Leadership, skill, attitude, community key to vital plant’s success in delicate ecosystem

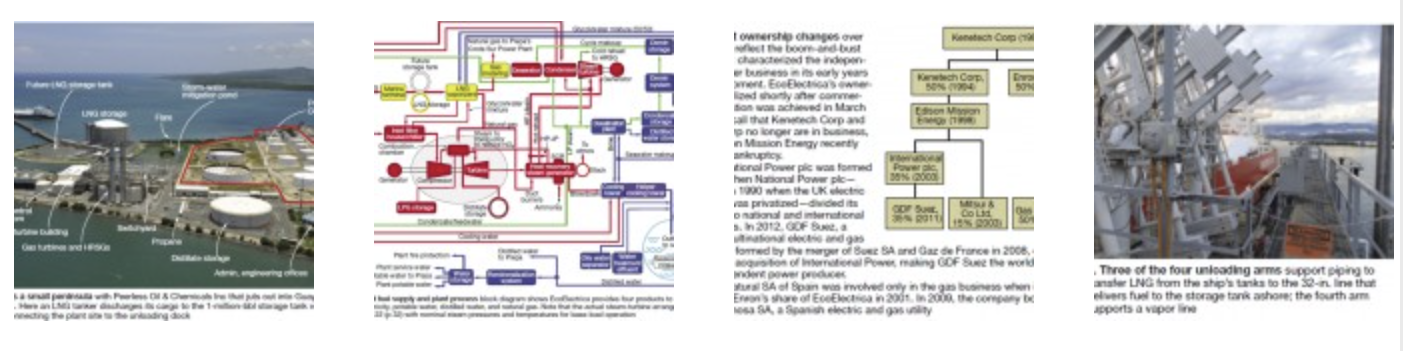

EcoElectrica LP, located on the southern coast of Puerto Rico in Punta Guayanilla (municipality of Penuelas) a few miles west of Ponce, is critical to the economic health of the Commonwealth. One of the cleanest generating stations in the world and a staunch protector of the local environment, EcoElectrica’s 507-MW 2 x 1 F-class combined cycle burns liquefied natural gas (LNG) to produce 16% of Puerto Rico’s electricity (Fig 1). It also receives 30% of the fuel burned on the island for electric generation through its terminal.

When EcoElectrica began commercial operation in March 2000 as Puerto Rico’s first independent power producer (IPP), it was the only generating station in the world with an integrated LNG terminal (Fig 2). It continues as the only such facility in the Western Hemisphere today, according to the CCJ’s editorial researchers. Although there are several LNG terminals in the Americas supplying pipelines that deliver gas to generating facilities, they do not benefit economically from the integration of power and regasification operations as does EcoElectrica.

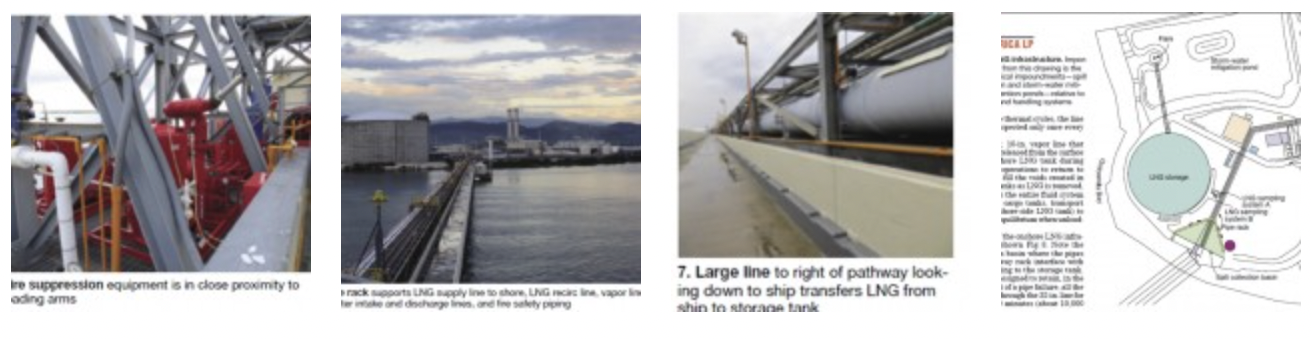

Capturing the heat for regasification from the air inlets to the gas turbines, and from plant cooling water, allows the 501FC engines to operate year-round at rated output independent of ambient temperature and reduces the combined-cycle heat rate to save about $9 million in fuel cost annually.

In 2012, EcoElectrica expanded the regasification capacity at its terminal to supply fuel to two nominal 400-MW conventional steam units at Puerto Rico Electric Power Authority’s (Prepa) Costa Sur Power Plant a couple of miles away. The boilers at that facility, installed 40 years ago and designed to burn only No. 6 oil, were re-equipped for dual-fuel operation in 2011.

Costa Sur currently receives 93 million standard cubic feet per day (scfd) of gas from the EcoElectrica terminal—enough to produce about 400 MW. Output could double if required additional FERC permits are received.

Prepa is the offtaker for all the power produced by the independent generator, which also provides grid ancillary services—such as reactive power, frequency control, and spinning reserve. In addition, EcoElectrica supplies the utility distilled water from its 2-million-gal/day desalination facility and sells excess potable water to the Puerto Rico Aqueduct and Sewer Authority (Prasa).

The electric-power supply contract with Prepa is for 22 years; dispatch is by grid operators between 54% and 100% of the generating plant’s full-load rating. Price of power is fixed annually for up to 76% of rated output; above that level the price is based on spot offers. EcoElectrica is required by the utility to maintain its availability at a minimum of 93%; plus, thermal efficiency must be at least 45%. Regarding gas supply, Prepa contracts for LNG directly; EcoElectrica is paid a fee for LNG handling, storage, and regasification, and for delivery of the product gas to Costa Sur.

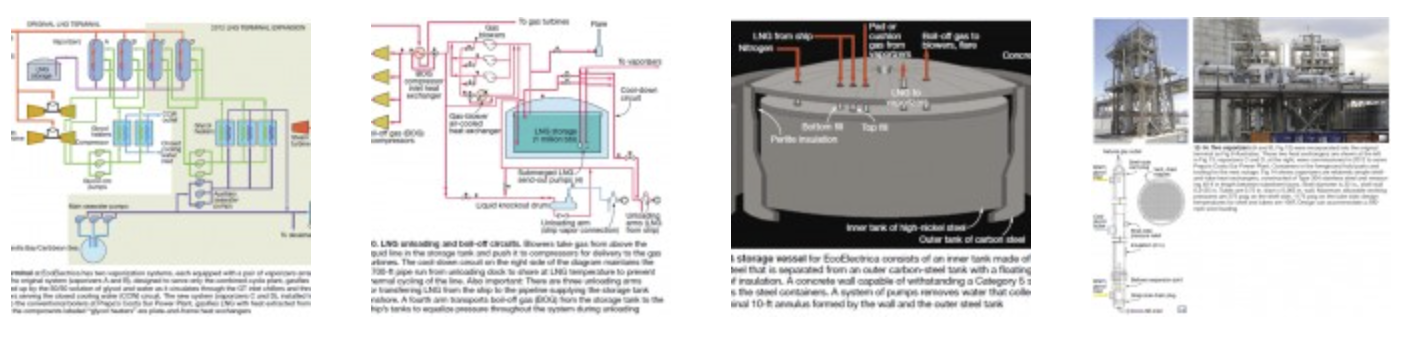

The facility’s business success is attributed in large part to its knowledgeable and loyal can-do workforce and to the plant’s proactive social and environmental programs. The owners (Fig 3) have never wavered from their strong support of employee and local-area education initiatives, and of environmental protection.

Examples of ongoing investments in education and community development are substantial and include the following:

- Annual scholarships for 40 graduates of local high schools.

- Learning materials for two-dozen schools in the area.

- Sponsorship of science fairs.

- Contributions to local community and civic organizations.

Evidence of the deep concern for the environment shared by both the ownership team and plant personnel include the programs EcoElectrica supports and conducts internally as well as through local institutions—such as the University of Puerto Rico (UPR). Projects that illustrate the level of commitment to the environment include these:

- Removal of coral and sea grass prior to LNG terminal construction and their transplant after project completion.

- Mangrove planting.

- Ongoing aerial manatee survey.

- Construction of a mitigation pond for university research.

- Rescues of marine animals.

The plant has received nearly two dozen awards over the years for its community and environmental work and for its sterling safety record. Continuity of success and top performance speak volumes about the quality and commitment of both the facility’s leadership and its workforce (Sidebar).

LNG terminal

You’re almost sure to find mention of LNG somewhere in the news on a daily basis. Back in 2008, when the Henry Hub price of natural gas reached almost $14/million Btu, the focus was on import terminals and regasification facilities (in June 2012, 91 were operating worldwide). Then the price plummeted to less than $2 in 2012, courtesy of shale-gas production, and the focus shifted to liquefaction facilities and export terminals (25 worldwide in June 2012).

The environmental benefits of gas have increased demand for the fuel, and also contributed to the interest in inland peak-shaving facilities for storing and vaporizing LNG on an intermittent basis to meet short-term peak requirements. More than 260 of these facilities were in service worldwide as of June 2012, some operating since the mid-1960s, according to the experts at CH-IV International, located in Hanover, Md, and Houston. This number does not include the many small vehicle fueling stations and industrial LNG facilities around the globe.

