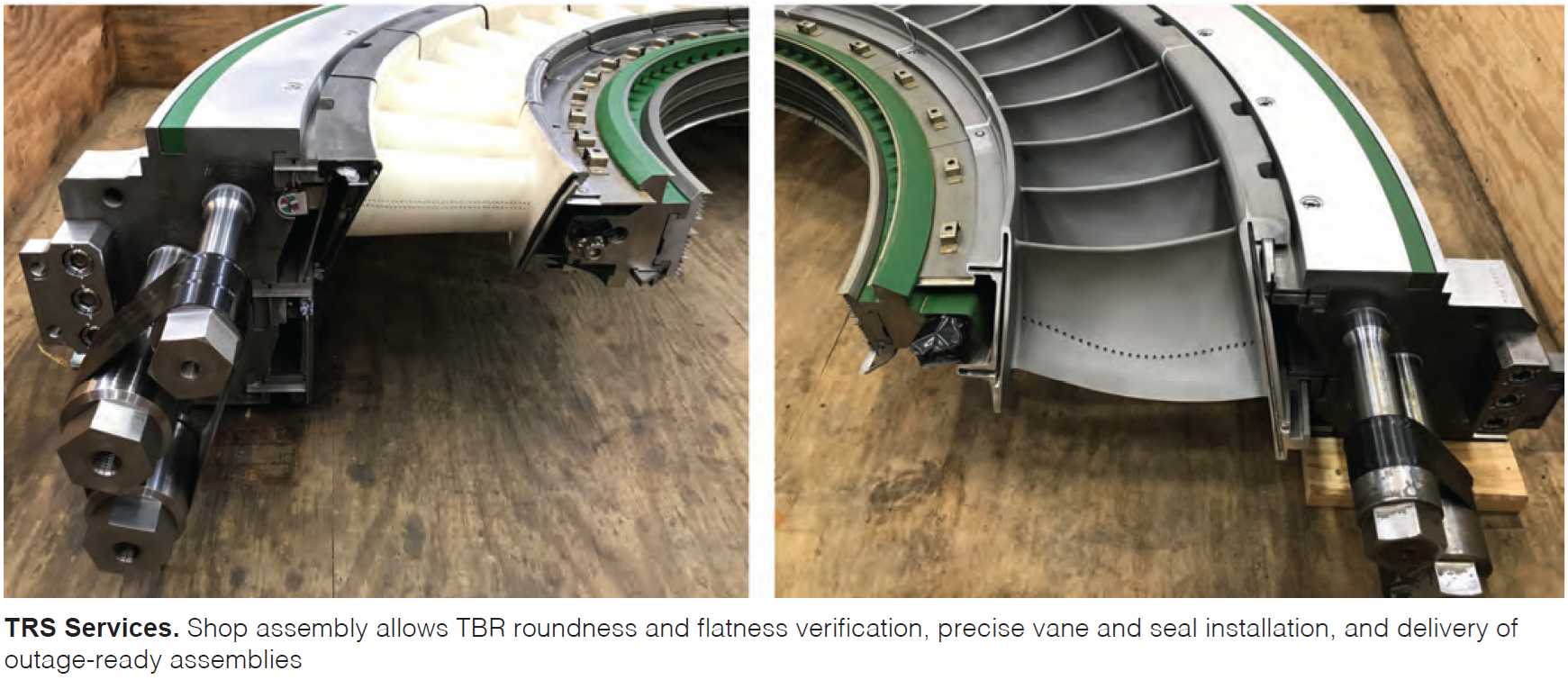

Comprehensive approach to blade ring repair and assembly

TRS Services

TRS Services discussed a structured approach to repairing and assembling 501F and 501G turbine blade rings (TBRs) to reduce outage delays and improve fit-up accuracy. Field cases show that TBRs often exhibit radial out-of-roundness and axial distortion after engine service, affecting vane alignment and interstage seal housing fit.

Using precision jacking fixtures, TRS restores roundness from 0.117 to 0.037 in. total indicator runout and flatness from 0.085 to 0.022 in. Repairs include dimensional restoration, downstream deflection correction, and braze preform applications for vane and seal surfaces. Performing TBR centralization and assembly in a controlled shop environment ensures alignment accuracy, minimizes on-site labor, and shortens outage duration.

Four-way-joint and coupling-bolt solutions

Nord-Lock Group

Company provides engineered solutions addressing persistent leakage and maintenance issues at turbine four-way joints and coupling interfaces. The four-way joint design combines a variety of custom solutions to correct cylinder misalignment and achieve uniform tensioning. The system integrates an internal sealing assembly with adjustable retainers that prevent air escape and accommodate thermal expansion during operation.

For coupling interfaces, the EzFit mechanical expansion bolt replaces traditional fitted bolts that are prone to galling and removal difficulties. EzFit allows installation and removal with hand tools while maintaining high torque transmission and precise shaft alignment.

Field cases show installations completed in under three hours, significantly reducing outage duration and machining time. Together, these technologies improve sealing reliability, alignment precision, and maintenance efficiency for the 501F and 501G fleets.

