A spirited Roundtable discussion among users kicked off the conference. Some of the more salient topics and concerns include:

- Changing maintenance strategies to reflect cycling of baseload designed units.

- Frequency of inspecting l-p blades for erosion from low-load operation (several say once a year, one user inspects twice annually)

- Incorporating drones into inspection programs (they can help justify a full-scale inspection financially)

- Inexpensive ways to inspect without putting bodies into machines.

- When to deal with high hardness on journal bearings

- Frequency of testing for main-steam stop and control valves and balancing OEM, insurer, and owner/operator (O/O) recommendations/requirements

- New demands by insurers after an overspeed event and best levels for overspeed tests

- Protective relays and logic changes for lube-oil DC pumps

- Unforeseen balance of plant (BOP) consequences from a GT uprate/upgrade, such as upgrading circ water pumps and steam turbine impacts such as HP/IP rotor and blade erosion

Three user presentations and some roundtable discussion time were devoted to HP/IP turbine issues with the D11 model. These slides are must-read for anyone considering their options for older D11s. Keep in mind that the ages of these units under discussion are not specified, so you should contact the presenters to gage applicability to your situation.

Other presentations focused on specific component condition, repairs, and replacements. Keep in mind that, while some of these presentations may appear to be “one-offs,” the thought process and analytical methodologies can be universally applied when confronting similar issues.

“D11 Replacement Strategy” features a collaboration of three utilities, with 18 such turbines among them, to develop a scoping document and RFQ template.

Each user had its own reasons for developing such a strategy – some combination of shell cracking, thermal stress, creep deformation, diaphragm dishing, materials end-of-life, turbine train alignment difficulties, shell leakage, weak points from low-cycle fatigue, etc. The lead utility for the first replacement conducted deformation/distortion creep modeling using structured light scanning “at a fraction of the cost of laser scanning.” First replacement, based on three bids received from four vendors queried, is scheduled for Fall 2027.

“D11 HIP Major Evolution x 4” is mostly one utility’s pictorial journey as specialists sequentially evaluate four HP/IP turbines, witness the scope expand as more issues are found, and unearth surprises in the LP section. The “major planning takeaways” slide is the money shot, especially the words in bold, underlined red: “discoveries induce panic.” A few of the more salient takeaways:

- Diaphragm refurbishments – request detailed scopes

- Boring bar – + 6 months reservation

- Rotor bow risks – review the data

- N2 packing area fits (deformation)