But to nearly all personnel at gas-turbine-powered simple- and combined-cycle facilities, LNG exists only as an acronym because it is regasified and injected into existing gas-pipeline infrastructure well before the plant boundary.

Natural gas condenses at atmospheric pressure only after cooling to about minus 260F. The LNG produced occupies 1/600 the volume of its gaseous cousin and generally can be transported and stored economically—assuming oil is used as the basis for comparison. Note that a gallon of LNG has a nominal energy content of 80,000 Btu; ultra-low-sulfur diesel oil contains about 138,500 Btu/gal.

While importing LNG to the mainland US at today’s domestic gas prices is unlikely—except, perhaps, where pipelines are maxed out or unavailable—it makes perfect sense in ecologically minded Puerto Rico, which has no meaningful indigenous fuel resources. EcoElectrica is the industry’s pioneer in the development of an integrated LNG/power generation system for the safe and efficient production of electricity with minimal environmental impact. Its LNG experience is particularly valuable to other power producers serving areas where traditional fuel supplies are constrained.

Carlos A Reyes, PE, EcoElectrica’s general manager of operations, led the discussion on LNG terminal design and operation between the editors and two of the plant’s foremost experts on the subject: Oscar Cedeno, PE, LNG terminal manager, and Project Engineer Dr Jose M Rullan, PE.

By way of background, Reyes is a 30-yr industry professional who appreciates the value of gas-turbine user groups—in particular, the 501F Users Group. He came to EcoElectrica as plant manager in 2004 and was promoted to his current position three years later. Before that Reyes spent 17 years with Prepa, seven of those as the head of operations for the island’s electric system, and three years with coal-fired AES Puerto Rico LLC, leaving that assignment as VP engineering.

An hour-long interview and follow-on tour of offloading operations revealed a relatively simple system and familiar equipment for unloading, onsite transport, storage, and regasification of LNG. However, the fuel’s idiosyncrasies—such as its extremely low temperature and behavior in storage—spoke volumes about the respect LNG deserves and the knowledge and experience required to assure its safe and reliable use (Sidebar).

The EcoElectrica O&M team left no doubt that safety was of primary importance both in terminal design and operation. Certification to OHSAS 18001, the global occupational health and safety management standard, is evidence of the efforts undertaken at the plant to assure a safe and healthy work culture. Reyes pointed to a long list of regulations and enforcement agencies, both national and local (Sidebar), to assure the facility would maintain the unblemished safety record compiled during his tenure (no lost-time accidents last nine years). Protection of the environment and security, both often linked to safety, also have a high profile in that list of agencies.

Cedeno and Rullan described the terminal and its operation beginning with the docking of a tanker. The S/S Sestao-Knutsen’s cargo of 867,990 bbl of LNG was offloaded to the 1,006,400-bbl storage tank during the editors’ visit (Sidebar). That’s enough fuel to operate EcoElectrica for about 40 days, assuming no gas delivery to Costa Sur.

The S/S Sestao-Knutsen is typical in terms of size for an LNG tanker. Nearly 70% of the more than 350 vessels in the global LNG fleet carry between 820,000 and 940,000 bbl. Such vessels typically travel routes of from 1500 to 6000 nautical miles, but the S-K’s voyage from Trinidad is only around 560 miles.

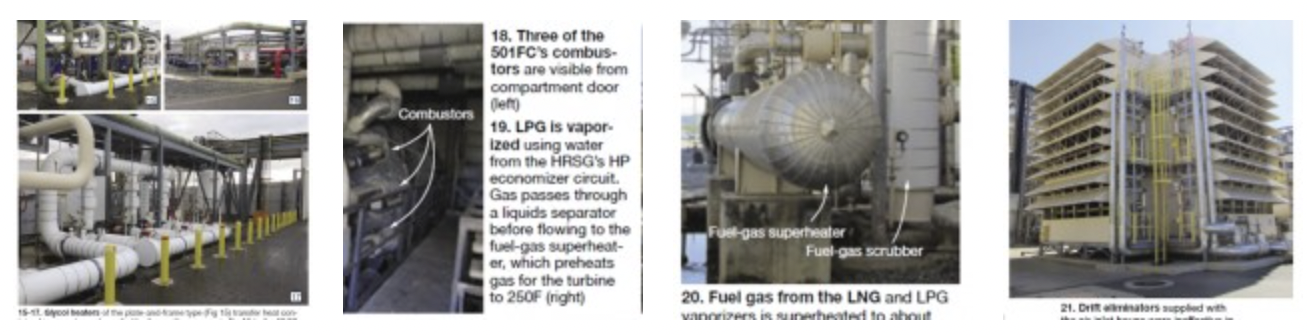

A 32-in.-diam LNG line capable of delivering nearly 40,000 gpm of fuel to the storage tank (Fig 7).The dock is located about 1700 ft offshore as shown in Fig 1. Four unloading arms support cargo operations: Three handle liquid LNG, one natural gas (Figs 4, 5). The pipe rack on the causeway from the ship to the shore (Fig 6) includes the following:

- A 6-in. recirc line that moves LNG from the storage tank to the pier on a continuous basis for a return trip through the 32-in. pipe to keep it cool when a ship is not unloading—this to prevent thermal cycling. There are 12 expansion joints in the 32-in. line and each would expand by 1 ft if the pipe were allowed to return to ambient temperature after a fuel delivery. Regulations require internal inspection of the line every five LNG/ambient temperature cycles, so avoiding them is critical. Absent five thermal cycles, the line must be inspected only once every five years.

- A two-way, 10-in. vapor line that allows gas released from the surface of the onshore LNG tank during unloading operations to return to the ship to fill the voids created in the cargo tanks as LNG is removed. This allows the entire fluid system (shipboard cargo tanks, transport pipe, and shore-side LNG tank) to remain in equilibrium when unloading.

A layout of the onshore LNG infrastructure is shown in Fig 8. Note the spill collection basin where the pipes on the causeway rack interface with those connecting to the storage tank. The basin is designed to retain, in the unlikely event of a pipe failure, all the LNG flowing through the 32-in. line for a period of 10 minutes (about 10,000 bbl). This is a code requirement.

Located between the storage tank and the shore-side pipe rack are systems for sampling incoming LNG every four minutes during the unloading process to verify that the product being unloaded meets specifications and is compatible with LNG already in the tank. This is particularly important for avoiding rollover and operating problems associated with it (Sidebar). The homogeneity of the LNG in storage is maintained by continuous recirculation of the fuel between deliveries.

Plant personnel rely on data from tests of LNG samples to calculate the Modified Wobbe Index (MWI) for analyzing the expected impacts of fuel variations on gas turbine operation. In mathematical terms, the MWI is equal to the lower heating value of the fuel in Btu/scf divided by the square root of the absolute temperature of the gas fuel (deg R) multiplied by the ratio of the molecular weight of the gas fuel to that of dry air.

In more simple terms, MWI is the ratio of energy density to the relative density of the fuel. Because control of a gas turbine depends on regulating energy input to the engine, a variation in the MWI will dictate a change in the volumetric fuel flow to the machine.

To illustrate: When MWI increases, volumetric flow decreases; when MWI decreases, as it does when natural gas is blended with, or replaced by, a fuel of lower heating value, fuel flow must increase. Most combustion systems can accommodate changes in MWI that extend from 95% to 105% of the design value before hardware or operational changes are required.

Terminal infrastructure. Figs 9 and 10 illustrate how the storage tank is integrated into the terminal fluid systems; Fig 11 gives details on tank design. Both Figs 10 and 11 show the tank can be filled from the top or the bottom, depending on the characteristics of LNG in the tank and that being unloaded. The table in Sidebar 2 reveals the wide variations in LNG composition possible, depending on the source.

The reinforced-concrete cylinder that encircles the double-wall storage tank—inner tank constructed of 9% nickel steel and the outer tank of carbon steel separated by a thick layer of perlite insulation—offers protection against a Category 5 storm. It also prevents the release of LNG to the environment in the unlikely breach of both tank walls. Regulations require spill containment equivalent to 110% of storage-tank capacity. At EcoElectrica, the nominal 10-ft annulus formed by the inner diameter of the concrete cylinder and the outer diameter of the steel secondary containment vessel is sufficient to retain up to 150% of tank capacity. Any rainwater accumulating in the annulus is pumped to the 30-million-gal storm-water retention pond.

Important standards governing the design of LNG terminals include the Dept of Transportation’s (DOT) 49CFR193, “LNG Facilities: Federal Safety Standards.” CFR is the acronym for the Code of Federal Regulations. This standard relies heavily on NFPA 59A (2001 edition), “Standard for the Production, Storage, and Handling of LNG.” For EcoElectrica, compliance with 49CFR192, “Transportation of Natural Gas by Pipeline: Minimum Federal Safety Standards,” also was necessary because it is responsible for the delivery of gas to Prepa’s Costa Sur.

Among the safety features incorporated into EcoElectrica’s LNG terminal are the following:

- A flare is provided to burn off excess gas released in the storage tank during unloading operations, or when the plant is operating on propane.

- A fence is installed to mitigate vapor release from the terminal area. An unintended release of LNG would hug the ground because of its low temperature and higher density compared to air; the fence serves as a barrier to prevent its aimless migration.