Steam Turbines

Steam turbine major contingency planning

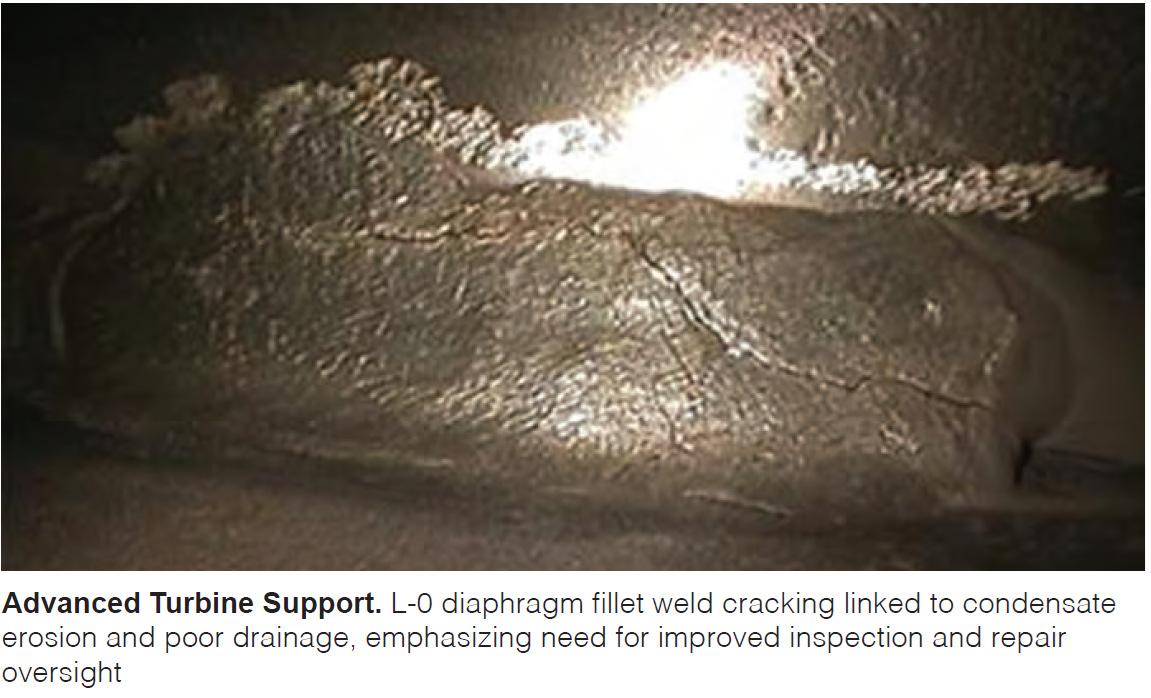

Advanced Turbine Support

In a lively vendor session led by Bryan Grant, attendees were urged to treat steam-turbine major-outage contingency planning as a structured, 18-month process. The goal: lock down scope, suppliers, spares, people and specialty tooling early enough to avoid delaying the outage critical path.

Start 18 months out. Grant recommended beginning with scope development, budget approvals and RFQ packages; supplier vetting and parts quote lead times often dictate schedule realism. Aim to release POs roughly a year ahead to secure shop and field capacity.

Build scope from history and TILs. Use outage, operations and fleet history to frame risk; then review OEM technical information letters (TILs), confirm open/closed status, and bring in independent technical expertise. Don’t rely solely on OEM guidance; leverage user groups and subject-matter experts to stress-test “what-if” scenarios.

Identify critical spares. Priority components include diaphragms (with L-0 fillet-weld issues), rotors, HP/IP front-end blades, L-0 mid-span sleeves, stationary packing and heads, valves, bearings, and oil-system hardware.

Plan roughly 90 days for RFQ through PO, which covers shop support, repair resources and contracts. Then hold 60-day gates for scope finalization and maintenance/operations review to keep alignment.

Control manufacturing and repair risks. Top shop-floor defect drivers called out: drawing-revision errors, insufficient CNC-program verification, operator qualification gaps, missed operations in the manufacturing process plan, documentation and gauge errors, and material-selection mistakes. Treat finger-dovetail and cover installs as high-risk steps; verify fit before reaming and inspect before closing.

Steam turbine warming system for CCGT flexibility

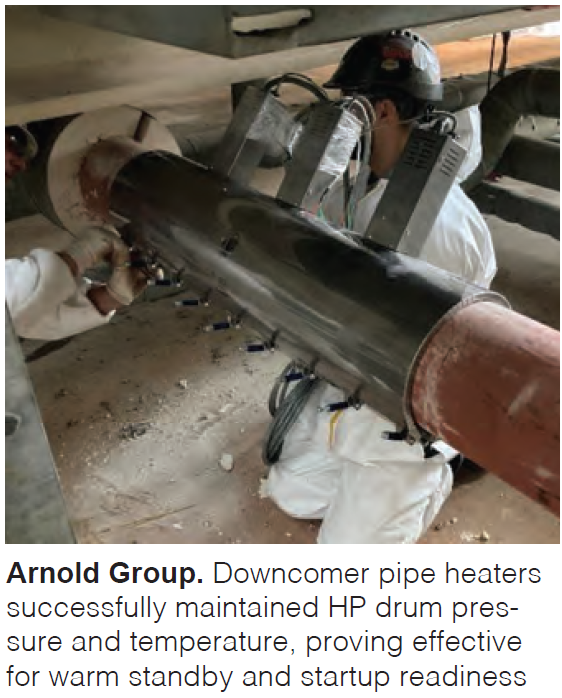

Arnold Group

If dispatch appeal and reduced startup costs are what you desire, then Norm Gagnon urged users to consider this three-pronged approach—steam-turbine warming, HRSG warming, and steam-valve service—aimed at improving starting reliability, emissions performance, and cycling life for your CCGT units.

