Lawrence Generating Station

Owned by Hoosier Energy (four units) and Wabash Valley Power Assn (two units)

Operated by NAES Corp

258 MW, six simple-cycle LM6000 natural-gas-fired peaking units, located in Lawrence County, Ind, and connected to Hoosier’s 161-kV transmission line

Plant manager: Robert VanDenburgh

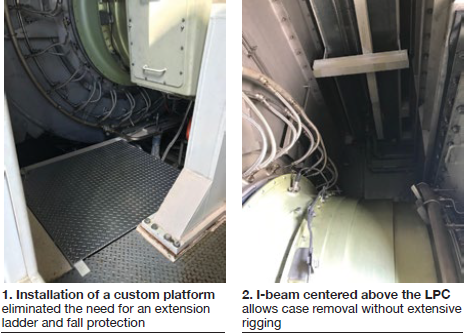

Challenge. At Hoosier Energy’s Lawrence Generating Station certain maintenance evolutions inside the gas-turbine package required technicians to use an extension ladder. Example: The Kvaerner package does not have a deck at engine level so technicians had to use an extension ladder to work on the low-pressure compressor (LPC).

The ladder was lowered 4 ft from engine level so the footing could be safely secured to the package floor. This required the technician to don fall protection to complete both routine and non-routine LPC maintenance and created an ergonomically uncomfortable work environment.

Another challenge was to eliminate the rigging necessary to remove the LPC case. Rigging chains create a major safety hazard to the technicians and to the equipment. Chain-falls become a trip hazard and create several pinch points and hand traps. Chain-fall rigging requires extreme care while removing the LPC case in order to prevent airfoil damage.

Solution. The safety committee discussed options and decided that a custom diamond-plate platform would eliminate the need for an extension ladder and fall protection (Fig 1). It also would allow technicians to work safely from an ergonomically friendly position.

The operations team discussed options and concluded installing an I-beam above the LPC case would allow technicians to remove the case without extensive rigging (Fig 2). One technician can comfortably work from the installed platform to complete the LPC case removal without the dangers associated with ladders and rigging.

Results. The custom platform installed in the LPC work area eliminated the fall hazard. The LPC now can be accessed without the need for an extension ladder or fall protection. Plus, ergonomics of this work environment have been improved dramatically.

The I-beam installed above LPC aft of the VBV ductwork allows for safe and level case lifts without need for extensive rigging.

Project participants:

Matthew O’Hara, lead O&M technician

Kevin Wildner and Jared Thomas, plant operators