- Gas and flame detectors are strategically positioned at all joints in the LNG tank.

Two vaporizers, A and B, were part of the original installation; C and D were added in 2012 to provide gas for Costa Sur (Figs 12-14). All are conventional shell-and-tube heat exchangers measuring 32 in. in diameter and 40 ft long between tubesheets. As Fig 14 shows, LNG received from the storage tank flows upward through the tube bundle, exiting from the top as a gas at about 72F. It can be directed to either the gas turbines or to the Costa Sur pipeline.There are four submerged LNG sendout pumps installed at the bottom of the storage tank. The discharge lines from all pumps are connected to the LNG header supplying the four vaporizers and to the recirculation line that assures homogeneity of the product in storage. Two of the pumps also are plumbed to circulate LNG from the tank to the dock and back through the unloading line when a ship is not discharging cargo. You can trace these flow patterns in Fig 10.

The warm 50/50 glycol/water mixture (nominally 75F) enters the shell side of the exchanger at two points—one near the bottom and one near the top—and exits in the middle at a nominal 50F. Vaporizers A and B are arranged to supply cool glycol to the inlet-air cooling coils in the gas-turbine filter houses as well as to the closed cooling water (CCW) system. The latter helps improve the performance of steam-turbine lube-oil coolers, GT auxiliaries coolers, generator exciter coolers, etc.

Glycol leaving vaporizers C and D cools seawater to boost the thermal performance of the condenser and the main heat rejection system. The plate-and-frame exchangers that enable heat transfer are shown in Fig 15. The auxiliary seawater pumps are in Fig 16 and the pumps that return warm glycol to the vaporizers for converting LNG to natural gas are in Fig 17.

Gas that vaporizes from the surface of the LNG in storage—so-called boil-off gas (BOG)—is assisted by blowers to the suction side of compressors for delivery to the gas turbines or to Prepa. Plant personnel report that a significant maintenance effort is required to keep these gas-handling components in top condition.

At first blush, EcoElectrica’s 2 x 1 F-class combined cycle appears ordinary; but it is not. The suppliers of main components tell part of the story:

Powerplant

- Two 501FC gas turbine/generators made by Westinghouse Electric Corp before Siemens AG purchased the company.

- Two supplementary-fired heat-recovery steam generators designed and fabricated by ABB Combustion Engineering before Alstom purchased ABB.

- A single-casing, single-flow steam turbine/generator built by offshore manufacturer Toshiba Corp.

- Two 100% boiler-feed pumps for each HRSG purchased from Ingersoll-Dresser Pump Co—now part of Flowserve Corp.

- Surface condenser manufactured by Ecolaire before it was purchased by Alstom and later sold to current owner SPX Heat Transfer Inc.

Add to this short (15-year) historical perspective of an industry in transition the following facts: (1) Station equipment was ordered by Enron Equipment Procurement Corp, which went bankrupt before the plant had been in service for two years, and (2) EcoElectrica was the first IPP and gas-fired generating facility in Puerto Rico.

Ask yourself, were you managing this facility, who would you have called when problems arose, when parts were needed, when drawings were missing, etc? No doubt a fundamental reason for EcoElectrica’s success over the years is the survivor instincts developed by its can-do O&M team during the early years. Many of these people are still at the facility, several are first-line managers today.

Wilbert De La Paz, manager of mechanical maintenance, reviewed for the editors some issues identified with the plant’s large rotating machines over the years, and the solutions implemented—which significantly to the industry’s collective knowledge. The gas turbines presented the biggest challenges simply because EcoElectrica’s engines were among the first in the Westinghouse F-class fleet. As De La Paz recalled, these units were ordered in the 1997-1998 timeframe and installed during 1998-1999; he was an OEM employee at the time and a member of the erection team for a short period.

To put EcoElectrica’s GT pedigree in perspective, consider that the first Westinghouse F-class machines began commercial operation in May 1993, only a few years before the engines for Puerto Rico were ordered. When the purchase order was signed, there only were about twenty 501Fs in operation or on order, with total fleet operating hours in the neighborhood of 200,000.

Only 19 W501FCs were built, according to Siemens statistics, together operating for about 560,000 hours through December 2011. The 501F in-service fleet at that time numbered 248 units; operating hours totaled nearly 7.6 million. Also of note, only six Fs each had rung up more than 100,000 operating hours, including the two machines in Puerto Rico.

A review of the EcoElectrica engine’s specs reveals 16 compressor stages and a 14:1 compression ratio. Normal start as-built was 29.5 min to full load. When the unit was installed, the variable inlet guide vanes were of AISI 616 stainless steel; actuator was pneumatic. Compressor rotor and stator blades were made of AISI 403.

The combustion section was equipped with 16 combustors, two igniters, two UV flame detectors, pressure-atomizing system for liquid fuels and orifice jets for gas (Fig 18). The four-stage turbine section came with IN-738 rotating blades in the first three stages, U-520 in the last; first two vane rows were of ECY-768, last two X-45.

The gas-turbine generators are relatively standard, 60-Hz, hydrogen-cooled units rated 13.8 kV, 205 MVA at 0.85 power factor (174 MW).

Fuels, combustion

EcoElectrica’s GTs are unique in the Siemens F fleet, having the capability to operate on LNG, LPG, and distillate oil. The units started on fuel oil and ran on LPG (liquefied petroleum gas, or more simply, propane) exclusively for about the first five months they were in service because the LNG terminal was not completed until August 2000. In a way this was beneficial, because valuable lessons were learned in how to operate the alternative fuel systems and how to start on oil. The plant is permitted to burn distillate for up to three months in any rolling 12-month period.

Today, the engines run relatively few hours on the back-up fuels: Reliability of the LNG terminal is better than 99.9% and annual availability averages about 99.5%. When the rare upset in terminal operations occurs, operators immediately switch to ultra-low-sulfur (0.04% S) distillate stored onsite (refer back to Fig 1; large tank in foreground).

It takes about two hours to line up the propane “day” tank at the plant site (to the left of the distillate oil tank in Fig 1) and the LPG vaporizers serving each of the engines (Fig 19). As soon as that can be done, fuel is switched from oil to LPG. Onsite LPG inventory is replenished from a storage tank maintained by ProCaribe, a division of Terminal Acquisition Co at its tank farm approximately three miles from EcoElectrica.

Limiting run time on diesel oil to the minimum required stretches the fuel budget and reduces the potential for fouling in the hot gas path (HGP) and of the SCR (selective catalytic reduction) catalyst. Ultra-low-sulfur distillate is known to degrade over time, faster in warm, high-moisture climates such as that characteristic of southern Puerto Rico. Physical and chemical properties of the stored distillate are closely monitored and upgraded as necessary.

Online fuel transfers are relatively smooth when engine operation is stable and output is about 120 MW, GM Reyes told the editors. In 2011, he said, EcoElectrica operated a total of 411 hours on LPG; more than 20 fuel swaps were involved and there were no material issues.

Feedwater from the HRSG’s HP circuit at a nominal 380 psig/300F is used to vaporize propane. Fuel gas supplied from either the propane or LNG vaporizers, depending on which is in service, is superheated in the horizontal heat exchanger shown in Fig 20 using IP feedwater at a nominal 380 psig/250F. Gas exiting that heater passes through a scrubber (vertical vessel to the right of the heater in the photo) on its way to the gas turbines—this to protect against the unlikely carryover of liquids. A chromatograph monitors gas characteristics in real time to assure that the fuel being fed to the turbines is in compliance with OEM specifications.

The original diffusion-flame combustors (DF-42) still serve the gas turbines. Although some DF-42 owners have migrated to dry low-NOx (DLN) combustors, this is not possible at EcoElectrica because the OEM will not support their use on propane. The plant has had a long-term service agreement in place with the manufacturer since 2008.

NOx control is by way of IP steam injection and SCR. PSD (Prevention of Significant Deterioration) permit limits are 7 ppm on natural gas and 9 ppm on LPG. Reyes noted that ammonia injection increases significantly when burning LPG. In round numbers, he said, you can expect to use four times as much of the reagent when firing LPG than you would with natural gas.

GT issues, upgrades

With EcoElectrica’s engines among the first Westinghouse F-class gas turbines to enter commercial operation, most industry observers would expect these machines to have experienced more problems early in life than a unit going into service today. They did. One indicator: A forced-outage rate of more than 3% during the first two years of operation. But the OEM generally was close by with the support necessary to transition the engines from a prolonged teething period of about three years to the relatively reliable power producers they had become by the time Reyes took over as plant manager in 2004.

Over the last eight years or so, the combined cycle has operated reliably in base-load service with daily load-following dispatch—typically achieving an annual service factor above 90% and a capacity factor of about 80%. Improvements introduced before and during the first major inspections (Unit 1 in 2003 and Unit 2 in 2004) get credit for the lion’s share of this success.

What follows are notes on some of the specific issues encountered over the years by De La Paz and his mechanical O&M team, as well as solutions/upgrades implemented:

Transition pieces dominated among the early issues. The first TPs were of a single-layer design. A switch to the later double-layer design eliminated problems experienced previously. Transition seals still require periodic maintenance. That is done under contract with a company specializing in such work.

Combustion dynamics were problematic, particularly when burning propane. A combustion dynamics monitoring system (CDMS) installed by Siemens has been beneficial.