- LP inner casing will require bolt deformation, specifically at split

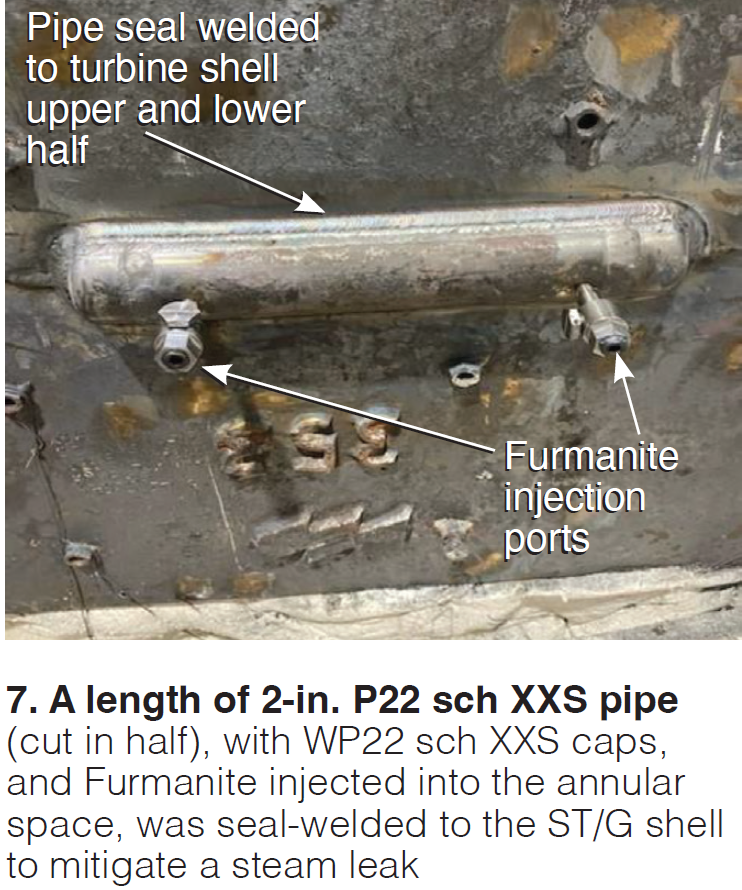

“Steam Turbine Shell Leak Repair” describes a home-grown solution to a D11 shell leak discovered through thermography on the right side of the IP section. Specialists fabricated a capped, ported piece of pipe cut axially, and seal-welded it to the turbine shell after heating the shell to 400F (Fig 7).

Furmanite, a material specifically designed to seal high pressure leaks, was then injected by hydraulic pump into the ports to fill the space between the shell and the pipe, and the ports capped off. Afterwards, welds were inspected using MPE (magnetic particle).

“LP Inspections,” titled “Steam Turbine Discovery” in the slide deck, includes photos and diagrams of indications found on numerous steam turbine models, but including D11 nested finger L0 removal and D11 shell indications. Though not a D11, the photos from a combined cycle steam turbine chemistry excursion event are particularly gruesome.

During the STUG conference initial “open forum & discussion,” the topic of D11 rotor life came up and users noted that the OEM has no engineering supporting its recommendation to replace rotors for another 25 years of life. One user suggested buying a spare rotor or two for quick turnarounds. Another commented that “people are buying full spare components like valves and internals,” and that “shop time to weld repair an L-0 wheel costs more than buying a whole new rotor.”

Electrohydraulic control (EHC) systems, described by one user as a “the lifeblood of the ST/G,” got also good airtime during the forum.

“EHC System Issues” (slides not available at publication) describes how a combination of OEM deficiencies and inattention from the plant and owner/operator led to failure of the HYDAC EHC (electrohydraulic control) skid just a few months after commissioning a CC facility in 2022. High particle counts and varnish issues were observed immediately. Numerous contributing factors are noted following the root cause analysis (RCA).

From the plant side, factors included enclosure doors broken since commissioning (plastic hinges were replaced with steel) and inadequately sealed control box panel, allowing water intrusion. Presenters acknowledged that the owner/operator accepted the plant this way.

From the vendor side, drying air flow was set too low, heating and cooling fan set point range was inadequate, and the pumps exhibited premature physical wear because they were not being lubricated sufficiently. The OEM had acknowledged failures on these pumps at other sites.

Pumps exhibited other problems, such as high axial tension. Replacement pumps, arriving after 25 weeks, failed. Spare pumps also failed. The HYDAC design was determined to be faulty. Even after installing a temperature control pump skid and blowers for cooling, the fluid was still “cooking.” Both cooling circuits were needed to maintain fluid temperature.

It turned out that the two varnish pumps were essentially “fighting each other,” and simultaneous operation is detrimental to varnish pump reliability. Now, the pumps operate independently of each other and are able to maintain the fluid temperature range.

Later, a main steam stop valve, fitted with a cold weather “heat orifice feature” inside the control block, failed. Plant plugged the orifice, as it turned out to be detrimental to reliability.

Lessons learned: slight variations in skid location and ambient conditions can lead to significant performance degradation; and plant personnel need to pay attention to this equipment, be diligent about sampling and analysis and planned maintenance checks, and maintain adequate stock of M&S items, like filters.

“Electrohydraulic Systems,” by an EPRI specialist, is a primer on EHC and includes refresher material on subsystem components, types of hydraulic fluids, deeper dive into phosphate ester fluids and degradation mechanisms, fluid handling component maladies and causes, recommendations for walkdowns/operator rounds, preventive maintenance and O&M best practices, phosphate ester sampling and testing, comprehensive system sensor plan, and other subjects all sourced from larger EPRI documents referenced at the end.