A D11 steam-turbine warming case study reports total plant cycle time cut from 266 to 149 minutes, ~25% HP-rotor LCF reduction, and hot-start temperature hold for ~60 hours using insulation alone; casing differentials dropped up to 95% with active warming. Key takeaways include up to 75% startup-time reduction and ~50 kW parasitic to maintain temperature at shutdown.

An evolving HRSG warming concept, verified in an EPRI project, uses custom heating panels and PLC control to maintain ~200°F in HP drum downcomer piping with ~300 kW power; test demonstrated maintaining ~20 psig drum pressure for hours and reduced thermal shocks compared to sister unit.

Steam-valve service from Arnold Group utilizes its vast expertise in onsite machining and valve-parts partnerships to create opportunities for heat-rate gains from leak repairs and testing.

Generators/Electrical

Generator fleet maintenance and rewind practices

National Electric Coil

Howard Moudy briefed attendees on maturing 501F/G generator fleets. With most units at or beyond 30-year design life he reiterated persistent focus areas: air-cooled generator issues, cyclic-operation damage, GVPI failure modes, and model-specific known issues.

For AEROPAC I units, common pain points include partial discharge (PD), end-winding looseness/resonance, phase-ring and flex-link failures, and rotor pole-to-pole risks. NEC’s response centers on pole-to-pole crossover upgrades (in-situ or rotor-out) and stator rewinds using optimized coil designs, upgraded OCP, improved coil-to-slot interfaces, and verified detuning via bump tests.

AEROPAC II (GVPI) machines show PD, end-winding looseness/harmonics, slot movement, and end-winding failures near the core exit; diagnostics emphasize bump tests, EMI/PD monitoring, and borescope inspections. Solutions range from pole-to-pole hardware replacements (connectors, shrouds, radial blocks) to selective stator rewinds, sometimes converting GVPI to conventional systems.

NEC’s closing message: know your unit’s known issues, monitor them methodically, and plan proactive fixes to avoid forced outages.

Online non-destructive PD testing

Doble Engineering

This presentation reviews Doble’s approach to online, non-destructive partial discharge (PD) testing for assessing the condition of medium- and high-voltage cable systems. PD activity serves as an early indicator of insulation degradation, allowing operators to identify developing faults without taking equipment offline. Doble’s method applies capacitive or inductive sensors on energized cables to capture high-frequency discharge signals for laboratory analysis.

The proprietary time-frequency mapping software separates PD sources from noise and distinguishes between internal, surface, and corona discharges. Case studies in utility and industrial settings demonstrate how early PD detection supports maintenance prioritization, reduces unplanned outages, and verifies installation quality across complex power networks.

Comprehensive rotating machine health assessment through PD and EMI diagnostics

Doble Engineering

The presentation explains how combining partial discharge (PD) and electromagnetic interference (EMI) analysis provides a more complete understanding of generator and motor insulation health. EMI testing detects high-frequency activity from 50 kHz to 100 MHz without requiring permanent sensors, allowing early identification of loose connections, damaged joints, or diode failures. PD testing characterizes localized insulation breakdowns, including void, slot, and end-winding discharges.

Case studies on 115-MVA and 105-MVA air-cooled generators show that integrating PD and EMI diagnostics can detect both electrical degradation and mechanical issues such as contamination and busbar joint defects. The approach improves root-cause analysis, enabling operators to plan targeted maintenance, reduce unplanned outages, and extend the operational life of rotating machinery

Protective relay life cycle planning for power stations

Shermco Industries

Slide deck reviews best practices for upgrading obsolete protective relays in generator and auxiliary switchgear systems. Modern digital relays enhance reliability, provide event recording, and integrate with DCS platforms for remote monitoring. Aligning relay replacements with breaker refurbishment and PRC-005 testing reduces costs by up to 50% while improving protection and arc-flash mitigation.