Air intake. Plastic drift eliminators installed with the air-inlet house never met expectations (Fig 21). Rainwater got by them, damaged filters, and entered the compressor. In addition, silica migrated through the prefilters and after filters in the two-stage system.

A change in operating procedures helped somewhat. Plant personnel now admit glycol/water coolant to the chiller only after the GTs are at full load. Note that air entering the inlet house first passes through the chiller coils—then, in turn, through the demister, prefilters, and main filters. Condensate collected from the chiller is sent to the cooling-tower basin as makeup.

New air filters and demisters were installed on both GTs in 2012. Munters Corp’s (Kista, Sweden) mist elimination solution was selected along with Viledon® F-45 prefilters and MX-98 second-stage air filters from Freudenberg Filtration Technologies KG, Weinheim, Germany. These changes immediately reduced the inlet loss by 0.5 in. H2O, De La Paz said. He added that thorough check of filter condition and performance would be done as part of the January 2013 planned outage. Current plan is to change out the V-panel prefilters annually, the after filters every other year.

Pneumatic fuel-gas control valves originally installed proved unreliable. About the time Reyes arrived at the plant, Siemens and the EcoElectrica O&M team had decided to replace them with a hydraulically operated/digitally controlled offering from Moog Inc (servo)/Fisher Controls (fuel valve). Starting reliability improved immediately. The small reservoir of hydraulic oil is changed annually to avoid varnish and other oil-related problems.

Vibration monitoring capabilities have improved with a Bently 3500 system. It replaced a Bently 3300. Many other users have done the same.

Generator thermal imbalance, caused by obstructions in cooling passages, dictated replacement of the rotor (field) in one GT in 2003. It has worked well since. Both generators were fully re-wedged by the OEM during their second major inspections.

Proof of flame. Unreliable UV scanners for flame detection were the source of many unit trips in the first few years of operation. The plant O&M team, working with Siemens engineers, developed a software solution that uses blade-path temperatures to verify flame and significantly improve starting reliability.

Water wash systems supplied with the GTs failed to keep the compressors clean. Inspections of the machines during their respective first majors identified deposits of dirt on and excess detergent within stationary and rotating components. Blades were cleaned only through Row 6, De La Paz said, and there was evidence of leading-edge droplet erosion on some airfoils.

Wash systems were replaced on both units in 2006 with ones supplied by Rochem Technical Services Group. Online cleaning is done every other night using plain water. Weekly, a 5-min detergent wash is initiated, followed by a 10-min rinse cycle. Offline washes are done perhaps three times a year, as the GT operating regimen permits. Compressor efficiency calculations using EtaPRO™ from GP Strategies Corp indicates that the cleaning program is effective and provides economic benefit.

Weld cracking on struts supporting the compressor inlet scroll were found during an inspection suggested by the OEM. The redesigned strut configuration implemented consists of Z-shaped pipes to replace the existing straight struts and pipe flanges bolted to the inlet wall for attachment.

Anti-rotation pin relocation. Diaphragm/blade-ring mod for Rows 7 to 15 of FA-FC compressors was implemented to prevent failure of anti-rotation screws. Relatively simple fix involved changing the location of the anti-rotation screw to the opposite side of the cylinder and diaphragm—this to load the screw in compression instead of tension.

Cracking of Row 2 turbine blades on 501F engines, covered extensively by the editors in articles available online at www.ccj-online.com, was found in both EcoElectrica GTs. The OEM replaced 30 of the 66 R2 blades in Unit 1 and 18 in Unit 2 because of (1) indications emanating from the trailing edge within about an inch of the platform and (2) blade pedigree concerns.

Clearances were increased between the inlet-guide-vane pucks and their respective counterbores to mitigate IGV sticking caused by corrosion.

Cracks in the exhaust manifold are patched as needed; turbine-end expansion joints are replaced during every major.

The second major was conducted in 2009 for Unit 1 and in 2010 for Unit 2. These GTs rank second in the 501F fleet in terms of service hours. EcoElectrica arranged a rotor swap for Unit 1, which had accumulated 96,000 equivalent operating hours (EOH) when the second major began. This was close to the 100,000-hr trigger point for the OEM’s Class IIB inspection. To access details on what’s involved in so-called “lifetime inspections” for gas turbine rotors, use the search function at the top of the page.

The Unit 1 rotor passed its inspection. No significant issues were identified, marriage-coupling surfaces were flat, through-bolts were fine. New compressor blades were installed in-kind. The bottom line: The rotor was “zero-houred” and returned to Puerto Rico to be used in Unit 2 the following year. The Unit 2 rotor, in turn, would be refurbished by the OEM and returned to the pool.

Borescope access ports were installed at Rows 4 and 6 in both compressor casings during their second majors to allow more thorough inspections from outside the machine. Also, new insulation was installed on the GTs before they were returned to service. De La Paz said the Crossby Dewar Inc (Ontario) product is easier to remove and replace than the original insulation and it contributes to better thermal efficiency.

Machining was done during the second majors to address the potential for wear on the outer-diameter hook and hook-fits as found on some 501FCs—particularly at the 9 to 10 o’clock and 3 to 4 o’clock locations (looking in the direction of flow). The motivation: Inner shroud and seal holders had migrated forward in some instances and contacted upstream rotor blades, resulting in liberated material and downstream effects.

Looking ahead to the major inspections in 2015 and 2016, the O&M team already has proposed a series of reliability upgrades. One upgrade planned is a swap-out of the pneumatic actuators supplied with the variable inlet guide vanes with hydraulic actuators.

Rankine cycle

There was relatively little discussion on the heat-recovery steam generators during the editors’ visit to EcoElectrica suggesting they essentially are meeting expectations. One might expect that given their generally modest design pressures, temperatures, and flows and the plant’s conservative base-load operating regimen. The arrangement of heat-transfer surfaces for these triple-pressure HRSGs is presented in Sidebar.

When the GTs are firing LNG, 3.575 million lb/hr of exhaust gas at 1137F enters each of the boilers, producing 515,000 lb/hr of HP steam at 1625 psig/990F with duct burners turned off. IP steam flow is nominally 65,000 lb/hr at 350 psig/512F. Gas temperature at the stack is 207F. Gas-side pressure loss is 13.7 in. H2O.

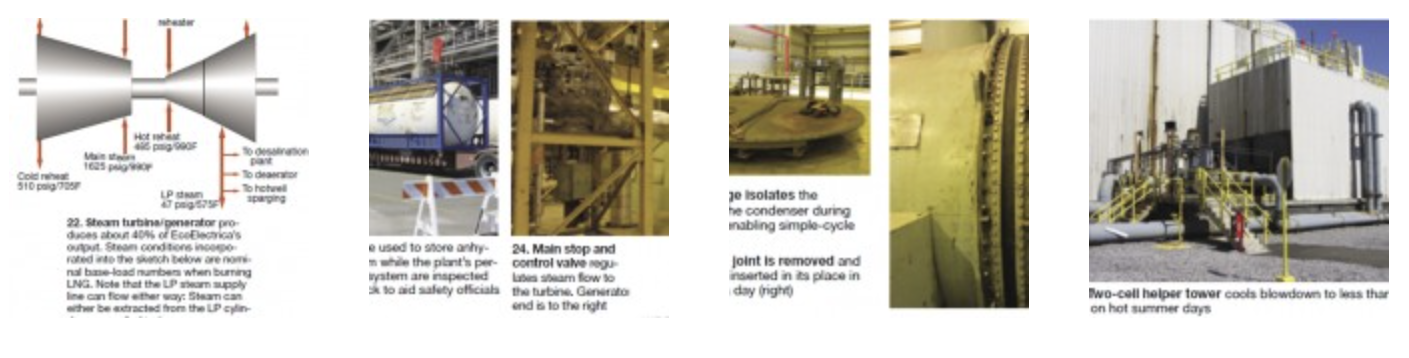

Steam leaving the HP superheater goes to the six-stage HP turbine, does work, and exhausts to the reheater (Fig 22). There the temperature of the 510-psig cold reheat steam is increased by about 300 deg F to a nominal 990F. This hot reheat steam drives the single-flow IP/LP turbine section (five stages in each turbine), which exhausts to the condenser at about 2.5 in. Hg abs. All steam-system drains are routed to a blowdown tank in the generation building and its contents are directed to the condenser.

Lube oil system. The hydrogen-cooled 18-kV generator for the steam turbine is rated 252 MVA at 0.85 power factor (214 MW). The generator and turbine share a common lube-oil system underpinned by a 3600-gal carbon-steel reservoir coated with aluminum paint. Thermal off-take points in the cycle include the following: IP steam is injected into the GT combustion section for NOx control, heat from HP feedwater is used for vaporizing LPG, heat from the IP feedwater is used for superheating the fuel gas in service (LNG or LPG), and LP steam, either extracted from the last turbine section or provided by the HRSG, drives the desalination process.

Dual-cartridge filters remove particles entrained in the oil large than 5 microns (nominal); oil coolers are of the fin-fan type, heaters of the electric immersion type. Main and auxiliary ac submerged lube-oil pumps, rated 600 gpm at 140 psig, have 125-hp, 460-V, 3-phase motor drivers. The emergency dc pump is rated 530 gpm at 25 psig.