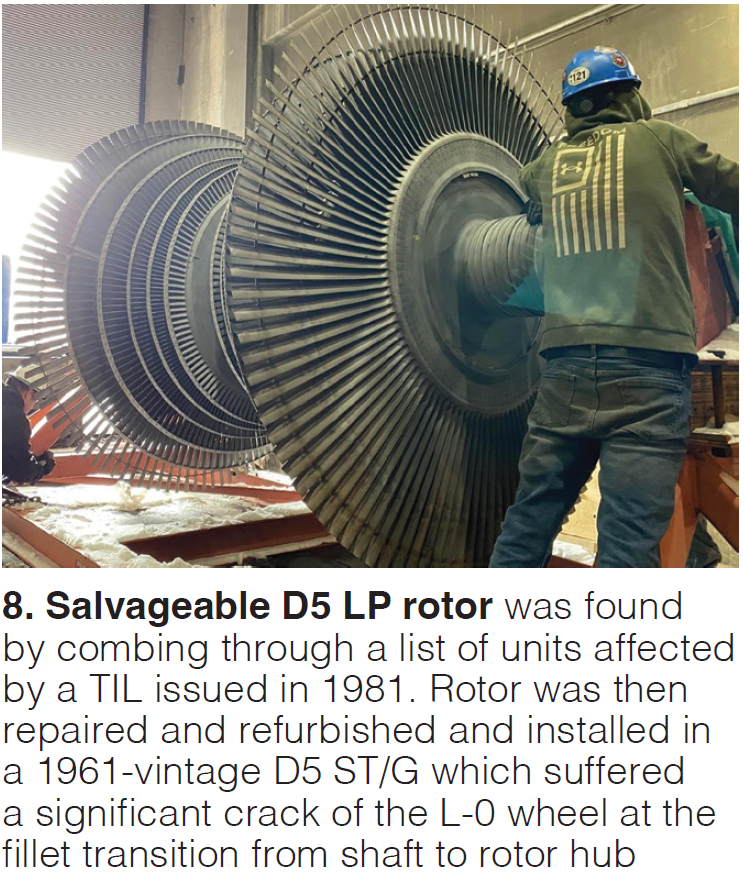

“D5 10-month Outage & Cracked LP Rotor.” Desperate times call for desperate measures, or when you need peaking capacity, you’ll go to any lengths not to permanently retire an ancient unit. This presentation is the saga, thankfully with a happy ending, of a 1961-vintage D5 ST/G LP rotor coupled to conventional gas boiler unit that suffered a 21-inch indication on the L-0 wheel at the fillet transition from shaft to rotor hub.

For six months in early 2023, vibrations at the T3, T4, and T5 bearings were increasing while the unit was progressively derated to compensate. When it became unbearable, an outage was taken, originally scheduled for two and a half months. The indication turned out to be a crack at least three inches deep.

Utility personnel searched their archives and found TIL931-3 from the early 1980s on wheel fillet machining recommendations for LP rotors with 26-in last stage blades. That document offered one option: procure, fabricate and weld a stub shaft in place of the last stage wheel (generator end).

Other options were to order a new LP rotor, repair the existing rotor, or find a salvageable replacement rotor. First two options had prohibitive schedules, and the plant did not have confidence in the repair option. Fortunately, the TIL documentation also included a list of affected units, sites possibly having decommissioned rotors. The plant managed to find a D5 rotor of appropriate length which was refurbished and fitted to the existing components (Fig 8).

Although the outage had to be extended by seven and half months, the unit is now able to deliver its full output to automatic generation control (AGC). Others who improbably find themselves in a similar situation may have to resort to options one through three: This may have been the last decommissioned D5 LP rotor available, at least in this length range.

“Siemens BB43 to GE HP/IP retrofit” covers the retrofit of a high-risk 1967-vintage (originally Westinghouse) ST/G with 370,000 operating hours with a fully bladed HP/IP rotor (with reaction blading design), HP inner casing, IP blade carrier, and IP packing heads (N1-N3) fabricated by GE in Poland. An HP/IP assessment showed an unacceptable level of rotor bowing (runout), creep/embrittlement, and casing cracks.