HRSGs

KinetiClean™ HRSG tube cleaning technology

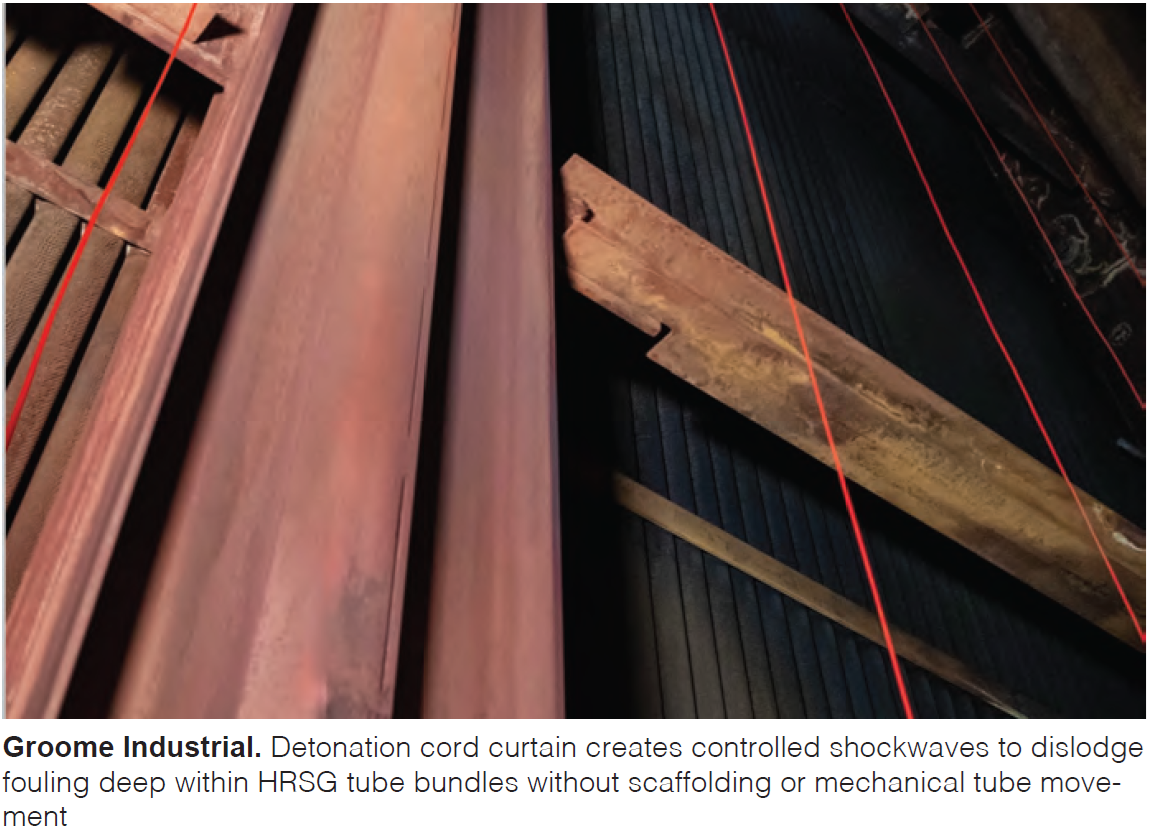

Groome Industrial Service Group

Growing demand for peak output and efficiency places HRSG cleaning in the spotlight, offering one of the most attractive ROIs in CCGT plant optimization regardless of cleanind method. The patented KinetiClean™ process removes fouling and deposits from HRSG finned tubes using a controlled three-step method. The system combines a kinetic shockwave generated by a detonation cord curtain, automated high-pressure air distribution, and in-house debris removal to achieve full-coverage cleaning without tube spreading, scaffolding, or manual handling.

Each curtain is engineered for the HRSG’s size, fouling level, and fin configuration, ensuring deep penetration into tube bundles and removal of iron oxides, ammonia salts, and other contaminants. The detonation cord is cap-sensitive and handled only by licensed blasting professionals, ensuring safe, non-destructive operation.

Case studies demonstrate measurable performance gains: a derated Northeast CCGT plant reduced backpressure by 2.4-in water column (WC), recovered 9 tons of debris, and restored baseload operation, while a Southeast site saw a 1.5-in WC drop in dP and a 2–4 MW output increase across two units.

KinetiClean improves heat transfer, lowers stack temperature, and restores gas turbine heat rate while minimizing outage duration. Independently reviewed by EPRI and approved by Siemens Energy, the method offers a reliable, repeatable, and safe approach to HRSG cleaning that supports efficiency recovery and sustained CCGT performance.

How GT upgrades affect downstream equipment

Tetra Engineering Group

Tetra Engineering examines how gas turbine and combined-cycle upgrades improve output, efficiency, and operational flexibility while affecting downstream systems. Typical gas turbine modifications—such as increased firing temperature, upgraded blading, and improved combustor design—can yield 3–5% higher peak power and lower heat rate. However, these upgrades alter exhaust temperature, flow, and composition, influencing HRSG steam production, casing vibration, and emission control performance.

Proper assessment requires digital modeling to evaluate system impacts, confirm safety valve and pressure ratings, and prevent fatigue in high-temperature components. Financial and regulatory planning remains critical to manage investment, supply chain constraints, and commissioning risk.

BOP

The role of the owner’s engineer in outage execution

Gulf Turbine Services (GTS)

Joe Mitchell, a former end user and frequent attendee of the 501F Users Group, showcased how engineering oversight services enhance outage planning, execution, and quality assurance in GT-based powerplants. Acting as technical representatives for plant owners, GTS embeds SMEs within project teams to ensure compliance with specifications, maintain schedule discipline, and protect asset reliability.

The owner’s engineer functions as an independent oversight layer, bridging plant management and contractors through technical validation, quality control, and risk mitigation. Services include monitoring progress against budget and schedule, verifying contractor workmanship, ensuring adherence to foreign material exclusion policies, and overseeing component testing and commissioning. GTS also emphasizes its staff augmentation model, which leverages experienced engineers, like Mitchell, to offset attrition-related knowledge gaps and provide niche technical skills during major outages.

Operational efficiency benefits stem from early involvement in pre-outage planning, structured quality control metrics, and lessons-learned integration across projects. This approach reduces change orders, improves schedule predictability, and ensures that both OEM and third-party work meets industry standards.