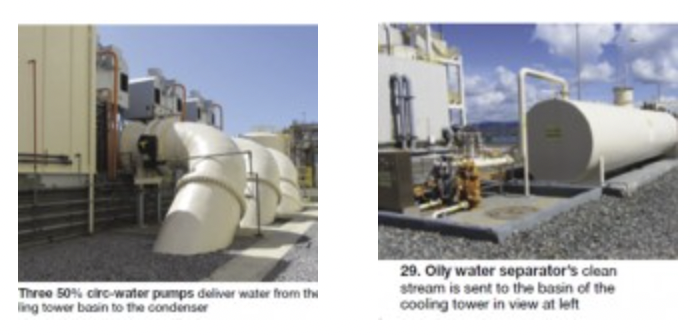

Ammonia system. While the editors were onsite, EcoElectrica was conducting its five-year inspection of the SCR reagent system. A certified third-party company was inspecting the anhydrous ammonia tank serving each unit for metal deterioration. Ammonia lines to the SCR are replaced in parallel with this effort. One challenge associated with this inspection is to remove the anhydrous ammonia in onsite tanks and transfer it to portable tanks (Fig 23), conduct the inspection and replace the ammonia distribution piping, and then transfer the reagent in temporary storage back to the permanent plant tanks.

The blank flange in Fig 25 was ready to install between the LP turbine and condenser at the start of the outage. The expansion joint in Fig 26 would be removed and the blank bolted in place to isolate the condenser from the turbine, thereby enabling operation of both GTs in simple-cycle mode and bypassing steam to the condenser without risk to personnel while the steamer is inspected and refurbished. De La Paz said station personnel had the procedure well in hand and could swap-out the blank plate for the expansion joint in half a day or less—perhaps in as little as eight hours.Steamer overhaul. Also during the editorial visit, preparations were underway for the steam turbine’s second major inspection in January 2013. The main steam stop and control valve for the HP turbine is shown in Fig 24. Generator is to the right of the main steam line entering the unit, turbine and condenser to the left.

Heat rejection system. The two-pass condenser has 18,556 1-in.-diam x 22 BWG B338 (Gr 2) tubes in its main condensing and gas removal sections with an effective length of 30.7 ft and an effective surface area of 149,000 ft2. Duty is 1.1 billion Btu/hr; average circulating water velocity is 7 ft/sec. Design seawater temperature is 90F. Conventional steam-jet air ejectors are used to maintain condenser vacuum.

The Caribbean Sea (Guayanilla Bay) is the source of cooling water for the Rankine cycle; its temperature can vary from 74F to 92F depending on the season. Heat absorbed by circulating water in the condenser, and by cooling water in the CCW system and desalination plant, is rejected in an eight-cell, induced-draft tower, built by Belgium’s Hamon & Cie. Its basin and frame are made of concrete; fan decks, stacks and siding of fire-retardant FRP with stainless-steel hardware. Fill is 15-mil Hamon AFNCS.

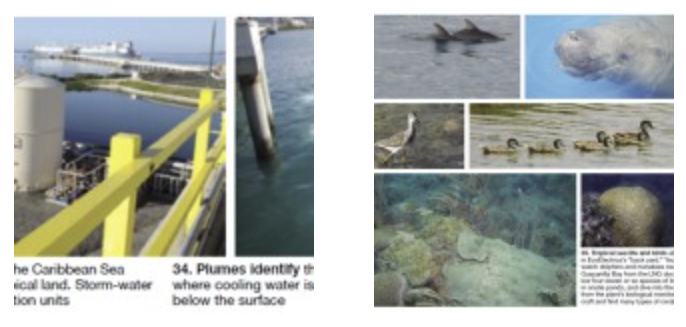

The tower typically operates at from 1.2 to 1.3 cycles of concentration to restrict total dissolved solids in the blowdown stream to 50,000 ppm. Discharge to the sea is via three diffusers located 30 ft below the water surface near the LNG pier. The plant’s operating permit limits the temperature of return water to 90F. In summer, use of a two-cell booster tower sometimes is required to cool blowdown prior to its discharge (Fig 27).

Water required by the condenser, 142,000 gpm, is delivered by two of three 50% circ pumps taking suction from the tower basin (Fig 28). These pumps also provide 8000 gpm to the closed cooling water system and 6000 gpm to the desalination plant. The tower is designed to cool the 156,000-gpm return flow from100F to 86F at a wet-bulb temperature of 73F.

Performance improvement. The additional LNG vaporization capacity installed in 2012 allows the glycol heaters serving the new vaporizers to reduce the seawater temperature for all plant services—condenser circulating water, CCW, and desalination plant (Sidebar)—by 10 deg F. This cycle enhancement has enabled better and more predicable thermal performance. The heat-rate improvement for the condenser alone is approximately 35 Btu/kWh when 77 million scf/day of LNG is vaporized, according to Dr Jose Rullan, PE, project engineer.

As mentioned earlier, the boiler blowdown tank empties into the cooling-tower basin after filtration to remove any solids present. The clean stream from the oily water separator also discharges to the basin (Fig 29). The physical and chemical properties of basin water are monitored twice monthly for a period of 24 hours; tests capable of detecting the presence of hexavalent chromium are conducted weekly. A diver removes dirt and deposits from the basin twice annually; quarterly, all catch basins and the oily water separator are cleaned.

Cooling-tower fans, supplied by Netherlands-based Howden Group Ltd, are 30 ft in diameter and have six fiber-reinforced polyester blades with leading-edge protection. High-efficiency, severe-duty, motors with windings designed for the tropical environment turn the fans at 127 rpm through right-angle double-reduction gears. Japan’s Toshiba Corp supplied the 250-hp, 460-V, 1800-rpm motors; Texas-based Amarillo Gear Co LLC, the gears. Vibration and low-oil-level switches and protection against reverse rotation were included in the drive package.

During normal combined-cycle operation, two of the three 50% condensate pumps take suction from the 13,350-gal condenser hotwell and push nominal 110F cycle water through air-ejector condensers, gland condenser, and rotor air coolers (RACs) before entering the plate-and-frame preheaters.

The RACs boost condensate temperature by about 35 deg F to a nominal 150F ahead of the preheaters. The latter use LP drum water to add another 30 to 40 deg F before condensate enters the LP economizers at about 175F to 190F. Note that water samples for analysis are withdrawn downstream of the condensate pump and cycle chemistry is adjusted with chemical injections just ahead of the air-ejector condensers.

Gaspar Bibiloni, PE, has a great deal of responsibility at EcoElectrica. He manages the Electrical, I&C, and DCS Maintenance Dept (E/I Dept) as well as the Engineering Dept—the two groups having a total employee count second only to Adolfo Antompietri’s Operations Dept.

Gaspar Bibiloni, PE, has a great deal of responsibility at EcoElectrica. He manages the Electrical, I&C, and DCS Maintenance Dept (E/I Dept) as well as the Engineering Dept—the two groups having a total employee count second only to Adolfo Antompietri’s Operations Dept.

Electrical, I&C

The E/I Dept is responsible for the predictive (PdM), preventive (PM), and corrective (CM) maintenance of all electrical equipment and I&C devices—including the DCS, CEMS, and PLC controllers—in the powerplant, water treatment area, and LNG terminal. This encompasses some 3100 instruments and 1150 pieces of electrical equipment. Electricians are certified in thermography, ultrasound, and substation maintenance, I&C techs in DCS hardware, PLCs, analytic instrumentation, and CEMS. Training is ongoing in these areas as well as others.

Not all work is done by station staff. EcoElectrica has maintenance and inspection contracts with several OEMs and experts for specialized equipment and/or crafts. Examples: Emerson Process Management for the DCS, Rockwell Automation Inc for PLCs, Cummins Inc for the emergency diesel/generators. In addition, the plant has contracts with safety and test experts, and laboratories, for specialized analyses and/or certifications. Examples include lift equipment certifications, dissolved-gas analysis for transformer oil, and thermography.

Plant personnel and contract experts are supported by continuous monitoring on important equipment to warn of potential issues. Some examples are listed below:

- Online monitoring of transformer oil for dissolved gas and moisture (Hydran, General Electric Co).

- Flux probes to detect shorted turns in generator fields (Generatortech Inc).

- Partial discharge detector for advance warning of insulation problems in unit substation dry-type power transformers (InsulGard, Eaton Corp).

- Battery diagnostic system tracks cell voltage, overall string voltage, current, temperature, and internal resistance. Automatic periodic tests verify battery integrity; alarms on out-of-tolerance condition (MPM-100, Alber).

- Generator condition monitor detects pyrolytic and hotspot activity which can lead to overheating and failure (GCM-X, Environment One Corp).

- Transient recorder/power meter with power-quality and communications capability, installed on all generators and the 230-kV transmission line (Nexus® 1500, Electro Industries/GaugeTech).

- Transient recorder to analyze utility and facility transient disturbances, power swings, frequency events, etc (IDM, Qualitrol Corp).

- Software to monitor/collect data on metering events, protective relay settings, etc, for analysis (acSELerator®, Schweitzer Engineering Laboratories).

- Motor/asset management tool integrates testing, diagnostics, inventory control, scheduling, and cost containment. It monitors potential fault zones and notifies on alarm conditions (MCEmax™, PdMA Corp).

One of the reasons for developing expertise in the monitoring of electrical equipment and circuits is that there are many grid disruptions on the island and it’s necessary for EcoElectrica to determine quickly if the problem is in the plant or on the electrical system at large.