The slides offer dozens of detailed diagrams and photos of scope work items, field modifications, component drawings, module casting, pre-assembly, major component removal and install, fit-up, and final assembly. A list of lessons learned includes these:

- Have the shop put the module together (pre-assembly) before shipping to the site

- Negotiate to have field welding performed at the shop when applicable

- Have a steam turbine engineer assess parts prior to the outage

- Manufacture inserts early in the outage; it took five tops on/tops off iterations to complete the installation and jack bolt holes were damaged in the process

- Make sure special tooling is accounted for and inspected

- Have sealing OEM come to site to measure hook fits thickness, diameters, out of roundness, etc

- Include in base scope disposal of old components

- Insist that the OEM provide detailed assembly iterations before the outage to fine-tune the schedule

- Fabricate inner and outer gland packing to fit; do not rely on part numbers

“Steam Turbine Crossover Assembly Tie Rod Failures” on an ST/G in a 1376-MW 3×1 CC facility were experienced after only 27 starts. While the failure was likely due to fatigue, the cause was not conclusively identified. Testing showed that the AISI 4140 steel material was compositionally verified and its tensile strength within range.

Also discovered was that the tie rod shafts had cut, not rolled, threads with relatively rough machining marks. This could have contributed to the failure but only as a secondary factor. It turns out that the 2nd and 3rd harmonics of the tie rods are very close to 60 Hz. Also discovered was that a similar unit at another site featured lateral supports.

Proposed solutions include: increase rod diameter, change rod material, seek better surface finish in threads, change to rolled threads, add lateral supports, and/or use tapered threads in the load-bearing nuts.

“A10 In-situ Bull Gear Replacement” includes this on slide 2: “Instead of thinking outside the box, throw out the box.” That perks your ears up when dealing with complex engineered systems in the field. At this 1228-MW CC with four A10 ST/Gs, premature wear of a turning gear ring (bull gear) was caused by inadequate oil flow, and the gear had to be replaced. The plant procured a new bull gear (with extra stock) and devised what is thought to be a never-before-tried method of removing the old one.

Since the gear is friction-fit, expanding it with heat would allow it to be removed in the field, leaving the HP shell/rotor untouched, while uncoupling the generator field, sliding it six inches with a yolk-anvil, and placing it on skid pans. Differential expansion ratio calculations showed that the shaft would not be adversely affected by the necessary heat.

Heating the gear to 450F with heating elements installed on the gear with belt-type sling, and insulation to protect the shaft, allowed the ring to come off. You’ll have to check out the slides to see how the plant solved an emergent problem when the front standard (part of the speed control governor and trip system) interfered with full ring removal by approximately two inches.

“SCC in an LP Turbine (Present and Future Impacts)” is a cautionary tale about what happens when you postpone addressing a chemistry excursion because the unit could soon be scheduled for retirement. In May 2020, a 740-MW ST/G (part of a coal-fired unit) experienced a 13-day operating period with elevated sodium in the steam, with subsequent 1% loss of megawatts from the HP and IP sections. However, the greater concern was the progressive impact from stress corrosion cracking (SCC) in the LP section.

The utility’s services team evaluated options and decided that deferring all cleaning and SCC-related inspections until a planned major outage in 2025 would be best based on technical and business risk. However, L-0 and L-1 blades were pre-ordered as a contingency, since this unit had become the highest risk in the utility’s fleet because of the SCC.

The balance of the slides review the findings from a spring 2024 outage inspection, and subsequent immediate and longer-term tactics to address the SCC damage and general LP maintenance. Planners are now considering extending the unit’s retirement date for another 20 years. Sage advice: Do not neglect older fossil units on the assumption of imminent retirement. Consider this observation as well: Lots of plants are taking big risks by not having on-site chemistry specialists.