Access the slides to view case studies of oversight of F-class flange-to-flange upgrades, diverter damper overhauls, and major turbine inspections.

Transition duct enhancement: A 3D-scanned approach

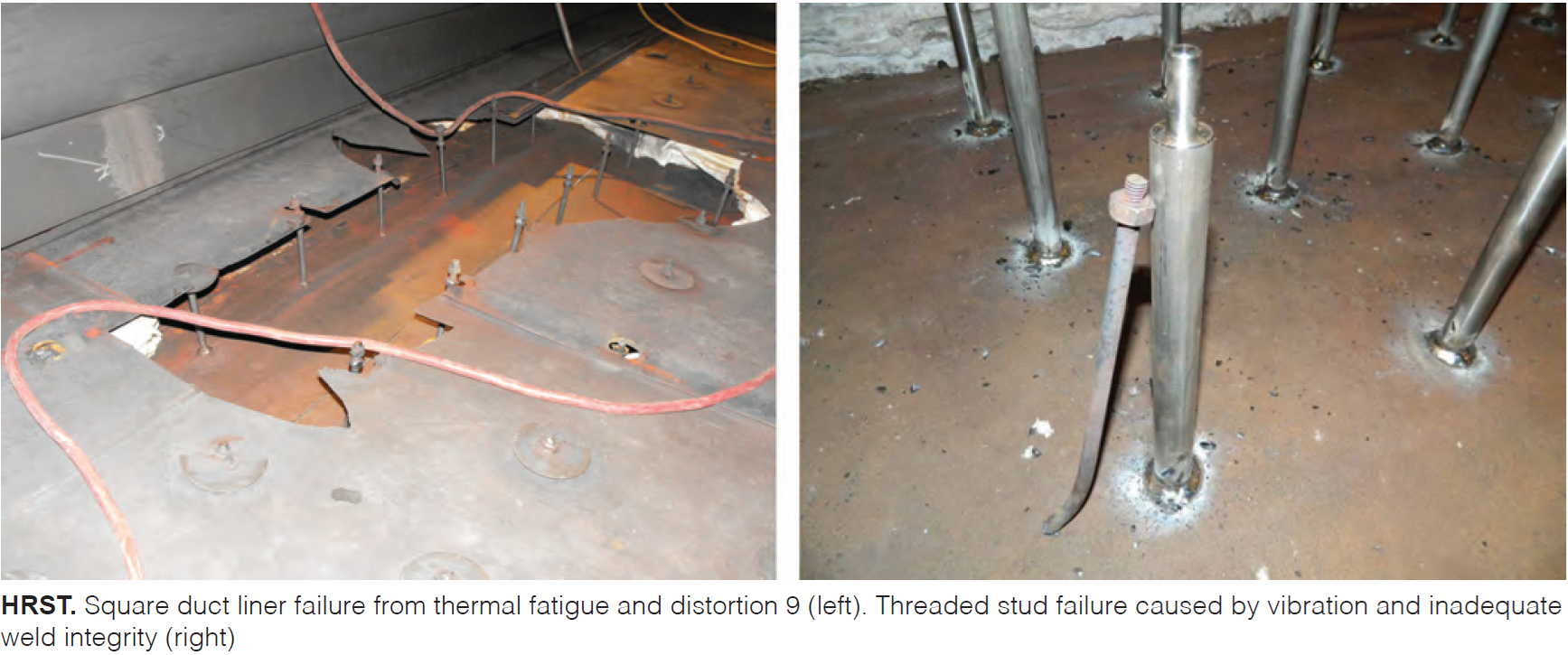

HRST Inc

Slides detail a case study on improving the Siemens SGT6-5000F transition duct using LiDAR-based 3D scanning to address common liner and stud failures. The round-to-square duct, measuring roughly 13 ft in diameter and 14 ft in length, presents geometric challenges that have historically led to stud cracking, scallop bar detachment, and liner misalignment. Traditional field measurements and incomplete fabrication drawings made precision retrofits difficult.

To overcome these issues, HRST deployed LiDAR scanning to capture a detailed point-cloud dataset of the duct interior. Integrating this data with CAD tools enabled accurate modeling of stud locations, liner geometry, and sheet-metal cut patterns to ensure exact fit-up. The 3D overlay verified component interfaces before fabrication, minimizing rework and installation errors.

Installation procedures emphasized alignment of centerlines, shingled liner orientation for gas-flow optimization, and welded washer retention for structural integrity. The approach demonstrated how combining high-resolution scanning with disciplined installation practices can extend duct life, enhance reliability, and reduce turnaround times.