To keep up with developments in technology, plant safety practices, regulations, and best practices, GM Reyes and Bibiloni encourage key personnel to participate proactively as members of the International Society of Automation (ISA), National Society of Professional Engineers (NSPE), National Electrical Testing Assn (NETA), and the College of Engineers and Land Surveyors of Puerto Rico (CIAPR), as well as in the iMaint, Ovation, and 501F Users Groups.

The plant also subscribes to standards of the National Fire Protection Assn (NFPA), National Electrical Code (NEC), and the IEEE.

Critical to this department’s operation is the iMaint computerized maintenance management system (CMMS), developed and supported by DPSI, Greenville, NC. It generates work orders, schedules preventive maintenance, maintains parts inventory, tracks costs and budgets, facilitates reporting and analysis, etc. The plant’s work planning and scheduling process is summarized in Fig 30.

Specifically, maintenance supervisors, coordinators, managers, and the health and safety (H&S) coordinator discuss week-ahead plans every Thursday at 1030. Maintenance supervisors, shift supervisor, and planner gather at the planner’s office each afternoon at 1530 to review plans for the coming day. Day’s plans are reviewed at the daily operations meeting at 0900; it is open to O&M managers, supervisors, and coordinators, and financial personnel.Bibiloni began by explaining EcoElectrica’s work planning and scheduling processes. Work orders, he said, are the result of work requests made by operations supervisors and other departments plus scheduled PM. Planning is very regimented and conducted/adjusted on a week-ahead basis, day ahead, and current.

Specifically, maintenance supervisors, coordinators, managers, and the health and safety (H&S) coordinator discuss week-ahead plans every Thursday at 1030. Maintenance supervisors, shift supervisor, and planner gather at the planner’s office each afternoon at 1530 to review plans for the coming day. Day’s plans are reviewed at the daily operations meeting at 0900; it is open to O&M managers, supervisors, and coordinators, and financial personnel.Bibiloni began by explaining EcoElectrica’s work planning and scheduling processes. Work orders, he said, are the result of work requests made by operations supervisors and other departments plus scheduled PM. Planning is very regimented and conducted/adjusted on a week-ahead basis, day ahead, and current.

Ovation™ migration. The biggest controls project in EcoElectrica’s relatively brief history was its migration from the as-installed WDPF (Westinghouse Distributed Processing Family) to Emerson’s Ovation during the 2008 plant outage (original I/O was retained). Only the Toshiba steam turbine/generator did not have WDPF controls.

Process Control Solutions LLC (PCS), Hattiesburg, Miss, was hired by EcoElectrica as the customer’s engineer to provide control-system engineering for the project—including total plant as-built review, factory acceptance testing, onsite operator training, and commissioning support.

Mitch Cochran, founder of PCS, was no newcomer to EcoElectrica. He had been involved with the project since before its commissioning in March 2000 as a Siemens Westinghouse Power Corp employee. Cochran had done some of the original programming work for the gas turbines, HRSGs, and balance of plant.

His first significant controls project at the Puerto Rican facility was in 2005 when Cochran performed a “Mem-Free” procedure on GT drops to free up DPU memory capacity, thereby allowing implementation of several gas-turbine mods by Siemens. At that time he conducted an as-built review of GT controls for Siemens and upgraded the WDPF controls to improve plant reliability. Cochran has presented several times at 501D5-D5A User meetings on how to free up DPU memory capacity.

A year later, Cochran conducted an as-built review of HRSG/BOP drops for EcoElectrica, as well as a WDPF assessment, in preparation for the Ovation migration. While involved in the control-system retrofit, he added controls for a third LNG sendout pump. In 2011 and 2012 Cochran was back onsite to implement controls modes in support of the LNG expansion project described earlier. He supported installation and commissioning of the expansion project and added an interface for the export fuel-gas metering skid. During the upcoming 2013 outage Cochran will be back at the plant—this time to implement HRSG attemperator drain-valve mods and GT hydraulic IGV actuator mods.

Electrical system. Three generators produce power for sale and internal use—two are driven by the gas turbines and rated 205 MVA each at 0.85 pf, one by the steam turbine and rated 252 MVA at 0.85 pf. Emergency power at 4160 V can be provided throughout the facility by a 1250-kW Cummins diesel/generator and to the administration building and warehouse by a 150-kW Cummins diesel/generator. For the combined cycle to be black-start capable, 10 MW of emergency generation would be required.

EcoElectrica delivers power at 230 kV to the island grid via the IPP’s 2-mi tie line to the Costa Sur switchyard. The switchyard at the combined-cycle plant is equipped with four ABB SF6 gas circuit breakers arranged in a ring-bus configuration. The main transformers for the gas and steam turbines step up the voltage from 18 to 230 kV (Fig 31). Two station service transformers, each rated 42 MVA, step down the voltage from 18 kV to 4.16 kV. An additional step down to 480 V provides power to a dozen motor control centers throughout the facility.

Four battery banks and chargers provide emergency power at 125 Vdc to the steam turbine building, GT 1 and 2 electrical packages, and the 230-kV switchyard. Battery banks for the emergency generators and diesel-driven fire pump are 48 Vdc.

A recent initiative was the upgrading of protective systems. Specifically, relays for major equipment and the main 4.16-kV switchgear were replaced with relays from Schweitzer Engineering Laboratories. System provides protection, data acquisition, recording of disturbances, and other benefits.

Bibiloni next reviewed with the editors some electrical system maintenance activities beyond the normal PM, including the following:

- Annual infrared surveys of the 230-kV tie line.

- Periodic electromagnetic interference (EMI) surveys by Doble Engineering of all generators, isophase bus ducts, and some major motors.

- Annual frequency response analysis (FRA) of all generators and transformers.

- Verify integrity of cathodic protection systems. An outside grounding expert does this.

- Inspection by divers of sacrificial anodes on LNG pier piles.

- Manage and support the Health and Safety Dept in all electrical-safety activities—including the inspection of power cabinets, electrical integrity testing of power cords and tools, ground integrity testing, and testing of high-voltage gloves, rescue hooks, sleeves, and sticks.

Environment

Environmental management at many generating facilities powered by gas turbines equates to meeting permit limits for air and water emissions, cleaning up inadvertent spills of fluids, and preventing uncontrolled releases of potentially harmful gases such as ammonia and sulfur hexafluoride. Nothing wrong with that in most places.

But not along the southern coast of Puerto Rico, a sun-bathed resort area (Fig 33). Preservation of this ecologically sensitive tropical environment is a top priority among EcoElectrica’s owners and employees—most of the latter living in the immediate area, some for their entire lives. Guidance for the plant’s environmental program is provided by its ISO 14001 certification. In case you’re not familiar with this global standard, it is a management tool enabling an organization of any size or type, and in any location, to achieve the following:

But not along the southern coast of Puerto Rico, a sun-bathed resort area (Fig 33). Preservation of this ecologically sensitive tropical environment is a top priority among EcoElectrica’s owners and employees—most of the latter living in the immediate area, some for their entire lives. Guidance for the plant’s environmental program is provided by its ISO 14001 certification. In case you’re not familiar with this global standard, it is a management tool enabling an organization of any size or type, and in any location, to achieve the following:

- Identify and control the environmental impact of its activities, products, and services.

- Improve continually its environmental performance.

- Implement a systematic approach to setting environmental objectives, to achieving these objectives, and to demonstrating that they have been achieved.

- Ensure legal compliance.

The air pollutant of primary concern for combustion turbines burning natural gas is NOx. At EcoElectrica, emissions are controlled in two steps. The first is to minimize NOx production by quenching combustion-zone temperature with steam. Final step, selective catalytic reduction (SCR), uses a catalyst to react injected ammonia to chemically reduce most of the remaining NOx. Permit limits are 7 ppm when burning natural gas, 9 ppm when burning propane.

Water is withdrawn from the Caribbean Sea in Guayanilla Bay for cooling the main condenser and plant auxiliaries, for vaporizing LNG, and for processing by the demineralizers into distilled water. An induced-draft, wet cooling tower and a monitoring station assure that water returned to the bay is at a maximum temperature of 90F, contains less than 50,000 ppm of total dissolved solids, and meets chemical discharge criteria (Fig 34). Physical and chemical properties of the discharges are monitored twice monthly for a period of 24 hours.

Releases of water from the storm-water retention pond seen in Fig 33 are tightly controlled. Most is not discharged to the bay; it evaporates. Physical and chemical properties of the pond water are checked quarterly.

Damaris Negron-Alvarez, environmental compliance manager, told the editors that the plant has implemented since its beginning innovative programs focused on the conservation and protection of endangered species and sensitive ecosystem that coexist with its operations in the Tallaboa and Guayanilla Bays.

Plant operators and maintenance technicians are trained as ISO and OHSAS internal auditors and really make a difference in controlling the processes and work at the facility to maintain the compliance culture and environmental stewardship that distinguish EcoElectrica from others.

The facility’s NPDES permit requires ongoing biological monitoring of Guaynilla Bay—a process that began 14 years ago. EcoElectrica has been an uncompromising protector of the environment from the beginning. Over the 14 years, no significant impacts have been recorded. This has been confirmed by professionals and graduate students associated with the Univ of Puerto Rico’s Dept of Marine Sciences at the Mayaguez Campus (Sidebar).