“Lack of Skilled Labor” points out some alarming workforce trends impacting the ability of the power industry to attract necessary expertise, including the COVID-related exodus of skilled labor, baby boomer retirements, decline in apprenticeships, appeal of digital- and computer-related positions, disparities between cost of living and salaries in key regions, high cost of earning engineering degrees, and changes in 6-12 curriculum eliminating classes nurturing mechanical skills (e.g., shop).

Five recommendations for mitigating the skilled labor shortage are: bring back apprenticeship programs, reimburse tuition and training expenses, attend jobs fairs, hire employees direct from high school, and retain skilled and qualified personnel.

STUG VENDOR PRESENTATIONS

“Safety Differently: A Story About How Your Organization Could Learn Differently,” Matt Barnes, MD&A

Message here is that team performance improves when you work through a safety event with positives instead of the absence of negatives. Positives include the capacity to be successful under varying conditions, the ethical responsibility to the organization which has to handle messy, risky work, and making sure the people perceived to be part of the problem (those involved in the safety mishap) become part of the solution.

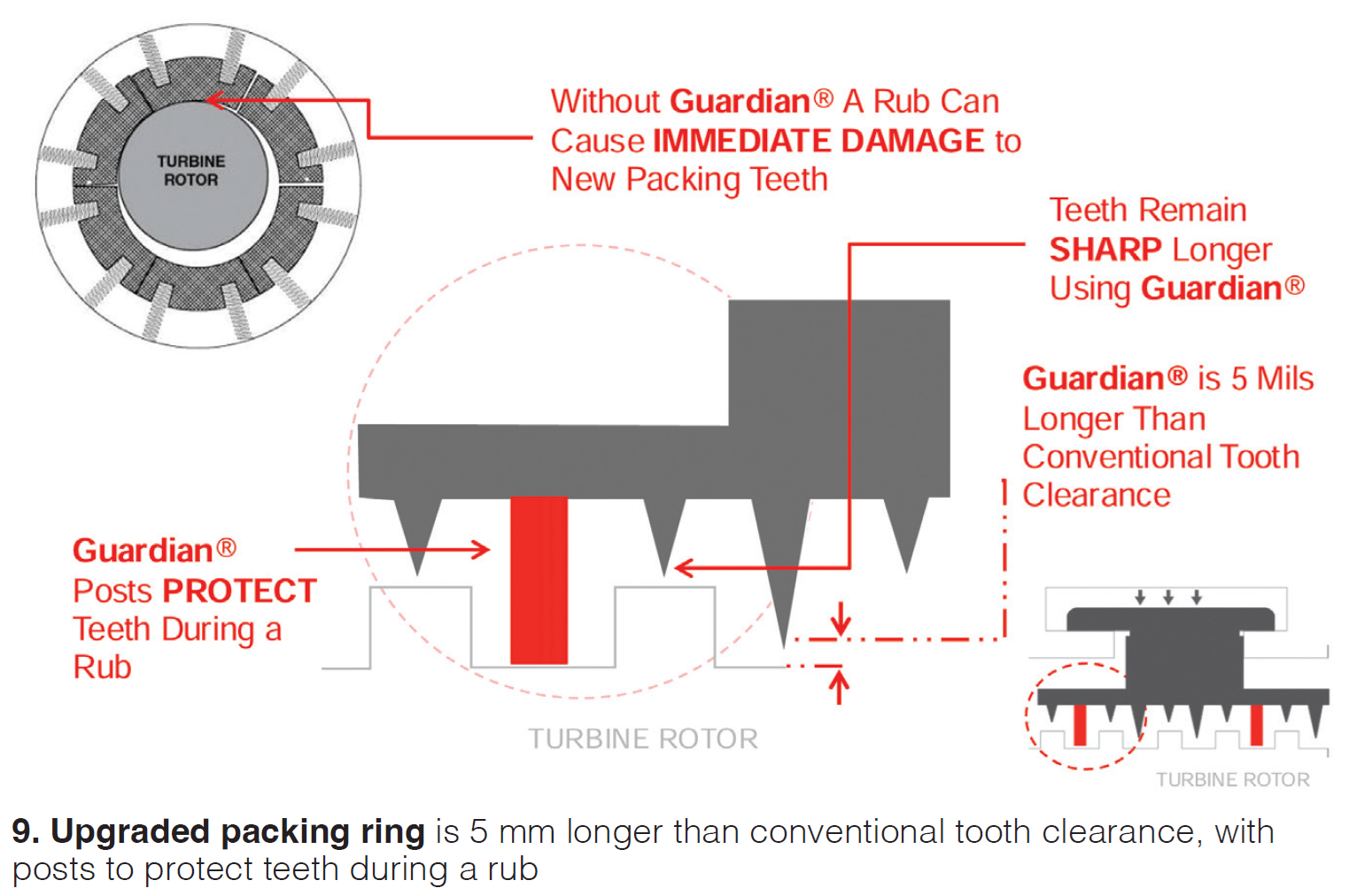

“MD&A Parts – Guardian™ and Vortex Shedder™ Design, Installation Process, Benefits,” Jacques Amyot, MD&A

Title refers to parts for the ST/G steam sealing (packing) rings installed in over 300 units of all OEMs which are “proven to increase efficiency by 1.5-4.5%.” Slides cover steam sealing basics (with excellent diagrams), product design descriptions, reverse engineering measurements, installation steps, and case studies (Fig 9).

“Steam Turbine Valves,” Dean Casey, MD&A

Improperly functioning valves can and have led to catastrophic ST/G failures, begins this slide deck, which then reviews virtually all aspects of valve and component outage planning, inspection, issues and repairs (including slides specific to common ST/G models), reassembly, shipping, and final reports from the service vendor. Bonus topics include integral strainer basket replacement, control valve seat replacements, and indications in, and refurbishments of, steam chests.

“Alstom HP Inner Block Shop Inspection and Repair,” Satish Amand, Power Services Group