CT exhaust silencer design approach

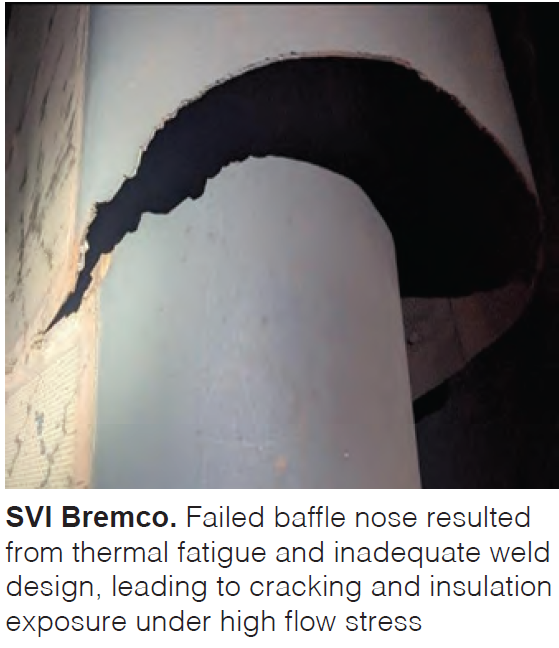

SVI BREMCO

Tucker York invites end users to read up on his engineering-based approach to CT exhaust silencer design, emphasizing material selection, structural integrity, and long-term reliability. The presentation covers parallel, bar, and cylindrical silencer types used in simple-cycle, bypass, and HRSG exhaust systems, each engineered to reduce turbine-generated noise and backpressure.

Design methodology incorporates finite element and computational fluid dynamics analysis to assess thermal fatigue, creep rupture, and vortex-induced vibration. Material choice—typically 409SS, 11Cr-Cb, 304SS, or 321SS—is guided by ASME II, Part D allowable stress limits for high-temperature service.

Fabrication guidance covered stitch and plug-weld techniques for perforated skins, protection of acoustical pillows/insulation, and common failure root causes with corrective practices.

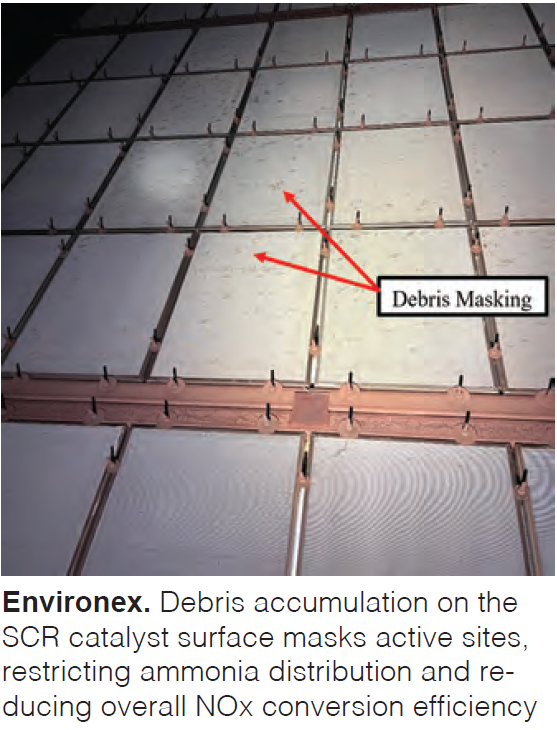

Extending catalyst life through proper system evaluation

Environex Inc

Andy Toback dove deep into strategies to extend the operating life of SCR and oxidation catalyst systems through detailed system evaluation, data analysis, and sample testing. Accessing his extensive slide deck is highly recommended after reading the Cliffs Notes version below.

Catalyst degradation is often accelerated by factors external to the catalyst itself, including exhaust temperature variability, uneven ammonia injection, seal leakage, and particulate buildup. Comprehensive inspections assess catalyst face fouling, side and floor seal integrity, bypass leakage, and ammonia injection grid condition to identify non-catalyst issues limiting performance.

Operational data analysis, typically spanning two to three years, includes load profiles, catalyst differential pressure, NOx inlet and outlet concentrations, ammonia slip, and vaporizer performance. Laboratory testing of catalyst samples across multiple temperatures and NH3-to-NOx ratios determines true activity levels and projects remaining service life based on the most demanding operating mode.

Field experience shows that a full-system approach (mechanical inspection, operational review, and analytical testing) extends catalyst service intervals, minimizes ammonia slip, and maintains emissions compliance at lower reagent consumption. Targeted corrective actions can realign catalyst performance with design expectations, helping operators preserve compliance margins, reduce operating cost, and avoid premature catalyst replacement in both combined-cycle and simple-cycle gas turbine applications.

Oil, your hidden asset

CC Jensen

Presentation highlights the value of treating lubricating oil as a long-term asset rather than a consumable. Clean, properly maintained oil extends the life of critical rotating equipment, reduces downtime, and lowers total operating costs. Examples include a ball mill bearing system where optimized filtration and testing reduced oil changes from six times per year to once every three years, cutting oil use by 80% and extending bearing life by 50%.

Key testing methods are viscosity, total acid number, additive depletion, and particle count analysis to determine oil condition and remaining life. Advanced diagnostics, including FTIR, membrane patch colorimetry, and RULER tests, help detect varnish, oxidation, and additive loss before failure occurs.

Effective maintenance combines continuous monitoring, inline and offline filtration, and moisture control. By maintaining cleanliness, dryness, and chemical stability, operators can increase bearing and gear life by factors of four to five and significantly improve equipment reliability across the power plant.

Improvements in freeze protection technology

CIAC Systems

Tim Mullen reviews advancements in electric freeze protection systems designed to maintain reliable operation of balance-of-plant piping and instrumentation in cold-weather CCGT facilities. CIAC’s latest heating solutions use self-regulating heat trace technology with integrated monitoring and control to maintain uniform temperature across exposed surfaces. The system minimizes thermal stress, prevents ice formation, and ensures consistent startup capability during subfreezing conditions.