To illustrate how serious and thorough the environmental protection program is, consider that before construction of the LNG pier began, coral and sea grass in the area was moved to other parts of the bay for safe keeping. After the pier was complete, these species were transplanted successfully from where they were removed.

Negron-Alvarez also mentioned the following:

- Manatees and turtles are protected species and their populations are monitored on an ongoing basis (Fig 35). In 2011, EcoElectrica donated $75,000 for the construction of a manatee study center at the Bayamon Campus of Interamerican Univ. During the 2012 survey period, 70 manatees were observed. Surveys of marine turtles are conducted by graduate students in biology from the Rio Piedras Campus of UPR. Fifteen nests were identified in 2010.

- LNG tankers must have “spotters” to assure that the ships will not collide with manatees, turtles, dolphins, etc.

- Contractors receive detailed instruction on environmental sensitivities.

- EcoElectrica maintains more than 60 environmental permits. Jurisdiction among the Federal Energy Regulatory Commission, Dept of Transportation, and local authorities often overlap, making compliance challenging at times.

- Expansion of the LNG facilities in 2011-2012 added 30 environmental requirements and required the services of a third-party inspector for about six months to assure compliance.

- More than 50 species of waterfowl and other birds have been identified with the ponds over the years—most preferring the mitigation pond. Interestingly, some species always seem to return to a given pond.

People

In power generation, like other businesses sharing a common technology with their competitors, people are the differentiators between a “world-class” organization and one that’s merely “ordinary.” At combined-cycle plants, talented and motivated employees might well make a bigger difference than at other types generating facilities simply because the permanent staffs are so small—typically one employee for every 30 MW of nameplate capability. An army can tolerate a goldbricker, a Swat team cannot.

This final section of the EcoElectrica report focuses on the plant’s hiring, training, and employee retention practices, and safety programs. No nuts and bolts here, but a quick read might offer some “pearls” on how to reduce turnover and build a stronger team at your facility. To be fair, much of EcoElectrica’s success probably can be attributed to the continuity of its ownership and management, mission, and location. More specifically:

- GDF Suez’s acquisition of International Power plc aside, plant ownership has not changed in a decade. One reason for this, perhaps, is that the three owners are in the energy business and they understand the value of EcoElectrica—a crown jewel, in a manner of speaking.

By contrast, many combined cycles and peaking gas turbines in the US are owned by financial interests with little or no professional appreciation of their asset base; they buy and sell powerplants much like they do hotels and pizza parlors.

- General Manager Reyes has managed operations since 2004 and several of his first-line managers have been associated with the plant for almost as long, longer in some cases. Spend a couple of days with Reyes and you’ll find his hand is always on the pulse of the plant.

- The multi-purpose facility is woven into the fabric of Puerto Rico. EcoElectrica’s mission to meet customer expectations in the supply of electricity, gas, and water while protecting the environment cannot be compromised. Workforce pride is at stake here: About 90% of the employees live within a 30-min drive of the plant. Their homes rely on electricity and, in some cases, drinking water from EcoElectrica; plus, they and their families swim and fish in the same waters the plant depends on for cooling. One might consider the plant and community as having a symbiotic relationship.

Operations

Operations Manager Adolfo Antompietri has a team of 25 operators and five supervisors. Five operators are needed to run the entire facility—including the combined cycle, demineralizers, and LNG regasification plant. Operations personnel may be certified in one or more of the following positions: powerplant outside operator, powerplant DCS, LNG outside operator, LNG DCS, water plant outside operator, and performance technician—the last a relatively new certification, put into effect in 2008. About 85% of the plant is instrumented in a manner that permits operation via the DCS. Remainder of the equipment and systems are controlled by the outside operators.

Antompietri, who hired on as an operator before commissioning, stressed the need for careful review of candidates for employment. EcoElectrica has relatively few openings for operators in any given year—no one gets bored at this plant—so managers can be particularly selective. The successful candidate will have to understand basic powerplant processes and have some operational experience either at a generating facility, refinery, pharmaceutical plant, etc.

Resumes from industrial mechanics, electricians, and I/E techs get top priority. Antompietri said he’ll select about 10 resumes for one open position from a pile of a couple of hundred. Those people will take a demanding written test that requires the candidates to solve complex physical problems. The top performers are invited in for an interview (by a single manager or a panel of operations team members). The finalists are then ranked and the top scorer receives an offer.

The first assignment for an employee in Antompietri’s department is either as an outside powerplant, LNG, or water plant operator on the day shift, working alongside team members qualified for that position. Having the new person work days enables them to learn from operators on all five shifts. Depending on the employee’s background, an appropriate training program is developed.

Typically, it begins with GP Strategies Corp’s GPiLearn™ lessons and one-on-one training by supervisors on standard operating procedures and system design details. The latter is facilitated by use of P&IDs (piping and instrumentation diagrams) accessible to employees on demand.

After two to three weeks of classroom sessions, coupled with the requisite tracing of lines for key systems, the new hire is ready for day shifts in the field. It takes the average employee three or four months of classroom and hands-on daytime training before he or she is ready to transition to a shift team. After nine months to a year of shift work, the newest member of the team generally is certified as a qualified operator in the first assigned position.

Next step on the ladder of success is to qualify for one of the remaining operator positions, with a raise for each certification achieved. It takes about four years to qualify for the three outside positions. Operator Pascual Ortiz, one of the persons in the control room during the editors’ visit, is qualified in all six operator positions; plus he’s the union leader for the operators. EcoElectrica has some unionized employees, some non-union.

DCS training takes about a year, then you have to work in the control room for a year before receiving the first “inside” certification. It takes eight to nine years for a highly motivated employee, like Ortiz, to achieve all six certifications.

The performance technician position is challenging and very rewarding. The latter refers to the good feeling you get when an audit finds Btus escaping the process and the leak path is blocked. GP Strategies’ EtaPRO™ performance and condition monitoring system is a big help in this regard.

The performance technician also is responsible for the plant’s car-seal and lock-seal program. Car seals, like the one shown in Fig 36, prevents the inadvertent opening or closing of a valve. Lock seals are step up in safety hierarchy; a physical lock must be opened with a key to change the position of the valve.

This program, a federal requirement for the LNG terminal, has been expanded to the powerplant because of its obvious safety benefits. Another positive step taken during the expansion of the regasification system was to put bar codes on valves so roving operators can retrieve all necessary O&M information on their digital devices.

Operations support is provided by an electronic toolkit that includes the following systems:

- WIN_TS™ diagnostic system, a Siemens AG product, gathers operational data on the gas turbines from the Ovation DCS via a dedicated interface that enables real-time transfer of process digital and analog point values with 1-sec resolution. The OEM accesses EcoElectrica’s WIN_TS servers daily, after midnight, to batch-transfer data compiled the previous day to the Siemens Power Diagnostic Center. There engineers use diagnostic tools to correlate data and analyze trends with the help of expert algorithms. Plant management is informed by email of significant deviations in key parameters and provided an assessment of operational and hardware risks associated with continued operation in the same manner.

- EtaPRO is EcoElectrica’s solution of choice for performance condition monitoring. It interfaces with the Ovation DCS, water plant PLCs, and online fuel analyzers. EtaPRO can display, trend, and report automatically, information needed by different plant users—from the control-room operators to the O&M management team.

- ControlWave®, an Emerson product, provides the management team read-only remote access to the Ovation DCS displays, as well as to process data, via secure link. This enables the technical staff to support the operations team from outside the plant boundaries, thereby expediting resolution of system upsets and, in the extreme, minimizing the restoration time from a forced outage.

One final note on operations: The grid controls EcoElectric’s operation between 290 and 480 MW. Above that, duct burners are required and the plant operators ignite them and take control.

RCA. Antompietri also leads the plant’s forced-outage investigation team to determine the root cause. He is the one constant on the four- or five-person team, convened to analyze anything that affects dispatch and/or availability and impacts operations. Goal is to complete the root cause analysis and provide mitigation recommendations within six months. Necessary changes to hardware, software, and/or procedures are implemented during the next planned outage. If the RCA is not conclusive, further investigation is done during the ensuing outage.

HR programs

No business unit wants to loose good employees. EcoElectric is proactive in this regard, having designed its human resources programs to retain employees. This means going beyond the traditional healthcare plans, IRA offerings, life insurance, vacation, nondiscriminatory job postings, etc, that have become “table stakes” in the HR field.

Damaris Rivera, manager of human resources, and GM Reyes walked the editors through some of the elements of the plant’s program to strengthen interpersonal relationships among employees, provide a better working environment, contribute to wellness, promote advanced education, and develop closer ties to the community. The plan must be working: A third-party surveyor interviewed employees and found 87% gave EcoElectrica a high satisfaction rating. Here are some highlights of the program managed by Rivera:

- Cooperative group lunches Tuesday and Thursday (company pays two-thirds, employees one-third) have been especially beneficial for building interpersonal relationships and promoting team-building, she said. In addition, shift supervisors are given a modest quarterly allocation for dinners with employees to achieve the same objectives.

- Employee wellness: (1) Two graduate students from the Univ of Puerto Rico (UPR) conduct a physical education/exercise program from 1600 to 1700, and again from 1700 to 1800, four days a week. About 50 employees participate on a regular basis. (2) A nutritionist complements the exercise program by weighing employees, monitoring their health, and offering dietary suggestions. Weight loss plant-wide was well into the triple digits during 2012. (3) An annual field day offers “fun” competitions in calisthenics, street skiing, and other competitive contests. (4) No employee or contractor is allowed to work more than six days in any seven-day period.