Slides cover inspection and findings, disassembly and assembly, shop repair base scope items, engineering evaluations and repair processes, and R1-R4 blade replacements not in the original scope for a 190-MW 2001-vintage ST/G. Company’s Gainesville, FL, facility is being expanded to handle steam path component repairs.

“Turbine Outage, Lessons Learned, and Maintenance Case Studies,” Scott Cavendish, Independent Turbine Consulting LLC (also presented in the CCUG)

The first section summarizes general observations over multiple outages worth paying attention to. Among them:

- Experience deficit is leading to technical errors in the field

- Little standardization exists for lockout tagout (LOTO) from site to site, for example great variation on “temporary” lifts for systems such as lube and lift oil

- Outages are often longer than planned, being planned at the last minute, and lack contingency options

- Lighting is often inadequate where work needs to be conducted

- Lack of attention to the low-hanging fruit of logistics – toilets, office space, scaffolding, forklifts, tooling rentals, welding gases, etc – often leads to major delays

The second section covers the following case histories of field problems and solutions: bobbing V1 valves in the mechanical hydraulic controls (MHC) of a 1961-vintage D5 ST/G, recovery from a Front Standard fire, high generator vibration after major inspection (two separate cases), and lube oil and varnish buildup.

Closing reminder. End users registered at www.powerusers.org are encouraged to download the full slide decks from the 2024 conference and put the shared experience and lessons learned to immediate use. The material spans everything from outage planning and controls upgrades to generator rewinds and cold-weather prep—practical, field-tested guidance that speaks directly to today’s plant challenges. And if you’re not already planning to attend the 2025 Combined Conference, set for August 25–28 in Washington DC, now’s the time. Few events offer as much actionable content, peer exchange, and expert access in one place.

More from the 2024 Combined Conference:

- Life-long learning abounds across five user group conferences @ Power Users Combined Conference

- Addressing weather resilience, risk management, and outage execution @ CCUG

- Focus on D11 strategies, EHC pitfalls, and skilled labor shortages @ STUG

- Generator users share failures, fixes, and forward planning @ GUG

- Advanced controls strategy and fundamentals @ PPCUG