Recent developments include improved insulation interfaces, real-time temperature feedback, and energy-efficient circuit design that reduces parasitic load. Field applications demonstrate enhanced performance compared to conventional trace systems, with faster response time and reduced maintenance requirements, supporting improved winter reliability for plant operators.

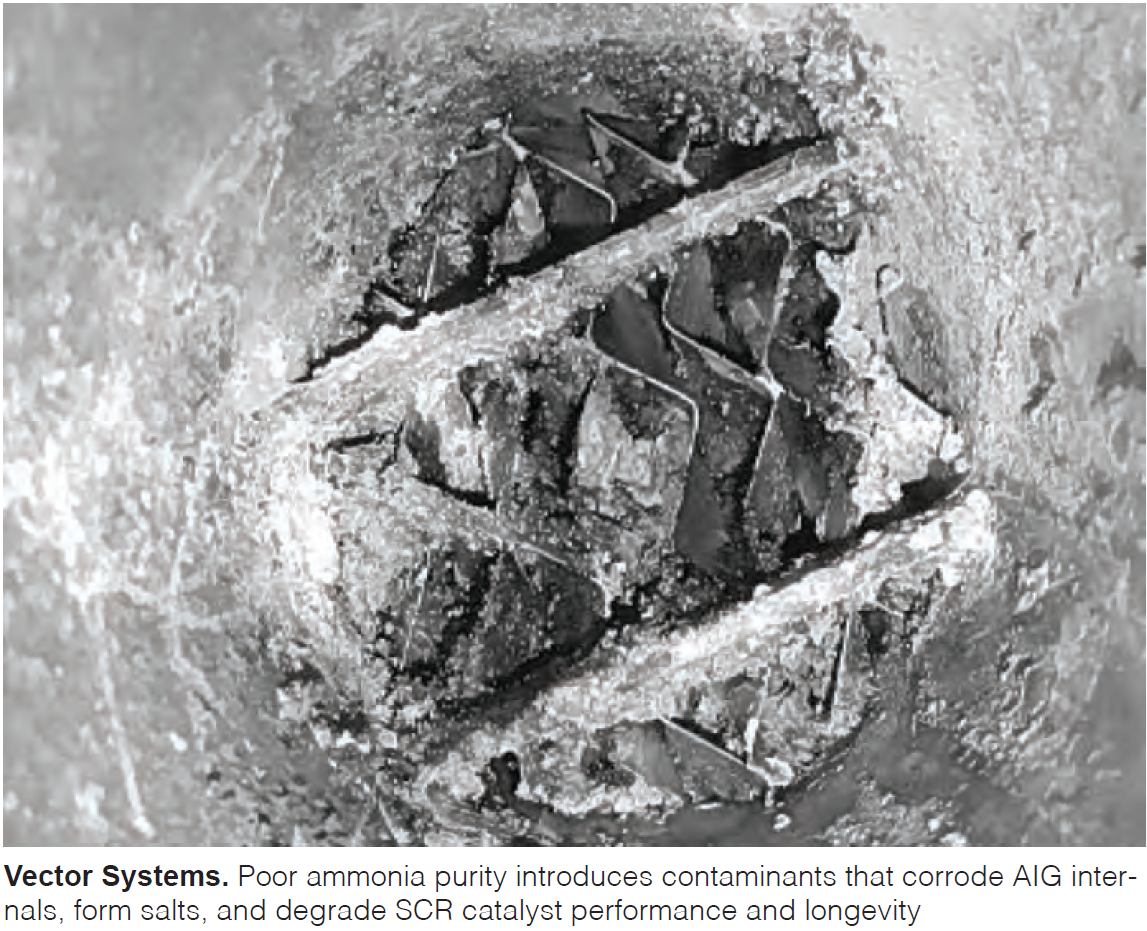

Distribution effects on SCR system performance

Vector Systems

Vaughn Watson dives into how AIG tuning directly affects SCR performance and catalyst life. Uneven NH3-to-NOx ratios often stem from maldistribution, velocity stratification, and fouling in AIG lances, leading to elevated slip and inefficient NOx reduction. Precise tuning aligns NH3 flow with measured NOx profiles, optimizing reaction uniformity and minimizing reagent use.

Case studies highlight these benefits. In one F-class CCGT retrofit, Vector’s Katana AIG reduced ammonia consumption by up to 40% and stabilized NOx control without catalyst replacement. Another 501F site resolved poor performance in a new catalyst by rebalancing AIG flow after discovering excessive maldistribution caused by reduced system pressure drop. Together, the results demonstrate how AIG geometry, orifice precision, and in-situ tuning restore SCR performance, extend catalyst service life, and reduce total operating costs.

