CO2 cleaning of high-voltage windings—a cautionary tale

Sean Orchuk, Electric Machinery’s field service manager, reminded GUG attendees that the use of CO2 pellets as a generator cleaning tool is well-documented, but long-term insulation loss must be weighed against the potential benefits of dry-ice blasting.

Generators are expected to function for decades with minimal intervention, he said, and between maintenance cycles the stator windings may be exposed to oil and other sticky substances. There is a strong motivation to remove surface films because they attract contaminants, thereby reducing insulation resistance, increasing the propagation of corona, and ultimately causing winding failure.

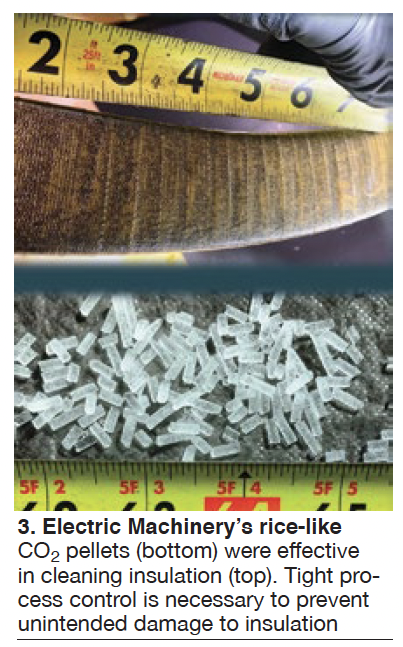

CO2 pellets, Orchuk continued, offer the promise of a cleaning medium without the challenges associated with chemical cleaning and are proven to remove dust, carbon, oil, etc, from windings and other irregular surfaces (Fig 3). The high velocities used in CO2 cleaning processes create a risk of damage to the insulation systems of generator windings. When improperly used or misapplied, dry-ice particles can damage brittle mica and other materials used in winding tapes—an unintended consequence of the maintenance process.

In addition, the cleaning medium is limited by the line of sight from the nozzle, and significant areas of the generator winding may not receive direct benefit from this method. Case studies provided in the PowerPoint on the Power Users website review cleaning methods for typical insulation systems, as well as typical typical contaminants and the range of velocities recommended for their removal with minimal or no insulation damage.