- Scholarships: (1) EcoElectrica pays 90% of the tuition for college courses if the employee achieves a grade of at least a “B.” Several employees earned their Master’s degrees this way. (2) Scholarships for employee children attending college are given in the amount of $1000 per annum for the first child; $500 per annum for the second.

- A co-op program with UPR’s Mayaguez Engineering Campus has benefitted 35 students to date. One semester is spent working at EcoElectrica after completing three years of college courses. Two students are selected for each semester and assigned to different departments. Thus far, two co-op students have been hired by the plant: One is now a project manager in the engineering department. The other, Kanyra Padilla, a professional electrical engineer, supervises the I/E techs and is an excellent model of EcoElectgrica values.

- Community support: (1) Scholarships are given annually to 40 students from local high schools (Fig 37). (2) Learning materials are provided to two-dozen schools in the area. (3) Sponsorships support science fairs. (4) Contributions are made to local community and civic organizations. (5) Three Kings Dream (Sueno de Tres Reyes) is a gift—presented on the Christian feast of the Epiphany, January 6—to a needy child in the community with an illness or disability. Employees raise money, matched by the company, and present the gift. One year the gift was an electric wheelchair; another, it was special furniture for the child’s home to accommodate medical needs.

Employee and contractor health and safety at EcoElectrica are managed by Pedro Martinez, who is supported by Luis Cruz. Both H&S professions are ideally qualified for the work they do and have complementary backgrounds. Martinez has a Bachelor of Science degree in biology and a Master’s in occupational health from UPR; Cruz has a Bachelor of Science degree and hands-on experience in emergency response as a US Coast Guard reservist; plus, he’s a certified plant operator.

Employee and contractor health and safety at EcoElectrica are managed by Pedro Martinez, who is supported by Luis Cruz. Both H&S professions are ideally qualified for the work they do and have complementary backgrounds. Martinez has a Bachelor of Science degree in biology and a Master’s in occupational health from UPR; Cruz has a Bachelor of Science degree and hands-on experience in emergency response as a US Coast Guard reservist; plus, he’s a certified plant operator.

Safety

One of Martinez’s responsibilities is to meet periodically with the leaders of local first-responder agencies to better understand their capabilities and limitations and to familiarize first- responder teams (firefighters, police, EMT, etc) with the plant and its procedures to assure peak effectiveness if needed. Responsibilities are shared: For example, local agencies lead on firefighting, hazardous materials, and explosives; the plant is the lead on LNG response because EcoElectrica’s personnel are most familiar with the idiosyncrasies of the cryogenic fluid.

To illustrate how closely EcoElectrica works with local agencies, consider the following:

- The plant supports the training of local firefighters on how to deal with an LNG leak. In 2012, for example, 15 EcoElectrica employees (Fig 38) and eight local firefighters attended a special fire academy in Massachusetts—all at the plant’s expense.

- When it comes to confined-space rescue training, it’s the firefighters who train plant personnel. One take-away from this activity for employees is that they better understand the limitations of first-responders.

- The police instruct plant personnel on how to deal with bomb threats and conduct explosion training.

Martinez also participates in the activities of several local groups that address safety/security/environmental concerns and encourage participation by local industry. These include the following:

- Area Maritime Security Committee.

- South Harbor Safety Committee meets quarterly, generally with participation by important federal and local government agencies—such as US Customs and Border Protection and the FBI. Information shared includes best practices and lessons learned.

- Industrial Sector Committee and the Community Awareness Emergency Response Committee meet monthly to share information on hazardous materials, training, emergencies addressed, response plans, etc.

Drills to practice response to such emergencies as fire, spill, tsunami, earthquake (EcoElectrica is in a seismically active area), are an important aspect of normal plant operations. Quarterly, separate full-scale environmental and safety exercises are conducted to test the entire plant and its systems. During these exercises, in which the operations supervisor is the incident commander, the entire plant is evacuated—except for the fully equipped employees assigned to deal with the emergency simulated. Personnel are rated on response.

A tsunami drill is conducted annually in March/April, sponsored by the National Weather Service. Everyone leaves except the operations supervisor; he moves to the highest building in the plant, which has supplies for several days.

An earthquake drill—called “Shakeout”—is sponsored by the Federal Emergency Management Agency (FEMA) and the National Oceanic and Atmospheric Administration (NOAA) and conducted each October 18 at 1018.

In addition, the plant conducts a hurricane walk-down in June as part of its emergency drills. Everything that could be liberated or moved by a high wind and/or high rain is secured. The power block is designed to withstand a Category 3 storm, the LNG terminal a Category 5 storm. If a Category 4 storm was likely, the power block would be shut down. Important to note here is that EcoElectrica would be the last plant to come offline in the event of a weather emergency and the first to start up afterward—because of its operational flexibility.

EcoElectrica is certified as an OHSAS 18001 organization. Background: OHSAS is the acronym for Occupational Health and Safety Management Systems. The standard was developed by the British Standards Institute and first published in 1999. Certification speaks to an organization’s commitment to meeting health and safety guidelines both now and in the future, thereby creating a safer working environment for employees and contractors.

Although this is not an ISO standard, per se, it is an internationally accepted method for assessing and auditing occupational health and safety management systems. OHSAS 18001 is maintained by the International Standards Organization, however, and it lines up synergistically with ISO 9001 and ISO 14001. Recall that EcoElectrica is certified to the ISO 14001 environmental management process, which is similar in structure to OHSAS 18001.

GM Reyes next reviewed for the editors what he calls EcoElectrica’s critical safety elements—a hierarchy of steps reflecting the intent of OHSAS 18001 to ensure the safest plant possible:

- Process design is the first step. It builds safety into the facility by designing and constructing systems and equipment to the world’s most rigorous standards. For the LNG terminal the list of standards includes NFPA 59A and 75, 49CFR192 and 193, and ASME B31.8, among many others.

- Process control. The DCS, Scada, standalone PLCs, etc, are arranged and programmed to protect against operation in unsafe regimes.

- Operator intervention complements control-system response when alarms warn of process upsets. Personnel are trained and drilled continuously on operating procedures to maintain their competency and certifications.

- Safety instrumented systems—such as leak and fire detection systems, ignition control, etc—are designed to shut down equipment/systems when unsafe conditions are detected.

- Active protection during incidents—such as that afforded by pressure-relief valves, fire protection/suppression systems, etc—prevents an unsafe condition from getting worse and contributes to elimination of the hazard.

- Passive protection is provided by features designed into the plant and its equipment—such as the double containment for the LNG tank, impoundment areas, vapor fence (Fig 39), etc.

- If all else fails, the emergency response plan is implemented. This may include participation by local first responders, evacuation of personnel in possible danger, etc.

The safety culture nurtured at EcoElectrica underlies the plant’s many achievements, including these:

- Annual inspections from FERC and the US Coast Guard consistently without material findings or recommendations.

- Security requirements of federal agencies consistently exceeded on audits.

- No safety incidents reported during more than 165 LNG tanker deliveries since plant startup.

- Evaluations by insurers since 2008 have improved to a “better than a standard facility.” Evidence: In 2012, the plant’s annual premium was reduced by $1 million. Note that EcoElectrica is not benchmarked against other combined cycles, but rather against petrochemical facilities, which are evaluated to a higher standard.

Training. Health and safety are incorporated into all training modules. Much of this instruction is required by regulatory agencies and part of the plant’s compliance program managed by Martinez and Cruz. GPiLearn’s online modules are the foundation of the plant’s training activities. Employee progress in this activity is monitored by HR Manager Rivera.

Reyes said that a big advantage of GPiLearn is that lessons can be done at home, or on-shift during slack periods. This means the plant can reduce classroom time to a minimum and save on the overtime pay associated with live instruction. Additionally, employees get more time to spend with their families, improving the quality of life. EcoElectrica is working with GP Strategies to develop new training modules and to translate some into Spanish.

Martinez schedules practical training sessions after employees complete their GPiLearn program. Some of these sessions are conducted annually, some on a biannual or triennial basis:

- LNG terminal.

- Security.

- DOT-regulated pipeline.

- Fire brigade.

- Water treatment (boiler chemicals).

- IT procedures.

- Confined-space entry.

- Title V.

- Spill prevention, control, and countermeasures.

- Emergency response.

- Commercial ethics (including sexual harassment).

- CPR.

- Fire extinguishing.

- Hazardous waste operations and emergency response.

Contractor safety. No plant’s health and safety program is complete without contractor participation. It is very difficult to bring disparate contractors and other outside organizations up to speed on plant practices in the limited time available for indoctrination and training. Martinez addresses this issue in two ways: An H&S prequalification process to eliminate risky prospective contractors before purchase orders are cut and reliance on the vigilance of plant personnel to identify risky work practices onsite.

The contractor questionnaire is designed to assess a given company’s safety rules, training, history of accidents, etc. It also requires detail on the type of work the contractor will be doing, the type of equipment and hazardous gases and liquids required, the safety risks involved, and how they will be addressed. Contractors with 25 or more employees onsite must have a dedicated safety person at the plant at all times the company’s crew is working.