Challenge. OSHA’s Voluntary Protection Programs recognize and partner with businesses and worksites that exhibit excellence in occupational safety and health. Sites are committed to effective employee protection beyond the requirements of OSHA standards. VPP participants develop and implement systems to effectively identify, evaluate, prevent, and control occupational hazards to prevent employee injuries and illnesses. Contractor safety is a major component in being awarded the OSHA VPP Star.

Solution. Tenaska Virginia has incorporated the following into its contractor safety program which is being used by OSHA as a model:

- Contractor Safety Verification Questionnaire.

- Proof of contractor insurance.

- Explain site access instructions so contractors know what to expect when they get on site the first day (security, briefings, etc).

- Site requirements: site access, speed limits, possible vehicle searches, weapons rules, parking/vehicles access, tools, cleanliness, fall protection, PPE, evacuation route, etc.

- Inspect all contractor equipment used on site (forklifts, man lifts, etc).

- Ensure contractors fully understand the plant’s safety standards.

- Contractors to participate in the “job hazard analysis” process.

- Contractors must have a translator on site if the company uses non-English-speaking employees.

- Annual contractor written exams both in English and Spanish.

- Each contractor is listed in a database and issued a serial number.

- Safety walk-down inspections are required every work shift.

- Any employee can stop work for safety violations.

- Any employee can stop work for housekeeping violations.

- Approve all contractor chemicals prior to use on-site.

- Daily LOTOs are always reviewed.

- Ensure contractor understands there is no chemicals discharge allowed from the plant.

- An employee is assigned to contractors.

- An employee is our outage coordinator.

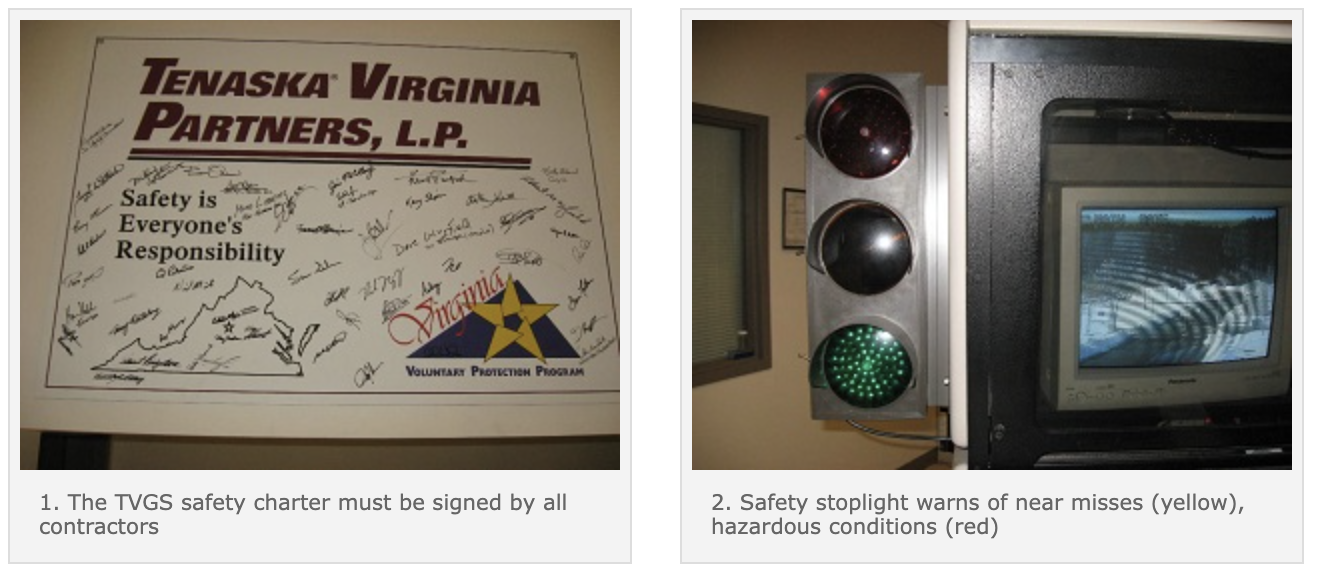

- New contractors are required to sign the plant’s safety charter (Fig 1).

- Obtain and verify adequate spill containment equipment.

- Stage spill kits, dumpsters, waste barrels, and smoking areas.

- Communicate waste disposal areas/rules.

- An outage safety barbecue is held with all contractors and employees to express the importance of following our safety policies, sharing safety ideas, and understanding our commitment to safety and “esprit de corps”.

- A safety traffic stop light is mounted in the control room (Fig 2). This stoplight shows the colors red, yellow, and green. Green light represents no safety near misses or missed opportunities; a yellow light indicates a near miss; a red light indicates an accident or hazardous situation.

- Contractor supervisors and all employees are required to sign the plant’s safety charter. This ensures we are all on board in maintaining an open honest safety culture.

- Every year the facility votes for our “Contractor of the Year.”

Results. OSHA is using our contractor safety program as a benchmark for future OSHA VPP inspections. We were recertified as OSHA VPP Star in 2013.

Project participants:

Dr Robert Mayfield, plant manager

Donnie Scott, operations manager

Sam Graham, maintenance manager