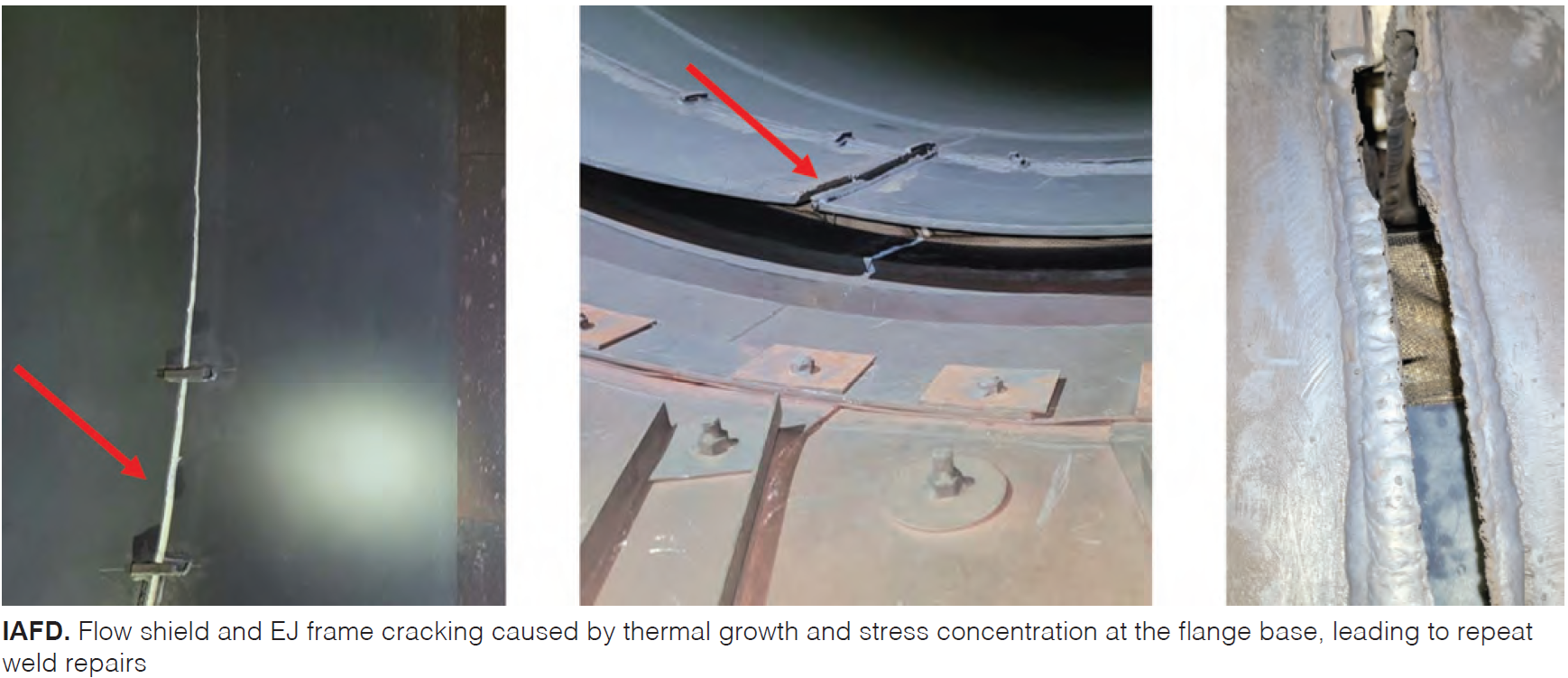

CT outlet expansion joint and transition duct liner issues

IAFD

This presentation analyzes failure mechanisms and upgrade strategies for Siemens 501F/G outlet expansion joints and adjacent transition duct liner systems. Accelerated wear in fabric joints is traced to startup vibration and operational flutter, all intensified by engine performance upgrades that increase exhaust energy. Original joint materials and frame geometries exhibit high stress at the base of the EJ flange, promoting cracking at weld interfaces.

IAFD recommends redesigned flanges that accommodate thermal growth and flexible, heavy-duty PTFE-based joint materials with improved insulation to resist fatigue and flutter. Thermographic inspections reveal consistent liner plate deterioration, misaligned overlaps, and insulation breakdown contributing to localized hot spots.

Corrective actions include increased stud density, proper baton channel installation, and re-lapping of liner plates to maintain gas-tight integrity. These targeted upgrades enhance structural flexibility, extend component life, and reduce recurrent welding and outage frequency in aging units.

Proper prediction of turbine oil degradation to prevent varnish formation

Shell Lubricant Solutions

Slides provide a review of oil degradation mechanisms and predictive testing methods to prevent varnish formation in gas and steam turbine lubrication systems. Oxidation by-products such as acids, aldehydes, and ketones agglomerate into sludge and varnish, reducing bearing clearances, fouling valves, and accelerating wear.

Key predictive tools include the RULER test to quantify antioxidant depletion, FTIR spectroscopy for oxidative species, TAN for acidity, and MPC for deposit potential. Routine trending of these parameters enables timely oil replacement or varnish filtration. Effective monitoring minimizes forced outages, extends fluid service life, and preserves turbine reliability.

Expansion joint upgrades for legacy 501FD and 5000F units

Frenzelit Inc

Case studies were presented on recent field upgrades to exhaust expansion joints on legacy 501F units. Failures in original manifold sections are linked to moisture intrusion, vibration during low-load operation, and thermal cycling fatigue. The upgraded design introduces scalloped TEM flanges and reinforced flow shields to reduce stress concentration at weld joints. Enhanced soft goods protect against water ingress and startup pulsing, while redesigned hard parts maintain flexibility through repeated thermal cycles. Externally, spring-loaded insulation bands keep the manifold wrap tight during expansion and contraction, preventing radiant heat exposure on the lower joint. The improvements extend durability and minimize maintenance frequency for aging F-class equipment. CCJ